Intambo iyi-helix esikwe ibe yi-workpiece kusuka ngaphandle noma ngaphakathi futhi isebenza imisebenzi eminingana ebalulekile. Okokuqala, izintambo zakha uxhumano lwemishini ngokuhlanganisa umkhiqizo ofakwe ngaphakathi nomkhiqizo oxhumeke ngaphandle. Lokhu kuxhumana kuqinisekisa ukuthi izingxenye ezahlukene ze-workpiece zingaxhunywa ngokuqinile komunye nomunye.

Ngaphezu kwalokho, imicu idlala indima ebalulekile ekudluliseni ukunyakaza. Bangakwazi ukuguqula ukunyakaza kwe-rotary kube ukunyakaza okuqondile futhi ngokuphambene nalokho. Leli khono liwusizo ikakhulukazi ezinhlelweni eziningi, njengasemishinini edinga ukunyakaza okuqondile ukwenza imisebenzi ethile.

Ngaphezu kwalokho, imicu inikeza izinzuzo mechanical. Ngokusebenzisa imicu, ukusebenza okuphezulu kwemishini kungafinyelelwa kuzo zonke izici. Lokhu kuhlanganisa ukukhushulwa komthamo wokuthwala, ukumelana okuthuthukisiwe ekuxegisweni noma ukudlidliza, kanye nokusebenza kahle kokudluliswa kwamandla okuthuthukisiwe.

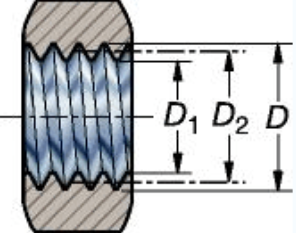

Kunezinhlobo ezahlukene zentambo, ngayinye enquma i-geometry yentambo. Isici esibalulekile sephrofayili yentambo ubukhulu be-workpiece. Lokhu kuhlanganisa ububanzi obukhulu (ububanzi obukhulu bentambo) kanye nobubanzi bephimbo (ububanzi endaweni ecatshangwayo lapho ububanzi bentambo buziro). Lezi zilinganiso zibalulekile ekuqinisekiseni ukuthi imicu ilingana kahle futhi isebenza ngempumelelo.

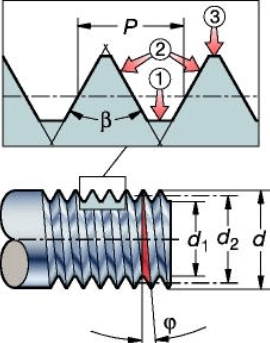

Ukuqonda amatemu entambo kubalulekile ukuze usebenzise imicu ngempumelelo. Amanye amagama abalulekile ahlanganisa ukuhola (ibanga le-axial uchungechunge oluhambayo ekuguqukeni okukodwa okuphelele) kanye nephimbo (ibanga eliphakathi kwamaphoyinti ahambisanayo emicu eseduze). Ukulinganiswa okunembile komthofu nephimbo kubalulekile ukuze kuqinisekiswe ukwakheka okunembile kwentambo nokuhambisana.

Kafushane, imicu yenza imisebenzi eminingana ebalulekile ezimbonini ezahlukahlukene. Benza lula ukuxhumana kwemishini, badlulise ukunyakaza futhi banikeze izinzuzo zemishini. Ukuqonda amaphrofayili ochungechunge kanye namagama ahlobene kubalulekile ekusebenziseni imicu ngempumelelo nokuqinisekisa ukusebenza kahle.

Ukuxazulula Imfihlakalo Yephimbo: Ukuhlola Incazelo Yayo kanye nendlela yokubala

I-Thread pitch iyisici esibalulekile emkhakheni wokukhiqiza nokwenza imishini. Ukuqonda ukuthi kusho ukuthini nokubala ngendlela efanele kubalulekile ekwenzeni izingxenye zomshini ezisezingeni eliphezulu. Kulesi sihloko, sizocwilisa ebunzimeni be-thread pitch, i-geometry yayo, nokuthi ungayinquma kanjani ngokunembile. Ukwengeza, sizokwethula i-Anebon, inkampani enguchwepheshe bezinsizakalo zemishini ye-CNC eyisibonelo kanye nokugaya okungokwezifiso kwe-CNC, enikeza izingcaphuno ezisheshayo nezithembekile ze-inthanethi zomshini we-CNC.

