Ezinjinini, izakhi ze-shaft ezifana nama-crankshafts, ama-camshaft, nama-cylinder liners zisebenzisa ama-chucks kunqubo ngayinye yokucubungula. Ngesikhathi sokucutshungulwa, isikhungo se-chucks, sibambe futhi sishayele i-workpiece. Ngokusho kwekhono le-chuck ukubamba ucezu lokusebenza nokugcina isikhungo, ihlukaniswe yaba i-chuck eqinile kanye ne-chuck entantayo. Lesi sihloko sidingida ikakhulukazi lezi zimiso ezimbili zokukhetha ama-chucks kanye namaphuzu okunakekela nsuku zonke.5aixs CNC izingxenye zemishini

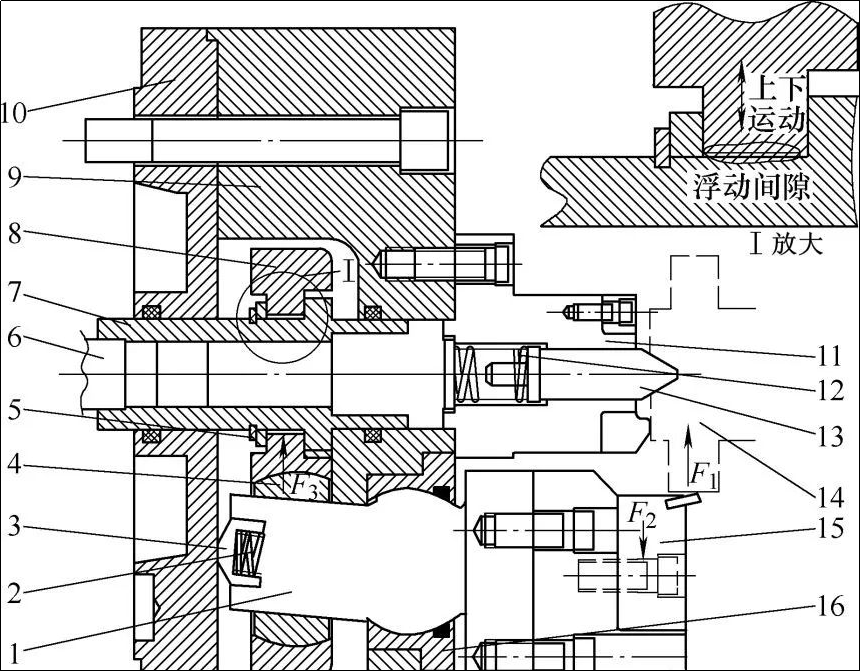

Ama-chucks aqinile kanye nama-chucks antantayo ahluke kakhulu ngesakhiwo kanye nezindlela zokulungisa. Sithatha uchungechunge lwama-chuck ohlobo lwase-Japan njengesibonelo, Umfanekiso 1 ubonisa inqubo yesenzo se-chuck entantayo: ucezu lokusebenza lungaphansi kwesenzo sebhulokhi yokubeka indawo nangaphezulu. I-axial kanye ne-radial positioning kanye ne-clamping iyenziwa. Bese, i-chuck cylinder ishayela i-chuck center tie rod, ipuleti lokulungiswa kwegebe, ipuleti lokusekela ingalo yomhlathi, ilunga eliyindilinga, nengalo yomhlathi kuthayi rod, ekugcineni ibone umhlathi we-chuck ukuze ubambe ucezu lomsebenzi.

Uma kukhona ukuchezuka okubalulekile kwe-coaxially phakathi kwenkaba yemihlathi emithathu ye-chuck kanye nendawo ephakathi nendawo yokusebenza, umhlathi we-chuck othinta i-workpiece kuqala uzofakwa ngaphansi kwe-F2, edluliselwa emhlathini. ipuleti lokusekela ingalo engalweni yomhlathi kanye nelunga eliyindilinga. I-F3 isebenza kupuleti lokusekela ingalo yozipho. Ku-chuck entantayo, kunegebe phakathi kwenduku yokudonsa emaphakathi ye-chuck kanye nepuleti lokusekela lengalo yozipho. Ngaphansi kwesenzo se-force F3, ipuleti lokusekela lengalo yozipho lisebenzisa igebe elintantayo (ipuleti lokulungisa igebe, I-central pull rod ye-chuck, kanye nepuleti lokusekela lengalo yomhlathi ndawonye lakha indlela entantayo ye-chuck), okuzokwenza hamba uye ohlangothini lwamandla kuze kube yilapho imihlathi emithathu ibamba i-workpiece ngokuphelele.

