1. Kunekhono lokuthola ukudla okuncane okujulile. Enqubweni yokujika, umsebenzi kanxantathu uvame ukusetshenziselwa ukucubungula ezinye izinto zokusebenza ezineziyingi zangaphakathi nezingaphandle ngaphezu kokunemba kwesibili. Ngenxa yokushisa okusikayo, ukungqubuzana phakathi kwendawo yokusebenza kanye nethuluzi kubangela ukuguga kwethuluzi kanye nokunemba kokubeka okuphindaphindiwe komnikazi wamathuluzi wesikwele, njll., ngakho-ke ikhwalithi kunzima ukuyiqinisekisa. Ukuze sixazulule ukujula okunembile kokujula okuncane enqubweni yokujika, singasebenzisa ubudlelwano phakathi kolunye uhlangothi nohlangothi olutshekile lukanxantathu njengoba kudingekile ukuhambisa isibambi sommese esincane esibude nge-engeli ukuze sifinyelele ngokunembile ekujuleni kokudla okuvundlile ithuluzi lokujika elihamba kancane. Inhloso: yonga abasebenzi nesikhathi, qinisekisa ikhwalithi yomkhiqizo, futhi uthuthukise ukusebenza kahle komsebenzi. Ivelu yesikali sesibambi sethuluzi le-lathe ye-C620 singu-0.05mm kugridi ngayinye. Uma ufuna ukuthola inani lokujula lokudla okuvundlile elingu-0.005mm, hlola ithebula lomsebenzi we-sine trigonometric: sinα=0.005/0.05=0.1 α=5o44′, ngakho hambisa isibambi sommese esincane. Uma ingu-5o44', uma uhambisa i-disc eqoshwe ngobude esibambi sommese omncane, ingafinyelela ukunyakaza okuncane kwethuluzi lokusika elinenani elijulile elingu-0.005mm ohlangothini olusemaceleni.

2. Ukusetshenziswa kobuchwepheshe be-reverse turning ezenzweni ezintathu zokukhiqiza zesikhathi eside kufakazela ukuthi enqubweni ethile yokuguqula, ubuchwepheshe bokusika okuphambene bungafinyelela imiphumela emihle. Izibonelo ezilandelayo zimi kanje:

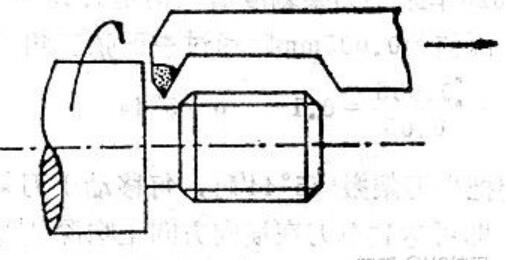

(1) Uma intambo yokusika okubuyela emuva kuyinsimbi engagqwali ye-martensitic enocwecwe lokusebenza lwentambo yangaphakathi neyangaphandle enephimbo elingu-1.25 no-1.75 mm njengoba iphimbo lesikulufu se-lathe lisuswa yi-pitch yesiqeshana sokusebenza, inani elitholiwe. iyinani elingapheli. Uma intambo yenziwe ngomshini ngokuphakamisa isibambo se-counter nut, intambo ivame ukuphulwa. Ngokuvamile, i-lathe evamile ayinayo idivayisi ye-buckle engahlelekile, futhi isethi yokuzenzela yediski idla isikhathi ekucubunguleni iphimbo elinjalo. Lapho uthunga, kuvame ukuvela. Indlela eyamukelwe iyindlela yokujika eshelelayo enesivinini esiphansi ngoba ukucosha ngesivinini esikhulu akwanele ukuhoxisa ummese, ngakho-ke ukusebenza kahle kokukhiqiza kuphansi, ifayela lenziwa kalula ngesikhathi sokuJika, futhi ukuhwashaza komhlaba akwanele, ikakhulukazi. ekucubunguleni insimbi engagqwali ye-martensite efana ne-1Crl3, 2 Crl3, njll. Uma usikwa ngesivinini esiphansi, i-sickle phenomenon ivelele kakhulu. Izindlela zokusika ezihlanekezela emuva, zokuhlehla-hlane, kanye neziqondiso eziphambene neziqondiso zokuthi "ezintathu zibuyela emuva" ezidalwe ekwenziweni komshini zingafeza umphumela omuhle wokusika ngoba indlela ingajika intambo ngesivinini esikhulu, kanye nendlela enyakazayo yethuluzi. ihlehliswa ukusuka kwesobunxele kuya kwesokudla, ngakho-ke akukho mphumela wokuthi ithuluzi alikwazi ukuhlehliswa lapho lisika intambo ngesivinini esikhulu. Indlela ethize yilena elandelayo: Uma intambo yangaphandle isetshenziswa, gaya ithuluzi elifanayo lokuguqula intambo yangaphakathi (Fig. 1);

