Ukuqhekeka okucisha kuyiziphambeko ezivamile zokucisha ku-CNC machining, futhi kunezizathu eziningi zazo. Ngenxa yokuthi izinkinga zokwelashwa kokushisa ziqala ekwakhiweni komkhiqizo, i-Anebon ikholelwa ukuthi umsebenzi wokuvimbela imifantu kufanele uqale ekwakhiweni komkhiqizo. Kuyadingeka ukukhetha kahle izinto zokwakha, ukwenza ukwakheka kwesakhiwo ngokunengqondo, ukubeka phambili izidingo zobuchwepheshe zokwelashwa kokushisa, ukuhlela kahle imizila yenqubo, nokukhetha izinga lokushisa elifanele lokushisa, isikhathi sokubamba, indawo yokushisa, indawo yokupholisa, indlela yokupholisa kanye nemodi yokusebenza, njll.

1. Izinto zokwakha

1.1Ikhabhoni iyisici esibalulekile esithinta ukuthambekela kokucisha nokuqhekeka. Okuqukethwe kwekhabhoni kuyanda, iphuzu le-MS liyehla, futhi ukuthambekela kokuqhekeka kokucisha kuyanda. Ngakho-ke, ngaphansi kwesimo sokwanelisa izakhiwo eziyisisekelo ezifana nobunzima namandla, okuqukethwe kwekhabhoni ephansi kufanele kukhethwe ngangokunokwenzeka ukuze kuqinisekiswe ukuthi akulula ukucisha nokuqhekeka.

1.2Umthelela wezakhi ze-alloying ekucimeni kokuqhekeka ubonakala ikakhulukazi ethonyeni lokuba lukhuni, iphuzu le-MS, ukuthambekela kokukhula kosayizi wokusanhlamvu kanye nokubola kwe-carburization. Izakhi ze-alloying zithinta ukuthambekela kokuqhekeka okucishayo ngenxa yethonya lokuqina. Ngokuvamile, ukuqina kuyanda futhi ukuqina kuyanda, kodwa ngesikhathi esifanayo njengoba ukuqina kukhuphuka, kungenzeka ukusebenzisa i-medium quenching enamandla okupholisa abuthakathaka ukuze kuncishiswe ukucisha ukucisha ukuvimbela ukuguqulwa nokuqhekeka kwezingxenye eziyinkimbinkimbi. Ngakho-ke, ezingxenyeni ezinobunjwa obuyinkimbinkimbi, ukuze ugweme ukucima imifantu, kuyisixazululo esingcono sokukhetha insimbi enobunzima obuhle futhi usebenzise i-medium quenching enamandla okupholisa abuthakathaka.

Izakhi ze-alloying zinethonya elikhulu endaweni ye-MS. Ngokuvamile, lapho i-MS iphansi, kuyanda ukuthambekela kokuqhekeka kokucisha. Lapho iphuzu le-MS liphakeme, i-martensite eyakhiwe ukuguqulwa kwesigaba ingase ikwazi ukuzibamba ngokushesha, ngaleyo ndlela iqede ingxenye yokuguqulwa kwesigaba. Ukucindezeleka kungagwema ukucima ukuqhekeka. Ngakho-ke, lapho okuqukethwe kwekhabhoni kunqunywa, inani elincane lezinto ezihlanganisiwe kufanele kukhethwe, noma amamaki ensimbi aqukethe izakhi ezinomphumela omncane kuphoyinti le-MS.

1.3Lapho ukhetha izinto zensimbi, ukuzwela kokushisa ngokweqile kufanele kucatshangelwe. Insimbi ezwela ukushisa ngokweqile ijwayele ukuqhekeka, ngakho-ke kufanele kuqashelwe ekukhethweni kwezinto.

