I. Izinto Ezingavuthiwe Zezingxenye Zokugxiviza Zezingxenyekazi Zekhompyutha

1. Ukuhlaziywa kwamakhemikhali kanye nokuhlolwa kwe-metallographic

Okuqukethwe kwezakhi zamakhemikhali kokuqukethwe kwahlaziywa, kwanqunywa usayizi wokusanhlamvu nokufana kwento, izinga likasimende wamahhala, isakhiwo esinebhande, nokufakwa okungeyona insimbi endabeni kwahlolwa, kanye nokuncipha nokuqina kwento. zahlolwa.

2. Ukuhlolwa kwezinto

Izinto zokugxiviza ngokuyinhloko ziyimpahla yensimbi egoqelwe eshisayo noma egoqeke ngokubanda. Impahla eluhlaza yokugxiviza kwensimbi kufanele ibe nesitifiketi sekhwalithi, esiqinisekisa ukuthi impahla ihlangabezana nezidingo zobuchwepheshe ezidingekayo. Uma singekho isitifiketi sekhwalithi noma ngenxa yezinye izizathu, imboni yezingxenye zehadiwe yokugxiviza izitembu ingakhetha izinto zokusetshenziswa ukuze zihlolwe kabusha njengoba kudingeka.

3. Ukuhlolwa kokuhleleka

Ukuhlolwa kokugoba nokufaka izinkomishi kuyenziwa ukuze kunqunywe inkomba yokuqina komsebenzi wezinto ezibonakalayo kanye nesilinganiso sohlobo lwepulasitiki. Ngaphezu kwalokho, indlela yokuhlola ukwakheka kweshidi lensimbi ingenziwa ngokuvumelana nezidingo zokubunjwa kanye nendlela yokuhlola yeshidi lensimbi elincanyana.