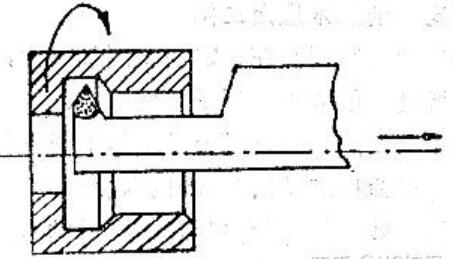

Gaya ithuluzi lokuguqula intambo yangaphakathi ehlehlayo (Umfanekiso 2).

Ngaphambiliimishini, lungisa i-spindle yepuleti lokungqubuzana okubuyela emuva kancane ukuze uqinisekise isivinini sokuzungezisa okubuyela emuva. Ukuze uthole i-thread cutter enhle, vala i-nati yokuvula nokuvala, qala ijubane eliya phambili neliphansi ukuya ku-sipe engenalutho, bese ubeka ithuluzi lokuguqula intambo ekujuleni okufanelekile kokusika; ungakwazi ukuhlehlisa ukuzungezisa. Ngalesi sikhathi, ithuluzi lokuguqula lishiywe ngesivinini esikhulu. Ngokusika ummese ngakwesokudla futhi usike inani lemimese ngokwale ndlela, intambo enobulukhuni obuphezulu kanye nokunemba okuphezulu kungenziwa ngomshini.

(2) Enqubweni yendabuko yokugoqa i-reverse knurling, amafayili ensimbi kanye nemfucumfucu kungena kalula phakathi kwe-workpiece kanye nommese wokugoqa, okubangela ukuthi i-workpiece icindezeleke ngokweqile, okubangela ukuthi imigqa igoqwe, iphethini igaywe noma i-ghosted, njll. . Uma indlela entsha yokusebenza ye- Turning and knurling ye-lathe spindle yamukelwa, ukonakala okubangelwa ukusebenza okushelelayo kungaba kuvinjelwe ngempumelelo, futhi umphumela omuhle ophelele ungatholakala.

(3) Ukuhlehlisa ukuhlehla kwentambo yepayipi ye-taper yangaphakathi nangaphandle Lapho uphendulela imicu yepayipi ye-taper ehlukahlukene yangaphakathi neyangaphandle ngokunemba okuncane kanye nenqwaba encane, kungenzeka ukusebenzisa ngokuqondile ukusika okuhlanekezelwe kanye nokulayisha ukubuyisela emuva ngaphandle kwedivayisi yokubumba. Endleleni entsha yokusebenza, ngenkathi isika uhlangothi lwethuluzi, ithuluzi lihanjiswa ngokuvundlile ukusuka kwesokunxele kuya kwesokudla. Ifayela eliguquguqukayo lenza kube lula ukubamba ukujula kwefayela ukusuka kububanzi obukhulu ukuya kububanzi obuncane. Isizathu ifayela. Kukhona pre-stress. Ububanzi bezinhlelo zokusebenza zalolu hlobo olusha lobuchwepheshe obusebenzayo ekuguquleni ubuchwepheshe buyanda kakhulu futhi bungasetshenziswa ngokuguquguqukayo ezimweni ezithile ezihlukile.

