Ukusebenza kahle kwemishini yethuluzi lomshini we-CNC kuhlobene eduze nokunemba kwayo, okuyenza ibe yinto ehamba phambili ezinkampanini uma zithenga noma zithuthukisa amathuluzi anjalo. Kodwa-ke, ukunemba kwamathuluzi amaningi emishini emisha ngokuvamile kuyasilela kumazinga adingekayo lapho uphuma efekthri. Ukwengeza, ukwenzeka kokugijima nokugqokwa kwemishini ngesikhathi sokusetshenziswa isikhathi eside kugcizelela isidingo esibalulekile sokulungisa ukunemba kwamathuluzi omshini we-CNC ukuze kuqinisekiswe ukusebenza kahle kokukhiqiza.

1. Isinxephezelo sokuhlehla

Ukunciphisa Ukubuyela emuvaNgaphakathi kwamathuluzi omshini we-CNC, amaphutha asuka ezindaweni ezifile ezihlehlayo zezingxenye zokushayela ochungechungeni lokudluliswa kokuphakelayo kwe-eksisi ngayinye exhumanisayo kanye nokuhlehla okuphambene kwepheya ngalinye lomshini wokuhambisa ukunyakaza kuholela ekuphambukeni njengoba i-eksisi ngayinye ixhumanisa ukusuka phambili ukuya emuva ukunyakaza. Lokhu kuchezuka, okwaziwa nangokuthi ukuhlehla kwemvume noma ukulahleka komfutho, kungaba nomthelela omkhulu ekunembeni kokuma kanye nokunemba kokuma okuphindaphindayo kwethuluzi lomshini lapho kusetshenziswa amasistimu e-servo e-semi-closed-loop servo. Ngaphezu kwalokho, ukwanda kancane kancane kokuvunyelwa kwe-kinematic pair ngenxa yokuguga ngokuhamba kwesikhathi kuholela ekwenyukeni okuhambisanayo kokuchezuka. Ngakho-ke, ukulinganisa okujwayelekile nesinxephezelo sokuchezuka okubuyela emuva kwe-axis yokuxhumanisa ngayinye yethuluzi lomshini kubalulekile.

Ukulinganisa Ukubuyela emuva

Ukuze uhlole ukuchezuka kokuhlehla, qala ngaphakathi kwebanga lokuhamba le-eksisi yokuxhumanisa. Okokuqala, sungula iphoyinti lereferensi ngokuhambisa ibanga elimisiwe ukuya phambili noma ukuhlehla. Ngemva kwalokhu, khipha umyalo othize wokunyakaza ohlangothini olufanayo ukuze uhlanganise ibanga elithile. Okulandelayo, qhubeka nokuhambisa ibanga elifanayo uye ohlangothini oluhlukile futhi unqume umehluko phakathi kwereferensi kanye nezindawo zokumisa. Ngokuvamile, izilinganiso eziningi (ngokuvamile eziyisikhombisa) zenziwa ezindaweni ezintathu eduze nendawo emaphakathi kanye nakho kokubili okudlulele kwebanga lokuhamba. Inani elimaphakathi libe selibalwa endaweni ngayinye, kanye nomkhawulo phakathi kwalezi zilinganiso ezisetshenziswa njengesilinganiso sokuchezuka okuhlehla. Kubalulekile ukuhambisa ibanga elithile phakathi nezilinganiso ukuze unqume ngokunembile inani lokuchezuka okuhlanekezelwe.

Uma uhlola ukuchezuka okubuyela emuva kwe-eksisi yokunyakaza ewumugqa, kuvamile ukusebenzisa inkomba yokudayela noma igeji yokudayela njengethuluzi lokulinganisa. Uma izimo zivuma, i-dual-frequency laser interferometer nayo ingasetshenziswa ngale njongo. Uma usebenzisa inkomba yokudayela izilinganiso, kubalulekile ukuqinisekisa ukuthi isisekelo samamitha nesiqu akunwebeki ngokweqile, njengoba i-cantilever ende phakathi nokulinganisa ingabangela isisekelo samamitha ukuba sinyakaze ngenxa yokuphoqelela, okuholela ekufundweni okungalungile namanani esinxephezelo angenangqondo.