Umfanekiso 1 Isakhiwo se-chuck esintantayo

1. Ingalo yozipho

2. Intwasahlobo engunxande

3. Ikhava yangaphezulu eyindilinga

4. Ilunga eliyindilinga

5. Ipuleti lokulungisa lokusula

6. Induku yokudonsa isilinda

7. Chuck isikhungo sokudonsa induku

8. Ipuleti lokusekela ingalo yozipho

9. Umzimba ka-Chuck 10. Ikhava yokugcina ka-Chuck

10. Ibhulokhi yokusekela yokuma

12. Umsebenzi ozocutshungulwa

13. Chuck Emihlathini 16. Ukusekela ibhola

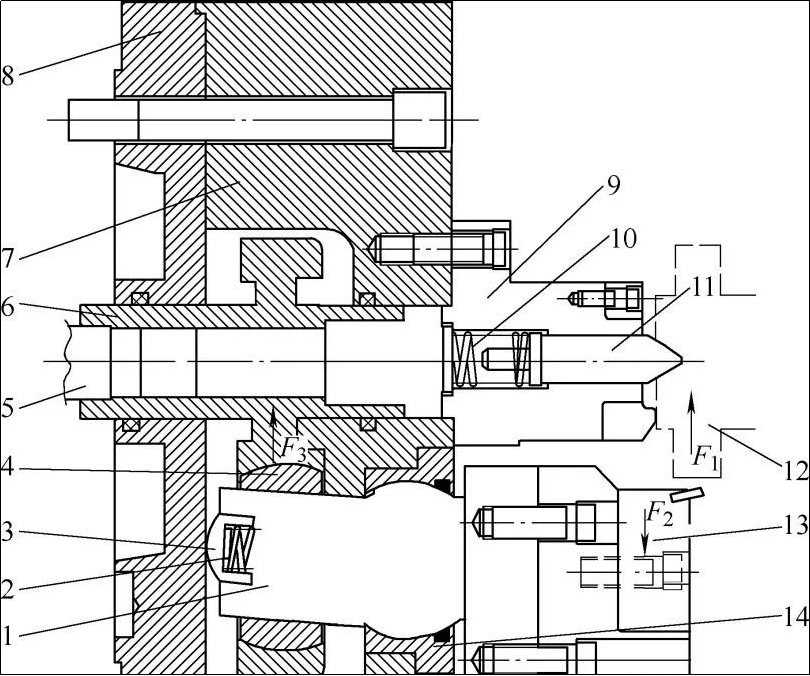

Umfanekiso wesi-2 ubonisa inqubo yesenzo se-chuck eqinile

Ngaphansi kwesenzo sebhulokhi yokumisa indawo nangaphezulu, ucezu lokusebenza lumiswa futhi luboshwe nge-axially kanye ne-radially, bese isilinda sikawoyela we-chuck sishayela induku yokudonsa emaphakathi, ilunga eliyindilinga kanye nomhlathi we-chuck ngentonga yokudonsa. Ingalo iyanyakaza, futhi ekugcineni, imihlathi ye-chuck ibamba ucezu lomsebenzi. Njengoba induku yokudonsa emaphakathi ye-chuck ixhunywe ngokuqinile nelunga eliyindilinga kanye nengalo yomhlathi, ngemva kokuba imihlathi ye-chuck (imihlathi emithathu) iboshiwe, isikhungo sokubopha sizokwakhiwa. Isikhungo sokubopha esakhiwe phezulu asidluleli, futhi indawo yokusebenza izoba ne-deformation esobala yokugoqa ngemva kokuba i-chuck iboshiwe. Ngaphambi kokuthi i-chuck isetshenziswe, kuyadingeka ukulungisa ukugqagqana phakathi kwesikhungo se-chuck kanye nendawo ephakathi nendawo ukuze uqinisekise ukuthi i-chuck ngeke ibonakale njenge-virtual ngemva kokubopha. Isimo esibanjiwe.