2. Ukuklama kwesakhiwo sezingxenye

2.1Usayizi wesigaba ufana. Izingxenye ezinoshintsho olubukhali kusayizi we-cross-sectional zizoba nemifantu ngenxa yokucindezeleka kwangaphakathi ngesikhathi sokwelashwa kokushisa. Ngakho-ke, ukuguqulwa okungazelelwe kosayizi wesigaba kufanele kugwenywe ngangokunokwenzeka ngesikhathi sokuklama. Ubukhulu bodonga kufanele bufane. Uma kunesidingo, izimbobo zingabhojwa ezingxenyeni ezinodonga oluqinile ezingahlobene ngokuqondile nesicelo. Imigodi kufanele yenziwe ngezimbobo ngangokunokwenzeka. Ngobacnc machining aluminium izingxenyengokuqina okuhlukile, ukwakheka okuhlukile kungenziwa, bese kuhlanganiswe ngemuva kokwelashwa kokushisa.

2.2Inguquko yekhona eliyindilinga. Lapho izingxenye zinamakona, amakhona abukhali, ama-grooves kanye nezimbobo ezivundlile, lezi zingxenye zijwayele ukugxila ekucindezelekeni, okuzoholela ekucimeni nasekuqhekekeni kwezingxenye. Ngenxa yalesi sizathu, izingxenye kufanele zenziwe ngendlela engabangeli ukugxila kokucindezeleka ngangokunokwenzeka, futhi amakhona abukhali nezinyathelo zicutshungulwa zibe amakhona ayindilinga.

2.3Umehluko kuzinga lokupholisa ngenxa yesici somumo. Ijubane lokupholisa liyahlukahluka ngokuma kwezingxenye lapho izingxenye zicinywa. Ngisho nakwehlukeneizingxenye ze-cncyengxenye efanayo, izinga lokupholisa lizohluka ngenxa yezici ezihlukahlukene. Ngakho-ke, zama ukugwema ukwehluka kokupholisa ngokweqile ukuze uvimbele ukucisha imifantu.

3. Izimo zezobuchwepheshe zokwelashwa kokushisa

3.1Ukucisha indawo noma ukuqina kwendawo kufanele kusetshenziswe ngangokunokwenzeka.

3.2Ukulungisa ngokufanele ubulukhuni bendawo bezingxenye ezicishiwe ngokuvumelana nezimo zesevisi yezingxenye. Uma isidingo sokuqina kwendawo sokucisha siphansi, zama ukungaphoqi ubulukhuni obuphelele ukuthi buhambisane.

3.3Naka umphumela omkhulu wensimbi.

3.4Gwema ukuthukuthela ohlotsheni lokuqala lwendawo eshisayo.

4. Hlela ngokunengqondo umzila wenqubo kanye namapharamitha wokucubungula

Kanye impahla, isakhiwo kanye nezimo lobuchwephesheizingxenye zensimbikunqunywa, ochwepheshe bokwelashwa kokushisa kufanele benze ukuhlaziya inqubo ukuze banqume indlela yenqubo enengqondo, okungukuthi, ukuhlela kahle izikhundla zokulungiselela ukushisa kokushisa, ukucubungula okubandayo nokucubungula okushisayo nokunquma imingcele yokushisa.

Ukucisha i-crack

4.1Ngaphansi kuka-500X, inamatshe, ukuqhekeka ekuqaleni kubanzi, futhi ukuqhekeka ekugcineni kuncane kokungabi nalutho.

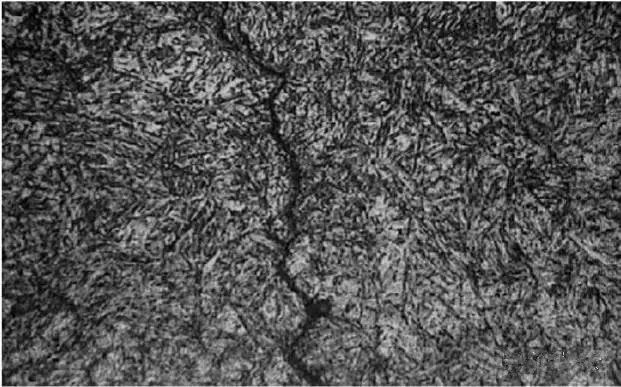

4.2 Ukuhlaziywa kwe-Microscopic: ukufakwa kwe-metallurgical okungavamile, imifantu enwebekayo esimweni esimangelengele; kuqashelwe ngemva kokugqwala ngotshwala obuyi-nitric acid engu-4%, asikho isenzakalo se-decarburization, futhi ukubukeka kwe-microscopic kuboniswa esithombeni esingezansi:

1# isampula

Akukho ukufakwa kwe-metallurgical okungavamile kanye ne-decarburization etholwe emifantwini yomkhiqizo, futhi imifantu enwetshiwe ngesimo se-zigzag, esinezici ezijwayelekile zokucisha imifantu.

