Ukuguqula, ukugaya, ukuhlela, ukugaya, ukubhola, ukubhora, ukunemba okuphezulu kakhulu kwalawa mathuluzi omshini kanye namazinga okubekezelela okungafinyelelwa ngezindlela ezihlukahlukene zokucubungula zonke zikhona.

Ukuphenduka

Inqubo yokusika lapho i-workpiece ijikeleza futhi ithuluzi lokuguqula lihamba ngendlela eqondile noma ijika endizeni. Ukuphenduka kuvame ukwenziwa nge-lathe, esetshenziselwa ukucubungula indawo yangaphakathi nengaphandle yesilinda, ubuso bokuphela, ubuso obuyi-conical, ukwakheka kwezindawo kanye nemicu yezinto zokusebenza.

Ukunemba kokuphenduka kuvame ukuba yi-IT8-IT7, futhi ubulukhuni obungaphezulu bungu-1.6~0.8 μ m.

I-1) Ukuphenduka okungalungile kuzothatha ukujula okukhulu kokusika kanye nezinga lokuphakelayo elikhulu ukuze kuthuthukiswe ukusebenza kahle kokujika ngaphandle kokunciphisa isivinini sokusika, kodwa ukunemba komshini kungafinyelela kuphela ku-IT11 futhi ukuhwaqeka kwendawo kungu-R α 20~10 μ m.

2) Isivinini esikhulu kanye nezinga lokudla okuncane kanye nokujula kokusika kuzokwamukelwa ngangokunokwenzeka ukuze kuphendulwe kancane futhi kuqedwe ukuphenduka. Ukunemba komshini kungafinyelela ku-IT10~IT7, futhi ubulukhuni obungaphezulu bungu-R α 10~0.16 μ m.

3) Ijubane eliphezuluukunemba ukuphenduka kwezingxenye zensimbi ezingenayo insimbingethuluzi lokujika ledayimane elipholishelwe kahle ku-lathe enembayo ephezulu lingenza ukunemba komshini kufinyelele ku-IT7~IT5, futhi ubulukhuni obungaphezulu bungu-R α 0.04~0.01 μ m. Lolu hlobo lokuphenduka lubizwa ngokuthi "i-mirror turning".

Ukugaya

Ukugaya kubhekisela ekusetshenzisweni kwamathuluzi azungezayo ama-multi edge ukusika izingcezu zokusebenza, okuyindlela yokucubungula esebenza kahle kakhulu. Ilungele indiza yomshini, i-groove, izindawo ezihlukahlukene zokwakha (njenge-spline, igiya kanye nentambo) kanye nendawo ekhethekile yokufa. Ngokuya ngendlela efanayo noma ephambene nesivinini sokunyakaza okuyinhloko kanye nesiqondiso sokuphakelayo kocezu lokusebenza ngesikhathi sokugaya, ingahlukaniswa ibe yi-milling eya phambili kanye ne-reverse milling.

Ukunemba komshini wokugaya ngokuvamile kungafinyelela ku-IT8~IT7, futhi ubulukhuni bobuso bungu-6.3~1.6 μm.

1) Ukunemba komshini ngesikhathi sokugaya okungalungile yi-IT11~IT13, futhi ubulukhuni obungaphezulu bungu-5~20 μ m.

2) Ukunemba komshini IT8~IT11 kanye nobulukhuni bobuso obungu-2.5~10 ekugayeni okunembayo okuncane okungu-μ m.

3) Ukunemba komshini ngesikhathi sokugaya okunembayo yi-IT16~IT8, futhi ubulukhuni obungaphezulu bungu-0.63~5 μ m.

Ukuhlela

Ukuhlela kuyindlela yokusika esebenzisa iplanethi ukwenza umnyakazo ovundlile ohambisanayo ohambisanayo endaweni yokusebenza, esetshenziselwa ikakhulukazi ukucubungula izingxenye zekhonta.

Ukunemba komshini wokuhlela ngokuvamile kungafinyelela ku-IT9~IT7, futhi ubulukhuni obungaphezulu bungu-Ra6.3~1.6 μ m.

1) Ukunemba komshini oqinile kungafinyelela ku-IT12~IT11, futhi ubulukhuni bangaphandle bungu-25~12.5 μ m.

2) Ukunemba komshini wokuqeda kancane kungafinyelela ku-IT10~IT9, futhi ubulukhuni obungaphezulu bungu-6.2~3.2 μ m.

3) Ukunemba kokuqedela ukuhlela kungafinyelela ku-IT8~IT7, futhi ubulukhuni obungaphezulu bungu-3.2~1.6 μ m.

Ukugaya

Ukugaya kubhekisela endleleni yokucubungula yokukhipha izinto ezidlulele kucezu lokusebenza ngamathuluzi abrasive futhi abrasive. Ingowokuqedela futhi isetshenziswa kabanzi embonini yokukhiqiza imishini.

