1. Izigigaba ezibonakalayo zemishini ye-titanium

Amandla okusika we-titanium alloy processing aphakeme kancane kunalawo ensimbi enobulukhuni obufanayo. Noma kunjalo, isenzakalo esibonakalayo sokucubungula i-titanium alloy siyinkimbinkimbi kakhulu kunokucubungula insimbi, okwenza ukucubungula kwe-titanium alloy kubhekane nobunzima obukhulu.

I-thermal conductivity yama-alloys amaningi e-titanium iphansi kakhulu, i-1/7 kuphela yensimbi kanye ne-1/16 ye-aluminium. Ngakho-ke, ukushisa okukhiqizwa lapho kusika ama-alloys e-titanium ngeke kudluliselwe ngokushesha ku-workpiece noma kuthathwe ama-chips. Noma kunjalo, izonqwabelana endaweni yokusika, futhi izinga lokushisa elikhiqizwayo lingaba phezulu njengo-1,000 °C noma ngaphezulu, okuzokwenza ukuthi unqenqema lokusika lwethuluzi luguge, luqhume, futhi luqhekeke ngokushesha. Ukwakheka konqenqema olwakhiwe kanye nokubukeka ngokushesha konqenqema olugugile kukhiqiza ukushisa okwengeziwe endaweni yokusika, okuqhubeka kufinyeza impilo yethuluzi.umshini we-titanium

Amazinga okushisa aphezulu akhiqizwa phakathi nenqubo yokusika aphinde abhubhise ubuqotho obungaphezulu bezingxenye ze-titanium alloy, okuholela ekwehleni kokunemba kwejometri yezingxenye kanye nokusebenza kanzima okunciphisa kakhulu amandla abo okukhathala.

I-elasticity ye-titanium alloys ingase ibe nenzuzo ekusebenzeni kwengxenye, kodwa ngesikhathi sokusika, ukuguqulwa kwe-elastic kwe-workpiece kuyimbangela ebalulekile yokudlidliza. Ingcindezi yokusika idala ukuthi i-workpiece "elastic" isuke kude nethuluzi bese igxuma, ngakho-ke ukungqubuzana phakathi kwethuluzi nomsebenzi kukhulu kunesenzo sokusika. Inqubo yokungqubuzana iphinde ikhiqize ukushisa, ibhebhethekise inkinga yokungaphatheki kahle kokushisa kwezingxube ze-titanium.

Le nkinga iba nzima nakakhulu lapho kwenziwa izingxenye ezinezindonga ezincane noma ezimise okwendandatho, ezigogeke kalula. Akulula ukufaka izingxenye zengxube ye-titanium enezindonga ezincane zibe nokunemba kobukhulu obulindelekile. Lapho ithuluzi liphushela kude okokusebenza, ukwakheka kwendawo kodonga oluncane kudlula ububanzi obunwebekayo; ukuguqulwa kwepulasitiki kwenzeka, futhi amandla ezinto ezibonakalayo nobulukhuni bephuzu lokusika kukhula kakhulu. Ukucupha ngesivinini esinqunyiwe ngaphambilini sokusika kuba phezulu kakhulu, okuholela ekugugeni kwamathuluzi abukhali.

"Hot" "yicala" elenza kube inselele ukucubungula ama-alloys e-titanium!

2. Ulwazi lwezobuchwepheshe lwe-titanium CNC machining

Ngokusekelwe ekuqondeni indlela yokucubungula ye-titanium alloys kanye nokwengeza ulwazi, inqubo eyinhloko yolwazi lokucubungula ama-alloys e-titanium imi kanje:

(1) Ukufakwa okunejiyomethri ephozithivu kusetshenziselwa ukunciphisa amandla okusika ama-workpiece, ukushisa okusika, kanye nokuguqulwa.

(2) Gcina okuphakelayo njalo ukuze ugweme ukuqina kwe-workpiece. Ithuluzi kufanele lihlale lisesimweni sokuphakela ngesikhathi sokusika, futhi inani lokusika i-radial kufanele libe ngu-30% werediyasi ngesikhathi sokugaya.

(3) Uketshezi lokusika olunomfutho ophezulu kanye nokugeleza okukhulu lusetshenziselwa ukuqinisekisa ukuzinza okushisayo kwenqubo yomshini futhi kuvimbele ukuwohloka kwendawo yokusebenzela kanye nokulimala kwamathuluzi ngenxa yokushisa ngokweqile.

(4) Gcina umphetho wensingo ubukhali; amathuluzi abuthuntu abangela ukunqwabelana kokushisa nokuguga, okuholela ngokushesha ekuhlulekeni kwamathuluzi.

