1. Ukusetshenziswa kwama-calipers

I-caliper ingakwazi ukukala ububanzi bangaphakathi, ububanzi bangaphandle, ubude, ububanzi, ukujiya, umehluko wesinyathelo, ubude, nokujula kwento; i-caliper iyithuluzi lokulinganisa elisetshenziswa kakhulu futhi elisebenziseka kalula futhi elisetshenziswa njalo endaweni yokucubungula.

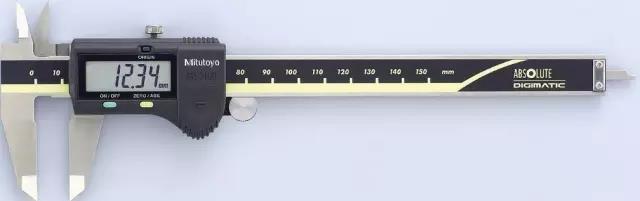

I-Digital Caliper: Ukulungiswa okungu-0.01mm, okusetshenziselwa ukulinganisa usayizi ngokubekezelela okuncane (ukunemba okuphezulu).

Ikhadi lethebula: ukulungiswa okungu-0.02mm, kusetshenziselwa ukulinganisa usayizi ovamile.

I-Vernier caliper: 0.02mm ukulungiswa, isetshenziselwa ukulinganisa okuqinile.

Ngaphambi kokusebenzisa i-caliper, susa uthuli nokungcola ngephepha elimhlophe elihlanzekile (sebenzisa indawo yangaphandle ye-caliper ukuze ubambe iphepha elimhlophe bese ulikhipha ngokwemvelo; phinda izikhathi ezingu-2-3)

Uma ulinganisa nge-caliper, indawo yokulinganisa ye-caliper kufanele ibe njenge-parallel noma i-perpendicular ebusweni bokulinganisa bento elinganisiwe ngangokunokwenzeka;

Uma usebenzisa ukulinganisa ukujula, uma into elinganisiwe ine-engeli engu-R, kuyadingeka ukugwema i-engeli engu-R kodwa eduze ne-engeli engu-R, futhi irula elijulile kufanele libe mpo ngangokunokwenzeka ekuphakameni okulinganiselwe;

Lapho i-caliper ikala isilinda, idinga ukujikeleziswa, futhi inani eliphakeme likalwa ngezigaba:Ingxenye yemishini ye-CNC.

Ngenxa yemvamisa ephezulu yokusebenzisa ama-caliper, umsebenzi wokulungisa udinga ukuba ube ngongcono kakhulu. Ngemuva kokusetshenziswa kosuku ngalunye, idinga ukusulwa futhi ifakwe ebhokisini. Ngaphambi kokusetshenziswa, i-block iyadingeka ukuze kuhlolwe ukunemba kwe-caliper.

2. Ukusetshenziswa kwe-micrometer

Ngaphambi kokusebenzisa i-micrometer, susa uthuli nokungcola ngephepha elimhlophe elihlanzekile (sebenzisa i-micrometer ukukala indawo yokuxhumana kanye ne-screw surface kanye nephepha elimhlophe linamathele bese ulikhipha ngokwemvelo, phinda izikhathi ezingu-2-3), bese u-twist. i-knob yokulinganisa othintana naye Lapho indawo engaphezulu ithintana ngokushesha ne-screw surface, ukulungiswa okuhle kuyasetshenziswa, futhi lapho izindawo ezimbili zixhumene ngokuphelele, ukulungiswa kwe-zero kungenziwa ukuze kulinganiswe.ingxenye eyenziwe ngomshini

Uma ukala i-hardware nge-micrometer, hambisa iknob, futhi uma ihlangana nento yokusebenza, sebenzisa ifindo lokushuna kahle ukuze ungene ngesikulufi. Yima futhi ufunde idatha evela kusibonisi noma esikalini lapho uzwa ukuchofoza kathathu.

