Ucabanga ukuthi buyini ubudlelwano phakathi kwejubane lokusika, ukusebenzelana kwamathuluzi, nesivinini sokuphakelayo kumashini we-CNC?

Ukuze usebenze kahle, kubalulekile ukuqonda ubudlelwano phakathi kwesivinini sokuphakelayo, isivinini sokusika kanye nokuzibandakanya kwamathuluzi kumashini we-CNC.

Isivinini sokusika:

Isivinini sokusika izinga lokujikeleza noma ukunyakaza ngokusebenzisa impahla. Isivinini sivamise ukukalwa ngamamitha angaphezulu ngamaminithi (SFM) noma amamitha/umzuzu (m/min). Isivinini sokusika sinqunywa ngezinto ezizokwenziwa ngomshini, ithuluzi lokusika, kanye nokuqedwa kwendawo oyithandayo.

Ukuhlanganyela Kwethuluzi

Ukusebenzelana kwethuluzi ukujula lapho ithuluzi lokusika lingena khona endaweni yokusebenza ngesikhathi somshini. Ukusebenzelana kwethuluzi kuthintwa izici ezifana nokusika ijiyomethri yamathuluzi kanye nokuphakelayo nesivinini kanye nekhwalithi yendawo efiselekayo kanye nezinga lokususwa kwezinto. Ngokukhetha usayizi wethuluzi elifanele, ukujula kokusikwa nokubandakanyeka kwe-radial, ungalungisa ukusebenzelana kwethuluzi.

Isivinini Sokuphakelayo

Ijubane lokudla libizwa nangokuthi izinga lokuphakelayo noma okuphakelayo ngezinyo ngalinye. Izinga ithuluzi lokusika elithuthukela kulo ngoguquko ngalunye ngokusebenzisa impahla ye-workpiece. Ijubane likalwa ngamamilimitha noma amayintshi ngomzuzu. Izinga lokuphakelayo lithinta ngqo impilo yamathuluzi, ikhwalithi yendawo ephezulu, kanye nokusebenza komshini kukonke.

Ngokuvamile, isivinini sokusika esiphezulu siholela emazingeni amakhulu okususwa kwezinto. Nokho, ziphinde zikhiqize ukushisa okwengeziwe. Ikhono lethuluzi lokusika lokusingatha isivinini esikhulu, kanye nempumelelo yesipholisaji ekukhipheni ukushisa yizici ezibalulekile.

Ukusebenzelana kwamathuluzi kufanele kulungiswe ngokuya ngezinto ezibonakalayo ze-workpiece, i-geometry yamathuluzi okusika, kanye nesiphetho esidingekayo. Ukusebenzisana kwamathuluzi ngendlela efanele kuzoqinisekisa ukuphuma okusebenzayo kwe-chip futhi kunciphise ukuphambuka kwamathuluzi. Izophinde ithuthukise ukusebenza kokusika.

Ijubane lokuphakelayo kufanele likhethwe ukuze kuzuzwe izinga elifiswayo lokususwa nokuqeda impahla, ngaphandle kokulayisha kakhulu ithuluzi. Izinga lokuphakela eliphezulu lingabangela ukuguga kwamathuluzi okweqile. Kodwa-ke, isivinini sokuphakela esiphansi sizoholela ekuqedeni kahle kwendawo kanye nomshini ongasebenzi kahle.

Umenzi wohlelo kufanele abhale imiyalelo ohlelweni lwe-CNC ukuze anqume inani lokusikwa kwenqubo ngayinye. Isivinini sokusika, inani lokusika emuva, isivinini sokuphakelayo nokunye konke kuyingxenye yokusika ukusetshenziswa. Kudingeka amanani ahlukene okusika ezindleleni ezihlukene zokucubungula.