(5) Ukucupha esimweni esithambile kakhulu sengxubevange ye-titanium ngangokunokwenzeka ngenxa yokuthi impahla iba inselele kakhulu emshinini ngemva kokuqina, futhi ukwelashwa kokushisa kwandisa amandla wento kanye nokuguga kokufakiwe.

(6) Sebenzisa indawo enkulu yekhala noma i-chamfer ukusika ngangokunokwenzeka onqenqemeni lokusika. Lokhu kunciphisa amandla okusika nokushisa kuzo zonke izindawo futhi kuvimbela ukuphuka kwendawo. Lapho kugaywa ama-alloys e-titanium, phakathi kwemingcele yokusika, isivinini sokusika sinethonya elibaluleke kakhulu empilweni yethuluzi vc, okulandelwa ukubandakanyeka kwe-radial (ukujula kokugaya) ae.

3. Qala nge-blade ukuxazulula inkinga yokucubungula i-titanium

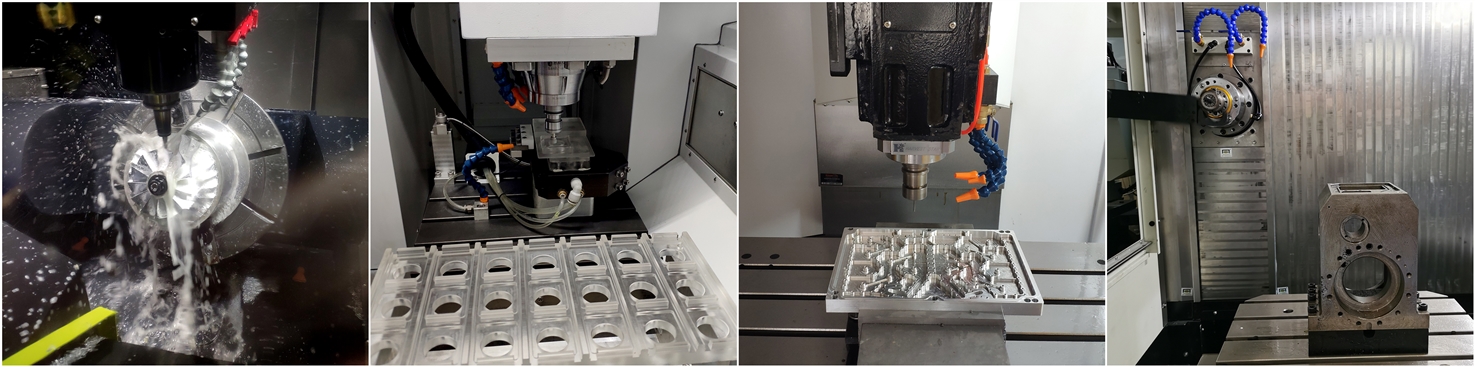

Ukuguga kwe-groove yokufaka phakathi nomshini wama-alloys e-titanium ukuguga kwendawo ngemuva nangaphambili kubheke ekujuleni kokusikwa, okuvame ukubangelwa ungqimba oluqinile olushiywe ukucutshungulwa kwangaphambilini. Ukusabela kwamakhemikhali nokusatshalaliswa kwethuluzi kanye nezinto zokusebenza endaweni yokushisa yokucubungula engaphezu kuka-800 °C nakho kuyizizathu zokwakheka kokugqoka kwe-groove. Ngoba ngesikhathi senqubo yomshini, ama-molecule e-titanium we-workpiece aqoqana phambi kwe-blade futhi "ahlanganiswe" emaphethelweni e-blade ngaphansi kwengcindezi ephakeme kanye nokushisa okuphezulu, okwenza unqenqema olwakhiwe. Lapho unqenqema olwakhiwe lucweba onqenqemeni lokusika, lususa uqweqwe lwe-carbide lokufaka, ngakho-ke umshini we-titanium udinga izinto zokufaka eziyingqayizivele namajometri.cCustomprecision machining

4. Isakhiwo sethuluzi esilungele ukwenziwa kwe-titanium machining

Ukugxila kokucubungula i-titanium alloy ukushisa, futhi inani elikhulu loketshezi lokusika olunomfutho ophezulu kufanele lufafazwe onqenqemeni lokusika ngokushesha futhi ngokunembile ukuze kususwe ukushisa ngokushesha. Kukhona ukucushwa okuhlukile kwabasiki be-milling ikakhulukazi ukwenza imishini ye-titanium.

I-Anebon Metal Products Limited inganikeza i-CNC Machining, i-Die Casting, isevisi yokwenziwa kwe-Sheet Metal, sicela ukhululeke ukuxhumana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Isikhathi sokuthumela: Jan-18-2022