Umfanekiso 2 Isakhiwo se-chuck esiqinile

1. Ingalo yozipho

2. 10. Intwasahlobo engunxande

3. Ikhava yangaphezulu eyindilinga

4. Ilunga eliyindilinga

5. I-cylinder tie induku

6. Chuck centre tie induku

7. Umzimba kaChuck

8. Ikhava engemuva ka-Chuck

9. Ibhulokhi yokusekela yokuma

10. Phezulu

11. Umsebenzi ozocutshungulwa

12. Imihlathi kaChuck

13. Ukusekelwa okuyisiyingi

Kusukela ekuhlaziyweni kwendlela ye-chuck kuMfanekiso 1 kanye noMdwebo 2, i-chuck entantayo kanye ne-chuck eqinile zinokuhluka okulandelayo.

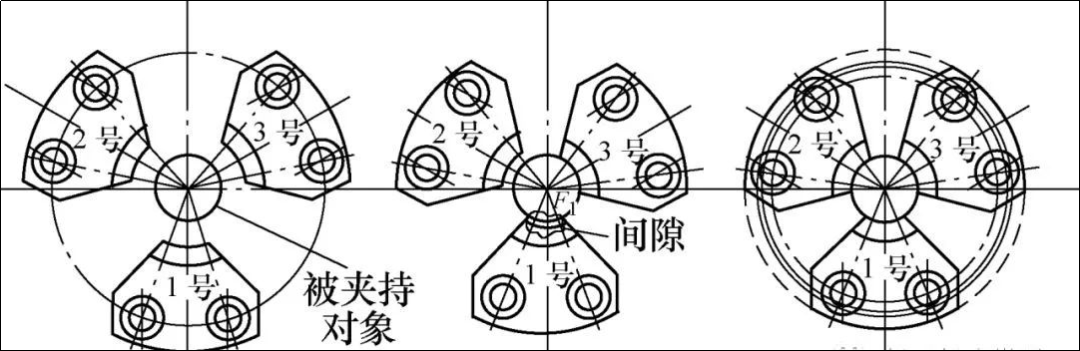

I-chuck entantayo: Njengoba kukhonjisiwe kuMfanekiso 3, ngesikhathi sokubopha ucezu lokusebenza, ngenxa yobude obuhlukene bendawo engenalutho noma ukubekezelela okukhulu kokuyindilinga kokungenalutho, umhlathi wesi-3 uzohlangana nendawo yokusebenza futhi kuzovela imihlathi enguNombolo 1 noNo. 2. Uma i-workpiece ingakathintwa okwamanje, ngalesi sikhathi, indlela entantayo ye-chuck entantayo isebenza, isebenzisa ingaphezulu le-workpiece njengesisekelo sokuntanta umhlathi wesi-3. Uma nje inani elintantayo lanele, imihlathi engu-No. 1 kanye no-No. 2 izogcina iboshiwe. I-workpiece inomphumela omncane phakathi nendawo yomsebenzi.