3. Indlela entsha yokusebenza kanye nokusha kwamathuluzi okubhoboza izimbobo ezincane Enqubweni yokujika, lapho imbobo ingaphansi kuka-0.6mm, ububanzi be-drill buncane, ukuqina akulungile, ijubane lokusika alikho phezulu, kanye nempahla yokusebenza. iyingxubevange engangeni ekushiseni nensimbi engagqwali, futhi ukumelana nokusika Kukhulu, ngakho-ke lapho ubhoboza, njengokusetshenziswa kokuphakelayo komshini, umshini wokubhola kulula kakhulu ukuphuka, okulandelayo kuchaza ithuluzi elilula nelisebenzayo kanye nendlela yokuphakela ngesandla. Okokuqala, i-drill chuck yasekuqaleni iguqulwa ibe uhlobo oluntantayo lwe-shank eqondile. Uma i-drill bit encane iboshiwe ku-drill chuck entantayo, ukubhola kungenziwa kahle. Ngenxa yokuthi ingxenye engemuva yebhithi yokubhoboza iwukulingana kwe-shank eqondile, ingahamba ngokukhululeka kumkhono wokudonsa. Lapho imbobo encane ibhojwa, i-drill chuck ingabanjwa ngesandla ngesineke, i-micro feed ingenziwa ngesandla, futhi imbobo encane ingabhobolwa ngokushesha. Ikhwalithi kanye nenani kanye nokwelula impilo yesevisi yama-drill amancane. I-drill chuck eguquliwe enezinjongo eziningi ingase futhi isetshenziselwe ukuthepha intambo yangaphakathi enobubanzi obuncane, ukulungisa kabusha, njll. (Uma imbobo enkulu ibhojwa, iphinikhodi yomkhawulo ingafakwa phakathi komkhono wokudonsa kanye ne-shank eqondile).

4. I-Anti-vibration emishinini ye-deep-hole Emishinini ye-deep-hole, ngenxa yembobo encane, ibha yamathuluzi eyisicefe incane. Akunakugwenywa ukukhiqiza ukudlidliza lapho ububanzi bembobo bungu-Φ30~50mm, futhi imbobo ejulile icishe ibe ngu-1000mm. Yiyona ephumelela kakhulu futhi ephumelelayo ukuvimbela ukudlidliza kwe-arbor. Indlela yokunamathisela izisekelo ezimbili (usebenzisa into efana ne-cloth bakelite) emzimbeni we-shank, futhi usayizi ufana ncamashi nosayizi wokuvula. Phakathi nenqubo yokusika, i-arbor ayijwayele ukudlidliza ngenxa yokubeka ama-slats, futhi izingxenye zembobo ejulile yekhwalithi enhle zingacutshungulwa.

5. I-anti-break yokubhoboza indawo encane ingaphansi kwembobo emaphakathi engu-Φ1.5mm lapho ukubhola kungaphansi kwembobo ephakathi engu-Φ1.5mm. Indlela elula nesebenzayo yokunqanda ukunqamuka ukuvala i-tailstock lapho ubhoboza imbobo ephakathi kodwa uyeke isitaki. Isisindo somuntu siqu kanye nokungqubuzana okukhiqizwa phakathi kombhede womshini kusetshenziselwa ukubhoboza imbobo ephakathi. Lapho ukumelana nokusika kukukhulu kakhulu, i-tailstock izohlehla yodwa, ngaleyo ndlela ivikele i-drill ephakathi.

6. I-Anti-vibration yokuguqula ama-workpieces anezindonga ezincane Phakathi nenqubo yokuguqula ama-workpieces anezindonga ezincane, ukudlidliza kuvame ukukhiqizwa ngenxa yezakhiwo zensimbi ezimbi ze-workpieces; ikakhulukazi umaukuguqula insimbi engagqwalikanye nama-alloys amelana nokushisa, ukudlidliza kugqame kakhulu, ukuhwashala kwendawo yokusebenza kubi kakhulu, futhi impilo yesevisi yethuluzi iba mfishane. Izindlela ezilula zokuhlukanisa ukushaqeka emikhiqizweni eminingi zichazwe ngezansi.

(1) Lapho uphendula indilinga yangaphandle yensimbi engagqwali enembobo encane yokusebenza kweshubhu, imbobo ingagcwaliswa ngokhuni bese ixhunywa. Ngasikhathi sinye, iziphetho zombili ze-workpiece zixhunywe ngepulaki ye-bakelite, bese i-claw yokusekela kumphathi wamathuluzi ithathelwa indawo Ikhabe elisekela lezinto ze-bakelite lingalungisa i-arc edingekayo ukuze wenze Ukuphenduka kwe-stainless steel hollow. induku encane. Le ndlela elula ingavimbela ngokuphumelelayo ukudlidliza kanye nokuguqulwa kwenduku encane engenalutho phakathi nenqubo yokusika.