1. Umgomo wokukhetha inani lokusika

Uma konakala, ukugxila okuyinhloko kuvamise ukuthuthukisa ukukhiqiza, kodwa izindleko zezomnotho nezokucubungula nazo kufanele zicatshangelwe; lapho semi-finishing and finishing, ukusika ukusebenza kahle, umnotho, kanye nezindleko zokucubungula kufanele kucatshangelwe ngenkathi kuqinisekiswa ikhwalithi yokucubungula. Amanani athile kufanele anqunywe ngokuya ngemanuwali yethuluzi lomshini, imanuwali yokusika yokusebenzisa, kanye nolwazi.

Kusukela ekuqineni kwethuluzi, ukuhleleka kokukhethwa kwenani lokusika: okokuqala thola inani lokusika emuva, bese unquma inani lokuphakelayo, futhi ekugcineni unqume isivinini sokusika.

2. Ukunqunywa kwenani lommese ngemuva

Inani lokusika emuva linqunywa ukuqina kwethuluzi lomshini, i-workpiece kanye nethuluzi. Uma ukuqina kuvumela, inani lokusika emuva kufanele lilingane nesabelo somshini we-workpiece ngangokunokwenzeka. Lokhu kunganciphisa inani lokudlula kwamathuluzi futhi kuthuthukise ukusebenza kahle kokukhiqiza.

Izimiso zokunquma inani lommese ngemuva:

1)

Lapho inani lobunzima obungaphezulu bocezu lokusebenza lidingeka ukuthi libe ngu-Ra12.5μm~25μm, uma isibonelelo somshiniCNC imishiniingaphansi kuka-5mm ~ 6mm, okuphakelayo okukodwa komshini onzima kungahlangabezana nezidingo. Kodwa-ke, uma imajini inkulu, ukuqina kwesistimu yenqubo kubi, noma amandla ethuluzi lomshini enganele, ingaqedelwa ngokuphakelayo okuningi.

2)

Lapho inani lobunzima bobuso bomsebenzi kudingeka ukuthi libe ngu-Ra3.2μm~12.5μm, lingahlukaniswa ngezinyathelo ezimbili: ukugoqa kanye nokuqeda kancane. Ukukhethwa kwenani lokusika emuva ngesikhathi sokusebenza kanzima kuyafana nangaphambili. Shiya imajini engu-0.5mm ukuya ku-1.0mm ngemva komshini onzima futhi uyisuse phakathi nokuqeda kancane.

3)

Lapho inani lobunzima bobuso bomsebenzi kudingeka libe ngu-Ra0.8μm~3.2μm, lingahlukaniswa ngezinyathelo ezintathu: ukugoqa, ukuqeda kancane kanye nokuqeda. Inani lokusika emuva ngesikhathi sokuqeda isigamu liyi-1.5mm ~ 2mm. Ngesikhathi sokuqeda, inani lokusika emuva kufanele libe ngu-0.3mm ~ 0.5mm.

3. Ukubalwa kwenani lokuphakelayo

Inani lokuphakelayo linqunywa ukunemba kwengxenye kanye nobulukhuni bobuso obudingekayo, kanye nezinto ezikhethelwe ithuluzi kanye nomsebenzi. Izinga eliphezulu lokuphakela lincike ekuqineni komshini kanye nezinga lokusebenza lesistimu yokuphakelayo.

Izimiso zokunquma isivinini sokuphakelayo:

1) Uma ikhwalithi ye-workpiece ingaqinisekiswa, futhi ufuna ukwandisa ukusebenza kahle kokukhiqiza, khona-ke isivinini sokuphakelayo esisheshayo siyanconywa. Ngokuvamile, isivinini sokuphakelayo sisethwe phakathi kuka-100m/min no-200m/min.

2) Uma usika noma ucubungula izimbobo ezijulile, noma usebenzisa izinsimbi ezinesivinini esikhulu, kungcono ukusebenzisa isivinini sokuphakela esihamba kancane. Lokhu kufanele kube phakathi kuka-20 no-50m/min.

