Ingabe isistimu yomshini wemigodi ejulile eyaziwa kakhulu isebenza kangakanani enqubweni yethu yokwenza imishini?

Imiphongolo yezibhamu nezinhlelo zezikhali:

Ukubhoboza i-deep bore kudlala indima ebalulekile ekukhiqizweni kwemiphongolo yezibhamu, ukuqinisekisa ukunemba nokunemba kobukhulu bemiphongolo, ukudubula, kanye nokuthungwa kwendawo.

Imboni ye-Aerospace:

Kusetshenziswa imishini ye-deep bore ekukhiqizeni igiya lokumisa indiza, izingxenye zezinjini zendiza, ama-rotor shafts wendiza enophephela emhlane, nezinye izingxenye ezibalulekile ezidinga ukunemba okukhethekile nokuqina.

Imboni kawoyela negesi:

Ukumba imbobo ejulile kusetshenziswa ekwenziweni kwezinto ezisetshenziswa ekuhloleni uwoyela negesi, okuhlanganisa amathuluzi okumba, izihloko zemithombo, namashubhu okukhiqiza.

Imboni yezimoto:

Ukwenziwa kwezingxenye zenjini njengama-crankshafts, ama-camshaft, izinduku zokuxhuma, nezingxenye zokujova uphethiloli kwenza kudingeke ukuthi kufakwe izimbobo ezijulile.

Ukunakekelwa kwezempilo nezempilo:

Ukwenza imbobo ejulile kubalulekile ekukhiqizeni amathuluzi okuhlinza, izimila, kanye nemishini yezokwelapha edinga izici zangaphakathi eziklanywe ngokunembile kanye nokuqedwa kwendawo.

Imboni yesikhunta kanye nokufa:

Ukumba imbobo ejulile kuthola ukusebenza ekukhiqizeni isikhunta sokujova, i-extrusion dies, nezinye izakhi zamathuluzi ezenza kudingeke iziteshi zokupholisa eziyinkimbinkimbi ukuze zikhiphe ukushisa ngempumelelo.

Ukulungisa ukufa nokukhunta:

Amasistimu wokugaya imbobo ejulile nawo asetshenziselwa ukulungisa noma ukuguqulwa kwesikhunta esivele sikhona futhi siyafa, okuvumela ukumbiwa kwamashaneli okupholisa, izimbobo zamaphini ejector, noma ezinye izici ezidingekayo.

Amasistimu okucubungula imbobo ejulile: amamodeli ayisithupha asetshenziswa kakhulu

Kuyini ukucutshungulwa kwe-deep-hole?

Imbobo ejulile yileyo isilinganiso sayo sobude nobubanzi sikhulu kuno-10. Isilinganiso sokujula nobubanzi bezimbobo ezijulile ngokuvamile singu-L/d>=100. Lokhu kufaka phakathi izimbobo zesilinda kanye nowoyela we-axial shaft, i-spindle engenalutho, namavalvu asebenza ngogesi. Lezi zimbobo zivame ukudinga ukunemba okuphezulu kanye nekhwalithi yendawo, kuyilapho ezinye izinto zinzima ukuklama, okungaba yinkinga ekukhiqizeni. Yiziphi ezinye izindlela ongacabanga ngazo ukuze ucubungule imigodi ejulile?

1. Ukubhola Kwendabuko

I-twist drill, eyasungulwa abantu baseMelika, ingumsuka wokucubungula imbobo ejulile. Lo mshini wokubhoboza unesakhiwo esilula uma kuqhathaniswa, futhi kulula ukwethula uketshezi lokusika, okuvumela izingcezu zokubhoboza zenziwe ngamadayimitha nobukhulu obuhlukene.