Ukusebenzisa indlela yokuhlela yokulinganisa kungathuthukisa ukunemba nokunemba kwenqubo. Isibonelo, ukuze kuhlolwe ukuchezuka okuhlanekezelwe kwe-eksisi engu-X ethuluzini lomshini ome mpo elinezixhumanisi ezintathu, inqubo ingaqala ngokucindezela imitha endaweni eyisilinda ye-spindle, kulandele ukusebenzisa uhlelo olumisiwe lokulinganisa.

I-N10G91G01X50F1000; hambisa ibhentshi kwesokudla

I-N20X-50;i-worktable ihamba kwesokunxele ukuze kuqedwe igebe lokudlulisela

I-N30G04X5; ima kancane ukuze ubuke

I-N40Z50; I-Z-eksisi iphakanyisiwe futhi yaphuma endleleni

I-N50X-50: Ibhentshi lokusebenzela liya kwesokunxele

I-N60X50: Ibhentshi lokusebenza lihamba kwesokudla bese lisetha kabusha

I-N70Z-50: Ukusetha kabusha i-eksisi ye-Z

I-N80G04X5: Misa isikhashana ukuze ubuke

I-N90M99;

Kubalulekile ukuqaphela ukuthi imiphumela elinganisiwe ingahluka ngokuya ngesivinini sokusebenza esihlukile sebhentshi lomsebenzi. Ngokuvamile, inani elilinganiselwe ngesivinini esiphansi likhulu kunalelo elihamba ngesivinini esikhulu, ikakhulukazi uma umthwalo we-eksisi wethuluzi lomshini nokumelana nokunyakaza kukukhulu. Ngezivinini eziphansi, ithebula lokusebenzela lihamba ngesivinini esincane, okuholela emathubeni amancane okudubula okudlulele kanye nokuhamba ngokwedlulele, okwenza kube nenani elilinganiselwe eliphezulu. Ngakolunye uhlangothi, ngesivinini esiphezulu, ukudubuleka ngokweqile kanye nokuhamba ngaphezulu kungenzeka kakhulu ngenxa yesivinini esisheshayo sokusebenza, okuholela enanini elilinganiselwe elincane. Indlela yokulinganisa yokuchezuka okubuyela emuva kwe-axis ejikelezayo ejikelezayo ilandela inqubo efanayo naleyo ye-eksisi yomugqa, okuwukuphela komehluko okuyithuluzi elisetshenziselwa ukutholwa.

Inxephezela i-backlash

Amathuluzi amaningi omshini we-CNC enziwe ezweni abonisa ukunemba kokuma okungaphezu kuka-0.02mm, kodwa awanawo amandla okunxeshezelwa. Ezimweni ezithile, amasu okuhlela angasetshenziswa ukuze kufezwe indawo eyodwa futhi kuqedwe ukuhlehla kwamathuluzi anjalo omshini. Inqobo nje uma ingxenye yomshini isalokhu ingashintshile, ukuqalisa ukucutshungulwa kwe-interpolation kungenzeka uma ukuma kwesivinini esiphansi, okuyindlela eyodwa kufika lapho kuqalwa khona ukuhumusha. Lapho uhlangabezana nokuhlehla phakathi kokuphakelayo kokuhumusha, ukuhlanganisa ngokusemthethweni inani lokuhlehla lokugunyazwa kunamandla okuthuthukisa ukunemba kokucubungula ukuhumusha futhi kuhlangabeze ngempumelelocnc ingxenye egayiweizidingo zokubekezelelana.

