Umehluko kanye nokusetshenziswa kwama-bolts aphezulu kanye nama-bolts ajwayelekile

Ama-bolts anamandla aphezulu kanye nama-bolts ajwayelekile yizinhlobo ezimbili zezinsimbi ezisetshenziswa ezinhlelweni ezihlukahlukene.

Nakhu ukuqhathanisa umehluko wabo kanye nezinhlelo zokusebenza ezijwayelekile:

Amandla: Amabhawodi anamandla aphezulu aklanyelwe ukuthi abe namandla aphakeme kakhulu we-tensile namandla okugunda uma kuqhathaniswa namabhawodi ajwayelekile. Zenziwe ngensimbi ye-alloy futhi zithola izinqubo ezikhethekile zokwelashwa kokushisa ukuze zithuthukise amandla azo. Ngakolunye uhlangothi, amabhawodi avamile anamandla aphansi futhi ngokuvamile enziwa ngekhabhoniimishini yensimbi.

Izimpawu: Amabhawodi aqine kakhulu avame ukuba nezimpawu emakhanda awo ukuze abonise ibanga lawo noma isigaba samandla. Lezi zimaki zisiza ukuhlonza ukucaciswa kwebhawodi, njengamandla alo aqinile kanye nezakhiwo zezinto ezibonakalayo. Amabhawodi ajwayelekile awanawo amamaki athile ahlobene namandla.

Ukufakwa: Amabhawodi anamandla aphezulu adinga izinqubo zokufaka eziqondile ukuze kuzuzwe amandla afunekayo nokusebenza. Zivame ukusetshenziswa ezinhlelweni lapho ubuqotho besakhiwo namandla okuthwala umthwalo kubalulekile. Izindlela zokufaka amabhawodi anamandla ngokuvamile zibandakanya ukusebenzisa izikrufu zetorque ezilinganisiwe noma okokusebenza kwe-hydraulic tensioning ukuze kuzuzwe ukulayisha kuqala okucacisiwe. Amabhawodi ajwayelekile alula ukuwafaka futhi awadingi okokusebenza okukhethekile noma ukulawulwa kwetorque.

Izinhlelo zokusebenza: Amabhawodi anamandla aphezulu avame ukusetshenziswa ekwakhiweni, kumaphrojekthi wengqalasizinda, amabhuloho, izakhiwo, nezinye izinhlelo zokusebenza lapho imithwalo esindayo noma amazinga okucindezeleka okukhulu kulindeleke. Abalulekile ekuhlanganiseni amalungu ensimbi yesakhiwo, njengemishayo, amakholomu, nama-trusses. Amabhawodi ajwayelekile athola ukusetshenziswa ezinhlelweni ezingafuneki kangako, okuhlanganisaizingxenye zemishini ye-cncukuhlanganisa ifenisha, izingxenye zezimoto, ukuxhumana okungezona ezakhiweni, kanye nokuqiniswa kwenhloso evamile.

Amazinga: Amabhawodi aqine kakhulu avame ukukhiqizwa futhi acaciswe ngokuvumelana nezindinganiso zomkhakha, njenge-ASTM A325 ne-ASTM A490 e-United States. Lawa mazinga achaza izidingo zezinto ezibonakalayo, izakhiwo zemishini, ubukhulu, nezinqubo zokufaka zamabhawodi aqine kakhulu. Amabhawodi ajwayelekile ngokuvamile alandela izindinganiso ezijwayelekile, njenge-ASTM A307, ehlanganisa uhla olubanzi lwezinhlelo zokusebenza kanye nezidingo zamandla aphansi.

Ayini amabhawodi anamandla aphezulu?

I-High-Strength Friction Grip Bolt , Ukuhumusha ngokwezwi nezwi kwesiNgisi yilezi: ibhowudi yokuqina yamandla aphezulu, isifinyezo sesiNgisi: HSFG. Kuyabonakala ukuthi amabhawodi anamandla aphezulu okukhulunywe ngawo ekwakhiweni kwethu kwamaShayina ayizifinyezo zamabhawodi alayishwa ngaphambili akhuhlana ngamandla. Ekuxhumaneni kwansuku zonke, amagama athi "Friction" kanye "Grip" ashiwo kafushane nje, kodwa onjiniyela abaningi nabachwepheshe abaqondi kahle incazelo eyisisekelo yamabhawodi anamandla amakhulu.

