Ukusika intambo eyodwa

Ngokujwayelekile, isho intambo yomshini endaweni yokusebenza enethuluzi lokwakha noma lokugaya, ikakhulukazi elihlanganisa ukuphenduka, ukugaya, ukuthepha nokuhlanganisa ukugaya, ukugaya, ukusika isivunguvungu, njll. ithuluzi lomshini liqinisekisa ukuthi ithuluzi elijikayo, i-milling cutter, noma isondo lokugaya lihambisa umthofu ngokunembile nangokulinganayo eduze kwe-axial ye-workpiece njalo. ukuzungeza. Uma uthepha noma ucucuza, ithuluzi (thepha noma shona) lizungeza ngokuhlobene nendawo yokusebenza, futhi i-groove yokuqala eyakhiwe iqondisa ithuluzi (noma ucezu lokusebenza) ukuhamba nge-axially.

Ukuphenduka kwemicu emibili

Amathuluzi ekhadi angasetshenziselwa ukujika noma ukuxhuma intambo ku-lathe (bona ithuluzi lokucubungula intambo). Ukuguqula intambo ngethuluzi lokuguqula ukwakha kuyindlela evamile yesiqeshana esisodwa kanye nokukhiqizwa kweqoqo elincane le-workpiece yentambo ngenxa yesakhiwo sayo esilula; intambo yokujika ngethuluzi lokukama intambo inokukhiqiza okuphezulu, kepha ukwakheka kwayo kuyinkimbinkimbi, ngakho-ke ifaneleka kuphela ukuguqula i-workpiece yentambo emfushane enamazinyo amahle ekukhiqizeni i-batch ephakathi nendawo enkulu. Ukunemba kwephimbo lokuguqula intambo ye-trapezoidal ene-lathe evamile ingafinyelela kuphela amazinga angu-8-9 (jb2886-81, okufanayo ngezansi); ukukhiqiza noma ukunemba kungathuthukiswa kakhulu lapho kwenziwa intambo emshinini okhethekile wentambo.

