Incazelo Yolwazi Lwemishini ngu-Anebon

Ulwazi lwemishini yikhono lokuqonda nokusebenzisa imiqondo ehlukahlukene yemishini, imigomo nezinqubo. Ulwazi lwemishini luhlanganisa ukuqonda kwemishini, izinqubo nezinto zokwakha kanye namathuluzi nezinqubo. Lokhu kubandakanya ulwazi lwezimiso zemishini, njengamandla nokunyakaza, amandla kanye nezinhlelo zamagiya nama-pulleys. Ulwazi lobunjiniyela bemishini luhlanganisa ukuklama, ukunakekela kanye namasu okuxazulula izinkinga, kanye nezimiso zobunjiniyela bemishini. Ulwazi lwemishini lubalulekile emisebenzini eminingi nasezimbonini ezisebenza ngezinhlelo zemishini. Lokhu kubandakanya ubunjiniyela, ukukhiqiza kanye nokwakha.

1. Yiziphi izindlela zokuhluleka kwezingxenye zemishini?

(1) Ukuqhekeka okuphelele

(2) Ukuhlanekezela unomphela ngokweqile

(3) Ukonakala kwengxenye yendawo

(4) Ukungasebenzi kahle ngenxa yokuphazamiseka kwezimo zokusebenza ezivamile

Siyini isizathu esibangela isidingo esivamile sokunqamula isikulufu ekuxhumekeni okunentambo?

Uyini umqondo owumongo wokulwa nokukhipha isikulufa?

Yiziphi izindlela ezehlukene ezitholakalayo zokuvimbela ukuxega?

Impendulo:

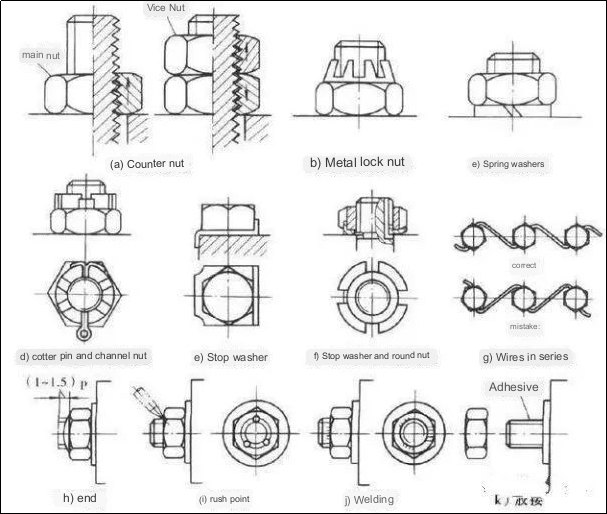

Ngokuvamile, uxhumo oluluchungechunge lungafeza imibandela yokuzikhiya futhi ngeke luzixege ngokuzenzekelayo. Kodwa-ke, ezimeni ezibandakanya ukudlidliza, ukugcwala komthelela, noma ukushintshashintsha kwezinga lokushisa okunamandla, kunethuba lokuxega kwentongomane exhumayo. Imbangela eyinhloko yokuxegiswa kwentambo isekuphendukeni okuhlobene phakathi kwamapheya entambo. Ngakho-ke, kubalulekile ukufaka izindlela zokulwa nokuxega ekwakhiweni kwangempela.

Izindlela ezisetshenziswa kakhulu zihlanganisa:

1. Ukunqanda ukuxegisa okusekelwe kufriction — ukugcina ukungqubuzana phakathi kwamapheya entambo ukuvimbela ukuxega, njengokusebenzisa amawasha asentwasahlobo namantongomane aphindwe kabili ohlangothini olungaphezulu;

2. Ukunqanda ukuthukulula kwemishini - kusetshenziswa okokuvimbelaizingxenye ezenziwe ngomshiniukuqinisekisa ukunqanda ukuthukululwa, ngokuvamile ukusebenzisa amantongomane acijile nezikhonkwane ze-cotter, phakathi kokunye;

3. Ukunqanda ukuxegiswa okusekelwe ekuphazameni kwamapheya entambo - ukulungisa nokushintsha ubudlelwano phakathi kwamapheya entambo, njengokusebenzisa indlela esekelwe nomthelela.

