Njengelungu lomkhakha, ingabe uyawuqonda ngempela umehluko phakathi kokwelapha okungaphezulu okuhlukile kwezinto ezihlukahlukene?

Kunamasu ahlukahlukene ajwayelekile okwelapha angaphezulu, afaka kodwa angagcini nje kulokhu:

Ukugqoka:Ukusebenzisa ungqimba oluncane lwento (njengopende, okoqweqwe lwawo, noma insimbi) ukuze kuvikelwe indawo engaphezulu, kuthuthukiswe ubuhle bobuhle, kuvinjwe ukugqwala, noma kuthuthukise ukusebenza okuthile.

Ukucwenga:I-Electroplating ihlanganisa ukufaka ungqimba oluncane lwensimbi phezu kwe-substrate ukuze kuthuthukiswe ukumelana nokugqwala, ukuguquguquka, noma ukubukeka.

Ukwelashwa kokushisa:Ukusebenzisa ukushisa okulawulwayo nezinqubo zokupholisa ukuze kuguqulwe i-microstructure nezici zezinsimbi, ezifana nokuthuthukisa ubulukhuni, amandla, noma i-ductility.

Ukuhlanza nokulungiswa kwendawo:Ukukhipha ukungcola, ukungcola, noma izendlalelo ze-oxidation ukusuka phezulu ukuze kuqinisekiswe ukunamathela okufanele kanye nokubopha okunamathelayo noma okunye ukwelashwa kwendawo.

Ukulungiswa kwendawo:Amasu afana nokufakwa kwe-ion, i-surface alloying, noma ukwelashwa nge-laser asetshenziselwa ukuguqula ukwakheka noma ukwakheka kwendawo ukuze kuthuthukiswe izici ezinjengokuqina, ukumelana nokuguga, noma ukungangeni kwamakhemikhali.

Ukuthumela umbhalo ebusweni:Ukudala amaphethini athile, ama-grooves, noma ukuthungwa ngaphezulu ukuze kuthuthukiswe ukubamba, ukunciphisa ukungqubuzana, noma ukuthuthukisa ukubukeka kobuhle.

Incazelo:

Ukwelashwa okungaphezulu kuyinqubo yokudala ungqimba lwento engaphezulu esisekelweni esinezici ezihlukene zomshini, zomzimba, kanye namakhemikhali.

Inhloso:

Ukwelashwa okungaphezulu kuvame ukwenziwa ukuze kuthuthukiswe ukusebenza komkhiqizo, njengokumelana nokugqwala, ukuqina, noma umhlobiso. Ukwelashwa okungaphezulu kwenziwa ngokugaya ngemishini, ukwelashwa kokushisa okungaphezulu, ukufuthwa kwendawo, nokwelashwa ngamakhemikhali. Ukwelashwa kwendawo kuhlanganisa ukuhlanza, ukushanela, ukukhipha, ukususa amafutha, kanye nokwehlisa ingaphezulu lesiqephu somsebenzi.