Uma isidingo sokunemba ekukhiqizeni imishini kanye nokuqina kwendawo kuphezulu, kungcono kakhulu ukukhetha isivinini esincane sokuphakelayo, ngokuvamile esiphakathi kuka-20m/min no-50m/min.

Ungakhetha isilinganiso esiphezulu sokuphakela esisethwe uhlelo lwethuluzi lomshini we-CNC lapho ithuluzi lingenzi lutho, futhi ikakhulukazi “uziro obuyiselayo” ebangeni.

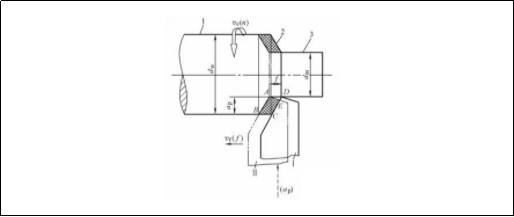

4. Ukuzimisela kwejubane lokuphotha

I-spindle kufanele ikhethwe ngokusekelwe kwijubane eliphezulu lokusika elivunyelwe kanye nobubanzi bomsebenzi wakho wokusebenza noma ithuluzi. Ifomula yokubala yejubane lokuphotha ithi:

n=1000v/pD

Ukuqina kwethuluzi kunquma isivinini.

Isivinini se-spindle silinganiswa ngo-r/min.

D —- Ububanzi bomsebenzi noma usayizi wethuluzi, kukalwa ngo-mm.

Isivinini sokugcina sokuphotha sibalwa ngokukhetha isivinini ithuluzi lomshini elingasifinyelela noma elisondela kuso, ngokuya ngemanuwali yalo.

Kafushane, inani lenani lokusika lingabalwa ngokufanisa, ngokusekelwe ekusebenzeni komshini, amamanuwali, nolwazi lwangempela lokuphila. Isivinini se-spindle kanye nokujula kokusika kungashintshwa kusivinini sokuphakelayo ukuze kwakhiwe inani eliphelele lokusika.

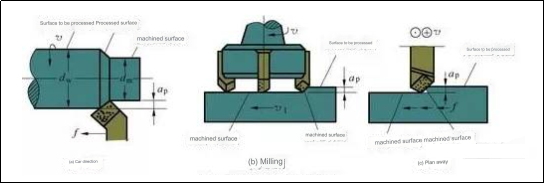

1) Inani lokusika emuva (ukujula kokusika) ap

Inani lokusika emuva liyibanga eliqondile phakathi kwendawo ukuya emshinini kanye nendawo eyenziwe ngomshini. Ukusika emuva yinani lokusika elikalwa nge-perpendicularly endizeni yomsebenzi ngokusebenzisa iphuzu lesisekelo. Ukujula kokusika inani lokusika elenziwa ithuluzi lokuphendula libe isiqeshana sokusebenza ngokuphakelayo ngakunye. Inani lokusikwa ngemuva kwendilinga yangaphandle lingabalwa kusetshenziswa ifomula engezansi:

ap = ( dw — dm ) /2

Kufomula, ap——inani lommese ngemuva (mm);

dw——Ububanzi bobuso obuzocutshungulwa kucezu lokusebenza (mm);

dm - ububanzi bomsebenzi owenziwe ngomshini we-workpiece (mm).

Isibonelo 1:Kuyaziwa ukuthi ububanzi obungaphezulu bomsebenzi ozosetshenzwa bungu-Φ95mm; manje ububanzi bungu-Φ90mm kokuphakelayo okukodwa, futhi inani lokusika emuva liyatholakala.

Isixazululo: ap = (dw — dm) /2= (95 —90) /2=2.5mm

2) Inani lokuphakelayo f

Ukugudluzwa okuhlobene kwethuluzi kanye nendawo yokusebenza lapho kuqondiswa khona ukunyakaza kokuphakelayo kwenguquko ngayinye yesiqeshana sokusebenza noma ithuluzi.