Umfanekiso 3 Inqubo yokubamba kwemihlathi ye-chuck entantayo

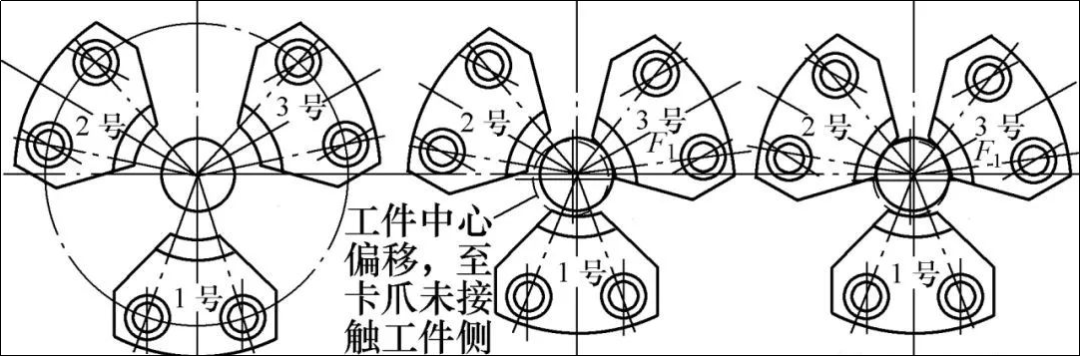

I-chuck eqinile: Njengoba kuboniswe kuMfanekiso 4, ngesikhathi senqubo yokubopha, uma ukugxila phakathi kwe-chuck kanye ne-workpiece kungalungiswanga kahle, umhlathi we-No. 3 uzothinta i-workpiece, futhi i-No. xhumana ne-workpiece. , bese i-chuck clamping force F1 izosebenza kucezu lokusebenza. Uma amandla makhulu ngokwanele, i-workpiece izosuswa kusukela esikhungweni esinqunywe kusengaphambili, okuphoqelela ucezu lokusebenza ukuba luthuthele phakathi nendawo ye-chuck; lapho i-clamping force ye-chuck incane, ezinye izimo zizokwenzeka. Lapho imihlathi ingakwazi ukuxhumana ngokugcwele ne-workpiece, ukudlidliza kwenzeka ngesikhathi somshini.isixhumi sokugaya se-cnc

Umfanekiso 4 Inqubo yokubamba kwemihlathi ye-chuck eqinile

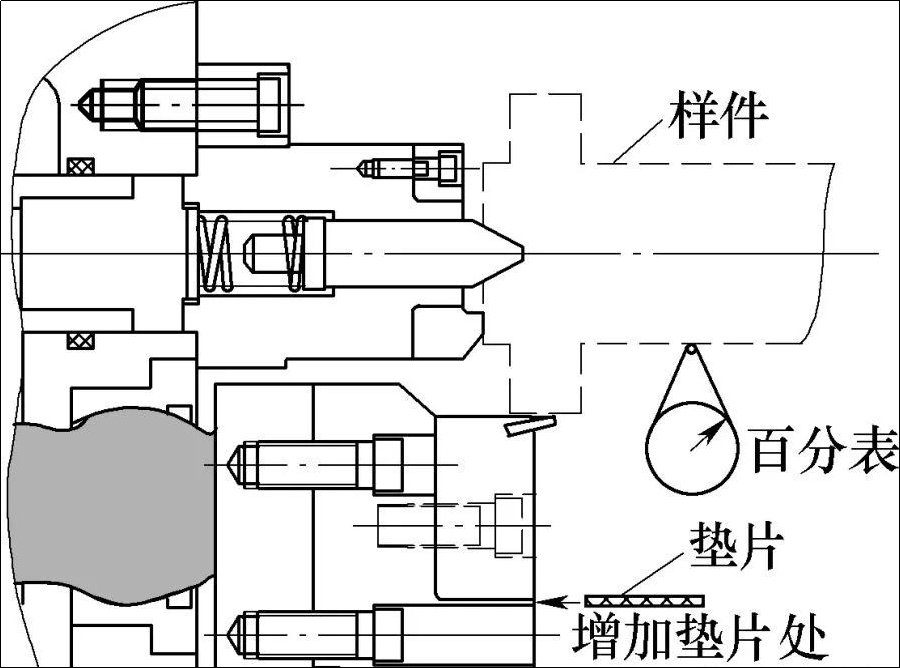

Izidingo zokulungisa ngaphambi kokuthi i-chuck isetshenziswe: I-chuck eqinile izokwakha isikhungo sokubopha se-chuck ngokwayo ngemva kokubopha. Uma usebenzisa i-chuck eqinile, kuyadingeka ukulungisa isikhungo sokugoqa se-chuck ukuze sihambisane nesikhungo sokubopha nokubeka indawo yomsebenzi, njengoba kukhonjisiwe kumfanekiso wesi-5.cnc machining aluminium ingxenye