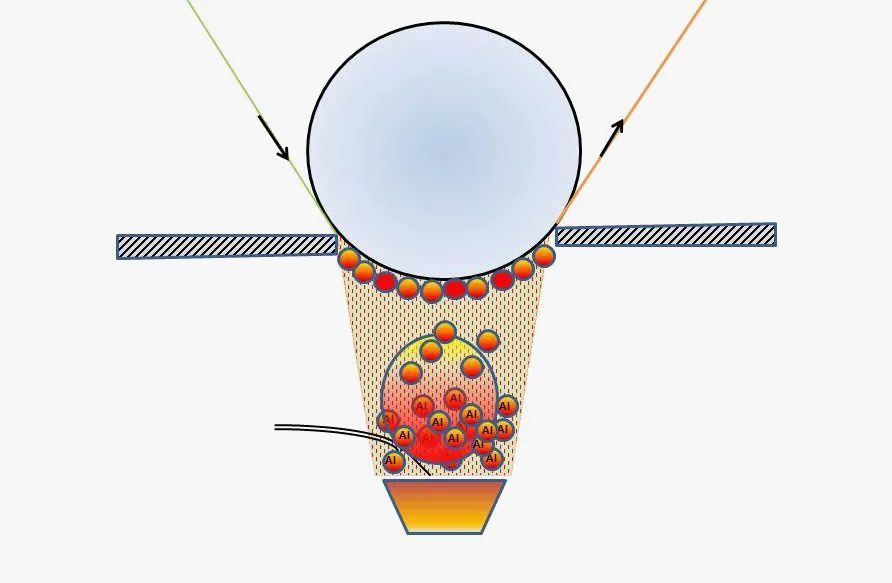

01. Vacuum plating

—— Vacuum Metalizing ——

I-vacuum plating kwenzeka ngenxa yenqubo yomzimba. Ku-vacuum, i-argon iyajovwa bese ishaya ithagethi. Ithagethi ibe isihlukaniswa ibe ama-molecule adsorbent by conductive goods, akha umfaniswano, ungqimba lwensimbi lokulingisa olubushelelezi.

Izinto ezisetshenziswayo:

1. I-vacuum plating ingenzeka ezinhlobonhlobo zezinto ezihlanganisa izinsimbi, izinhlanganisela, izitsha zobumba, ingilazi, namapulasitiki athambile futhi aqinile. I-Aluminium iyindlela ejwayelekile yokwelapha engaphezulu kwe-electroplating, ilandelwa ithusi nesiliva.

2. Izinto zemvelo azikwazi ukufakwa nge-vacuum ngoba umswakama wazo uzophazamisa indawo ye-vacuum.

Izindleko zenqubo:

Izindleko zabasebenzi ziphezulu kakhulu ekufakweni kwe-vacuum ngoba umsebenzi kufanele ufuthwe bese ulayishwa, wehliswe, bese ufafazwa kabusha. Kuphinde kuncike ekutheni i-workpiece iyinkimbinkimbi futhi inkulu kangakanani.

Umthelela wemvelo:

I-Vacuum Electroplating ifana nokufafaza ngokomthelela wayo kwezemvelo.

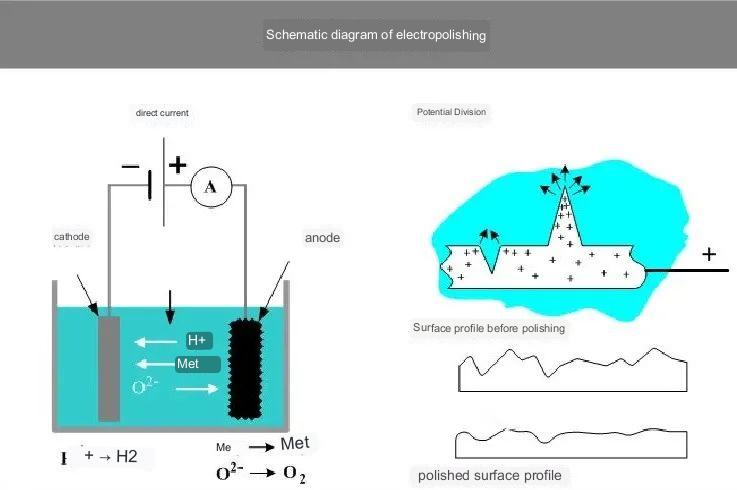

02. Electropolishing

—— Electropolishing ——

I-Electropolishing iyinqubo ye-electrochemical lapho ama-athomu ocwecwe lokusebenza acwiliswa ku-electrolyte aguqulwa abe ama-ion futhi asuswe phezulu ngenxa yokudlula kwamandla kagesi, ngaleyo ndlela kuzuzwe umphumela wokukhipha ama-burrs amahle nokwandisa ukukhanya kwendawo yokusebenza.

Izinto ezisetshenziswayo:

1. Izinsimbi eziningi zingapholishwa nge-electrolytically, phakathi kwazo okuvame ukusetshenziswa kakhulu ukupholishwa kwendawo yensimbi engagqwali (ikakhulukazi insimbi engagqwali ye-austenitic nuclear grade).