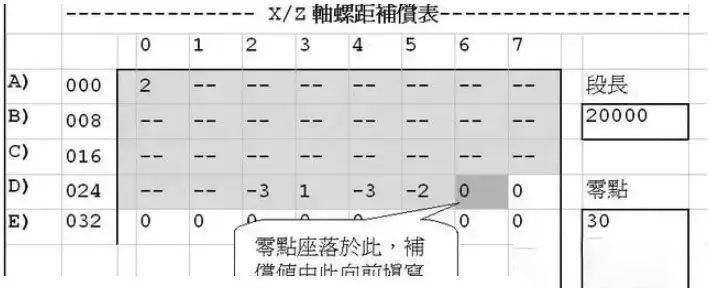

Kwezinye izinhlobo zamathuluzi omshini we-CNC, amakheli enkumbulo amaningi kudivayisi ye-CNC ngokuvamile anikezwa ukugcina inani lokuhlehla le-eksisi ngayinye. Uma i-eksisi yethuluzi lomshini iqondiswe ukushintsha indlela enyakaza ngayo, idivayisi ye-CNC izobuyisa ngokuzenzakalelayo inani lokuhlehla le-eksisi, elinxephezela futhi lilungise inani lomyalo wokuxhumanisa. Lokhu kuqinisekisa ukuthi ithuluzi lomshini lingamiswa ngokunembile endaweni yomyalo futhi kunciphisa umthelela omubi wokuchezuka kokuhlehla ekunembeni kwethuluzi lomshini.

Ngokuvamile, amasistimu e-CNC afakwe ivelu eyodwa etholakalayo yesinxephezelo sokubuyela emuva. Ukulinganisa ukunemba kokunyakaza kwesivinini esiphezulu nesiphansi, kanye nokubhekana nokuthuthukiswa komshini, kuba yinselele. Ngaphezu kwalokho, inani lokuchezuka elihlehliswayo elikalwa phakathi nokunyakaza okusheshayo lingasetshenziswa kuphela njengevelu yesinxephezelo yokokufaka. Ngakho-ke, ukufeza ukulingana phakathi kokunemba kokumisa ngokushesha kanye nokunemba kokuhumusha ngesikhathi sokusika kuba nzima.

Kuzinhlelo ze-CNC ezifana ne-FANUC0i ne-FANUC18i, kunezindlela ezimbili ezitholakalayo zesinxephezelo sokuhlehla sokunyakaza okusheshayo (G00) kanye nokunyakaza kokuphakelayo kokusika kwesivinini esincane (G01). Kuye ngendlela ekhethiwe yokudla, isistimu ye-CNC ikhetha ngokuzenzakalelayo futhi isebenzise amanani ahlukile esinxephezelo ukuze kuzuzwe ukunemba okuthuthukisiwe kokucubungula.

Inani le-backlash A, elitholwe ku-G01 cutting feed motion, kufanele lifakwe kupharamitha NO11851 (isivinini sesilingo se-G01 kufanele sinqunywe ngokusekelwe esivinini sokusika esisetshenziswa ngokuvamile nezici zethuluzi lomshini), kuyilapho inani lokuhlehla B elisuka ku-G00 kufanele lifakwe. kupharamitha NO11852. Kubalulekile ukuqaphela ukuthi uma uhlelo lwe-CNC lufuna ukwenza isinxephezelo sokuhlehla esichazwe ngokuhlukile, idijithi yesine (RBK) yenombolo yepharamitha engu-1800 kufanele isethwe ukuze ithi 1; uma kungenjalo, isinxephezelo esihlanekezelwe ngokwehlukana esishiwo ngokwehlukana ngeke senziwe. Isinxephezelo segebe. I-G02, G03, JOG, ne-G01 zonke zisebenzisa inani lesinxephezelo elifanayo.