Ukugaya izintambo ezintathu

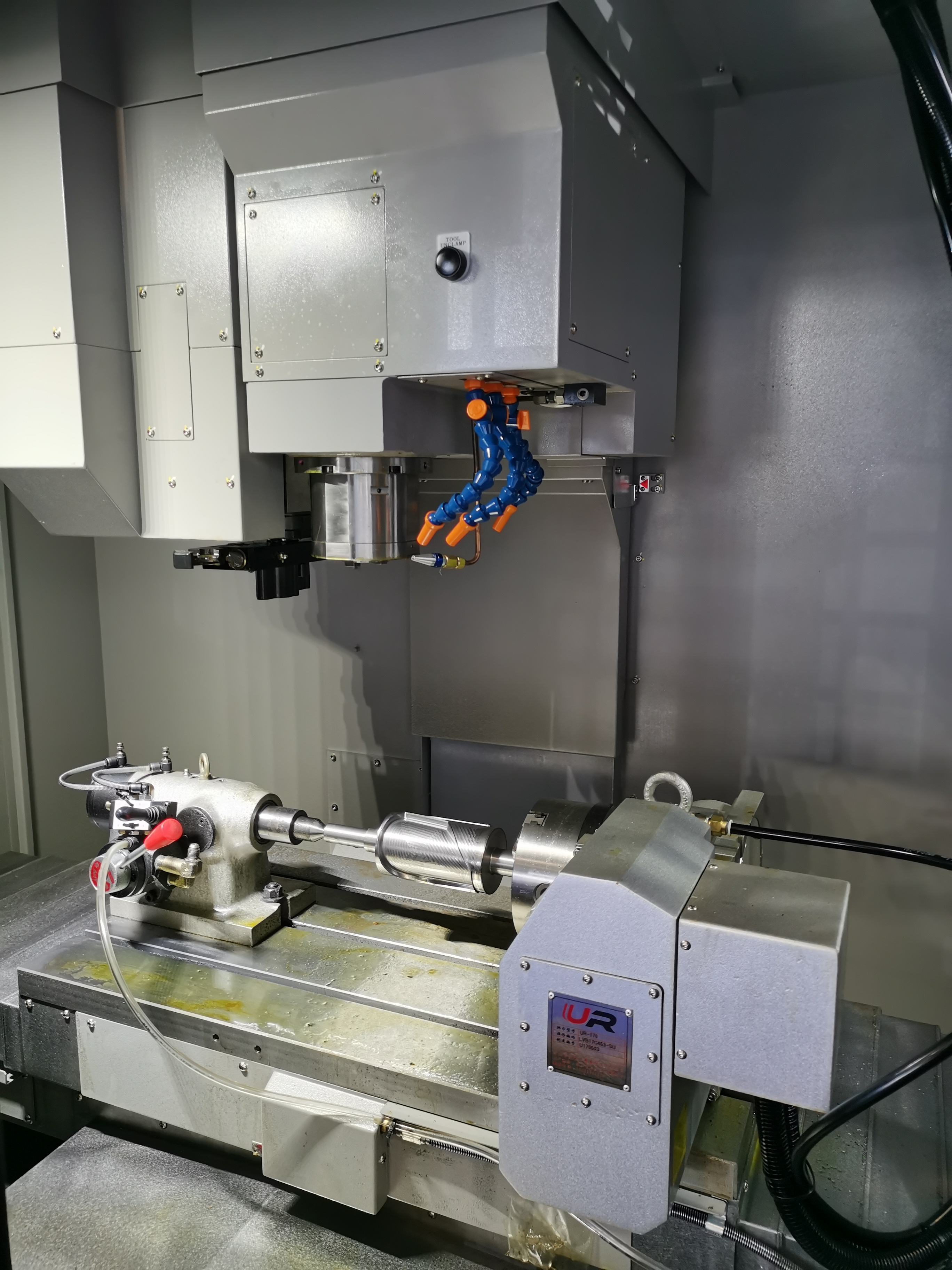

I-disc milling cutter noma i-comb milling cutter isetshenziselwa ukugaya emshinini wokugaya intambo. I-disc milling cutter isetshenziselwa ikakhulukazi imicu ye-trapezoid yangaphandle yokugaya yezikulufu, izikelemu, nezinye izinto zokusebenza. I-combo milling cutter mill yangaphakathi neyangaphandle intambo evamile kanye nentambo ye-taper. Ngenxa yokuthi ingxenye yayo yokusebenza yinde kunobude bentambo okufanele icutshungulwe yi-multi-edge milling cutter, umsebenzi wokusebenza ungacutshungulwa kuphela ngokuzungeza ukuguqulwa kwe-1.25-1.5, ngokukhiqiza okuphezulu. Ukunemba kwephimbo lokugaywa kwentambo kungafinyelela kumabanga angu-8-9, futhi ubulukhuni obungaphezulu bungu-r5-0.63 μ M. Le ndlela ifanele ukukhiqizwa ngobuningi bemishini yokusebenza yentambo enembayo noma ukugaywa okuqinile ngaphambi kokugaya.

Ezineukugaya intambo

Ngokuyinhloko isetshenziselwa ukucubungula intambo enembile ye-workpiece eqinile ku-grinder yentambo. Ngokwezimo ezihlukene zesondo lokugaya, zingahlukaniswa zibe izinhlobo ezimbili: isondo lokugaya elinomugqa owodwa kanye nesondo lokugaya elinemigqa eminingi. Ukunemba kwephimbo kwesondo lokugaya lomugqa owodwa kungamabanga ama-5-6, futhi ubulukhuni obungaphezulu bungu-r1.25-0.08 μ m, ngakho-ke kulula ukuqeda isondo lokugaya. Le ndlela ilungele ukugaya izikulufu ezinembayo, amageji entambo, izikelemu, amaqoqo amancane ezinto zokusebenza zentambo, kanye ne-hob yokunembaIzinhlobo ezimbili zokugaya bezikhona: ukugaya i-longitudinal kanye nokugaya okusikiwe. Ububanzi besondo lokugaya ngendlela yokugaya i-longitudinal bungaphansi kobude bentambo okufanele igaywe, futhi intambo ingacolwa kuze kube usayizi wokugcina ngemva kokuba isondo lokugaya lihamba ngobude kanye noma izikhathi eziningana. Ububanzi besondo lokugaya lendlela yokugaya bukhulu kunobude bentambo okufanele igaywe. Isondo lokugaya lisikeka ebusweni bomsebenzi wokusebenza ngokukhazimulayo, futhi ucezu lokusebenza lungaba phansi ngemuva kokuphenduka okungaba ngu-1.25. Ukukhiqiza kuphakeme, kodwa ukunemba kuphansi kancane, futhi ukugqoka kwesondo lokugaya kuyinkimbinkimbi. Indlela yokugaya yokusika ilungele ukufofa ompompi abaningi kanye nokugaya izintambo zokubopha. Ukucubungula kwensimbi kufanelekile ukunakwa!