2. Izinto ezihlukile azikwazi ukufakwa nge-electropolished ngesikhathi esisodwa, noma zifakwe ku-solvent efanayo ye-electrolytic.

Izindleko zokucubungula:

Yonke inqubo yokupholisha i-electrolytic ngokuyisisekelo iqedwa ngokuzenzakalelayo, ngakho-ke izindleko zabasebenzi ziphansi kakhulu. Umthelela wendawo: Ukupholisha nge-electrolytic kusebenzisa amakhemikhali angayingozi kangako. Yonke le nqubo idinga amanzi amancane futhi kulula ukuyisebenzisa. Ngaphezu kwalokho, ingakwazi ukwandisa izakhiwo zensimbi engagqwali futhi ibambezele ukugqwala kwensimbi engagqwali.

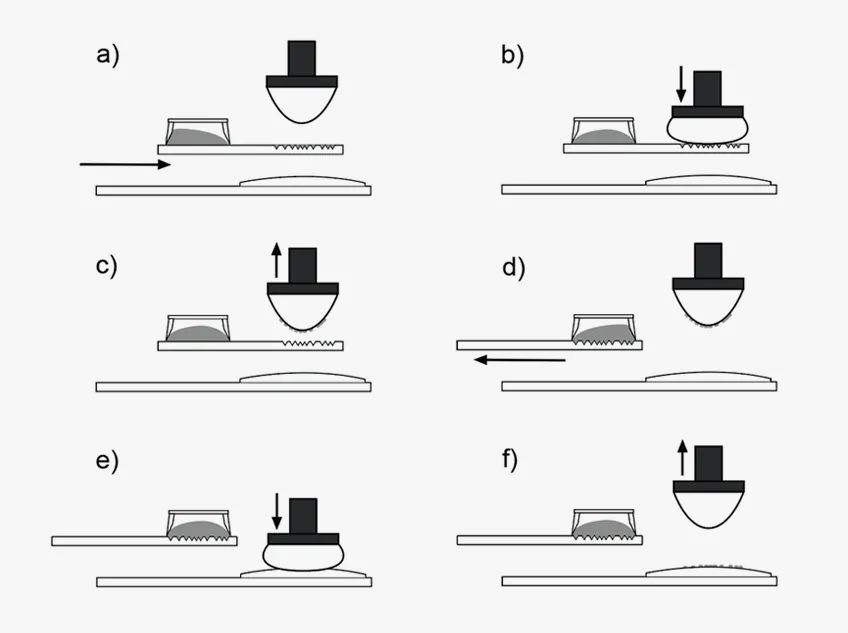

03. Inqubo yokuphrinta yephedi

——Ukuphrinta Kwephedi——

Ukwazi ukuphrinta umbhalo, ihluzo kanye nemifanekiso ebusweni bezinto ezimise okungavamile manje sekuba ukuphrinta okukhethekile okubalulekile.

Izinto ezisetshenziswayo:

Ukuphrinta kwephedi kungasetshenziselwa cishe zonke izinto zokwakha, ngaphandle kwezinto ezithambile kunamaphedi abicah, njenge-PTFE.

Izindleko zokucubungula:

izindleko zesikhunta eziphansi kanye nezindleko eziphansi zabasebenzi.

Umthelela wendawo: Njengoba le nqubo ilinganiselwe kumayinki ancibilikayo (aqukethe amakhemikhali ayingozi), inomthelela omkhulu kwezemvelo.