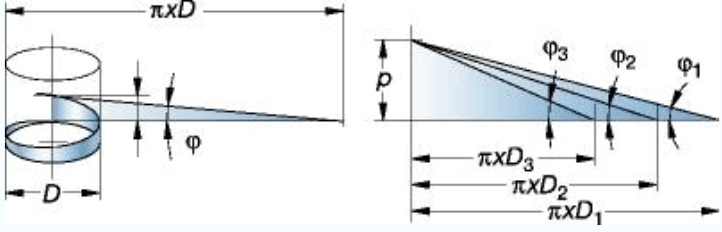

Ijiyomethri yentambo isekelwe kububanzi bephimbo lentambo (d, D) kanye nephimbo (P): ibanga le-axial eduze kwentambo ku-workpiece ukusuka kwelinye iphuzu kuphrofayili kuya ephuzwini elilandelayo elihambisanayo. Kucabange njengonxantathu ozungeza ucezu lokusebenza. Lesi sakhiwo esingunxantathu sinquma ukusebenza kahle kanye nokusebenza kwezingxenye ezinentambo. Ukubalwa okunembile kokuphakama kwentambo kubalulekile ukuze kuqinisekiswe ukulingana okulungile, ukusatshalaliswa komthwalo okulungile nokusebenza kahle kwezingxenye eziwumshini.

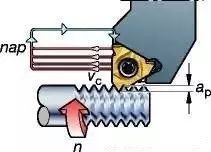

Ukuze unqume ngokunembile iphimbo, umenzi usebenzisa ubuchwepheshe bemishini be-CNC obuphambili. I-CNC machining, noma umshini wokulawula izinombolo wekhompuyutha, kuyinqubo yokukhiqiza esebenzisa amathuluzi omshini olawulwa ngekhompuyutha ukuze asuse ngokunembile impahla ezintweni ezingavuthiwe ukuze kwakheke izingxenye eziwumshini. I-CNC Machining Online Quoting iyisevisi enikezwa izinkampani eziningi ezingochwepheshe evumela amakhasimende ukuthi athole ngokushesha futhi kalula izilinganiso zamanani ngokwezifiso zawo.Izingxenye zemishini ye-CNC.

I-Anebon iyinkampani ehamba phambili embonini yezingxenyekazi zensimbi, ehlinzeka ngezinsizakalo zemishini ye-CNC eyisibonelo kanye nokugaya okwenziwe ngokwezifiso kwe-CNC kusukela yasungulwa ngo-2010. Ineqembu lochwepheshe kanye nemishini yesimanje, i-Anebon inikeza imikhiqizo esebenza kahle, ephezulu. . Imishini ejwayelekile engenisiwe ivela eJapan. Izigayo zabo ze-CNC namalathe kanye nezigayo zangaphezulu zibenza bakwazi ukuletha ukunemba komkhiqizo okuvelele kanye nekhwalithi. Ukwengeza, i-Anebon iqinisekisiwe nge-ISO 9001:2015, okubonisa ukuzibophezela kwabo ekugcineni amazinga aphezulu okukhiqiza kanye nokwaneliseka kwamakhasimende.

Lapho kubalwa iphimbo, ngokuvamile ivezwa ngemicu iyintshi ngayinye (TPI) noma amamilimitha. Kuchungechunge lwemethrikhi, ukuphakama kucaciswe njengebanga ngamamilimitha phakathi kwama-crest entambo amabili ancikene. Ngokuphambene, kumasistimu wentambo asekelwe ngamayintshi, i-TPI imele imicu ngeyintshi ngalinye lomugqa. Ukulinganisa ngokunembile ukuphakama kwentambo kubalulekile ekuqinisekiseni ukuhambisana phakathi kwezingxenye ezinentambo nokugwema izinkinga ezingaba khona njengokuxega, ukonakala noma ukusatshalaliswa komthwalo okwanele.

CNC imishiniidlala indima ebalulekile ekuzuzeni ukukalwa kwephimbo okunembile. Ngokusebenzisa ubuchwepheshe obusezingeni eliphezulu kanye nemishini enembayo, izingxenye zomshini we-CNC zingahlangabezana nezidingo eziqinile nezicaciso. Izinhlelo zesofthiwe ezithuthukisiwe zivumela imishini ye-CNC ukuthi yenze izibalo zentambo eziyinkimbinkimbi, iqinisekisa ukuthi ukuphimisa kwentambo okulungile kufinyelelwa kuhlelo lokusebenza olulodwa olulodwa.