4. Ukuhlola Ukuqina

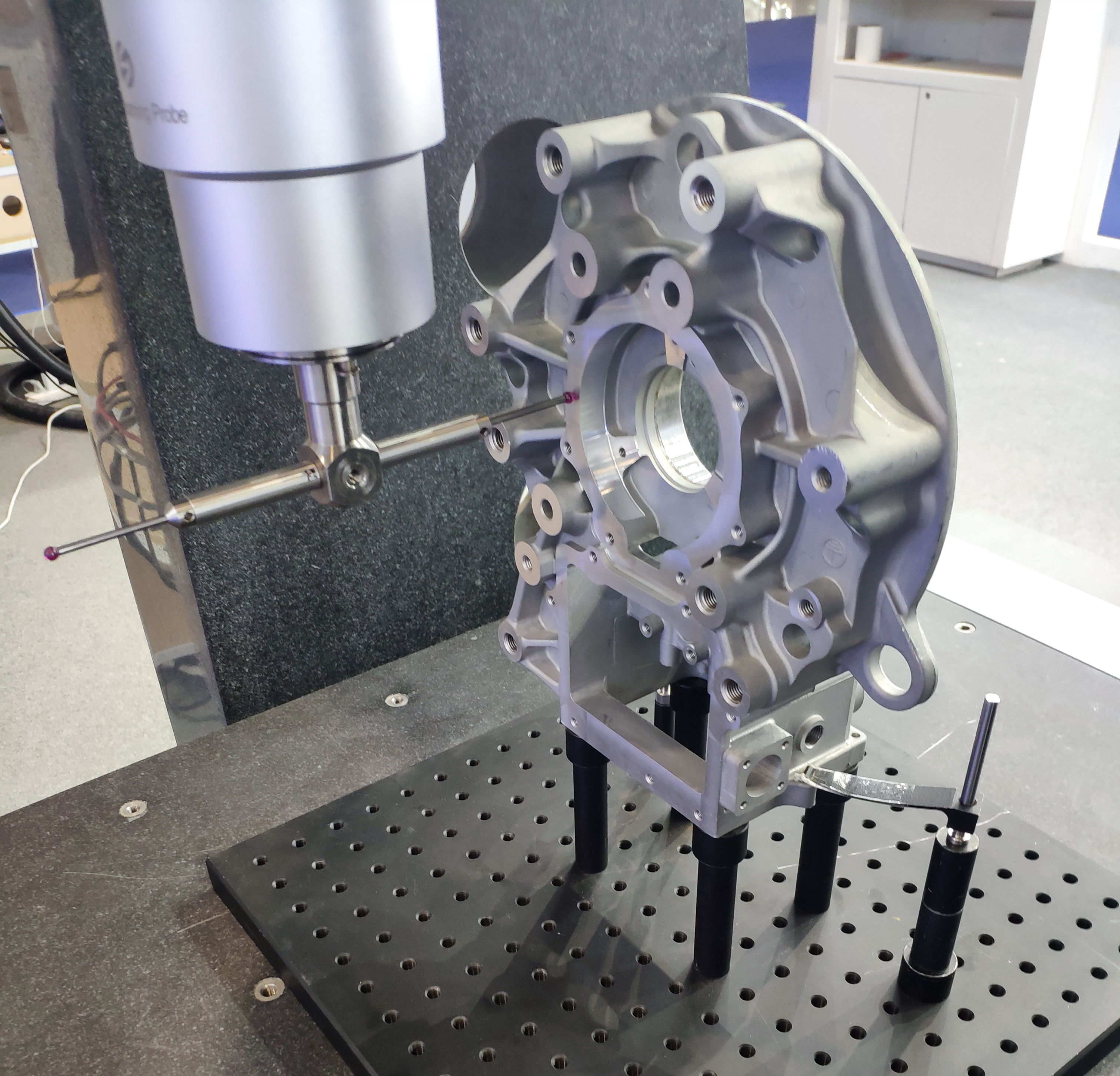

Umhloli wokuqina we-Rockwell uhlola ubulukhuni bezingxenye zokugxiviza zensimbi. Amanye amathuluzi okuhlola angahlola izingxenye ezincane zokugxiviza ezinomumo oyinkimbinkimbi.

II. Izidingo Zenqubo Yezingxenye Zezitembu Zezingxenyekazi Zekhompyutha

1. Lapho uklama ukwakheka kwesakhiwo sezingxenye, izingxenye zokugxiviza zensimbi kufanele zamukele indawo elula nenengqondo kanye nenhlanganisela yayo. Ngesikhathi esifanayo, kufanele banciphise inani lezindawo ezenziwe ngomshini kanye nendawo yokucubungula ngangokunokwenzeka.Ingxenye yemishini ye-CNC

2. Ukukhetha indlela enengqondo yokulungisa okungenalutho ekukhiqizeni ngomshini kungasebenzisa ngokuqondile amaphrofayili, ukusakaza, ukufoja, ukugxiviza, ukushisela, njll. Ukukhetha okungenalutho kuhlobene nezimo ezithile zobuchwepheshe bokukhiqiza, ngokuvamile ezincike ku-batch yokukhiqiza, impahla. izakhiwo, kanye namathuba okucubungula.

3. Imfuneko yensimbi stamping formability. Ukuze kuthuthukiswe ukuguqulwa kwesitembu kanye nekhwalithi, okubalulekile kufanele kube nepulasitiki enhle, isilinganiso esincane samandla esivuno, i-coefficient ebalulekile yokuqondisa kogqinsi lwepuleti, i-coefficient encane yokuqondisa yendiza yepuleti, kanye nesilinganiso esincane samandla esivuno ku-modulus elastic. Inqubo yokuhlukanisa ayidingi impahla ene-plasticity enhle kodwa nge-plasticity ethile.