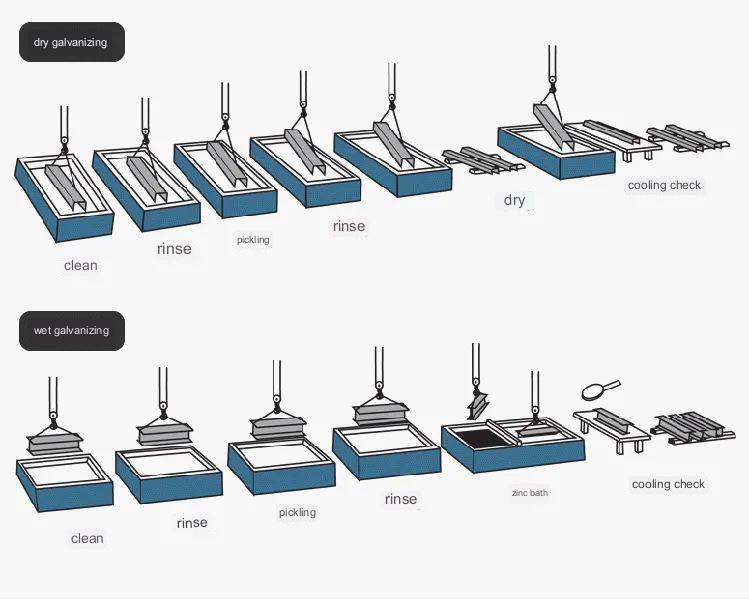

04. Inqubo yokugaya

-- Ukugqama --

Ukwelashwa okungaphezulu okusebenzisa ungqimba oluncane lwe-zinc ebusweni bezinto zensimbi ye-alloy. Lokhu kwenzelwa ubuhle, futhi kunezindawo zokulwa nokugqwala. I-zinc enamathelayo engaphezulu isebenza njengesendlalelo sokuvikela i-electrochemical ukuvimbela ukugqwala kwensimbi. I-hot-dip galvanizing iyindlela eyinhloko esetshenziswayo.

Izinto ezisetshenziswayo:

I-galvanizing iwukwelapha okungaphezulu kwensimbi nensimbi kuphela.

Izindleko zokucubungula:

Azikho izindleko zesikhunta. Umjikelezo omfushane/izindleko zabasebenzi ezimaphakathi. Izinga eliphezulu lesiqephu lincike kakhulu ekulungisweni kwendawo okwenziwa ngesandla ngaphambi kokuba kufakwe uthayela.

Inqubo yokufaka ama-galvanizing inomthelela omuhle emvelweni. Kwenyusa isikhathi sokuphila kwecnc izingxenye ezigayiwekusukela eminyakeni engu-40 kuya kweyikhulu, futhi ivimbela ukugqwala nokugqwala. Ucezu lukathayela lungabuye lubuyiselwe ethangini lalo lokuphehla uma selufinyelele ekupheleni kokusebenza kwalo. Lokhu ngeke kukhiqize udoti wamakhemikhali noma obonakalayo.

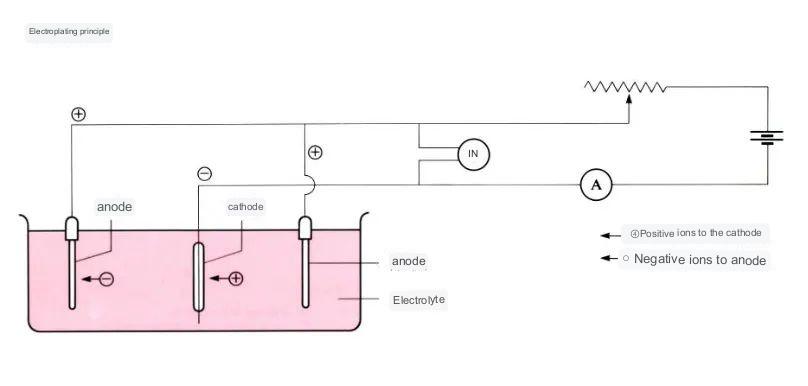

05. Inqubo ye-Electroplating

—- Electroplating —-

I-Electroplating inqubo yokusebenzisa ungqimba oluncane lwensimbi ezingxenyeni kusetshenziswa i-electrolysis. Lokhu kusiza ukuthuthukisa ukumelana nokugqwala, ukumelana nokugqoka, ukuqhutshwa kwe-conductivity kanye nobuhle. Izinhlamvu zemali eziningi zinezingqimba zazo zangaphandle ze-electroplated. .