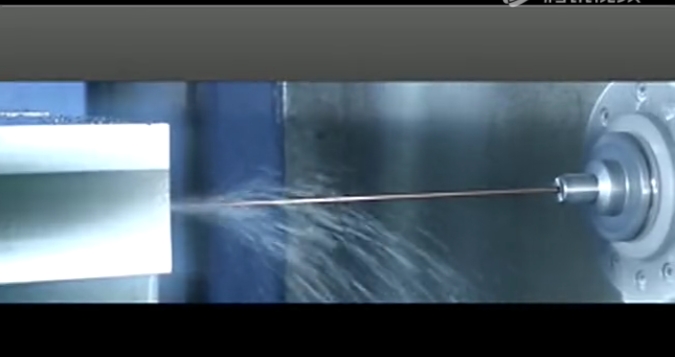

2. Ukubhoboza isibhamu

I-deep hole tube drill yaqala ukusetshenziswa ukwakha imiphongolo yezibhamu, eyaziwa nangokuthi amashubhu ajulile. Umshini wokumba izibhamu uqanjwe kanjalo ngenxa yokuthi imiphongolo yayingewona amashubhu anemba angenamthungo futhi inqubo yokukhiqiza ishubhu enembayo ayikwazanga ukuhlangabezana nemfuneko yokunemba. Ukucutshungulwa kwezimbobo ezijulile manje kuyindlela ethandwayo nephumelelayo yokucubungula ngenxa yokuthuthukiswa kwesayensi nobuchwepheshe kanye nemizamo yabakhiqizi bezinhlelo zemigodi ejulile. Zisetshenziswa emikhakheni eminingi, okuhlanganisa: imboni yezimoto, i-aerospace, ukwakhiwa kwesakhiwo, imishini yezokwelapha, isikhunta/ithuluzi/i-jig, imboni ye-hydraulic kanye nengcindezi.

Ukudubula isibhamu kuyisixazululo esihle kakhulu sokucubungula imbobo ejulile. Ukubhoboza izibhamu kuyindlela enhle yokuthola imiphumela enembayo. Ukumba izibhamu kungafinyelela imiphumela eqondile yokucubungula. Iyakwazi ukucubungula izinhlobonhlobo zezimbobo ezijulile kanye nezimbobo ezikhethekile ezijulile njengezimbobo ezingaboni kanye nezimbobo eziwela.

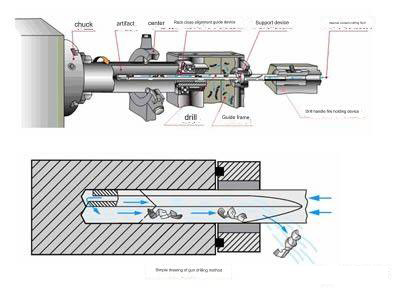

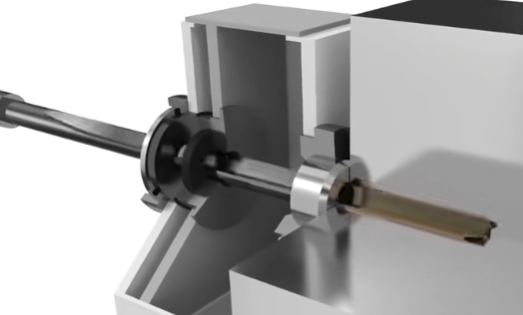

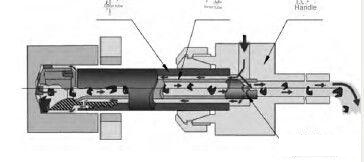

Izingxenye zesistimu yokumba izibhamu

Izibhamu zokubhoboza izibhamu

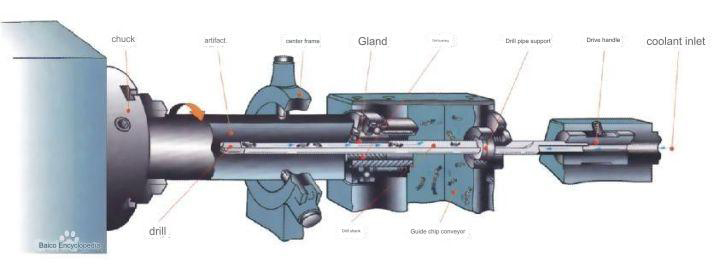

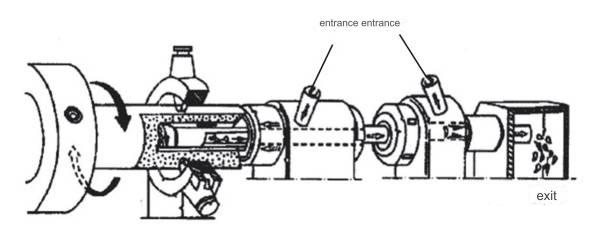

3. Uhlelo lwe-BTA

I-International Hole Processing Association isungule imbobo ejulile ekhipha ama-chips ngaphakathi. Uhlelo lwe-BTA lusebenzisa amasilinda angenalutho ku-drill rod nebhithi. Lokhu kuthuthukisa ukuqina kwethuluzi futhi kuvumela ukuhlangana okusheshayo nokuqaqa. Isibalo sibonisa isimiso saso sokusebenza. I-oil dispenser igcwele uketshezi lokusika ngaphansi kwengcindezi.

