Wonke umuntu ujwayelene nochungechunge. Njengozakwethu embonini yokukhiqiza, sivame ukudinga ukwengeza izintambo ngokuvumelana nezidingo zamakhasimende lapho sicubungula izesekeli ze-hardware ezifanaIzingxenye zemishini ye-CNC, Izingxenye zokuguqula ze-CNCfuthiIzingxenye zokugaya ze-CNC.

1. Yini intambo?

Umucu yi-helix esikwe ibe yi-workpiece kusuka ngaphandle noma ngaphakathi. Imisebenzi eyinhloko yezintambo yilezi:

1. Yakha uxhumano lwemishini ngokuhlanganisa imikhiqizo yentambo yangaphakathi kanye nemikhiqizo yentambo yangaphandle.

2. Dlulisa ukunyakaza ngokuguqula ukunyakaza okujikelezayo kube ukunyakaza okuqondile futhi ngokuphambene nalokho.

3. Thola izinzuzo mechanical.

2. Iphrofayili yochungechunge kanye namagama

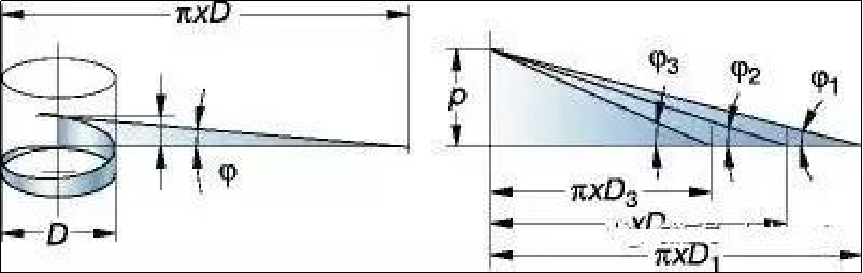

Iphrofayili yentambo inquma i-geometry yentambo, kufaka phakathi ububanzi be-workpiece (obukhulu, iphimbo, namadiamitha amancane); i-angle yephrofayili yentambo; i-pitch kanye ne-helix angle.

1. Imigomo yochungechunge

① Ngezansi: Indawo engezansi exhuma izintambo ezimbili ezincikene.

② iflenki: indawo eseceleni yochungechunge exhuma i-crest nephansi lezinyo.

③Crest: Indawo engaphezulu exhuma izinhlangothi ezimbili.

P = iphimbo, mm noma imicu iyintshi ngayinye (tpi)

ß = i-engeli yephrofayili

ϕ = intambo ye-helix angle

d = ububanzi obukhulu bentambo yangaphandle

D = ububanzi obukhulu bentambo yangaphakathi

d1 = ububanzi obuncane bentambo yangaphandle

D1 = Ububanzi obuncane bentambo yangaphakathi

d2 = i-pitch diameter yentambo yangaphandle

D2 = intambo yangaphakathi yephimbo ububanzi

Ububanzi be-pitch, d2/D2

Ububanzi obusebenzayo bomucu. Cishe uhhafu phakathi kwamadayamitha amakhulu namancane.

Ijiyomethri yentambo isekelwe kububanzi bephimbo lentambo (d, D) kanye nephimbo (P): ibanga le-axial eduze kwentambo ku-workpiece ukusuka kwelinye iphuzu kuphrofayili kuya ephuzwini elilandelayo elihambisanayo. Lokhu kungabuye kubonakale njengonxantathu odlula ucezu lokusebenza.

vc = isivinini sokusika (m/min)

i-ap = ukujula kwentambo ephelele (mm)

nap = ukujula kwentambo ephelele (mm)

tpi = imicu iyintshi ngayinye

Okuphakelayo = iphimbo

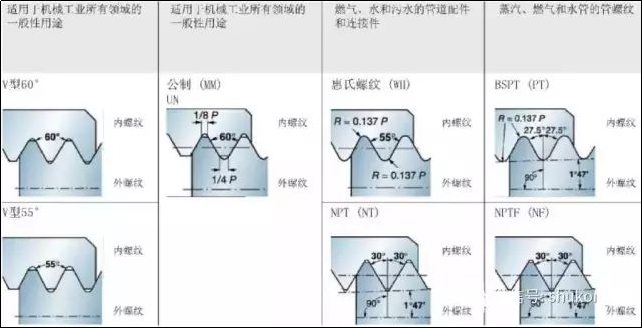

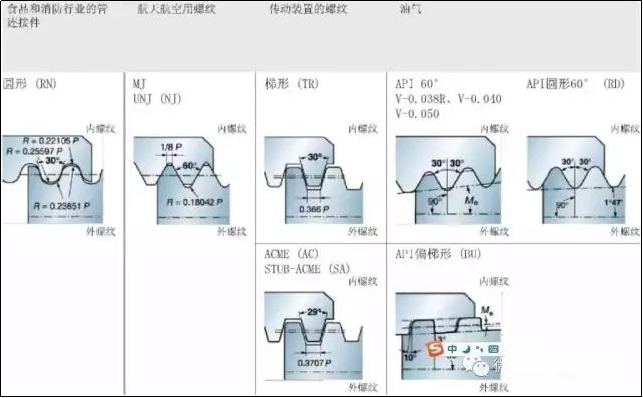

2. Iphrofayili yentambo evamile

1. Ukubalwa nokubekezelela kobubanzi bepitch yentambo yangaphandle engu-60° uhlobo lwamazinyo (izinga lezwe lonke elingu-GB197/196)