Izinto ezisetshenziswayo:

1. I-Electroplating ingenzeka ezinsimbi eziningi, kodwa ukuhlanzeka nokusebenza kahle kokucwenga kuyahlukahluka. Lezi zihlanganisa ithini ne-nickel.

2. I-ABS iyipulasitiki evamile esetshenziselwa i-electroplating.

3. I-nickel inobuthi futhi iyacasula esikhumbeni. Ngeke isetshenziswe emikhiqizweni ene-electroplated.

Izindleko zokucubungula:

Azikho izindleko zesikhunta, kodwa ukulungiswa kuyadingeka ukulungisa izingxenye. Izindleko zesikhathi zincike ohlotsheni lwensimbi nezinga lokushisa. Izindleko zomsebenzi (eziphakeme kakhulu) zincike ezingxenyeni ezithile zokucwenga. I-Silverware ne-jewelry plating idinga abasebenzi abanamakhono aphezulu ngenxa yezidingo zayo eziphezulu zokubukeka nokuqina.

Umthelela wemvelo:

I-Electroplating isebenzisa inani elikhulu lezinto ezinobuthi, ezidinga ukukhishwa kochwepheshe kanye nokuphambukisa ukuze kuncishiswe umthelela wendawo.

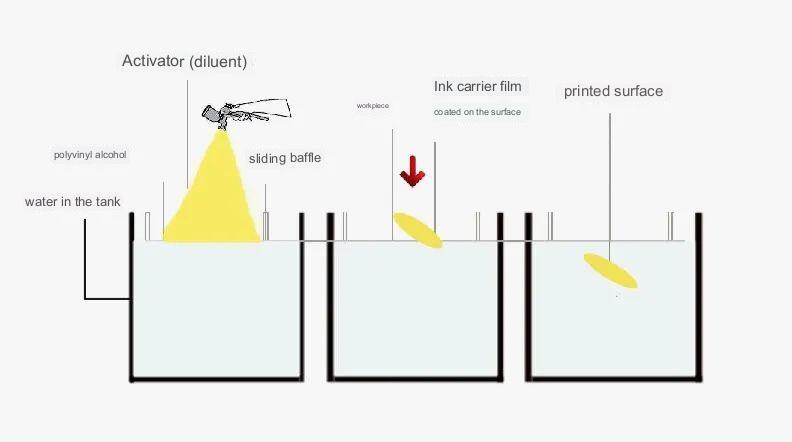

06. Ukuphrinta Ukudluliswa Kwamanzi

—- I-Hydro Transfer Printing —-

Ukucindezela kwamanzi kusetshenziselwa ukudlulisa iphethini yombala phezu kwemikhiqizo enezinhlangothi ezintathu. Ukuphrinta ukudluliswa kwamanzi sekudume kakhulu njengoba abantu belindele kakhulu ukupakishwa nokuhlobisa indawo.

Izinto ezisetshenziswayo:

Ukuphrinta ukudluliswa kwamanzi kungenzeka kuzo zonke izinto eziqinile. Izinto ezifanele zokufafaza nazo zifanelekile kulolu hlobo lokuphrinta. Umjovo obunjiwe futhicnc metal turning izingxenyeyizona ezivame kakhulu.

Izindleko zenqubo: Nakuba singekho isikhunta, imikhiqizo eminingi kufanele idluliselwe ngamanzi ngesikhathi esisodwa kusetshenziswa izinto ezilungiswayo. Isikhathi esidingekayo ngomjikelezo ngokuvamile asidluli imizuzu eyi-10.

Ukuphrinta ukudluliswa kwamanzi kunobungani bemvelo kunokufafaza umkhiqizo ngoba kusebenzisa upende wokuphrinta ngokwezinga elikhulu, ngaleyo ndlela kunciphisa ukuvuza kwemfucuza.