Uketshezi olusikiwe lube seludlula esikhaleni se-annular esidalwe yipayipi lokubhoboza, udonga lwembobo bese lugelezela endaweni yokusika ukuze luphole futhi lugcotshwe. Iphinde icindezele i-chip kuma-chips we-drill bit. Ingaphakathi lepayipi lokubhoboza yilapho kukhishwa khona ama-chips. Uhlelo lwe-BTA lungasetshenziselwa izimbobo ezijulile ezinobubanzi obukhulu kuno-12mm.

Ukwakheka kwesistimu ye-BAT↑

I-BAT drill bit↑

4. Umjovo kanye Nesistimu Yokudonsa

I-Jet Suction Drilling System iyindlela yokumba imbobo ejulile esebenzisa ishubhu ephindwe kabili esekelwe kusimiso sokudonsa ijethi sikamakhenikha oketshezi. Isistimu yokumunca isifutho isekelwe ethuluzini leshubhu lezendlalelo ezimbili. Ngemuva kokucindezelwa, uketshezi lokusika lujovwa ku-inlet. I-2/3 yoketshezi olusikayo olungena esikhaleni phakathi kwezinsimbi zokubhoboza zangaphandle nangaphakathi lugelezela kucnc inkambiso ukusika ingxenyeukulipholisa nokuligcoba.

Ama-chips aphushelwa endaweni engaphakathi. I-1/3 esele yoketshezi olusikiwe ifafazwa ngesivinini esikhulu epayipini elingaphakathi ngombobo omise okwecelo. Lokhu kudala indawo yokucindezela okuphansi ngaphakathi kwendawo yepayipi elingaphakathi, ukuncela uketshezi olunqunyiwe oluthwele ama-chips. Ama-chips akhishwa ngokushesha endaweni yokukhipha ngaphansi kwesifutho sesenzo esikabili kanye nokumuncwa. Amasistimu wokumba i-Jet suction asetshenziswa kakhulu ekucubunguleni imbobo ejulile, enobubanzi obungaphezu kuka-18mm.

Isimiso se-jet suction drilling system↑

I-Jet suction drill bit↑

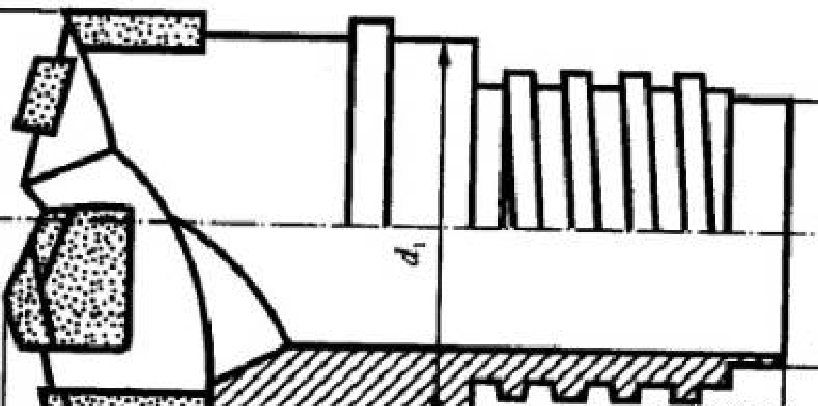

5.DF uhlelo

Uhlelo lwe-DF luwuhlelo lwe-dual-inlet single-tube yokususa i-chip yangaphakathi eyakhiwe yi-Nippon Metallurgical Co., Ltd. Uketshezi olusikwayo luhlukaniswe ngamagatsha amabili angaphambili nangemuva, angena asuka kuma-inlet amabili ngokulandelanayo. I-2/3 yoketshezi lokusika kweyokuqala igeleza iye ku-cnc metal ukusika ingxenyengokusebenzisa indawo eyi-annular eyakhiwe ipayipi lokubhoboza kanye nodonga lwembobo ecutshunguliwe, futhi iphushele ama-chips endaweni yokukhipha i-chip endaweni yokubhoboza, ingene epayipini lokubhoboza, futhi igeleze iye ku-chip extractor; ingxenye yokugcina engu-1/3 yoketshezi olusikiwe ingena ngqo kusikhiphi se-chip futhi isheshiswe ngegebe elincane le-conical phakathi kwemibhobho yangaphambili nangemuva, idale umphumela omubi wokudonsa ingcindezi ukuze kuzuzwe inhloso yokusheshisa ukususwa kwe-chip.