Kafushane, ukuqonda ubunkimbinkimbi bephimbo kanye nokubala ngokunembile kubalulekile ekwenzeni izingxenye zomshini ezisezingeni eliphezulu. Ngokusebenzisa i-prototype yezinsizakalo zemishini ye-CNC nokusebenzisa inkambisoI-CNC yokugaya, abakhiqizi bangafinyelela ukunemba okukhethekile kanye nekhwalithi emikhiqizweni yabo. Zizibophezele ekusebenzeni kahle nangemishini yesimanjemanje, izinkampani ezifana ne-Anebon zihola indlela ekuhlinzekeni ngezinsizakalo ezithembekile, ezisebenzayo ze-CNC zokucaphuna ku-inthanethi. Ngolwazi olunembile lwephimbo lentambo, abakhiqizi bangakha izingxenye ezinentambo ezihlangabezana namazinga aphezulu kakhulu okusebenza nokusebenza.

1. Ukubalwa nokubekezelela kobubanzi bokuphakama kwentambo yangaphandle emise okwezinyo elingu-60° (izinga lezwe lonke i-GB197/196)

a.Ukubalwa kosayizi oyisisekelo wobubanzi be-pitch

Usayizi oyisisekelo wobubanzi be-pitch wentambo = ububanzi obukhulu bentambo - iphimbo × inani le-coefficient.

Ukumelwa kwefomula: d/DP×0.6495

Isibonelo: Ukubalwa kobubanzi bokuphakama kwentambo yangaphandle engu-M8

8-1.25×0.6495=8-0.8119≈7.188

b. Okuvame ukusetshenziswa 6h intambo yangaphandle pitch ububanzi tolerance (ngokusekelwe pitch intambo)

Inani eliphezulu lomkhawulo lithi “0”

Umkhawulo ophansi ngu-P0.8-0.095P1.00-0.112P1.25-0.118

P1.5-0.132P1.75-0.150P2.0-0.16

P2.5-0.17

Ifomula yokubala yomkhawulo ongaphezulu iwusayizi oyisisekelo, futhi ifomula yokubala yomkhawulo ophansi ethi d2-hes-Td2 iwukuchezuka okuvunyelwe kosayizi wokuchezuka okuyisisekelo.

Ivelu yokubekezelela yebanga elingu-6h lobubanzi bokuphakama kwe-M8: inani eliphezulu lomkhawulo 7.188 inani eliphansi lomkhawulo: 7.188-0.118=7.07.

C. Okuvame ukusetshenziswa ebangeni elingu-6g lokuchezuka okuyisisekelo kwentambo yephimbo langaphandle: (kusekelwe ekuphakameni kwentambo)

P0.80-0.024P1.00-0.026P1.25-0.028P1.5-0.032

P1.75-0.034P2-0.038P2.5-0.042

Ifomula yokubala yomkhawulo ophezulu i-d2-ges iwukuchezuka kosayizi oyisisekelo

Ifomula yokubala yomkhawulo ophansi i-d2-ges-Td2 iwukubekezelela ukuchezuka kosayizi oyisisekelo

Isibonelo, inani lokubekezelela ububanzi bebanga le-6g lebanga le-M8: inani eliphezulu lomkhawulo 7.188-0.028=7.16 inani eliphansi lomkhawulo: 7.188-0.028-0.118=7.042.

Qaphela:

①Ukubekezelelwa kwentambo okungenhla kususelwa kuzintambo ezimahhadla, futhi ukubekezelelwa kwentambo kwemicu emihle nakho kuyashintshwa ngokufanele, kodwa ukubekezelela kukhuliswa kuphela, ngakho-ke ukulawula ngeke kweqe umkhawulo ojwayelekile, ngakho-ke akumakwa etafuleni. Kwaphuma phezulu.

②Ekukhiqizweni kwangempela, ngokuya ngokunemba okudingwa idizayini namandla okukhipha impahla yokucubungula intambo, ububanzi benduku epholishiwe epholishiwe bukhuphuke ngo-0.04-0.08 uma kuqhathaniswa nobubanzi bentambo eklanyelwe, okuwububanzi bentambo epholishiwe epholishiwe. induku. Isibonelo, ububanzi bentambo epholishiwe ye-M8 yenkampani yethu engu-6g ingu-7.08-7.13, okungaphakathi kwalolu hlu.

③Ngokucabangela izidingo zenqubo yokukhiqiza, umkhawulo wokulawula ophansi wedayamitha yephimbo yochungechunge lwangaphandle ngaphandle kokwelashwa kokushisa nokuphathwa kwendawo ekukhiqizeni kwangempela kufanele kugcinwe kuleveli engu-6h kakhulu ngangokunokwenzeka.