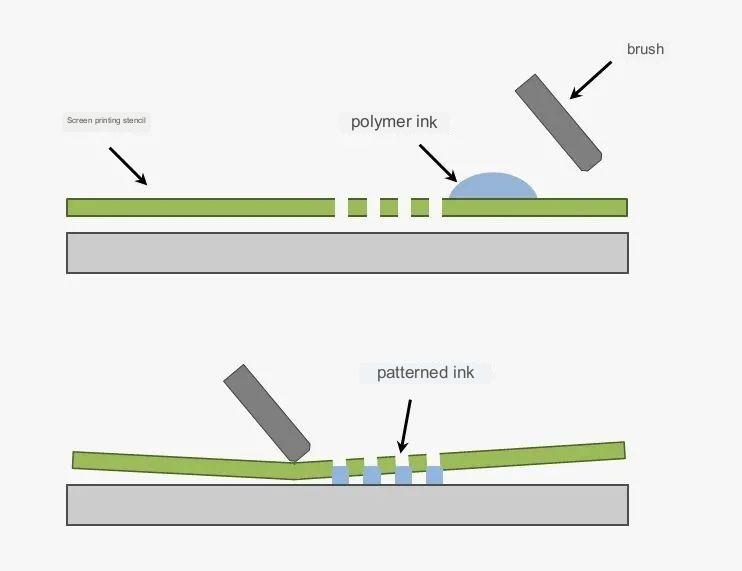

07. Ukuphrinta Isikrini

—- Ukuphrinta Isikrini —-

Uyinki udluliselwa nge-mesh engxenyeni yesithombe ku-substrate nge-extrusion. Lokhu kukhiqiza umfanekiso ofanayo nse nalowo wokuqala. Imishini yokuphrinta isikrini kulula ukuyisebenzisa, kulula ukwenza amapuleti nokuphrinta, futhi inezindleko eziphansi.

Izinto zokuphrinta ezivame ukusetshenziswa zihlanganisa imidwebo kawoyela onemibala namaphosta, amakhadi ebhizinisi kanye nesembozo esibophezelayo.

Izinto ezisetshenziswayo:

Ukuphrinta isikrini kungenziwa cishe kunoma iyiphi impahla, okuhlanganisa izitsha zobumba, ingilazi, izitsha zobumba nensimbi.

Izindleko zokucubungula:

Izindleko zesikhunta ziphansi kodwa zisancike emibaleni yezinombolo ngoba ipuleti ngalinye lombala lidinga ukwenziwa ngokuhlukana. Izindleko zabasebenzi ziphezulu uma uphrinta ngemibala eminingi.

Umthelela wemvelo:

Oyinki bokuphrinta isikrini abanemibala ekhanyayo banomthelela ophansi endaweni. Nokho, oyinki abaqukethe i-formaldehyde ne-PVC bangamakhemikhali ayingozi futhi kufanele bagaywe kabusha noma balahlwe ngesikhathi esifanele ukuze kugwenywe ukungcoliswa kwamanzi.