Isakhiwo sengxenye yokuqala yohlelo lwe-DF oludlala indima “yokuphusha” lufana nelohlelo lwe-BTA, futhi ukwakheka kwengxenye yesibili edlala indima “yokudonsa” kufana nokubhola kokudonsa indiza. uhlelo. Njengoba uhlelo lwe-DF lusebenzisa izinsimbi ezimbili zokungenisa uwoyela, lusebenzisa ipayipi elilodwa lokubhoboza kuphela. Indlela yokuphusha i-chip kanye nokumunca iqediwe, ngakho-ke ububanzi benduku yokubhoboza kungenziwa izimbobo ezincane kakhulu futhi ezincane zingacutshungulwa. Njengamanje, ububanzi obuncane bokucubungula bohlelo lwe-DF lungafinyelela ku-6mm.

Indlela uhlelo lwe-DF olusebenza ngayo↑

I-DF deep hole bit↑

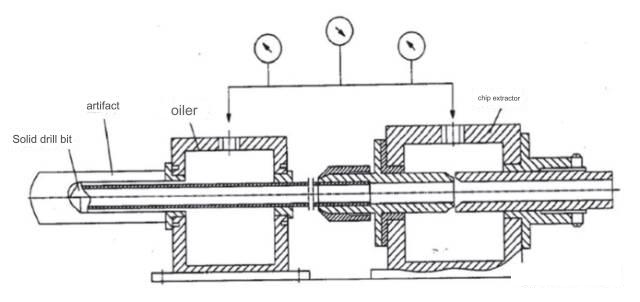

6. Uhlelo lwe-SIED

I-North China University yasungula uhlelo lwe-SIED, uhlelo olulodwa lokukhipha i-tube chip kanye nesistimu yokubhoboza. Lobu buchwepheshe busekelwe kubuchwepheshe obuthathu bokumba bangaphakathi bokususwa kwe-chip: i-BTA (i-jet-suction drill), isistimu ye-DF, kanye nohlelo lwe-DF. Isistimu ingeza idivayisi yokukhipha i-chip ekwazi ukuzilungiseka enikwa amandla amandla okulawula ukupholisa nokugeleza koketshezi lokukhishwa kwe-chip ngokuzimela. Njengoba kuboniswe emdwebeni, lesi yisimiso esiyisisekelo. Ipompo ye-hydraulic ikhipha uketshezi lokusika, olubuye luhlukaniswe lwaba yimifudlana emibili: uketshezi lokuqala lokusika lungena emshinini wokuletha uwoyela bese lugeleza ngegebe le-annular phakathi kodonga lwepayipi lokubhoboza kanye nomgodi ukuze lifinyelele engxenyeni yokusika, lisuse ama-chips.

Uketshezi lokuqala lokusika luphushelwa embotsheni yokubhoboza. Uketshezi lwesibili olusikiwe lungena ngegebe eliphakathi kwamapheya e-conical nozzle bese lugelezela kudivayisi yokukhipha i-chip. Lokhu kudala indiza enesivinini esiphezulu kanye nomfutho ongemuhle. I-SIED ifakwe amavalvu amabili azimele okulawula ingcindezi, elilodwa lokugeleza koketshezi ngakunye. Lezi zingalungiswa ngokuvumelana nezimo ezingcono kakhulu zokupholisa noma zokukhishwa kwe-chip. I-SlED iyisistimu ethuthukiswa kancane kancane. Iwuhlelo oluyinkimbinkimbi. Uhlelo lwe-SlED okwamanje luyakwazi ukunciphisa ububanzi obuncane bembobo yokumba bube ngaphansi kuka-5mm.

Indlela isistimu ye-SIED esebenza ngayo↑

Isicelo sokucubungula imbobo ejulile ku-CNC

Ukwenziwa kwezibhamu nezikhali:

Ukubhoboza izimbobo ezijulile kusetshenziswa ukwenza izibhamu nezinhlelo zezikhali. Iqinisekisa ubukhulu obuqondile, ukudubula kanye nokuqedwa kwangaphezulu kokusebenza kwesibhamu okunembayo nokuthembekile.