2# isampula

Isiphetho sokuhlaziya:

4.1.1 Ukwakhiwa kwesampula kuhlangabezana nezidingo zezinga futhi kuhambisana nokwakheka kwenombolo yesithando somlilo sokuqala.

4.1.2 Ngokusho kokuhlaziywa kwe-microscopic, akukho ukufakwa kwe-metallurgical okungavamile okutholwe emifantwini yesampula, futhi kwakungekho mkhuba wokukhipha i-carburization. Imifantu enwetshiwe ngesimo se-zigzag, esinezici ezijwayelekile zokucisha imifantu.

ukwakha i-crack

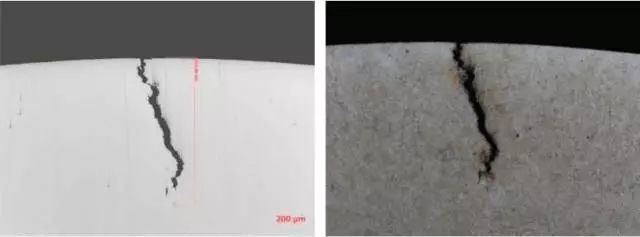

1. Imifantu ebangelwa yizinto ezibonakalayo ezijwayelekile, imiphetho iyi-oxides.

2. Ukubhekwa okuncane

Ungqimba olumhlophe olukhanyayo ebusweni kufanele kube ungqimba lwesibili lokucisha, futhi olumnyama olumnyama ngaphansi kwesendlalelo sesibili sokucisha ungqimba oluphezulu lokushisa.

Isiphetho sokuhlaziya:

Imifantu ene-decarburization kufanele ihlukaniswe ukuthi iyimifantu yempahla eluhlaza. Imvamisa, imifantu ejule ngokususa i-decarburization enkulu noma elingana nokujula kwe-surface decarburization iwukuqhekeka kwempahla eluhlaza, futhi imifantu ejulile ye-decarburization engaphansi kokujula kwe-surface decarburization idala imifantu.

Ngobuchwepheshe obuhamba phambili be-Anebon ngokufanayo nomoya wethu wokusungula izinto ezintsha, ukubambisana, izinzuzo kanye nentuthuko, sizokwakha ikusasa eliqhakazile kanye nebhizinisi lakho elihlonishwayo lezingxenye ze-aluminium Manufacturer Custom High Precision aluminium, izingxenye zensimbi eziphendulayo, izingxenye zensimbi yokugaya i-cnc, Futhi kukhona nenqwaba yabangane abasondelene baphesheya kwezilwandle abeze ukuze babonwe, noma basiphathise ukuthi sibathengele ezinye izinto. Uzokwamukeleka kakhulu ukuza e-China, edolobheni lase-Anebon kanye nasesikhungweni sokukhiqiza sase-Anebon!

I-China Wholesale yase-China eyenziwe ngomshini, imikhiqizo ye-cnc, izingxenye zensimbi eziphendulwe kanye nethusi lokunyathela. I-Anebon inobuchwepheshe obuthuthukisiwe bokukhiqiza, futhi iphishekela izinto ezintsha emikhiqizweni. Ngesikhathi esifanayo, inkonzo enhle iye yathuthukisa idumela elihle. I-Anebon ikholelwa ukuthi inqobo nje uma uqonda umkhiqizo wethu, kufanele uzimisele ukuba ozakwethu nathi. Ngibheke ngabomvu uphenyo lwakho.

Isikhathi sokuthumela: Feb-20-2023