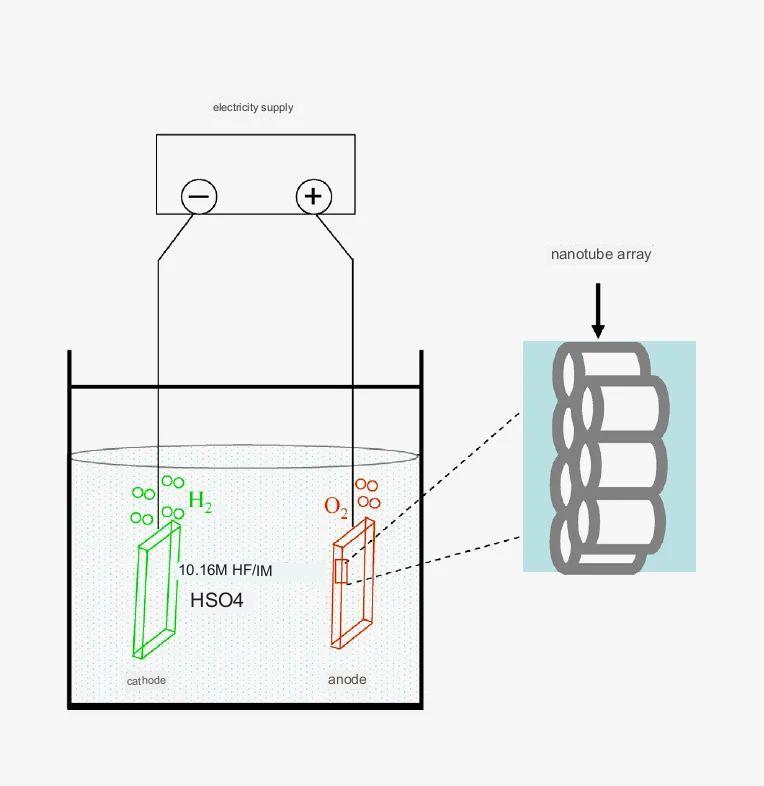

08. Anodizing

I-Anodic Oxidation ——

I-anodic oxidation ye-aluminium isekelwe ngokuyinhloko kusimiso se-electrochemical ukuze kwakhe ungqimba lwefilimu ye-Al2O3 (i-aluminium oxide) ebusweni be-aluminium ne-aluminium alloy. Lolu ngqimba lwefilimu ye-oxide lunezici ezikhethekile ezinjengokuvikela, ukuhlobisa, ukugquma, nokumelana nokugqoka.

Izinto ezisetshenziswayo:

I-aluminium, i-aluminium alloy nezinyecnc machining aluminium izingxenye

Izindleko zenqubo: Enqubweni yokukhiqiza, ukusetshenziswa kwamanzi nogesi kukhulu kakhulu, ikakhulukazi ohlelweni lwe-oxidation. Ukusetshenziswa kokushisa komshini ngokwawo kudinga ukupholiswa ngokuqhubekayo ngamanzi ajikelezayo, futhi ukusetshenziswa kwamandla ngethani ngokuvamile kuzungeze ama-degree angu-1000.

Umthelela wemvelo:

I-anodizing ayivelele mayelana nokusebenza kahle kwamandla, kuyilapho ekukhiqizeni i-aluminium electrolysis, umphumela we-anode uphinde ukhiqize amagesi anemiphumela emibi elimazayo kungqimba lwe-ozone emkhathini.

09. Umdwebo wocingo lwensimbi

—— Intambo Yensimbi ——

Kuyindlela yokwelapha engaphezulu eyenza imigqa ebusweni bomsebenzi womsebenzi ngokugaya umkhiqizo ukuze kuzuzwe umphumela wokuhlobisa. Ngokwendlela yokwenza ehlukene ngemva kokudweba ngocingo, ingahlukaniswa ibe: umdwebo wocingo oluqondile, umdwebo wocingo oluyisiphithiphithi, uthayela, nokuzungeza.

Izinto ezisetshenziswayo:

Cishe zonke izinto zensimbi zingasebenzisa inqubo yokudweba ucingo lwensimbi.