Iyini inhloso yokuqinisa ekuxhumekeni kwentambo?

Pinikeza izindlela eziningi zokulawula amandla asetshenzisiwe.

Impendulo:

Inhloso yokuqinisa ekuxhumekeni okunentambo ukuvumela amabhawodi ukuthi enze amandla okuqinisa ngaphambilini. Le nqubo yokuqinisa ngaphambilini ilwela ukuthuthukisa ukwethembeka nokuqina koxhumano ukuze kuvinjelwe noma yiziphi izikhala noma ukunyakaza okuhlobene phakathi kwezingxenye ezixhumene ngaphansi kwezimo zokulayisha. Izindlela ezimbili ezisebenzayo zokulawula amandla okuqinisa ukusebenzisa isikrufu se-torque noma isikrufu setorque esingaguquki. Uma i-torque edingekayo isifinyelelwe, ingavalelwa endaweni. Kungenjalo, ukwelulwa kwebhawodi kungakalwa ukuze kulawulwe amandla okuqinisa ngaphambili.

Ingabe ukuslayida okunwebekayo kuhluke kanjani ekushushuluzeni kumadrayivu amabhande?

Ekuklanyeni kwe-V-belt drive, kungani kunomkhawulo kububanzi obuncane be-pulley encane?

Impendulo:

I-Elastic sliding imelela isici esingokwemvelo samadrayivu ebhande angenakugwenywa. Kwenzeka uma kunomehluko ekucindezelekeni futhi impahla yebhande ngokwayo i-elastomer. Ngakolunye uhlangothi, ukushushuluza kuwuhlobo lokwehluleka okuvela ngenxa yokulayisha ngokweqile futhi kufanele kugwenywe ngazo zonke izindleko.

Ngokuqondile, ukushushuluza kwenzeka ku-pulley encane. Ukwenyuka kwemithwalo yangaphandle kuholela kumehluko omkhulu wokungezwani phakathi kwezinhlangothi ezimbili, okuholela ekwandeni kwendawo lapho ukuslayida okunwebeka kwenzeka khona. I-Elastic sliding imelela ushintsho lobuningi, kuyilapho ukushushuluza kubonisa ukuguqulwa kwekhwalithi. Ngakho-ke, ukuvimbela ukushushuluza, kunomkhawulo kububanzi obuncane be-pulley encane, njengoba ama-diameter emincane e-pulley ebangela ama-engeli amancane okugoqa kanye nezindawo zokuthintana ezincishisiwe, okwenza ukushelela kwenzeke kakhulu.

Ingabe isivinini sokuslayida sendawo yezinyo sihlobene kanjani nengcindezi yokuxhumana empunga kanye nezinjini zomoya ze-aluminium-iron bronze?

Impendulo:

Ingcindezi yokuxhumana evunyelwe ye-grey cast iron kanye nezinjini zethusi ze-aluminium-iron kuthonywa isivinini sokuslayida kwendawo yezinyo ngenxa yemodi yokwehluleka okuphawulekayo eyaziwa ngokuthi ukunamathela kwendawo yezinyo. Ukunamathela kuthinteka ngokuqondile isivinini sokushelela, ngaleyo ndlela kuthinte ingcindezi yokuxhumana evumelekile. Ngakolunye uhlangothi, imodi yokwehluleka eyinhloko yama-turbine e-cast tin bronze imigodi yamazinyo, ebangelwa ingcindezi yokuxhumana. Ngakho-ke, ingcindezi yokuxhumana evumelekile ayihlobene nesivinini sokushelela.

Enumbhala imithetho ejwayelekile yokunyakaza, izici zomthelela, nezimo ezifanele zomlandeli wekhamera yekhamera.

Impendulo:

Imithetho yokunyakaza yomlandeli wekhamera ihlanganisa ukunyakaza kwesivinini esingaguquki, imithetho ehlukahlukene yokunyakaza kwe-deceleration, nokunyakaza okulula kwe-harmonic (umthetho wokunyakaza we-cosine acceleration). Umthetho wokunyakaza kwesivinini esingaguquki ubonisa umthelela oqinile futhi uthola ukusebenza ezimeni zesivinini esiphansi kanye nezilayisha ukukhanya.