Ukugaya imicu emihlanu

Ithuluzi lokuhlanganisa intambo yohlobo lwenati noma lenziwe ngezinto ezithambile ezifana nensimbi ecijile. Izingxenye zochungechunge olucutshunguliwe kucezu lokusebenza ezinephutha lephimbo zigqitshwa ngokuzungezisa phambili nokuhlehla ukuze kuthuthukiswe ukunemba kwephimbo. Intambo yangaphakathi eqinile ivame ukuqedwa ngokugaya ukuze kuthuthukiswe ukunemba.

Ukuthepha okuyisithupha kanye nokucupha

Ukuthepha ukusebenzisa i-torque ethile ukujiya umpompi embobeni ebhoboziwe engezansi endaweni yokusebenza ukuze kucutshungulwe umucu wangaphakathi.

I-threading ukusika intambo yangaphandle kubha (noma ishubhu) ucezu lokusebenzela ngedayizi. Ukunemba komshini wokuthepha noma ukuthunga kuncike ekunembeni kompompi noma ukufa. Nakuba ziningi izindlela zokucubungula imicu yangaphakathi neyangaphandle, imicu yangaphakathi enobubanzi obuncane ingacutshungulwa kuphela ngompompi. Ukuthepha kanye nokulutha kungenziwa ngesandla noma nge-lathe, umshini wokubhoboza, umshini wokushaya, nomshini wokulutha.

Isikhombisaukugingqa intambo

Indlela yokucubungula yokwenza kanye nokugoqa idayisi ukuze kukhiqizwe ukuguquguquka kwepulasitiki kwe-workpiece ukuthola ukugoqa intambo ngokuvamile kwenziwa emshinini wokugoqa intambo noma i-lathe othomathikhi enamathiselwe ngekhanda eligoqayo lokuvula nokuvala intambo, elungele ukukhiqizwa ngobuningi. yephethini yentambo yangaphandle yezinsimbi ezijwayelekile kanye namanye amalunga anentambo. Ngokuvamile, ububanzi obungaphandle bentambo yokugoqa abukho ngaphezu kuka-25 mm, ubude abukho ngaphezu kwe-100 mm, futhi ukunemba kwentambo kungafinyelela ezingeni 2 (gb197-63). Ububanzi bento engenalutho esetshenzisiwe bucishe bulingane nobubanzi bephimbo lentambo ezocutshungulwa. Ngokuvamile, uchungechunge lwangaphakathi alukwazi ukucutshungulwa ngokugoqeka. Noma kunjalo, ku-workpiece ethambile, intambo yangaphakathi ye-extrusion ebandayo ingasetshenziswa ngaphandle kompompi we-slot extrusion (ububanzi obukhulu bungafinyelela cishe ku-30mm), futhi isimiso sokusebenza sifana nokuthinta. I-torque edingekayo ekukhipheni okubandayo kwentambo yangaphakathi icishe ibe yinkulu ngokuphindwe ngo-1 kunaleyo yokuthepha, futhi ukunemba komshini kanye nekhwalithi yendawo ephezulu iphakeme kancane kunaleyo yokuthepha.