Ngokwezikhombisi-ndlela ezihlukene zokuphakela, ihlukaniswa ngenani lokuphakelayo le-longitudinal kanye nenani lokuphakelayo eliphambene. Inani lokuphakelayo kwe-longitudinal libhekisela enanini lokuphakelayo eduze komzila wesitimela sombhede we-lathe, futhi inani lokuphakelayo eliphambene libhekisela ekuqondeni kwesitimela se-lathe bed guide. Izinga lokuphakelayo.

Qaphela:Isivinini sokuphakelayo i-vf sisho isivinini esisheshayo sephoyinti elikhethiwe onqenqemeni lokusika elihlobene nokunyakaza kokuphakelayo kocezu lokusebenza.

vf=fn

lapho i-vf——isivinini sokuphakelayo (mm/s);

n——Ijubane lokuphotha (r/s);

f——inani lokuphakelayo (mm/s).

3) Ukusika isivinini vc

Isivinini esisheshayo ekunyakazeni okuyinhloko endaweni ethile ku-blade yokusika ehlobene nendawo yokusebenza. Kubalwe ngu:

vc=(pdwn)/1000

Lapho vc —-ukusika isivinini (m/s);

dw = ububanzi bendawo okufanele iphathwe (mm);

—- Isivinini sokuzungezisa isiqeshana somsebenzi (r/min).

Izibalo kufanele zenziwe ngokusekelwe kwisivinini esikhulu sokusika. Izibalo kufanele, isibonelo, zenziwe ngokusekelwe kububanzi nezinga lokuguga lendawo esetshenziswayo.

Thola i-vc. Isibonelo sesi-2: Uma uphendula indilinga yangaphandle yento enobubanzi obungu-Ph60mm ku-lathe, ijubane lokuphotha elikhethiwe ngu-600r/min.

Isixazululo:vc=( pdwn)/1000 = 3.14x60x600/1000 = 113 m/min

Ekukhiqizeni kwangempela, kuvamile ukwazi ububanzi besiqephu. Isivinini sokusika sinqunywa izici ezifana nempahla ye-workpiece, impahla yamathuluzi kanye nezidingo zokucubungula. Ukuze ulungise i-lathe, ijubane lokusika liguqulwa libe yijubane lokuphotha le-lathe. Le fomula ingatholakala:

n=(1000vc)/pdw

Isibonelo sesi-3: Khetha i-vc ukuya ku-90m/min bese uthola u-n.

Isixazululo: n=(1000v c)/ pdw=(1000×90)/ (3.14×260) =110r/min

Ngemva kokubala isivinini sokuphotha i-lathe, khetha inani eliseduze ne-numberplate, isibonelo, n=100r/min njengejubane langempela le-lathe.

3. Isifinyezo:

Ukusika inani

1. Isamba sommese wangemuva ap (mm) ap= (dw – dm) / 2 (mm)

2. Inani lokudla f (mm/r)

3. Isivinini sokusika i-vc (m/min). Vc=dn/1000 (m/min).

n=1000vc/d(r/min)

Ngokuqondene nathi esivamileIzingxenye ze-aluminium ze-CNCbakhathazekile, yiziphi izindlela zokunciphisa ukuguqulwa kokucubungula kwezingxenye ze-aluminium?

Ukulungiswa Okufanelekile:

Ukulungisa ucezu lomsebenzi ngendlela efanele kubalulekile ukuze kuncishiswe ukuhlanekezela ngesikhathi somshini. Ngokuqinisekisa ukuthi ama-workpieces aboshwe ngokuphephile endaweni, ukudlidliza nokunyakaza kungancishiswa.

I-Adaptive Machining

Impendulo yenzwa isetshenziselwa ukulungisa amapharamitha okusika ngokuguquguqukayo. Lokhu kunxephezela ukuhluka kwezinto, futhi kunciphisa ukuguga.