Imithetho yokunyakaza kwe-Deceleration, okuhlanganisa ukusheshisa okuqhubekayo, ifaka umthelela oguquguqukayo futhi ifanele izimo zesivinini esimaphakathi nesiphansi. Ukunyakaza okulula kwe-harmonic (umthetho wokunyakaza we-cosine 4-chord acceleration) unikeza umthelela othambile uma kukhona isikhawu sokumisa isikhashana, okukwenza kube wusizo kuzimo zesivinini esimaphakathi ukuya esiphansi. Ezimeni zesivinini esikhulu ngaphandle kwezikhawu zokuphumula, awukho umthelela oguquguqukayo, okuwenza kufaneleke lezo zimo.

Fingqa izimiso ezibalulekile ezilawula iphrofayili yezinyo.

Impendulo:

Kungakhathaliseki ukuthi amaphrofayili wezinyo athintana kuphi, ulayini ovamile ovamile odlula endaweni okuthintana kuyo kufanele unqamule indawo ethile emugqeni ophakathi nendawo. Lesi simo siqinisekisa ukuthi isilinganiso sokudlulisa siyagcinwa.

Yiziphi izindlela ezehlukene zokulungisa izingxenye ze-circumferentially ku-shaft? (hlinzeka ngezindlela ezingaphezu kwezine)

Impendulo:

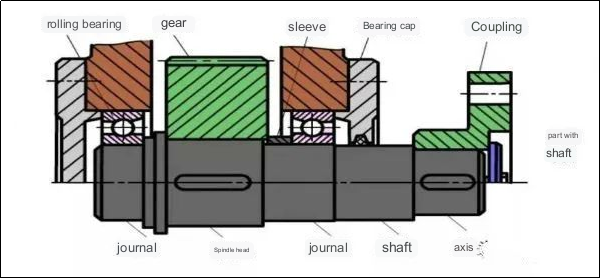

Amathuba okulungisa i-circumferential ahlanganisa ukusetshenziswa koxhumano olunokhiye, uxhumano oluhlukanisiwe, uxhumano lwe-interference fit, isethi yesikulufu, uxhumano lwephini, kanye nejoyinti lokunweba.

Yiziphi izinhlobo eziyinhloko zamasu okulungisa i-axial okunamathisela izingxenye ku-shaft?

Yiziphi izici ezihlukanisayo ngayinye? (yisho ngaphezu kwezine)

Impendulo:

Izindlela zokulungisa i-axial zokunamathisela izingxenye ku-shaft zihlanganisa izinhlobo eziningana ezibalulekile, ngayinye enezici ezihlukile. Lokhu kuhlanganisa ukulungiswa kwekholomu, ukulungiswa kwentambo, ukulungiswa kwe-hydraulic, nokulungiswa kwe-flange. Ukulungiswa kwekholomu kuhilela ukusetshenziswa kwekholomu noma i-clamp eqiniswe eduze kwe-shaft ukuze ivikele ingxenye nge-axially. Ukulungiswa okunentambo kuhlanganisa ukusetshenziswa kwemicu ku-shaft noma ingxenye ukuze ihlanganiswe ngokuqinile. Ukulungiswa kweHydraulic kusebenzisa ingcindezi ye-hydraulic ukudala ukuxhumana okuqinile phakathi kwengxenye ne-shaft. Ukulungiswa kwe-Flange kuhilela ukusetshenziswa kwe-flange eboshiwe noma eshiselweizingxenye zemishini ye-cnckanye ne-shaft, eqinisekisa ukunamathiselwe kwe-axial okuvikelekile.

Kungani kudingekile ukwenza izibalo zebhalansi yokushisa kumadrayivu e-worm avalelwe?

Phendula:

Amadrayivu e-worm avalelwe abonisa ukushelela okuhlobene namazinga aphezulu okungqubuzana. Ngenxa yamandla azo okuchitha ukushisa alinganiselwe kanye nokuthambekela kwezindaba zokunamathela, ukubala ibhalansi yokushisa kubaluleka.

Yiziphi izinkolelo-mbono zokubala zamandla ezimbili ezisetshenziswa ekubalweni kwamandla egiya?

Yiziphi ukwehluleka abaqondise kuzo?

Uma ukuhanjiswa kwegiya kusebenzisa indawo yezinyo elithambile elivaliwe, ithini indinganiso yokuklama kwayo?