Umfanekiso 5 Ukulungiswa kwesikhungo se-chuck esiqinile

Ngokusho kokuhlaziywa kwesakhiwo esingenhla, kunconywa ukulandela izimiso ezilandelayo ekulungiseni nasekugcinweni kwe-chuck: Ukugcotshwa kanye namafutha ezingxenye ezinyakazayo ngaphakathi kwe-chuck kushintshwa njalo. Ukunyakaza phakathi kwezingxenye ezihambayo ngaphakathi kwe-chuck ngokuyisisekelo kuwukungqubuzana kokuslayida. Kuyadingeka ukwengeza nokushintsha njalo ibanga elishiwo lamafutha okugcoba/amafutha ngokuya ngezidingo zokugcinwa kwe-chuck. Uma wengeza amafutha, kuyadingeka ukuthi ukhiphe wonke amafutha asetshenziswe esikhathini esidlule, bese uvimbele imbobo yokukhipha uwoyela ngemva kokubopha i-chuck ukuvimbela umgodi wangaphakathi we-chuck ukuthi ungabambeki.

Ukuhlola okuvamile nokulungiswa kwesikhungo sokugoqa se-chuck eqinile kanye nendawo ephakathi nendawo yokusebenza: I-chuck eqinile idinga ukukala ngezikhathi ezithile ukuthi ingabe isikhungo se-chuck kanye nesikhungo sendawo yokuphotha umsebenzi kuyahambisana. Linganisa ukuphuma kwediski. Uma idlula ububanzi obudingekayo, engeza ama-spacers ngokufanele emhlathini owodwa noma emibili ehambisana nendawo ephezulu, bese uphinda izinyathelo ezingenhla kuze kube yilapho izidingo zifinyelelwa.