2. Ukubalwa nokubekezelela kobubanzi bephimbo lentambo yangaphakathi engu-60° (GB197/196)

ukubekezelela ukubekezelela kobubanzi be-pitch yeleveli ye-a.6H (kusekelwe ekuphakameni kwentambo)

umkhawulo ophezulu:

P0.8+0.125P1.00+0.150P1.25+0.16P1.5+0.180

P1.25+0.00P2.0+0.212P2.5+0.224

Inani eliphansi lomkhawulo lithi “0″,

Ifomula yokubala yomkhawulo ophezulu 2+TD2 iwusayizi oyisisekelo + ukubekezelela.

Isibonelo, ububanzi be-pitch bentambo yangaphakathi ye-M8-6H yilokhu: 7.188+0.160=7.348 umkhawulo ophezulu: 7.188 umkhawulo ophansi.

b. Ifomula yokubala i-pitch diameter yentambo yangaphakathi iyafana naleyo yochungechunge lwangaphandle

Okungukuthi, i-D2=DP×0.6495, okungukuthi, ububanzi bephitshi bomucu wangaphakathi bulingana nobubanzi be-pitch×inani le-coefficient.

I-c.6G yekilasi ye-pitch pitch diameter yokuchezuka okuyisisekelo kwe-E1 (ngokusekelwe ekuphakameni kwentambo)

P0.8+0.024P1.00+0.026P1.25+0.028P1.5+0.032

P1.75+0.034P1.00+0.026P2.5+0.042

Isibonelo: Umkhawulo ophezulu wobubanzi bephimbo lentambo yangaphakathi ye-M86G: 7.188+0.026+0.16=7.374

Umkhawulo ophansi: 7.188+0.026=7.214

Ifomula yomkhawulo ophezulu 2+GE1+TD2 iwusayizi oyisisekelo we-pitch diameter+deviation+tolerance

Ifomula yenani lomkhawulo eliphansi 2+GE1 iwusayizi we-pitch diayamitha+ukuchezuka

3. Ukubalwa nokubekezelela ububanzi obukhulu bentambo yangaphandle (GB197/196)

a.Umkhawulo ophezulu we-6h ububanzi obukhulu bentambo yangaphandle

Okusho ukuthi, isibonelo senani lentambo yochungechunge i-M8 ngu-φ8.00, futhi ukubekezelela umkhawulo ophezulu ngu-“0″.

b. Ukubekezelela umkhawulo ophansi we-diameter enkulu yekilasi le-6h lentambo yangaphandle (ngokusekelwe ekuphakameni kwentambo)

P0.8-0.15P1.00-0.18P1.25-0.212P1.5-0.236P1.75-0.265

P2.0-0.28P2.5-0.335

Ifomula yokubala yomkhawulo ophansi wobubanzi obukhulu: i-d-Td iwukubekezelela kobukhulu obuyisisekelo kobubanzi obukhulu bochungechunge.

Isibonelo: Intambo yangaphandle engu-M8 6h usayizi wobubanzi obukhulu: umkhawulo ophezulu ngu-φ8, umkhawulo ophansi ngu-φ8-0.212=φ7.788

c.Ukubalwa Nokubekezelela Kodayamitha Olukhulu 6g Lochungechunge Lwangaphandle

6g ukuchezuka kwereferensi yochungechunge lwangaphandle (ngokusekelwe ekuphakameni kwentambo)

P0.8-0.024P1.00-0.026P1.25-0.028P1.5-0.032P1.25-0.024P1.75–0.034

P2.0-0.038P2.5-0.042

Ifomula yokubala yomkhawulo ophezulu i-d-ges iwubukhulu obuyisisekelo bokuchezuka kwereferensi yedayamitha enkulu

Ifomula yokubala yomkhawulo ophansi i-d-ges-Td iwubukhulu obuyisisekelo bokubekezelela ukuchezuka kwentambo enkulu yobubanzi-isisekelo

Isibonelo: Intambo yangaphandle engu-M8 6g isigaba esikhulu sobubanzi bomkhawulo ophezulu φ8-0.028=φ7.972.

Umkhawulo ophansi φ8-0.028-0.212=φ7.76

Qaphela: ①Ububanzi obukhulu bochungechunge bunqunywa ububanzi benduku epholishiwe yochungechunge kanye nezinga lokuguga kwepuleti eligoqa uchungechunge/iphrofayili yezinyo lerola, futhi inani lalo lihambisana ngokuphambene nobubanzi obungaphezulu naphakathi bochungechunge. Ngesisekelo sethuluzi elifanayo elingenalutho nelokucupha, i-diameter emaphakathi encane incane, i-diameter enkulu inkulu, futhi ngokuphambene nalokho, i-diameter emaphakathi inkulu, i-diameter enkulu encane.