Impendulo:

Izibalo zamandla egiya zibandakanya ukunquma amandla okukhathala othintana naye endaweni yezinyo kanye namandla okukhathala okugoba empande yezinyo. Amandla okukhathala othintana naye ahloselwe ukuvimbela ukuhluleka kokubhoboza ukukhathala endaweni yezinyo, kuyilapho amandla okukhathala okugoba abhekana nokuphuka kokukhathala empandeni yezinyo. Ukuhanjiswa kwegiya okusebenzisa indawo yezinyo elithambile evaliwe kulandela umbandela wokuklama wokucabangela amandla okukhathala othintana naye endaweni yezinyo kanye nokuqinisekisa amandla okukhathala okugoba empande yezinyo.

Yimiphi imisebenzi ehambisanayo yama-couplings nama-clutches?

Zihluke kanjani komunye nomunye?

Impendulo:

Kokubili ama-coupling nama-clutch kusebenzela inhloso yokuxhuma ama-shaft amabili ukuze unike amandla ukudluliswa kwe-torque nokuzungezisa okuvumelanisa. Kodwa-ke, ziyahlukahluka ngokuya ngamakhono abo wokungahlangani ngesikhathi sokusebenza. Cama-ouplings axhuma ama-shafts angakwazi ukuhlukaniswa ngenkathi esetshenziswa; ukunqanyulwa kwabo kungenzeka kuphela ngokuqaqaizingxenye eziphendukayongemva kokuvalwa. Ngakolunye uhlangothi, ama-clutches anikeza amandla okubandakanya noma ukukhulula ama-shafts amabili nganoma yisiphi isikhathi ngesikhathi sokusebenza komshini.

Chaza izimfuneko ezibalulekile ukuze ama-bearings amafilimu kawoyela asebenze kahle.

Impendulo:

Izingxenye ezimbili ezihambayo ezinyakazayo kufanele ziveze igebe elimise okwe-wedge; isivinini esishelelayo phakathi kwezindawo ezingaphezulu kufanele siqinisekise ukungena kwamafutha okugcoba ukusuka echwebeni elikhulu futhi uphume echwebeni elincane; amafutha okugcoba kufanele abe ne-viscosity ethile, futhi ukunikezwa kwamafutha okwanele kuyadingeka.

Nikeza incazelo emfushane mayelana nemithelela, izici ezihlukanisayo, kanye nokusetshenziswa okujwayelekile kwemodeli yokuthela 7310.

Impendulo:

Ukuhunyushwa kwekhodi: Ikhodi ethi “7″ imele ibhola lokuxhumana eliyi-angular. Igama elithi “(0)” libhekisela kububanzi obujwayelekile, ngokuthi “0” kube ozikhethela. Inombolo “3″ isho uchungechunge olumaphakathi ngokobubanzi. Okokugcina, "10" ihambisana nobubanzi obuphakathi obungu-50mm.

Izici kanye nezicelo:

Le modeli ethwalayo ingabekezelela kanyekanye imithwalo ye-radial ne-axial endaweni eyodwa. Inikeza isivinini somkhawulo ophezulu futhi ngokuvamile isetshenziswa ngababili.

Ngaphakathi kwesistimu yokudlulisa ehlanganisa ukudluliswa kwegiya, ukudluliswa kwebhande, nokudluliswa kweketango, yiluphi uhlobo lokudlulisela oluvamise ukubekwa ezingeni lesivinini esiphezulu?

Ngokuphambene, iyiphi ingxenye yokudlulisela ehlelwe endaweni ephansi yegiya?

Chaza isizathu saleli lungiselelo.

Impendulo:

Ngokuvamile, idrayivu yebhande ibekwe ezingeni lesivinini esiphezulu, kuyilapho i-chain drive ibekwe endaweni yegiya ephansi kakhulu. I-belt drive inezimfanelo ezifana nokudlulisa okuzinzile, ukugoba, nokumunca ukushaqeka, okuyenza ibe nenzuzo enjinini ngesivinini esiphezulu. Ngakolunye uhlangothi, ama-chain drives avame ukudala umsindo ngesikhathi sokusebenza futhi afaneleka kangcono izimo zesivinini esiphansi, ngaleyo ndlela abelwa esigabeni segiya eliphansi.