(2) Lapho uphendula imbobo yangaphakathi yensimbi engashisi (i-high-nickel-chromium) ingxubevange enodonga oluncane, ukuqina kwendawo yokusebenza kubi, i-shank incane, futhi kwenzeka into engathi sína yokukhala phakathi nenqubo yokusika; okuyicala elinzima kakhulu lokulimaza ithuluzi futhi lidale ukumosha. Uma into emunca ukushaqeka, njengomucu werabha noma isipontshi, iboshelwe endaweni eyindilinga yangaphandle yomsebenzi, umphumela wokushaqisa ungafinyelelwa ngempumelelo.

(3) Lapho uphendula isiyingi sangaphandle se-alloy engazweli ukushisa isiqeshana sokusebenzela esinezindonga ezincane esinezindonga, ngenxa yezici ezibanzi ezifana nokumelana okuphezulu kwe-alloy ukumelana nokushisa, kulula ukukhiqiza ukudlidliza kanye nokuguqulwa ngesikhathi sokusika. Uma imbobo yenjoloba noma intambo kakotini ifakwe emgodini wokusebenza, Imfucumfucu isetshenziswa, khona-ke indlela yokubopha emikhawulweni yomibili ingasetshenziswa ukuvimbela ngokuphumelelayo ukudlidliza kanye nokuguqulwa kwe-workpiece ngesikhathi sokusika, kanye nekhwalithi ephezulu. I-workpiece enezindonga ezincane ingacutshungulwa.

7. Ithuluzi elengeziwe lokulwa nokudlidliza likhiqiza kalula ukudlidliza ngenxa yokungaqini kahle kocezu lokusebenza olude lwe-shaft-type phakathi nenqubo yokusika ye-multi-groove, okuholela ekubunjweni okungekuhle kwendawo yokusebenza kanye nokulimala kwethuluzi. Iqoqo lamathuluzi engeziwe okuvimbela ukudlidliza lingaxazulula ngempumelelo inkinga yokudlidliza yezingxenye ezizacile enqubweni yokugoqa (bona Umfanekiso 10). Faka ithuluzi elenziwe ngokwalo le-shockproof endaweni efanelekile kusibambi samathuluzi esiyisikwele ngaphambi komsebenzi. Bese, faka ithuluzi elidingekayo lokujika elimise okwe-slot kusibambi sethuluzi lesikwele, ulungise ibanga kanye nenani lokuminyanisa lentwasahlobo, bese usebenza. Lapho ithuluzi eliphendukayo linqamula ku-workpiece, ithuluzi elengeziwe lokulwa nokudlidliza libekwa phezu kwendawo yokusebenza ngesikhathi esifanayo, elilungele ukushaqeka. Umphumela.

8. Izinto ezisetshenziswa kanzima emshinini ziyacijwa futhi ziqedwe. Uma sisezintweni ezinzima ukuya emshinini njengama-alloys asezingeni eliphezulu nezinsimbi eziqinile, ubulukhuni bomsebenzi ongaphezulu buyadingeka ukuthi bube ngu-Ra0.20-0.05μm, futhi ukunemba kobukhulu nakho kuphezulu. Ukuqedwa kokugcina kuvame ukwenziwa emshinini wokugaya. Yenza ithuluzi lokucija elilula elenziwe ngokwakho kanye nesondo lokucija, futhi uthole umphumela omuhle wezomnotho ngokucija esikhundleni senqubo yokugaya ku-lathe.