② Ezingxenyeni ezidinga ukwelashwa okushisayo nokwelashwa kwendawo, uma kucatshangelwa ubudlelwano phakathi kobuchwepheshe bokucubungula nokukhiqizwa kwangempela, ububanzi obukhulu bentambo kufanele bulawuleke emkhawulweni ophansi wekilasi 6h kanye no-0.04mm noma ngaphezulu. Isibonelo, ngentambo yangaphandle ye-M8, ububanzi obukhulu bentambo yokuhlikihla (egoqayo) kufanele kuqinisekiswe ukuthi bungaphezu kuka-7.83 nangaphansi kuka-7.95.

4. Ukubalwa nokubekezelelana kobubanzi obuncane bentambo yangaphakathi

a.Ukubalwa kosayizi oyisisekelo wobubanzi obuncane bochungechunge lwangaphakathi (D1)

Usayizi oyisisekelo wentambo yobubanzi obuncane = usayizi oyisisekelo wentambo yangaphakathi - iphimbo × i-coefficient

Isibonelo: Usayizi oyisisekelo wobubanzi obuncane bentambo yangaphakathi ye-M8 ngu-8-1.25×1.0825=6.646875≈6.647

b. Ukubalwa kwentambo yangaphakathi 6H ukubekezelelana kobubanzi obuncane (ngokusekelwe ku-pitch yentambo) kanye nenani lobubanzi obuncane

P0.8+0.2P1.0+0.236P1.25+0.265P1.5+0.3P1.75+0.335

P2.0+0.375P2.5+0.48

Ifomula yokuchezuka yomkhawulo ophansi D1+HE1 yekilasi lentambo yangaphakathi engu-6H iwusayizi oyisisekelo wentambo yangaphakathi ububanzi obuncane + ukuchezuka.

Qaphela: Inani lokuchema lithi “0″ kuleveli engu-6H

Ifomula yokubala yomkhawulo ongaphezulu wezinga le-6H lentambo yangaphakathi=D1+HE1+TD1, okungukuthi, usayizi oyisisekelo wobubanzi obuncane bentambo yangaphakathi + ukuchezuka + ukubekezelela.

Isibonelo: Umkhawulo ongaphezulu wobubanzi obuncane be-6H grade M8 intambo yangaphakathi ngu-6.647+0=6.647

Umkhawulo ophansi wobubanzi obuncane be-6H grade M8 intambo yangaphakathi ngu-6.647+0+0.265=6.912

c.Ukubalwa kokuchezuka okuyisisekelo kobubanzi obuncane bentambo yangaphakathi engu-6G (ngokusekelwe ekuphakameni) kanye nenani lobubanzi obuncane.

P0.8+0.024P1.0+0.026P1.25+0.028P1.5+0.032P1.75+0.034

P2.0+0.038P2.5+0.042

Ifomula yokubala yomkhawulo ophansi wobubanzi obuncane bentambo yangaphakathi 6G = D1 + GE1 usayizi oyisisekelo wentambo yangaphakathi + ukuphambuka.

Isibonelo: Umkhawulo ophansi we-diameter encane ye-6G grade M8 intambo yangaphakathi ngu-6.647+0.028=6.675

Ifomula ethi D1+GE1+TD1 yenani eliphezulu lomkhawulo lobubanzi obuncane be-6G grade M8 intambo yangaphakathi iwusayizi oyisisekelo wentambo yangaphakathi + ukuchezuka + ukubekezelelana.

Isibonelo: Umkhawulo ongaphezulu wobubanzi obuncane be-6G grade M8 intambo yangaphakathi ngu-6.647+0.028+0.265=6.94

Qaphela:

①Ubude bezinyo bentambo yangaphakathi buhlobene ngokuqondile nenkathi yokuthwala yochungechunge lwangaphakathi, ngakho-ke okungenalutho kufanele kube ngaphakathi komkhawulo ophezulu wesigaba esingu-6H ngangokunokwenzeka.

②Ngesikhathi sokukhanda intambo yangaphakathi, lapho i-diameter encane yochungechunge lwangaphakathi incane, kunciphisa ukusebenza kahle kwethuluzi lokucubungula—umpompi. Ngokombono wokusetshenziswa, i-diameter encane encane, kungcono, kodwa ukucatshangelwa okuphelele, ububanzi obuncane buvame ukusetshenziswa phakathi komkhawulo ophakathi nomkhawulo ongaphezulu, uma kuyinsimbi noma i-aluminium, kufanele isetshenziswe phakathi umkhawulo ophansi kanye nomkhawulo omaphakathi wobubanzi obuncane .