4. Cacisa ukunemba okufanele kokukhiqiza kanye nobulukhuni bendawo. Izindleko zezingxenye zokugxiviza zensimbi zizokhula ngokuthuthukiswa kokunemba, ikakhulukazi esimweni sokunemba okuphezulu; lokhu kwanda kubaluleke kakhulu. Ngakho-ke, ukunemba okuphezulu akufanele kulandelwe ngaphandle kwesisekelo esanele. Ngokufanayo, ubulukhuni obungaphezulu bezingxenye zokugxiviza zensimbi kufanele futhi bucaciswe ngokufanele ngokuya ngezidingo zangempela zendawo ehambisanayo.Ingxenye yokugxiviza yensimbi

Ⅲ. Izimiso Zokukhetha Zamafutha Esitembu Sezingxenyekazi Zekhompyutha

1. Ishidi lensimbi ye-Silicon: Insimbi ye-Silicon iyimpahla elula ukuyishaya. Ukwenza imikhiqizo eqediwe ihlanzeke, amafutha okubhoboza aphansi-viscosity azokhethwa endaweni yokuvimbela ukubhoboza i-punching burr.

2. Ipuleti lensimbi ye-Carbon: Ipuleti lensimbi ye-Carbon lisetshenziselwa ikakhulukazi ukucubungula okunemba okuphansi, njengepuleti elivikelayo lemishini ethile, ngakho-ke lapho sikhetha uwoyela wokubhoboza, into yokuqala okufanele siyinake i-viscosity yamafutha okudweba.

3. Ishidi lensimbi: Ishidi lensimbi elakhiwe yishidi lensimbi elishiselwe elinediphu elishisayo noma elinothayela ebusweni balo. Ngenxa yokuthi izosabela ngezithasiselo ze-chlorine, kufanele kuqashelwe ukuthi ukugqwala okumhlophe kungase kwenzeke emafutheni okugxiviza ohlobo lwe-chlorine lapho kukhethwa uwoyela wokugxiviza.

4. I-Copper ne-aluminium alloy sheet: Ngenxa yokuthi ithusi ne-aluminium zinokuguquguquka okuhle, lapho ukhetha ukugxiviza uwoyela, uwoyela wokugxiviza nge-oyiliness ejenti kanye nezindawo ezinhle zokushelela zingakhethwa, futhi uwoyela wokugxiviza oqukethe i-chlorine ungagwenywa, ngaphandle kwalokho indawo engaphezulu amafutha okugxiviza azoshintshwa umbala ngokugqwala.

5. Insimbi engagqwali: Insimbi engagqwali kulula ukuyikhiqiza njengento eqinisa umsebenzi, idinga uwoyela oqinile onamandla wefilimu nokumelana okuhle kwe-sintering. Amafutha acindezelayo aqukethe izithasiselo ezihlanganisiwe zesulfure ne-chlorine ngokuvamile asetshenziselwa ukuqinisekisa ukusebenza kokucubungula ukucindezela okukhulu nokugwema ama-burrs nokuqhekeka kucezu lokusebenza.

Izidingo zobuchwepheshe bokugxiviza ngezingxenyekazi zekhompuyutha zichazwe ngokuningiliziwe ngenhla. Ubuchwepheshe bokucubungula izingxenye zokugxiviza zensimbi yinkimbinkimbi. Ukuqinisekisa ukuthi ukusebenza komkhiqizo wezingxenye zokugxiviza zensimbi kungahlangabezana nezidingo zokusetshenziswa, kuyadingeka ukulandela izidingo zenqubo ehambisanayo ukuze kuqinisekiswe ukuthi kungenzeka ukukhiqiza.

| izinsiza zokunemba zemishini | Umdwebo wokugaya we-CNC | I-CNC yokugaya nokujika |

www.anebon.com

I-Anebon Metal Products Limited ingahlinzeka ngemishini ye-CNC, i-die casting, izinsizakalo zomshini wensimbi, sicela ukhululeke ukuxhumana nathi.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Isikhathi sokuthumela: Oct-01-2019