Ukusika Amapharamitha Ukuthuthukisa

Ukuguqulwa kungancishiswa ngokulungiselela amapharamitha afana nesivinini sokusika, i-feedrate, nokusika ukujula. Ngokunciphisa amandla okusika nokukhiqiza ukushisa ngokusebenzisa imingcele yokusika efanele, ukuhlanekezela kungancishiswa.

Ukunciphisa Ukukhiqiza Ukushisa:

Ukushisa okukhiqizwa ngesikhathi somshini kungase kuholele ekushintshashintsheni kokushisa nokwanda. Ukuze unciphise ukukhiqizwa kokushisa, sebenzisa okokupholisa noma okothambisa. Yehlisa isivinini sokusika. Sebenzisa amajazi amathuluzi asebenza kahle kakhulu.

Imishini Kancane Kancane

Kungcono ukwenza amaphasi amaningi lapho ukhiqiza i-aluminium kunokusika okukodwa esindayo. Ukwenza imishini kancane kancane kunciphisa ukuguga ngokunciphisa ukushisa namandla okusika.

Ukushisa ngaphambili:

Ukushisa kuqala i-aluminium ngaphambi komshini kunganciphisa ingozi yokuhlanekezela ezimweni ezithile. Ukushisa kwangaphambi kwesikhathi kuzinza into futhi kuyenza imelane nokuhlanekezelwa lapho kwenziwa imishini.

I-Stress Relief Annealing

Ukunciphisa ingcindezi kungenziwa ngemva komshini ukuze kuncishiswe ingcindezi esele. Ingxenye ingaqiniswa ngokuyishisisa ekushiseni okuthile, bese uyipholisa kancane.

Ukukhetha Amathuluzi Alungile

Ukuze unciphise ukuguqulwa, kubalulekile ukukhetha amathuluzi okusika afanele, anezingubo ezifanele kanye namajometri. Amathuluzi aklanywe ngokukhethekile omshini we-aluminium anciphisa amandla okusika, athuthukisa ukuqedwa kwendawo, futhi avimbele ukwakheka kwemiphetho eyakhelwe phezulu.

Umshini ngezigaba:

Imisebenzi eminingi yemishini noma izigaba zingasetshenziswa ukusabalalisa amandla okusika endaweni eyinkimbinkimbiizingxenye ze-aluminium cncfuthi unciphise ukuguqulwa. Le ndlela ivimbela ukucindezeleka kwendawo futhi inciphisa ukuhlanekezela.

Ukuphishekela i-Anebon nenjongo yenkampani iwukuba njalo “ukwanelisa izidingo zethu zabathengi njalo”. I-Anebon iqhubeka nokuthola nesitayela futhi iklame imikhiqizo yekhwalithi ephezulu encomekayo kumakhasimende ethu aphelelwe yisikhathi namasha futhi ifinyelele ithemba lokuwina kubathengi be-Anebon kanye nathi nge-Original Factory Profile extrusions aluminium,i-cnc iphendule ingxenye, cnc yokugaya inayiloni. Samukela ngobuqotho abangani ukuthi bahwebe ngebhizinisi futhi baqale ukubambisana nathi. I-Anebon inethemba lokuthi izobambana ngezandla nabangani abasondelene ezimbonini ezehlukene ukuze ikhiqize ikusasa eliqhakazile.

Umkhiqizi wase-China we-China High Precision kanye ne-Metal Stainless Steel Foundry, i-Anebon ifuna amathuba okuhlangana nabo bonke abangani abavela ekhaya naphesheya ukuze kuzuze ukubambisana. I-Anebon inethemba lobuqotho lokuba nokubambisana kwesikhathi eside nani nonke ezisekelweni zenzuzo efanayo nentuthuko efanayo.

Uma ufuna ukwazi okwengeziwe, sicela uxhumane nethimba le-Anebon kokuthiinfo@anebon.com.

Isikhathi sokuthumela: Nov-03-2023