Yini ebangela isivinini esingaguquki ekudluliselweni kweketango?

Yiziphi izici eziyinhloko eziwuthonya?

Kungaphansi kwaziphi izimo lapho isilinganiso sokudlulisa ngokushesha singahlala singashintshile?

Impendulo:

1) Isivinini esingavamile ekudlulisweni kweketango ngokuyinhloko sibangelwa umphumela we-polygonal otholakala kumshini weketango; 2) Izinto ezibalulekile eziyithonya zihlanganisa isivinini seketango, ukuphakama kweketango, kanye nokubala kwamazinyo e-sprocket; 3) Uma inani lamazinyo kuwo womabili ama-sprocket amakhulu namancane lilingana (okungukuthi, z1=z2) futhi ibanga eliphakathi kwawo liwukuphindaphinda ncamashi kwephimbo (p), isilinganiso sokudlulisela ngokushesha sihlala singashintshile ku-1.

Kungani ububanzi bezinyo (b1) bephinikhodi bukhulu kancane kunobubanzi bezinyo (b2) begiya elikhulu ekuncishisweni kwegiya eliyisilinda?

Lapho ubala amandla, ingabe i-coefficient yobubanzi bezinyo (ψd) kufanele isekelwe ku-b1 noma b2? Kungani?

Impendulo:

I-1) Ukuvimbela ukungahambi kahle kwe-axial kwamagiya ngenxa yamaphutha omhlangano, ububanzi bezinyo le-meshing buyancishiswa, okuholela ekwandeni komthwalo wokusebenza. Ngakho-ke, ububanzi bezinyo (b1) begiya elincane kufanele libe likhulu kancane kune-b2 yegiya elikhulu. Isibalo samandla kufanele sisekelwe kububanzi bezinyo (b2) begiya elikhudlwana ngoba limelela ububanzi bangempela bokuxhumana lapho ipheya yamagiya angama-cylindrical ehlanganyela.

Kungani ububanzi be-pulley encane (d1) kufanele bulingane noma bube bukhulu kunobukhulu obuncane (dmin) kanye ne-engeli yokugoqa yesondo lokushayela (α1) ilingane noma ibe nkulu kuno-120° ekushayeleni ibhande ledeceleration?

Ngokuvamile, isivinini sebhande esinconywayo siphakathi kuka-5 kuya ku-25 m/s.

Yini i-cukuvela uma ijubane lebhande lidlula lobu bubanzi?

Impendulo:

I-1) Ububanzi obuncane be-pulley encane buholela ekucindezelekeni okuphezulu kokugoba ebhandeni. Ukuvimbela ukucindezeleka okugoba ngokweqile, ububanzi obuncane be-pulley encane kufanele bugcinwe.

2) I-engeli yokugoqa (α1) yesondo lokushayela ithinta ukushuba okuphezulu okusebenzayo kwebhande. I-α1 encane iphumela kumandla aphansi aphezulu asebenzayo wokudonsa. Ukuthuthukisa amandla amakhulu okudonsa asebenzayo futhi uvimbele ukushelela, i-engeli yokugoqa engu-α1≥120° ngokuvamile iyanconywa.

I-3) Uma ijubane lebhande liwela ngaphandle kwebanga le-5 kuya ku-25 m / s, kungaba nemiphumela. Isivinini esingaphansi kobubanzi singase sidinge amandla amakhulu okudonsa asebenzayo (Fe), okuholela ekwenyukeni kwenani lamabhande (z) kanye nesakhiwo esikhulu sokushayela ibhande. Ngokuphambene, ijubane eleqile lebhande lingaholela kumandla aphezulu we-centrifugal (Fc), okudinga ukuqapha.

Izinzuzo nezingozi ze-helical rolling.

Impendulo:

Izinzuzo

I-1) Ibonisa ukuguga okuncane, futhi indlela yokulungisa ingasetshenziswa ukuze kuqedwe imvume futhi kufakwe izinga elithile lokuguquguquka kwangaphambili, ngaleyo ndlela kuthuthukise ukuqina nokufeza ukunemba okuphezulu kokudlulisela.