③Uma i-diameter encane yochungechunge lwangaphakathi ingu-6G, ingabonakala njengo-6H. Izinga lokunemba ngokuyinhloko licabangela ukumbozwa kobubanzi bephimbo lentambo. Ngakho-ke, ububanzi be-pitch kuphela bompompi bucatshangelwa ngesikhathi sokucubungula intambo, futhi ububanzi obuncane abubhekwa. Ububanzi bembobo yokukhanya.

5. Ifomula yokubala yokuhlukanisa ikhanda indlela eyodwa yokuhlukanisa

Ifomula yokubala yesigaba esisodwa: n=40/Z

n: inani lemibuthano okufanele ikhanda elihlukanisayo lijike

Z: ingxenye elinganayo ye-workpiece

40: inombolo yenhloko yenkomba engashintshi

Isibonelo: Isibalo sokugaya ihexagon

Faka esikhundleni sefomula: n=40/6

Ukubala: ① Yenza kube lula amafrakshini: thola isihlukanisi esincane kakhulu esingu-2 futhi uhlukanise, okungukuthi, hlukanisa inombolo nedenominator ngo-2 ngesikhathi esifanayo ukuze uthole u-20/3. Ngenkathi inciphisa amaphuzu, ukuhlukaniswa kwayo okulinganayo kuhlala kunjalo.

② Ukubalwa kwamafrakshini: Kuleli qophelo, kuncike emananini enumeretha nedinominetha; uma i-numerator nedenominator zinkulu, khona-ke ukubala kuyenziwa.

20÷3=6(2/3) inani lika-n, okungukuthi, ikhanda elihlukanisayo kufanele liphendule imibuthano engu-6(2/3). Ngalesi sikhathi, ingxenyenamba isibe yingxenyana; ingxenye ephelele yedesimali yesi-6 iyinhloko yokuhlukanisa kufanele iphendule imibuthano egcwele engu-6. Ingxenyana engu-2/3 eneqhezu ingaba ngu-2/3 kuphela wesiyingi futhi kufanele ibalwe kabusha kuleli phuzu.

③Ukukhethwa nokubalwa kwepuleti lokukhomba: ukubalwa kombuthano ongaphansi kowodwa kufanele kubonakale ngosizo lwepuleti lokukhomba lekhanda lokukhomba. Isinyathelo sokuqala ekubaleni ukukhulisa kanyekanye ingxenye ngo-2/3. Isibonelo: uma umphumela ukhuliswa izikhathi ezingu-14 ngesikhathi esifanayo, u-28/42; uma ikhuliswa izikhathi ezingu-10 ngesikhathi esifanayo, amaphuzu angu-20/30; uma sikhuliswe izikhathi ezingu-13 ngesikhathi esifanayo, amaphuzu angu-26/39…Isikali esikhulisiwe kufanele sihambisane nokudayela Khetha inombolo yezimbobo kuso.

Kuleli qophelo kufanele sinake:

①Inombolo yezimbobo zepuleti lokukhomba elikhethiwe kufanele lihlukaniseke idinominetha engu-3. Ngokwesibonelo, kulesi sibonelo esingenhla, izimbobo ezingu-42 ziyizikhathi ezingu-14 kwezingu-3, izimbobo ezingu-30 ziyizikhathi ezingu-10 kwezingu-3, futhi izimbobo ezingu-39 ziyizikhathi ezingu-13 kwezingu-3. .

②Ukunwetshwa kwamafrakshini kufanele kube ukuthi inombolo nedenominayitha zinwetshwa ngesikhathi esisodwa, futhi ukuhlukana okulinganayo kuhlala kungashintshile, isibonelo.

28/42=2/3×14=(2×14)/(3×14); 20/30=2/3×10=(2×10)/(3×10);

26/39=2/3×13=(2×13)/(3×13)

28/42 Idinomineyitha 42 iwukusebenzisa izimbobo ezingama-42 zenombolo yenkomba ukuze kufakwe inkomba; inombolo engu-28 iqhubekela phambili embobeni yokuma yesondo eliphezulu, bese ijika phezu kwembobo engu-28, okungukuthi, imbobo engu-29 iyimbobo yokuma yesondo lamanje, 20/30 izimbobo eziyi-10 phambili endaweni ezungezayo yesondo. Ipuleti lenkomba elinezimbobo ezingu-30, futhi imbobo ye-11 iyona kanye imbobo yokuma yaleli sondo. I-26/39 iyimbobo yokumisa yaleli sondo ku-index plate enezimbobo ezingu-39, futhi izimbobo ezingu-26 zezimbobo ezingu-27 zizungeziswa phambili.