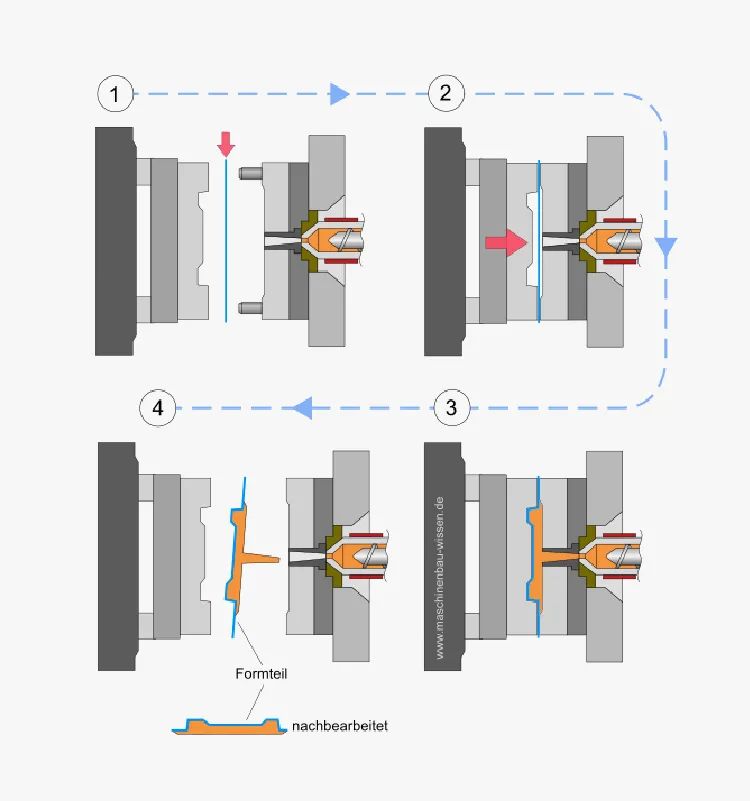

10. In-mold Decoration

—- In-Mold Decoration-IMD —-

Le ndlela yokubumba ihilela ukufaka i-diaphragm yensimbi ephrintiwe iphethini esibunjeni sensimbi, ukujova inhlaka esibunjeni, ukuhlanganisa i-diaphragm ndawonye, nokuhlanganisa inhlaka ne-diaphragm yensimbi ephrinte iphethini ukuze kwakhe umkhiqizo wokugcina.

Izinto ezisebenzayo:

Pindawo yokugcina

Izindleko zokucubungula:

Udinga kuphela ukuvula isethi eyodwa yesikhunta. Lokhu kunganciphisa izindleko namahora okusebenza, Ukukhiqiza Okuzenzakalelayo Okuphezulu, Inqubo Yokukhiqiza Elula, Indlela Yokubumba Umjovo Wesikhathi esisodwa, futhi kuzuzwe kokubili ukubumba nokuhlobisa ngesikhathi esifanayo.

Umthelela wemvelo:

Ubuchwepheshe bunobungani bemvelo futhi buluhlaza, futhi bugwema ukungcoliswa okudalwa yi-electroplating nokudweba kwendabuko.

Izindleko zokucubungula:

Indlela yenqubo ilula, okokusebenza kulula, ukusetshenziswa kwezinto ezibonakalayo kuncane kakhulu, izindleko ziphansi, futhi inzuzo yezomnotho iphezulu.

Umthelela wemvelo:

Imikhiqizo yensimbi ehlanzekile, akukho upende noma yiziphi izinto zamakhemikhali ezingaphezulu, izinga lokushisa eliphakeme elingu-600 degrees alishi, alikhiqizi amagesi anobuthi, lihlangabezana nezidingo zokuvikela umlilo kanye nezidingo zokuvikela imvelo.

Qhubeka uthuthuka, ukuze uqinisekise ukuthi umkhiqizo uhambisana namazinga emakethe kanye namakhasimende. I-Anebon inohlelo lokulawula ikhwalithi olusebenzayo lokuqinisekisa izinga eliphezulu lokuthengisa okushisayo kwezingxenye zango-2022 ze-ABS Plastic Drilling CNC Machining Turning Part Service, Trust Anebon futhi uzothola ezinye izinzuzo eziningi. Sicela uthathe isikhathi sokusithola ukuze uthole ulwazi olwengeziwe, i-Anebon ikuqinisekisa ukuthi sikunaka ngokugcwele usuku lonke.

Izingxenye ezisele ezizenzakalelayo zezingxenye zokugaya zekhwalithi ephezulu, izingxenye zensimbi eziphendulwe yi-China Anebon. Imikhiqizo evela e-Anebon iye yazuza ukuqashelwa okukhulayo kumakhasimende aphesheya futhi isisungule ubudlelwano besikhathi eside nobuzuzisa ngokufanayo ne-Anebon. I-Anebon izonikeza isevisi yekhwalithi ephezulu kakhulu kukhasimende ngalinye. Samukela ngokufudumele abangani abasha ukuthi bajoyine i-Anebon futhi badale izinzuzo ezifanayo.

Isikhathi sokuthumela: Jul-18-2023