a. Ukubalwa kosayizi oyisisekelo wobubanzi bephimbo

Usayizi oyisisekelo wobubanzi be-pitch wentambo = ububanzi obukhulu bentambo - iphimbo × inani le-coefficient.

Ukumelwa kwefomula: d/DP×0.6495

2. Ukubalwa nokubekezelela kobubanzi bephimbo obungu-60° umucu wangaphakathi (GB197/196)

ukubekezelela ukubekezelela kobubanzi be-pitch yeleveli ye-a.6H (kusekelwe ekuphakameni kwentambo)

Umkhawulo ophezulu:

P0.8+0.125P1.00+0.150P1.25+0.16P1.5+0.180

P1.25+0.00P2.0+0.212P2.5+0.224

Inani eliphansi lomkhawulo lithi “0″,

Ifomula yokubala yomkhawulo ophezulu 2+TD2 iwusayizi oyisisekelo + ukubekezelela.

Isibonelo, ububanzi be-pitch bentambo yangaphakathi ye-M8-6H ithi: 7.188+0.160=7.348 Umkhawulo ophezulu: 7.188 umkhawulo ophansi.

b. Ifomula yokubala ye-pitch diameter yentambo yangaphakathi iyafana naleyo yochungechunge lwangaphandle

Okungukuthi, i-D2=DP×0.6495, okungukuthi, ububanzi obuphakathi bentambo yangaphakathi bulingana nobubanzi obukhulu be-thread-pitch×coefficient value.

I-c.6G yekilasi ye-pitch pitch diameter yokuchezuka okuyisisekelo kwe-E1 (ngokusekelwe ekuphakameni kwentambo)

P0.8+0.024P1.00+0.026P1.25+0.028P1.5+0.032

P1.75+0.034P1.00+0.026P2.5+0.042

3. Ukubalwa nokubekezelela ububanzi obukhulu bentambo yangaphandle (GB197/196)

a. Umkhawulo ongaphezulu wobubanzi obuyi-6h obukhulu bentambo yangaphandle

Okusho ukuthi, isibonelo senani lochungechunge lwe-M8 ngu-φ8.00 futhi ukubekezelela umkhawulo ophezulu ngu-“0″.

b. Ukubekezelelwa kwenani eliphansi lomkhawulo lobubanzi obukhulu bekilasi elingu-6 lochungechunge lwangaphandle (kusekelwe ekuphakameni kwentambo)

P0.8-0.15P1.00-0.18P1.25-0.212P1.5-0.236P1.75-0.265

P2.0-0.28P2.5-0.335

Ifomula yokubala yomkhawulo ophansi wobubanzi obukhulu: i-d-Td ubukhulu obuyisisekelo bobubanzi obukhulu bochungechunge - ukubekezelelana.

4. Ukubalwa nokubekezelelana kobubanzi obuncane bentambo yangaphakathi

a. Ukubalwa kosayizi oyisisekelo wedayamitha encane yochungechunge lwangaphakathi (D1)

Ubukhulu obuyisisekelo bobubanzi obuncane bentambo = usayizi oyisisekelo wentambo yangaphakathi - i-pitch × factor

5. Ifomula yokubala yokuhlukanisa ikhanda indlela eyodwa yokuhlukanisa

Ifomula yokubala yendlela yokuhlukanisa okukodwa: n=40/Z

n: inani lama-revolution okufanele ikhanda elihlukanisayo lijike

Z: Ingxenye elinganayo ye-workpiece

40: inombolo engashintshi yekhanda elihlukanisayo

6. Ifomula yokubala ye-hexagon eqoshwe indilinga

① Thola uhlangothi olubhekene ne-hexagonal (i-S surface) yesiyingi D

S=0.866D ububanzi×0.866 (i-coefficient)

② Bala ububanzi besiyingi (D) kusuka ezinhlangothini ezihlukene zehexagon (S surface)

D=1.1547S ihlangothi eliphambene×1.1547 (i-coefficient)