Lapho ugaya ihexagon (isithupha), izimbobo ezinjengezimbobo ezingama-42, izimbobo ezingama-30, nezimbobo ezingama-39 ezingahlukaniseka ngo-3 zisetshenziswa njengezikali: umsebenzi uwukuzungezisa isibambo izikhathi eziyisi-6, bese uya phambili imbobo yokubeka kube isondo eliphezulu ngokulandelana. Vula i-28+1/10+1/26+ futhi! Imbobo engenhla engu-29/11/27 isetshenziswa njengembobo yokumisa isondo.

Isibonelo sesi-2: Isibalo sokugaya igiya lamazinyo ayi-15.

Faka esikhundleni sefomula: n=40/15

Bala n=2(2/3)

Kungukuvula imibuthano emi-2 egcwele, bese ukhetha izimbobo zokukhomba ezingahlukaniseka ngo-3, njengokuthi 24, 30, 39, 42.51. Engeza imbobo engu-1, okuyizimbobo ezingu-17, 21, 27, 29, 35, 37, 39, 45, njengembobo yokuma yaleli sondo.

Isibonelo sesi-3: Ukubalwa kwenkomba yokugaya amazinyo angama-82.

Faka esikhundleni sefomula: n=40/82

Bala n=20/41

Okusho ukuthi: inqobo nje uma ipuleti lenkomba elinezimbobo ezingama-41 likhethiwe, vula i-20+1 emgodini wokuma wesondo elingaphezulu, okungukuthi, izimbobo ezingama-21 zisetshenziswa njengembobo yokuma yesondo lamanje.

Isibonelo sesi-4: Ukubalwa kwenkomba yokugaya amazinyo angama-51

Ukufaka esikhundleni sefomula n = 40/51, njengoba amaphuzu awakwazi ukubalwa ngalesi sikhathi, ungakhetha kuphela imbobo ngokuqondile, okungukuthi, khetha ipuleti lenkomba elinezimbobo ezingama-51, bese uvula isondo elingaphezulu elingu-51+1 endaweni yokuma. imbobo, okungukuthi, 52 izimbobo, njengoba isondo lamanje. Izimbobo zokubeka okungukuthi.

Isibonelo sesi-5: Ukubalwa kwenkomba yokugaya amazinyo ayi-100.

Faka esikhundleni sefomula n=40/100

Bala n=4/10=12/30

Khetha ipuleti lenkomba elinezimbobo ezingu-30 ngesikhathi, bese ubeka izimbobo ezingu-12+1 noma ezingu-13 embotsheni engaphezulu yokumisa isondo njengembobo yamanje yokumisa isondo.

Uma wonke ama-indexing discs engafinyeleli inani lezimbobo ezidingekayo ekubaleni, indlela yokuhlanganisa inhlanganisela kufanele isetshenziselwe ukubala, engafakiwe kule ndlela yokubala. Emkhiqizweni wangempela, i-gear hobbing ngokuvamile isetshenziswa, ngoba ukusebenza kwangempela ngemva kokubalwa kwenkomba ehlanganisiwe akulula kakhulu.

6. Ifomula yokubala ye-hexagon eqoshwe indilinga

① Thola uhlangothi oluphambene lwe-hexagon (i-S surface) yendingiliza D

S=0.866D ububanzi×0.866 (i-coefficient)

② Bala ububanzi (D) besiyingi ukusuka kolunye uhlangothi lwehexagon (S surface)

D=1.1547S ohlangothini oluphambene×1.1547 (i-coefficient)

7. Ifomula yokubala yohlangothi oluphambene nomugqa we-diagonal we-hexagon kwinqubo yesihloko esibandayo

① Thola i-engeli ephambene yohlangothi oluphambene (S) lweheksagoni yangaphandle

e=1.13s Uhlangothi oluphambene×1.13

② Thola i-engeli ephambene (e) ukusuka kolunye uhlangothi (ama) lweheksagoni yangaphakathi

e=1.14s Uhlangothi oluphambene×1.14 (i-coefficient)

③ Thola ububanzi obubalulekile bekhanda elidayagonali (D) ukusuka ezinhlangothini ezihlukene (s) zeheksagoni yangaphandle

Ububanzi (D) besiyingi kufanele sibalwe ngokuya kolunye uhlangothi (indiza) yehexagon (ifomula yesibili ku-6), futhi inani lesikhungo se-offset kufanele lenyuswe ngokufanelekile, okungukuthi, D≥1.1547s. Inani le-offset kusuka maphakathi lingalinganiselwa kuphela.