Isinxephezelo samaphutha e-Pitch

Ukuma okunembayo kwamathuluzi omshini we-CNC kubandakanya ukuhlolwa kokunemba okungafinyelelwa ngakho izingxenye ezinyakazayo zethuluzi lomshini ngaphansi komyalo wesistimu ye-CNC. Lokhu kunemba kudlala indima ebalulekile ekuhlukaniseni amathuluzi omshini we-CNC kwavamile. Iqondaniswe nokunemba kwejiyomethri kwethuluzi lomshini, ithinta kakhulu ukunemba kokusika, ikakhulukazi emshinini wemigodi. Iphutha lokubhoboza imbobo linomthelela omkhulu. Ikhono lethuluzi lomshini we-CNC lokuhlola ukunemba kokucubungula kwalo lincike ekunembeni kokuma okuzuziwe. Ngakho-ke, ukutholwa nokulungiswa kokunemba kokumiswa kwamathuluzi omshini we-CNC kuyizinyathelo ezibalulekile zokuqinisekisa ikhwalithi yokucubungula.

Inqubo yokukala iphimbo

Njengamanje, indlela eyinhloko yokuhlola nokuphatha amathuluzi omshini ukusetshenziswa kwama-laser interferometers akabili-frequency. Lawa ma-interferometer asebenza ngezimiso ze-laser interferometry futhi asebenzisa ubude besikhathi be-laser besikhathi sangempela njengereferensi yokulinganisa, ngaleyo ndlela athuthukise ukunemba kokulinganisa nokwandisa ububanzi bezinhlelo zokusebenza.

Inqubo yokuthola iphimbo imi kanje:

- Faka i-dual-frequency laser interferometer.

- Misa idivayisi yokulinganisa yokubona eduze kwe-eksisi yethuluzi lomshini elidinga ukukalwa.

- Qondanisa ikhanda le-laser ukuze uqinisekise ukuthi i-axis yokulinganisa ihambisana noma i-collinear ne-eksisi yokunyakaza yethuluzi lomshini, ngaleyo ndlela ukuqondanisa ngaphambili indlela yokubona.

- Faka amapharamitha wokulinganisa uma i-laser isifinyelele izinga lokushisa layo lokusebenza.

- Yenza izinqubo zokulinganisa ezinqunyiwe ngokuhambisa ithuluzi lomshini.

- Lungiselela idatha futhi ukhiqize imiphumela.

Isinxephezelo Sephutha Le-pitch kanye Nokulinganisa Okuzenzakalelayo

Uma iphutha lokuma elilinganisiwe lethuluzi lomshini we-CNC lidlula ububanzi obuvunyelwe, kunesidingo sokulungisa iphutha. Indlela eyodwa evamile ihilela ukwenza ikhompuyutha ithebula lesinxephezelo sephutha lokukhala nokulifaka mathupha kusistimu ye-CNC yethuluzi lomshini ukuze kulungiswe iphutha lokuma. Kodwa-ke, ukunxeshezelwa okwenziwa ngesandla kungadla isikhathi futhi kuthambekele ekubeni namaphutha, ikakhulukazi uma usebenza ngamaphoyinti amaningi esinxephezelo kuzo zonke izimbazo ezintathu noma ezine zethuluzi lomshini we-CNC.

Ukuze kuthuthukiswe le nqubo, isisombululo senziwe. Ngokuxhumanisa ikhompuyutha nesilawuli se-CNC sethuluzi lomshini ngokusebenzisa isixhumi esibonakalayo se-RS232 kanye nokusebenzisa isofthiwe yokulinganisa okuzenzakalelayo edalwe ku-VB, kungenzeka ukuvumelanisa i-laser interferometer kanye nethuluzi lomshini we-CNC. Lokhu kuvumelanisa kuvumela ukutholwa okuzenzakalelayo kokunemba kokuma kwethuluzi lomshini we-CNC kanye nokuqaliswa kwesinxephezelo sephutha lokumisa okuzenzakalelayo. Indlela yesinxephezelo ihlanganisa:

- Ukudala ikhophi yasenqolobaneni yemingcele yesinxephezelo ekhona ohlelweni lokulawula lwe-CNC.