7. Ifomula yokubala yezinhlangothi eziphikisanayo eziyi-hexagonal kanye namadiagonali kunqubo yesihloko esibandayo

① Thola i-engeli ephambene u-e ukusuka kolunye uhlangothi (S) lweheksagoni yangaphandle

e=1.13s iwuhlangothi oluphambene×1.13

②Thola i-engeli ephambene (e) ukusuka kolunye uhlangothi (ama) lweheksagoni yangaphakathi

u-e=1.14s uhlangothi oluphambene×1.14 (i-coefficient)

③ Thola ububanzi obubalulekile bekhanda lekhona eliphambene (D) ukusuka kolunye uhlangothi (ama) lweheksagoni yangaphandle

Ububanzi besiyingi (D) kufanele sibalwe ngokuya (ifomula yesibili ku-6) ohlangothini oluphambene lwe-hexagonal (s surface), futhi inani lesikhungo se-offset kufanele lenyuke ngokufanele, okungukuthi, D≥1.1547s. Inani lesikhungo se-offset lingalinganiselwa kuphela.

8. Ifomula yokubala yesikwele esibhalwe indilinga

① Umbuthano (D) ukuze uthole olunye uhlangothi lwesikwele (S surface)

S=0.7071D ububanzi×0.7071

② Thola indilinga (D) ezinhlangothini ezihlukene zesikwele (S surface)

D=1.414S ihlangothi eliphambene×1.414

9. Ifomula yokubala yesikwele izinhlangothi eziphambene nama-engeli aphikisanayo kunqubo yesihloko esibandayo

① Thola i-engeli ephambene (e) ukusuka kolunye uhlangothi (S) lwesikwele esingaphandle

i-e=1.4s iwuhlangothi oluphambene (ama)×1.4 ipharamitha

② Thola i-engeli ephambene (e) ukusuka ohlangothini oluphambene (ama) wesikwele esingaphakathi

u-e=1.45s uhlangothi oluphambene (ama)×1.45 i-coefficient

10. Ifomula yokubala umthamo wehexagon

s20.866×H/m/k kusho uhlangothi oluphambene×ohlangothini oluphambene×0.866×ubude noma ukujiya.

11. Ifomula yokubala yevolumu ye-frustum (ikhoni) yomzimba

I-0.262H(D2+d2+D×d) ingu-0.262×ubude×(idayamitha yekhanda elikhulu×idayamitha yekhanda elikhulu+ikhanda elincane×ikhanda elincane+ikhanda+ikhanda elikhulu×ikhanda elincane).

12. Ifomula yokubala yevolumu yomzimba oyindilinga (njengekhanda eliyisiyingi)

3.1416h2(Rh/3) ingu-3.1416×ubude×ubude×(irediyasi-ubude÷3).

13. Ifomula yokubala yokulinganisa ubukhulu bompompi bochungechunge lwangaphakathi

1. Ukubalwa kompompi omkhulu ububanzi D0

I-D0=D+(0.866025P/8)×(0.5~1.3) iwusayizi oyisisekelo wentambo kampompi enobubanzi obukhulu + 0.866025 pitch ÷ 8×0.5 ukuya ku-1.3.

Qaphela: Ukukhethwa kuka-0.5 kuya ku-1.3 kufanele kuqinisekiswe ngokuya ngosayizi wephimbo. Uma likhulu inani lephimbo, kufanele kusetshenziswe i-coefficient encane. Ngokuphambene nalokho, inani lephimbo lincane, kufanele kusetshenziswe i-coefficient enkulu ehambelanayo.

2. Ukubalwa kobubanzi bephimbo lompompi (D2)

D2=(3×0.866025P)/8, okungukuthi, i-tap diameter=3×0.866025×pitch÷8

3. Ukubalwa kobubanzi bompompi (D1)

D1=(5×0.866025P)/8 ububanzi bompompi =5×0.866025×pitch÷8

14. Ifomula yokubala yobude bezinto ezisetshenziselwa ukwakhiwa kwesihloko esibandayo ngezindlela ezihlukahlukene

Kuyaziwa ukuthi ifomula yevolumu yendilinga ingudayamitha×ububanzi×0.7854×ubude noma irediyasi×3.1416×ubude. Okusho ukuthi, d2×0.7854×L noma R2×3.1416×L

Lapho kubalwa, ivolumu X÷diameter÷diameter÷0.7854 noma i-X÷radius÷radius÷3.1416 yezinto ezidingekayo ukuze kucutshungulweizingxenye zemishini ye-cncfuthiizingxenye eziphendukayo ze-cncubude bento.

Ifomula yekholomu = X/(3.1416R2) noma X/0.7854d2

X kufomula imele inani levolumu lento edingekayo;

L imele inani lobude lokondliwa kwangempela;

I-R/d imelela irediyasi noma ububanzi bokudla kwangempela.

Isikhathi sokuthumela: Jan-11-2023