8. Ifomula yokubala yesikwele esibhalwe indilinga

① Dweba indilinga (D) ukuthola uhlangothi oluphambene nesikwele (S surface)

S=0.7071D ububanzi×0.7071

② Thola indilinga (D) ukusuka kolunye uhlangothi lwesikwele (S surface)

D=1.414S ohlangothini oluphambene×1.414

9. Amafomula wokubala ezinhlangothi eziyisikwele eziphambene nama-engeli abhekene ngenqubo yesihloko esibandayo

① Thola i-engeli ephambene (e) ukusuka kolunye uhlangothi (S) lwesikwele esingaphandle

i-e=1.4s iwuhlangothi oluphambene (ama)×1.4 ipharamitha

② Thola i-engeli ephambene (e) yohlangothi oluphambene (ama) wesikwele esingaphakathi

u-e=1.45s uhlangothi oluphambene (ama)×1.45 i-coefficient

10. Ifomula yokubala ivolumu ye-Hexagon

s20.866×H/m/k kusho uhlangothi oluphambene×ohlangothini oluphambene×0.866×ubude noma ukujiya.

11. Ifomula yokubala yevolumu encishisiwe (ikhoni).

I-0.262H (D2+d2+D×d) ingu-0.262×ubude×(idayamitha yekhanda elikhulu×idayamitha yekhanda elikhulu+ikhanda elincane×ikhanda elincane+ikhanda+ikhanda elikhulu×ikhanda elincane).

12. Ifomula yokubala yevolumu yendilinga (njengekhanda eliyisiyingi)

3.1416h2(Rh/3) ingu-3.1416×ubude×ubude×(irediyasi-ubude÷3).

13. Ifomula yokubala yokulinganisa ubukhulu bompompi bochungechunge bangaphakathi

1. Ukubalwa kompompi omkhulu ububanzi D0

I-D0=D+(0.866025P/8)×(0.5~1.3) iwusayizi oyisisekelo wentambo kampompi enobubanzi obukhulu + 0.866025 pitch÷8×0.5~1.3.

Qaphela: Ukukhethwa kuka-0.5~1.3 kufanele kunqunywe ngokuya ngosayizi wephimbo. Uma likhulu inani lephimbo, kufanele kusetshenziswe i-coefficient encane. Ngokuphambene, inani lephimbo lincane, i-coefficient ehambisanayo kufanele ibe nkulu.

2. Ukubalwa kobubanzi bephimbo lompompi (D2)

D2=(3×0.866025P)/8, okungukuthi, i-tap diameter=3×0.866025×pitch÷8

3. Ukubalwa kobubanzi bompompi (D1)

I-D1=(5×0.866025P)/8 iwububanzi bompompi=5×0.866025×pitch÷8

Ishumi nane,

Ifomula yokubala yobude bempahla yesihloko esibandayo esakha izimo ezihlukahlukene

Ifomula yevolumu yendilinga eyaziwayo iwububanzi×ububanzi×0.7854×ubude noma irediyasi×irediyasi×3.1416×ubude. Okusho ukuthi, d2×0.7854×L noma R2×3.1416×L

Uma ubala, ivolumu X÷diameter÷diameter÷0.7854 noma i-X÷radius÷radius÷3.1416 yezinto ezidingekayo ubude bento.

Ifomula yekholomu = X/(3.1416R2) noma X/0.7854d2

Kufomula, u-X umele inani levolumu lento edingekayo;

L imele inani lobude lokondliwa kwangempela;

I-R/d imelela irediyasi yangempela yokudla noma ububanzi.

Inhloso ye-Anebon ukuqonda ukonakala okuhle kakhulu okuvela embonini futhi inikeze ukusekelwa okuphezulu kumakhasimende asekhaya nakwamanye amazwe ngenhliziyo yonke ngo-2022 Ikhwalithi ephezulu ye-Stainless Steel Aluminium High Precision Custom Made CNC Turning Milling Machining Spare Part for Aerospace, Ukuze sinwebe imakethe yethu yamazwe ngamazwe, i-Anebon. ikakhulukazi ukuhlinzeka ngamakhasimende ethu aphesheya kwezilwandle izingxenye zemishini ezisezingeni eliphezulu, izingxenye ezigayiwe kanye nensizakalo yokujika ye-cnc.

I-China wholesale China Machinery Parts kanye ne-CNC Machining Service, i-Anebon isekela umoya "wokusungula izinto ezintsha, ukuzwana, ukusebenza kweqembu nokwabelana, imikhondo, inqubekelaphambili ye-pragmatic". Sinike ithuba futhi sizobe sizokhombisa ikhono lethu. Ngosizo lwakho lomusa, i-Anebon ikholelwa ukuthi singakha ikusasa eliqhakazile nawe sindawonye.

Isikhathi sokuthumela: Jul-10-2023