Izinzuzo zokugingqa intambo zimi kanje:

① Ubulukhuni obungaphezulu bungaphansi kokuphenduka, ukugaya, nokugaya;

② Ingaphezulu lentambo ngemva kokugingqika lingathuthukisa amandla nobulukhuni ngenxa yokuqina komsebenzi obandayo;

③ izinga lokusebenzisa impahla liphezulu;

④ ukukhiqiza kuphindwe kabili uma kuqhathaniswa nenqubo yokusika, futhi kulula ukuqaphela okuzenzakalelayo;

⑤ impilo yesevisi ye-rolling die yinde kakhulu. Kodwa-ke, ubulukhuni bempahla yokusebenza abukho ngaphezu kwe-hrc40, ukunemba kosayizi ongenalutho kuyadingeka ukuba kube phezulu, futhi ukunemba nokuqina kwe-rolling die nakho kuphezulu, ngakho-ke kunzima ukukhiqiza ukufa. Ayilungele imicu enephrofayili egoqayo ye-asymmetric.

Ngokusho kwe-rolling dies ehlukene, ukugoqa intambo kungahlukaniswa ngezinhlobo ezimbili: ukugoqa intambo nokugingqa intambo.

Amapuleti amabili agoqa intambo anamaphrofayili entambo anyakaziswa ngu-1/2 pitch, ipuleti elimile ligxilile, futhi ipuleti elinyakazayo lihamba ngomugqa oqondile ophindaphindayo ohambisana nepuleti elimile. Uma ufuna ukufunda ukuhlelwa kwe-UG eqenjini 565120797, ingakusiza lapho ucezu lokusebenza lufakwa kumapuleti amabili, ukuhambisa ipuleti phambili ukuze uhlikihle futhi ucindezele ucezu lokusebenza, kwenze ukwakheka kwepulasitiki okungaphezulu kube intambo.

Kunezinhlobo ezintathu zokugingqa: i-radial, tangential, nekhanda eligoqayo.

① Ukugoqa kochungechunge:amasondo amabili (noma amathathu) okugoqa intambo afakwe emiphini ehambisanayo, i-workpiece ibekwe phezu kokusekelwa phakathi kwamasondo amabili, futhi amasondo amabili ajikeleza ngesivinini esifanayo ohlangothini olufanayo, elinye lawo futhi lenza i-radial. ukunyakaza kokuphakelayo. Isondo eligoqayo lishayela i-workpiece ukuze lijikelezise, futhi indawo engaphezulu ikhishwa nge-radially ukuze yakhe intambo. Indlela yokugoqa efanayo ingasetshenziswa kwezinye izikulufu ezinezidingo zokunemba okuphansi.

②ukugingqa kochungechunge:eyaziwa nangokuthi intambo yeplanethi. Ithuluzi eligoqayo lihlanganisa isondo elijikelezayo elimaphakathi elizungezayo kanye namapuleti entambo amathathu amile amise okwe-arc. I-workpiece ingaphakelwa ngokuqhubekayo ngesikhathi sokuginqika, ngakho-ke ukukhiqiza kuphezulu kunokokuhlikihlwa kwentambo nokugingqika kwe-radial.

③ Ukugoqa uchungechunge lwekhanda eligoqayo:yenziwa ku-lathe othomathikhi futhi ngokuvamile isetshenziselwa ukucubungula intambo emfushane ku-workpiece. Kunama-roller angama-3-4 asatshalaliswa ngokulinganayo endaweni yokusebenza. Lapho ugoqa, i-workpiece iyajikeleza, futhi ikhanda eligoqayo lidla i-axially ukuze ikhiphe umsebenzi ngaphandle kwentambo.

| Izingxenye zemishini ye-CNC | Amazing CNC Machining | Isevisi ye-inthanethi ye-Cnc |

| Izingxenye ze-Aluminium Machining | Izingxenye Zezindiza Zomshini | Custom Metal Manufacturing |

| I-CNC Processing | Izingxenye Zomshini Zethusi | Izingxenye ze-Brass CNC |

www.anebon.com

I-Anebon Metal Products Limited ingahlinzeka ngemishini ye-CNC, i-die casting, izinsizakalo zomshini wensimbi, sicela ukhululeke ukuxhumana nathi.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Isikhathi sokuthumela: Oct-04-2019