2) Ngokungafani nezinhlelo zokuzikhiya, iyakwazi ukuguqula ukunyakaza okuqondile kube ukunyakaza okujikelezayo.

Ukubi

1) Isakhiwo siyinkimbinkimbi futhi siletha izinselele ekukhiqizeni.

2) Izinqubo ezithile zingase zidinge indlela eyengeziwe yokuzivala ukuze kuvinjelwe ukuhlehla.

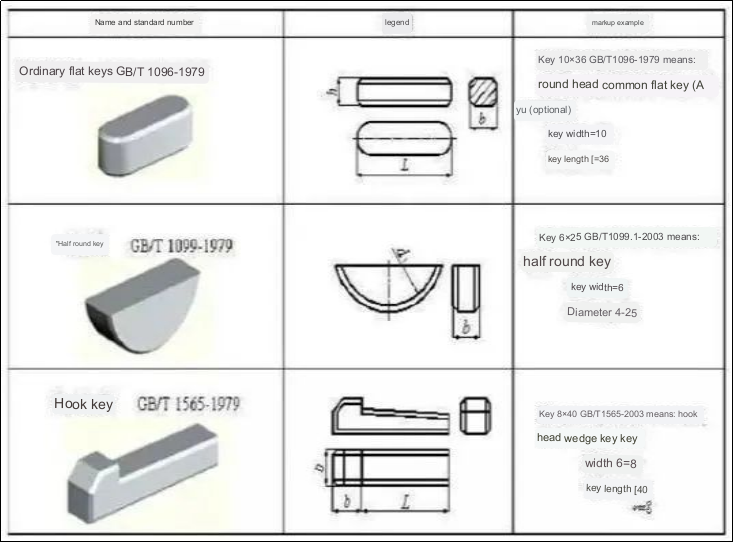

Isiphi isimiso esibalulekile sokukhetha okhiye?

Impendulo:

Lapho ukhetha okhiye, kucatshangelwa izinto ezimbili ezibalulekile: uhlobo nosayizi. Ukukhethwa kohlobo kuncike ezicini ezifana nezici zesakhiwo soxhumano oluyinhloko, izidingo zokusetshenziswa, nezimo zokusebenza.

Ngakolunye uhlangothi, ukukhethwa kosayizi kufanele kuhambisane nokucaciswa okujwayelekile kanye nezidingo zamandla. Usayizi wokhiye uqukethe izilinganiso ze-cross-sectional (ububanzi bokhiye b * ukuphakama kokhiye h) nobude L. Ukukhethwa kobukhulu be-cross-sectional b*h kunqunywa ububanzi be-shaft d, kuyilapho ubude bokhiye L bungakwazi ngokuvamile kunqunywa ngokusekelwe kubude behabhu, okusho ukuthi ubude bokhiye L akumele budlule ubude behabhu. Ukwengeza, okhiye abayisicaba abaqondisayo, ubude behabhu L' buvamise ukuzungeza (1.5-2) izikhathi ezinobubanzi beshafti d, kucatshangelwa ubude behabhu nebanga lokuslayida.

I-Anebon incike emandleni ayo obuchwepheshe aqinile futhi iqhubeka ithuthukisa ubuchwepheshe obuthuthukile ukuze ihlangabezane nezidingo zokucubungula insimbi ye-CNC,5 i-axis cnc milling, nokusakazwa kwezimoto. Sazisa kakhulu zonke iziphakamiso kanye nempendulo. Ngokubambisana okuhle, singakwazi ukufeza ukuthuthukiswa kanye nokwenza ngcono.

Njengomkhiqizi we-ODM e-China, i-Anebon igxile ekwenzeni izingxenye zesitembu se-aluminium ngokwezifiso kanye nezingxenye zemishini yokukhiqiza. Njengamanje, imikhiqizo yethu ithunyelwe emazweni angaphezu kwamashumi ayisithupha nasezifundeni ezihlukahlukene emhlabeni jikelele, kuhlanganise neNingizimu-mpumalanga ye-Asia, amazwe aseMelika, i-Afrika, iMpumalanga Yurophu, iRussia, neCanada. I-Anebon izibophezele ekusunguleni ukuxhumana okubanzi namakhasimende angaba khona e-China nakwezinye izingxenye zomhlaba.

Isikhathi sokuthumela: Aug-16-2023