Ukungaqondi okukodwa:

Amabhawodi anebanga lezinto ezibonakalayo elidlula u-8.8 “amabhawodi aqine kakhulu”?

Umehluko oyinhloko phakathi kwama-bolts aphezulu kanye nama-bolts ajwayelekile akuwona amandla ezinto ezisetshenzisiwe, kodwa uhlobo lwamandla. Ingqikithi iwukuba kufakwe ukulayisha kuqala futhi usebenzise ukungqubuzana okumile ukuze umelane nokugunda.

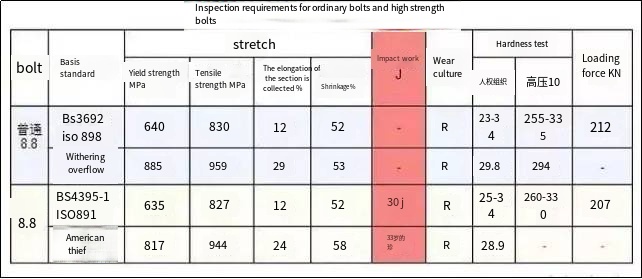

Eqinisweni, ama-bolts anamandla aphezulu (HSFG BOLT) okukhulunywe ngawo kuzinga laseBrithani kanye nezinga laseMelika liyi-8.8 kanye ne-10.9 kuphela (BS EN 14399 / ASTM-A325&ASTM-490), kuyilapho amabhawodi ajwayelekile ahlanganisa i-4.6, 5.6, 8.8, 10.9, 12.9, njll. (BS 3692 11 Ithebula 2); kungabonakala ukuthi amandla ezinto ezibonakalayo akusona isihluthulelo sokuhlukanisa ama-bolts anamandla aphezulu kusuka kuma-bolts ajwayelekile.

Ukuqonda kahle "amandla aphezulu", aphi amandla

Ngokusho kwe-GB50017, bala amandla okuqina nawokugunda webhawodi eyodwa ejwayelekile (Uhlobo B) ibanga le-8.8 kanye nebanga eliphakeme lamandla ebhawodi elingu-8.8.

Ngokubala, singabona ukuthi ngaphansi kwebanga elifanayo, umklamo kanyeisevisi ye-aluminium cncamanani wamandla aqinile namandla okugunda amabhawodi ajwayelekile aphezulu kunalawo amabhawodi anamandla aphezulu.

Ngakho-ke ikuphi "okunamandla" kwamabhawodi anamandla aphezulu?

Ukuze uphendule lo mbuzo, kuyadingeka ukuthi uqale ngesimo sokusebenza sokuklama kwama-bolts amabili, ufunde umthetho we-elastic-plastic deformation, futhi uqonde isimo somkhawulo ngesikhathi sokuhluleka kokuklama.

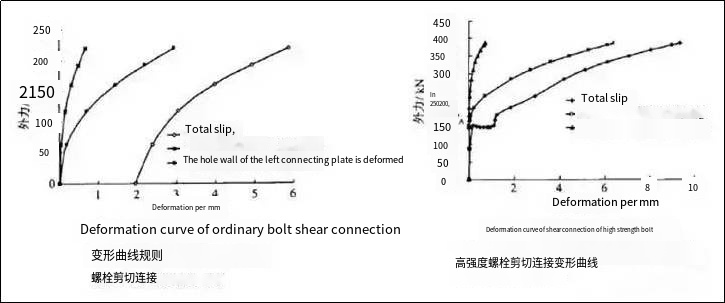

Amajika e-stress-strain ama-bolt ajwayelekile namabhawodi anamandla aphezulu ngaphansi kwezimo zokusebenza

Isimo somkhawulo ekuhlulekeni kwedizayini

Amabhawodi ajwayelekile: Ukuguqulwa kwepulasitiki kwesikulufu ngokwaso kudlula imvume yokuklama, futhi isikulufu sonakaliswa ukugunda.

Ukuze kuxhunywe umshudo ojwayelekile, ukushelela kwesihlobo kuzokwenzeka phakathi kwamapuleti axhumayo ngaphambi kokuba amandla okugunda aqale ukuthwala, bese kuthi induku yebhawudo kanye nokuxhumana kwepuleti yokuxhuma, ukuguqulwa kwe-elastic-plastic kwenzeka, futhi amandla okugunda ayabekezelelwa.