Lapho ukala imikhiqizo yepulasitiki, indawo yokuxhumana yesilinganiso nesikulufu zithinta kancane umkhiqizo.

Lapho ukala ububanzi be-shafts nge-micrometer, linganisa okungenani izikhombisi-ndlela ezimbili futhi ulinganise i-micrometer ngesilinganiso esiphezulu ezigabeni. Izindawo zokuthintana ezimbili kufanele zihlale zihlanzekile ukuze kuncishiswe amaphutha okulinganisa.

3. Ukusetshenziswa kwerula yobude

I-gauge yobude isetshenziswa kakhulu ukukala ubude, ukujula, ukucaba, ukuma, ukujula, ukuhlangana, ukudlidliza kwendawo, ukudlidliza kwamazinyo, ukujula, nokuphakama. Lapho ukala, qala uhlole i-probe nezingxenye zokuxhuma ukuthi azixege yini.

4. Ithuluzi lokulinganisa ukunemba: into yesibili

Isici sesibili ithuluzi lokulinganisa elingaxhunywanga elinokusebenza okuphezulu nokunemba. Isici sokuzwa sensimbi yokulinganisa asithintani ngqo nobuso bengxenye elinganisiwe, ngakho-ke awekho amandla okulinganisa ayimishini; isici sesibili sidlulisela isithombe esithwetshuliwe ngomugqa wedatha siye ekhadini lokutholwa kwedatha lekhompuyutha ngokusebenzisa indlela yokubonisa. Kuthwetshulwe kusiqapha sekhompiyutha isoftware: izakhi ezahlukahlukene zejiyomethri (amaphuzu, imigqa, imibuthano, ama-arcs, ama-ellipses, ama-rectangles), amabanga, ama-engeli, ukuphambana kwemigwaqo, ukubekezelelana kwejometri (ukujikeleza, ubuqotho, ukufana, ukuma) Idigri, ukuthambekela, indawo, ukugxila , i-symmetry), kanye nokukhishwa kwe-CAD komdwebo we-2D wohlaka. Ikhontatha ye-workpiece ingabonwa, futhi ukuma kwe-opaque workpiece kungalinganiswa.CNC

5. Amathuluzi okulinganisa okunembayo: ama-three-dimensional

Izici zesici esinezinhlangothi ezintathu ukunemba okuphezulu (kufika kuzinga elingu-μm), indawo yonke (ingashintsha amathuluzi okulinganisa ubude ahlukahlukene), ingasetshenziswa ukukala izici zejiyomethri (ngaphezu kwezakhi i-elementi yesibili engalinganisa, ingakwazi futhi ukukala amasilinda nama-cones), Ukubekezelelwa komumo nokuma (ngaphezu komumo nokubekezelelana kwesikhundla okungakalwa ngento yesibili, okuhlanganisa isilinda, flatness, iphrofayili yomugqa, indawo engaphezulu iphrofayili, i-coaxial, indawo eyinkimbinkimbi, inqobo nje uma i-probe enezinhlangothi ezintathu Lapho ingathinteka khona, usayizi wayo wejometri, indawo ehlangene, iphrofayili engaphezulu ingakalwa futhi ukucutshungulwa kwedatha kuqedwa kusetshenziswa ikhompyutha ngokunemba kwayo okuphezulu; ukuguquguquka, kanye nekhono elihle kakhulu ledijithali, sekuyingxenye ebalulekile yokucubungula isikhunta kanye nokukhiqiza kanye nokuqinisekiswa kwekhwalithi Izindlela, amathuluzi asebenzayo.

We are a reliable supplier and professional in CNC service. If you need our assistance, please get in touch with me at info@anebon.com.

I-Anebon Metal Products Limited ingahlinzeka ngemishini ye-CNC, i-die casting, izinsizakalo zomshini wensimbi, sicela ukhululeke ukuxhumana nathi.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Isikhathi sokuthumela: Apr-13-2020