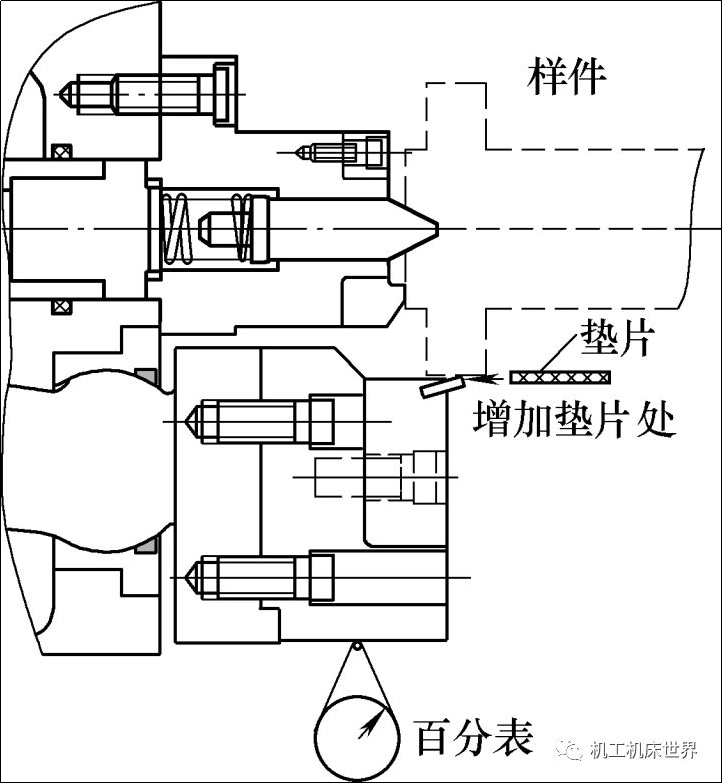

Ukuhlolwa ngezikhathi ezithile kwenani elintantayo le-chuck elintantayo (bona uMfanekiso 6). Ekulungiseni i-chuck yansuku zonke, kuyadingeka ukulinganisa njalo inani elintantayo nokunemba okuntantayo kwe-chuck entantayo, futhi unikeze isiqondiso sokunakekelwa kwangaphakathi kwe-chuck esigabeni sakamuva. Indlela yokulinganisa yokunemba okuntantayo: ngemuva kokuthi i-chuck ibambe isampula, beka i-chuck ukuze ikalwe. Zungezisa uzipho endaweni elula yokulinganisa, kala inkomba yokudayela (isidingo sokunamathisela isisekelo semitha kazibuthe ku-shaft ehambayo), bese umaka indawo yokulinganisa njengendawo yephoyinti elinguziro. Bese ulawula i-axis ye-servo ukuhambisa inkomba yokudayela, vula i-chuck, beka i-gasket enogqinsi lwe-Amm phakathi kwemihlathi ezolinganiswa nesampula, qinisa isampula ku-chuck, uhambise inkomba yokudayela endaweni yephuzu elinguziro, futhi uqinisekise ukuthi idatha ecindezelwe inkomba yokudayela imayelana no-Amm. Uma kunjalo, kusho ukuthi ukunemba okuntantayo kuhle. Uma idatha ihluka kakhulu, kusho ukuthi kunenkinga ngendlela entantayo ye-chuck. Isilinganiso seminye imihlathi siyefana nesingenhla.

Umfanekiso 6 Ukuhlolwa kwenani elintantayo le-chuck elintantayo

Ukushintshwa njalo kwezingxenye ezifana nezimvu zamanzi, ama-gaskets, neziphethu ngaphakathi kwe-chuck: iziphethu eziwunxande, umzimba we-chuck, isembozo esingemuva se-chuck, iziphethu eziwunxande, nezimpawu neziphethu ezisekelweni eziyindilinga kufanele kwenziwe ngokuya ngemvamisa yokusetshenziswa nokungenhla. imiphumela yokuhlolwa. Faka esikhundleni njalo. Uma kungenjalo, ukukhathala kuzoyilimaza, kubangele inani elintantayo kanye nokuphuma kwe-chuck eqinile.

Ngokuhlaziya okungenhla kwamaphuzu abalulekile okulungiswa nokugcinwa kwesakhiwo se-chuck, naka lezi zimiso ezilandelayo ekukhetheni ama-chucks: uma ingxenye ebamba i-chuck yengxenye ecutshunguliwe iyindawo engenalutho, i-chuck entantayo iyathandwa, kanye ne-chuck eqinile. isetshenziswa emsebenzini. I-chuck clamping surface yengxenye eyenziwe ngomshini ingaphezulu ngemva kokugoqa, ukuqeda kancane/ukuqeda. Ngemuva kokulandela imithetho eyisisekelo engenhla, ukukhetha okunembayo ngokwezimo zokusebenza ezihlukene kuyadingeka.

Ukukhetha i-chuck eqinile:

①Izimo zomshini zidinga inani elikhulu lokusika kanye namandla amakhulu okusika. Ngemva kokucindezelwa ucezu lokusebenza oluzocutshungulwa futhi lusekelwe uhlaka oluphakathi nendawo, ukuqina kocezu lwemisipha, namandla okushayela okujikelezayo okusebenza okukhulu kuyadingeka.

②Uma ingekho indlela yokubeka indawo eyodwa ngesikhathi esisodwa, njengenhla, idizayini ye-chuck centering iyadingeka.

Ukukhetha i-chuck entantayo:

①Izidingo eziphezulu zokubeka maphakathi nendawo yokuphotha umsebenzi. Ngemuva kokuthi i-chuck iboshiwe, ukuntanta kwayo ngeke kuphazamise ukugxila okuyinhloko kwe-spindle workpiece.

②Inani lokusika alilikhulu, futhi kuyadingeka kuphela ukushayela i-spindle ye-workpiece ukuze ujikeleze futhi ukhulise ukuqina kwesiqeshana sokusebenza.

Okungenhla kuchaza umehluko wesakhiwo nokugcinwa kanye nezidingo zokukhetha ama-chuck antantayo naqinile, awusizo ekusetshenzisweni nasekugcinweni. Udinga ukuqonda okujulile nokusebenzisa okuguquguqukayo; udinga njalo ukufingqa isipiliyoni ekusetshenzisweni nasekulungiseni indawo.

I-Anebon Metal Products Limited inganikeza i-CNC Machining, i-Die Casting, isevisi yokwenziwa kwe-Sheet Metal, sicela ukhululeke ukuxhumana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Isikhathi sokuthumela: Mar-31-2022