9. Ukulayisha okusheshayo nokuthulula ama-mandrel kuvame ukuhlangana nezinhlobo ezahlukene zokuthwala amasethi ekuguquleni. Indingilizi yangaphandle kanye ne-engeli ye-taper yegayidi ehlanekezelwe yenhlangano ethwalayo. Ngenxa yobukhulu be-batch enkulu, isikhathi sokulayisha nokukhipha singaphezu kwesikhathi sokusika. Ukusebenza kahle kokukhiqiza okude, okuphansi. I-mandrel esheshayo yokulayisha kanye nommese owodwa we-multi-blade (insimbi eqinile) amathuluzi okuguqula achazwe ngezansi angasindisa isikhathi esiwusizo futhi aqinisekise ikhwalithi yomkhiqizo ekucutshungulweni kwezingxenye ezihlukahlukene zemikhono yokuthwala. Indlela yokukhiqiza imi kanje. Yenza elula, e encane taper mandrel. Isimiso iwukuba ukusebenzisa trace 0.02mm taper ngemuva mandrel. Isethi yokuthwala iqiniswe ku-mandrel ngokungqubuzana, bese kusetshenziswa ithuluzi lokuguqula i-multi-blade ngommese owodwa. Ngemuva kokujikeleza, i-engeli ye-cone engu-15 ° iyahlehliswa, futhi indawo yokupaka iyenziwa ukuze kukhishwe izingxenye ngokushesha futhi kahle, njengoba kukhonjisiwe kuMfanekiso.

10. Ukuguqulwa kwezingxenye zensimbi eziqinile

(1) Esinye sezibonelo ezibalulekile zokujika kwensimbi eqinile 1 Ukwakhiwa kabusha kwensimbi enesivinini esiphezulu i-W18Cr4V (ukulungisa ngemva kokuphuka) i-gauge yepulaki yentambo engeyona evamile engu-2 (i-hardware eqinisayo) 3 i-hardware yokucisha kanye nokufuthaUkucisha izingcezu ezine ze-hardware yokucisha. i-smooth surface plugging 5 Ompompi abagingqekayo bentambo abenziwe ngamathuluzi ensimbi anesivinini esikhulu Okokucisha i-hardware kanye nezingxenye ezihlukahlukene ezinzima zezinto ezihlangatshezwane nazo ekukhiqizeni okungenhla, khetha ithuluzi elifanele kanye nenani lokusika kanye nethuluzi Ama-engeli weJiyomethri nezindlela zokusebenza zingafinyelela imiphumela emihle yezomnotho jikelele. Isibonelo, ngemuva kokuthi i-square broach iphukile, uma iphinda yethulwa ukuze kukhiqizwe i-square broach, akuwona nje umjikelezo wokukhiqiza mude kodwa futhi izindleko ziphezulu. Emsuka we-broach yasekuqaleni, sisebenzisa i-blade ye-hard alloy YM052 ukuyilola ibe yinegethivu. I-engeli yangaphambili r. =-6°~-8°, unqenqema lokusika lungaphendulwa ngokugaya ngokucophelela ngetshe lamafutha. Isivinini sokusika ngu-V=10~15m/min. Ngemuva kwendilinga yangaphandle, i-sipe engenalutho iyasikwa, futhi ekugcineni, intambo ihlukaniswa ibe mahhadla futhi ibe yinhle. ), ngemva kokugoqa, ithuluzi kufanele liphindwe futhi ligaywe ngemva kokucija nokugaya okusha. Khona-ke, intambo yangaphakathi yenduku yokuxhuma kufanele ilungiswe, futhi ukuhlanganyela kufanele kunqunywe. I-square broach ene-scrap ephukile yalungiswa ngemuva kokuphenduka, futhi yayindala njengentsha.

(2) Ukukhethwa kwezinto zamathuluzi okuguqula nokucisha i-hardware 1 Amabanga amasha afana ne-hard alloy YM052, YM053, YT05, njll., isivinini sokusika esijwayelekile singaphansi kwe-18m/min, futhi ubulukhuni bendawo yokusebenza bungafinyelela ku-Ra1.6 ~0.80μm. 2 ithuluzi le-cubic boron nitride FD lingacubungula zonke izinhlobo zensimbi eqinile nezingxenye ezifuthwe, ukusika isivinini esifika ku-100m / min, ukuhwaqeka komhlaba kufika ku-Ra0.80 ~ 0.20μm. Ithuluzi eliyinhlanganisela ye-cubic boron nitride i-DCS-F ekhiqizwe yi-State Capital Machinery Plant kanye ne-Guizhou No.6 Grinding Wheel Factory nayo inalokhu kusebenza. Umphumela wokucubungula mubi kakhulu kunalowo we-carbide enosimende (kodwa amandla awafani nalawo e-hard alloy; ijulile futhi ishibhile kune-alloy eqinile, futhi kulula ukuyilimaza uma isetshenziswe ngendlela engafanele). Amathuluzi ayisishiyagalolunye e-ceramic, isivinini sokusika esingu-40 ~ 60m / min, amandla ampofu. Wonke amathuluzi angenhla anezici zawo ekuphenduleni nasekucimeni izingxenye futhi kufanele akhethwe ngokuvumelana nezimo ezithile zokuguqula izinto ezihlukahlukene kanye nobunzima obuhlukile.