Ukugaya kuvame ukusetshenziselwa ukuqeda kancane nokuqeda, ngokunemba kwe-IT8~IT5 noma ngaphezulu, futhi ubulukhuni obungaphezulu buvamise ukuba ngu-1.25~0.16 μ m.

1) Ubulukhuni obungaphezulu bokugaya ngokunemba ngu-0.16~0.04 μ m.

2) Ubulukhuni bomhlaba bokugaya obunembe kakhulu ngu-0.04-0.01 μ m.

3) Ubulukhuni obungaphezulu kwesibuko sokugaya bungafinyelela ku-0.01 μ M ngezansi.

Ukubhoboza

Ukubhoboza kuyindlela eyisisekelo yokucubungula imbobo. Ukubhoboza kuvame ukwenziwa emishinini yokubhoboza namalatha, noma emishinini eyisicefe noma emishinini yokugaya.

Ukunemba komshini wokumba kuphansi uma kuqhathaniswa, ngokuvamile kufinyelela ku-IT10, futhi ubulukhuni bangaphandle ngokuvamile bungu-12.5~6.3 μ m. Ngemuva kokubhoboza, ukubuyisela kabusha nokuphinda kusetshenziswe kabusha kuvame ukusetshenziselwa ukuqeda kanye nokuqeda.

Okuyisicefe

I-Boring iwuhlobo lwenqubo yokusika i-diameter yangaphakathi esebenzisa ithuluzi lokukhulisa imbobo noma enye i-contour eyindilinga. Ibanga lesicelo salo ngokuvamile lisuka kumshini ongemuhle kuya ekuqedeni. Ithuluzi elisetshenziswayo livamise ukuba yithuluzi elilodwa eliyisicefe (elibizwa ngebha eyisicefe).

1) Ukunemba okuyisicefe kwezinto zensimbi ngokuvamile kungafinyelela ku-IT9~IT7, futhi ubulukhuni obungaphezulu bungu-2.5~0.16 μ m.

2) Ukunemba komshini kokunemba kokubhora kungafinyelela ku-IT7~IT6, futhi ubulukhuni obungaphezulu bungu-0.63~0.08 μ m.

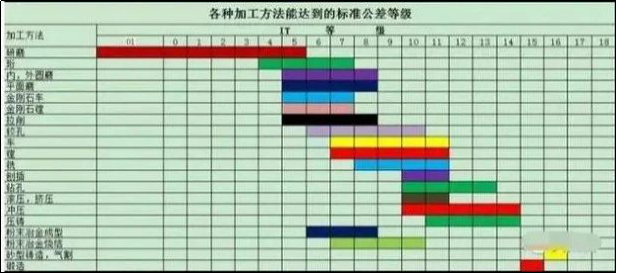

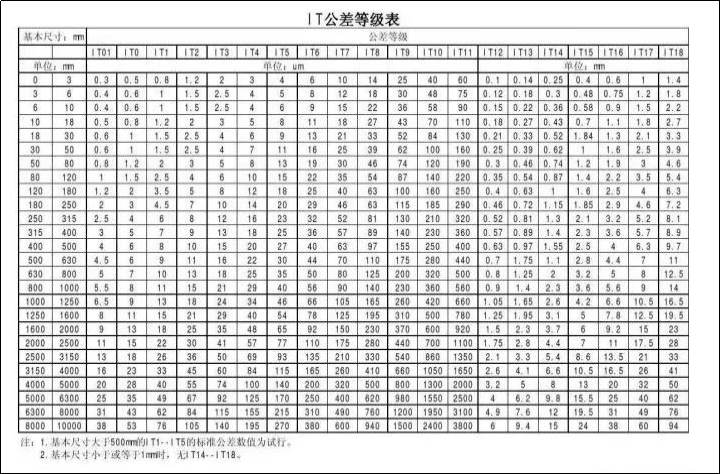

Qaphela:High ngokunemba Machiningisetshenziswa kakhulukazi ukukhombisa ubuhle bemikhiqizo, futhi yitemu elisetshenziselwa ukuhlola imingcele yejiyomethri yezindawo ezenziwe ngomshini. Izinga lokulinganisa ukunemba komshini yibanga lokubekezelela. Kunamazinga angama-20 asuka ku-IT01, IT0, IT1, IT2, IT3 kuya ku-IT18, phakathi kwawo i-IT01 imele ukunemba okuphezulu kakhulu kwengxenye, i-IT18 imele ukunemba komshini okuphansi kwengxenye. Imishini ejwayelekile yezimayini ingeye-IT7, kanti imishini yezolimo ejwayelekile ingeye-IT8. Ngokwemisebenzi ehlukene yezingxenye zomkhiqizo, ukunemba komshini okudingekayo ukuze kufezwe kuhlukile, futhi ifomu lokucubungula nenqubo ekhethiwe nakho kuhlukile.

Isikhathi sokuthumela: Nov-07-2022