Amabhawodi anamandla aphezulu: Ukungqubuzana okumile phakathi kwezindawo ezishayisanayo ezisebenzayo kuyanqotshwa, futhi ukugudluzwa okuhlobene kwamapuleti ensimbi amabili kwenzeka, okubhekwa njengokulimala ekucatshangelweni kokuklama.

Ekuxhumekeni kwebhawodi yamandla aphezulu, amandla okungqubuzana aqala athwale amandla okugunda. Lapho umthwalo ukhuphuka uze ufike endaweni lapho amandla okungqubuzana anganele ukumelana namandla okugunda, amandla okungqubuzana okumile ayanqotshwa, futhi ukushelela okuhlobene kwepuleti lokuxhuma kwenzeka (isimo somkhawulo). Kodwa-ke, nakuba ilimele ngalesi sikhathi, induku yebhawodi ixhumene nepuleti yokuxhuma, futhi isengasebenzisa i-elastic-plastic deformation yayo ukuze imelane namandla okugunda.

Ukungaqondi kahle 2:

Amandla okuthwala ama-bolts anamandla aphezulu aphakeme kunalawo ama-bolts ajwayelekile. Ingabe “ngamandla amakhulu”?

Kungabonakala ekubalweni kwebhawodi eyodwa ukuthi amandla okuklama amabhawodi anamandla aphezulu ekucindezelekeni nasekugundaneni aphansi kunalawo amabhawodi ajwayelekile. I-essence yayo yamandla aphezulu: ngesikhathi sokusebenza okujwayelekile, ama-node awavunyelwe ukuba nanoma yikuphi ukushelela okuhlobene, okungukuthi, i-deformation elastic-plastic deformation incane, futhi ukuqina kwe-node kukhulu.

Kungabonakala ukuthi esimweni somthwalo onikeziwe we-node design, i-node eklanyelwe ngamabhowuthi anamandla amakhulu ingase ingasindisi inani lama-bolts asetshenzisiwe, kodwa inokuguqulwa okuncane, ukuqina okuphezulu, nokugcinwa kokuphepha okuphezulu. Ifanele amagida ayinhloko nezinye izindawo ezidinga ukuqina kwe-node ephezulu, futhi ihambisana nesimiso esiyisisekelo sokuklama kwe-seismic "ama-node aqinile, amalungu abuthakathaka".

Amandla ama-bolts anamandla aphezulu awahlali enanini lokuklama lomthamo wayo wokuthwala, kodwa ngokuqina okuphezulu kwama-node okuklama kwawo, ukusebenza okuphezulu kokuphepha, nokumelana okuqinile nokulimala.

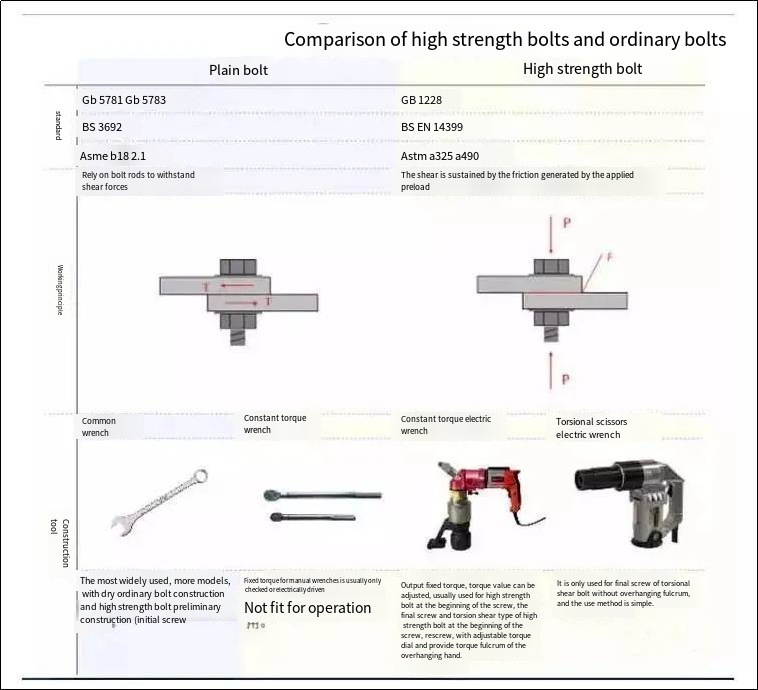

Ukuqhathaniswa kwama-bolts aphezulu kanye nama-bolts ajwayelekile

Ama-bolts ajwayelekile kanye nama-bolts aphezulu ahluke kakhulu ezindleleni zokuhlola ukwakhiwa ngenxa yezimiso zabo zokuklama ezahlukene.