- Ukukhiqiza ithuluzi lomshini uhlelo lwe-CNC lokulinganisa ukunemba kokubeka iphuzu nephuzu kusetshenziswa ikhompuyutha, bese idluliselwa ohlelweni lwe-CNC.

- Ukulinganisa ngokuzenzakalela iphutha lokuma kwephuzu ngalinye.

- Ukukhiqiza isethi entsha yemingcele yesinxephezelo ngokusekelwe kumaphuzu esinxephezelo anqunywe kusengaphambili futhi iwadlulisela ohlelweni lwe-CNC ukuze uthole isinxephezelo sephitshi esizenzakalelayo.

- Ukuqinisekisa ukunemba ngokuphindaphindiwe.

Lezi zixazululo ezithile zihlose ukuthuthukisa ukunemba kwamathuluzi omshini we-CNC. Noma kunjalo, kubalulekile ukuqaphela ukuthi ukunemba kwamathuluzi emishini ehlukene ye-CNC kungase kuhluke. Ngenxa yalokho, amathuluzi omshini kufanele akalwe ngokuya ngezimo zawo ngazinye.

Uma isinxephezelo sephutha singenziwa ethuluzini lomshini, kuzoba namuphi umthelela ezingxenyeni ze-CNC ezikhiqizwayo?

Uma isinxephezelo sephutha singanakwa ethuluzini lomshini, kungase kubangele ukungezwani kuIzingxenye ze-CNCkukhiqizwa. Isibonelo, uma ithuluzi lomshini linephutha lokuma elingalungisiwe, indawo yangempela yethuluzi noma ucezu lokusebenza lungase luhluke endaweni ehleliwe eshiwo ohlelweni lwe-CNC, okuholela ekungalungeni kobukhulu kanye namaphutha ejometri ezingxenyeni ezikhiqiziwe.

Isibonelo, uma umshini wokugaya we-CNC unephutha lokuma elingalungisiwe ku-X-eksisi, izikhala ezigayiwe noma izimbobo kucezu lokusebenza zingahle zingaqondani kahle noma zibe nobukhulu obungalungile. Ngokufanayo, ekusebenzeni kwe-lathe, amaphutha okumisa angalungisiwe angabangela ukungalungi kububanzi noma ubude bezingxenye eziphendukile. Lokhu kungafani kungase kuholele ezingxenyeni ezingavumelani ezihlulekayo

I-Anebon izokwenza umsebenzi ngamunye onzima ube muhle kakhulu futhi ube muhle kakhulu, futhi isheshise izinyathelo zethu zokuma kusukela ezingeni lamabhizinisi aphezulu e-intercontinental kanye nobuchwepheshe obuphezulu e-China Gold Supplier ye-OEM, Ngokwezifiso.isevisi yemishini ye-cnc, Isevisi yokwenziwa kwe-Sheet Metal, izinsiza zokugaya. I-Anebon izokwenza ukuthenga kwakho komuntu siqu ukuze uhlangabezane nokwanelisayo kwakho! Ibhizinisi le-Anebon limisa iminyango eminingana, okuhlanganisa umnyango wokuphumayo, umnyango wemali engenayo, umnyango wokulawula omuhle kakhulu kanye nesikhungo sesevisi, njll.

I-Factory Supply ChinaIngxenye Yokunemba kanye Nengxenye Ye-Aluminium, Ungakwazi ukwazisa i-Anebon umbono wakho wokuthuthukisa umklamo oyingqayizivele wemodeli yakho siqu ukuze uvimbele izingxenye ezifanayo kakhulu emakethe! Sizonikeza isevisi yethu engcono kakhulu ukwanelisa zonke izidingo zakho! Khumbula ukuxhumana ne-Anebon ngokushesha!

Isikhathi sokuthumela: Jan-09-2024