Imboni ye-Aerospace:

Inqubo yokwenza izimbobo ezijulile isetshenziselwa ukwenza izingxenye zamagiya okuhlala endiza kanye nezingxenye zenjini yomoya ophephela emhlane nezinye izingxenye ezibalulekile ze-aerospace ezidinga ikhwalithi ephezulu nokunemba.

Ukuhlola uwoyela negesi:

Ukubhoboza imigodi ejulile kusetshenziselwa ukukhiqiza izinto zokusebenza ezifana nezingcezu zokubhoboza, amapayipi, kanye nama-wellheads, abalulekile ekuhloleni uwoyela negesi. Izimbobo ezijulile zivumela ukukhishwa kwezinsiza ezivaleleke kumadamu angaphansi komhlaba.

Imboni yezimoto:

Ukucutshungulwa kwezimbobo ezijulile kubalulekile ekwakhiweni kwezingxenye zenjini njengama-crankshafts, ama-camshafts kanye nezinduku zokuxhuma. Lezi zingxenye zidinga ukunemba ezicini zazo zangaphakathi kanye nokuqeda ukuze zisebenze kahle kakhulu.

Ukunakekelwa kwezempilo nezokwelapha:

Inqubo yemishini ye-deep-hole isetshenziselwa ukwenza amathuluzi okuhlinza, izifakelo zezokwelapha kanye nezinsimbi ezahlukene zezokwelapha. Lawa madivayisi adinga izici zangaphakathi ezinembayo kanye nokuqedwa ukuze kuqinisekiswe ukusebenza okuphezulu nokuhambisana.

Imboni yesikhunta kanye nokufa:

I-deep hole drill idlala indima ebalulekile ekwakhiweni kwesikhunta kanye nokufa. Isikhunta kanye nokufa kudinga amashaneli okupholisa ukuze kuqinisekiswe ukuchithwa kokushisa okuphumelelayo lapho kusetshenziswa izinqubo ezifana nokubumba umjovo noma izinqubo zokukhiqiza ezihlukile.

Imboni yamandla:

Ukucutshungulwa kwezimbobo ezijulile kusetshenziselwa ukwakhiwa kwezingxenye ezihlobene namandla, njengama-turbine blades, izishintshisi zokushisa kanye nezingxenye zokudlulisa amandla. Lezi zingxenye ngokuvamile zidinga ukucaciswa okunembayo kwangaphakathi kanye nokuqedwa ukuze kuqinisekiswe ukusebenza kahle ekudaleni amandla.

Imboni yezokuvikela:

Ukubhoboza izimbobo ezijulile kusetshenziswa ekukhiqizeni okuhlobene nokuzivikelacnc izingxenye ezigayiwenjengamasistimu okuqondisa imicibisholo namapuleti ezikhali kanye nezingxenye zemoto yomkhathi. Lezicnc izingxenye zomshinizidinga ukunemba okuphezulu nokuqina okuhlala isikhathi eside ukuze kuqinisekiswe ukusebenza kahle nokuvikeleka kwazo.

I-Anebon iyakwazi ukuhlinzeka ngempahla yekhwalithi ephezulu, intengo yokuncintisana yokuthengisa kanye nokwesekwa kwamakhasimende okuhle kakhulu. Indawo ye-Anebon ithi “Uza lapha ngobunzima futhi sikunikeza ngokumamatheka ongahamba nakho” ukuze uthole isevisi yokugxiviza ngensimbi ngokwezifiso. Manje i-Anebon ibikucabangela konke okucacisiwe ukuze iqinisekise umkhiqizo ngamunye noma isevisi eyaneliswa ngabathengi bethu.

Siphinde sinikeze isevisi yensimbi ye-OEM enodized kanye ne-lazer yokusika ehlangabezana nezidingo zakho ezithile kanye nezidingo zakho. Ngeqembu eliqinile lonjiniyela abanolwazi ekwakhiweni nasekuthuthukisweni kwamapayipi, i-Anebon iwazisa ngokucophelela wonke amathuba okuhlinzeka ngemikhiqizo engcono kakhulu nezisombululo kumakhasimende ethu.

Uma ufuna ukwazi okwengeziwe, sicela uxhumane nomuntu osemthethweni ophethe i-Anebon nge info@anebon.com, ifoni+86-769-89802722

Isikhathi sokuthumela: Oct-27-2023