(3) Ukukhethwa kwezinhlobo ezahlukene zezingxenye zensimbi eziqinile kanye nezakhiwo zamathuluzi Izinto ezahlukene zezingxenye zensimbi eziqinile ngaphansi kokuqina okufanayo, izidingo zokusebenza kwethuluzi zihluke ngokuphelele, zinkulu njengezigaba ezintathu ezilandelayo: 1 insimbi ephezulu ye-alloy: ibhekisela ekuhlanganiseni i-alloying. izakhi Ithuluzi lensimbi nensimbi yokufa (ikakhulukazi izinsimbi ezihlukahlukene ezinesivinini esikhulu) ezinesisindo esingaphezu kuka-10%. 2 ingxubevange yensimbi: isho insimbi yamathuluzi nensimbi edayiyo enokuqukethwe kwe-alloying element engu-2~9%, efana ne-9SiCr, CrWMn, nensimbi yesakhiwo esinamandla aphezulu. Insimbi ye-carbon ezintathu: kufaka phakathi amashidi amathuluzi e-carbon ahlukahlukene ensimbi nensimbi eshisiwe njenge-T8, T10, 15 steel, noma i-20 gauge steel carburizing steel. Ngensimbi ye-carbon, i-microstructure ngemva kokucisha i-martensite efudumele kanye nenani elincane le-carbide, izinwele eziqinile i-HV800 ~ 1000, kunobulukhuni be-WC ne-TiC ku-carbide enosimende kanye ne-A12D3 kumathuluzi e-ceramic. Iphansi kakhulu, futhi ayishisi kakhulu kune-martensite ngaphandle kwezakhi ze-alloying futhi ngokuvamile aweqi ku-200 °C. Njengoba okuqukethwe kwezakhi ze-alloying ensimbi kukhula, okuqukethwe kwe-carbide yensimbi emva kokucisha nokushisa kuyanda, futhi uhlobo lwe-carbide luba nzima kakhulu. Ukuthatha insimbi enesivinini esikhulu njengesibonelo, okuqukethwe kwe-carbides ku-microstructure ngemva kokucisha nokushisa kungafinyelela ku-10-15% (isilinganiso sevolumu) futhi kuqukethe ama-carbides we-MC, M2C, M6 M3, 2C, njll. Ukuqina okuphezulu (HV2800) iphakeme kakhulu kunobulukhuni besigaba sephuzu eliqinile ezintweni ezisetshenziswayo ezijwayelekile. Ngaphezu kwalokho, ngenxa yokuba khona kwenani elikhulu lezakhi ze-alloying, ubulukhuni obushisayo be-martensite equkethe izakhi ezihlukahlukene ze-alloying bungakhuphuka bufinyelele ku-600 °C. Ukusebenza kanzima kwezinsimbi eziqinile ezine-microhardness efanayo akufani, futhi umehluko mkhulu kakhulu. Ngaphambi kokuguqula izingxenye zensimbi eziqinile, ziyahlaziywa ukuze zibe yingxenye yaleso sigaba. Bazi kahle izici bese ukhetha amathuluzi afanele, inani lokusika, kanye nejiyomethri yamathuluzi. I-engeli ingaqedela ngokushelela izintambo zezingxenye zensimbi eziqinile.

I-Anebon Metal Products Limited inganikeza i-CNC Machining, i-Die Casting, isevisi yokwenziwa kwe-Sheet Metal, sicela ukhululeke ukuxhumana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Isikhathi sokuthumela: Aug-30-2019