Izidingo zokusebenza komshini zamabhawodi ajwayelekile ebanga elifanayo ziphakeme kancane kunalawo amabhawodi anamandla aphezulu, kodwa amabhawodi aqine kakhulu anesidingo esisodwa sokwamukela amandla omthelela kunamabhawodi ajwayelekile.

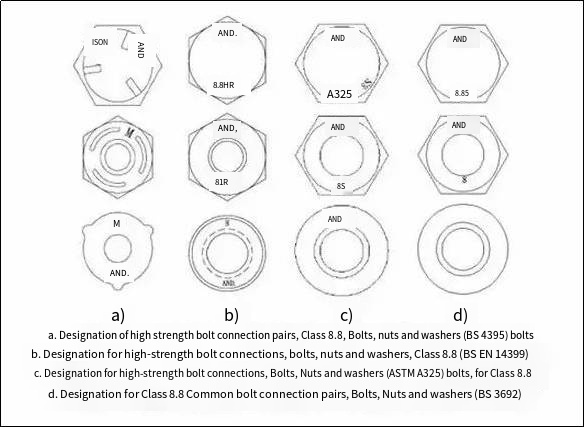

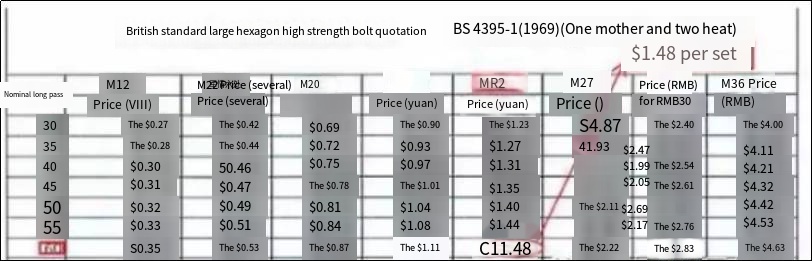

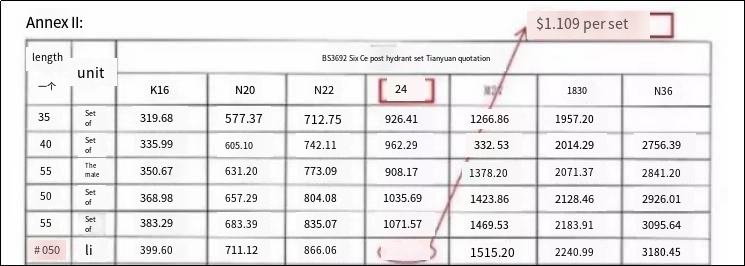

Ukumakwa kwamabhawodi ajwayelekile kanye namabhawodi anamandla aphezulu kuyindlela eyisisekelo yokuhlonza amabhawodi esizeni sebanga elifanayo. Njengoba amanani abalwe ngenani le-torque lama-bolts anamandla aphezulu ezindinganisweni zaseBrithani nezaseMelika azifani, kuyadingeka futhi ukukhomba amabhawodi wezindinganiso ezimbili.

Amabhawodi aqine kakhulu: (M24, L60, grade 8.8)

Amabhawodi ajwayelekile: (M24, L60, grade 8.8)

Kungabonakala ukuthi ama-bolts ajwayelekile angaba ngu-70% wentengo yama-bolts aphezulu. Kuhlanganiswe nokuqhathaniswa kwezidingo zabo zokwamukela, kungaphethwa ngokuthi ingxenye yeprimiyamu kufanele kube ukuqinisekisa ukusebenza kwamandla (ukuqina) kokusebenza kwento.

Fingqa

Enkingeni ebonakala ilula, akuyona into elula ukuba nokuqonda okujulile, okuphelele nokulungile kwengqikithi yayo. Incazelo, incazelo kanye nomehluko ojulile phakathi kwamabhawodi anamandla amakhulu namabhawodi ajwayelekile kuyisisekelo esiyisisekelo sokuba siqonde kahle, sisebenzise amabhawodi anamandla amakhulu, futhi siqhube nokuphatha ukwakha.

Buka:

I-1) Ngempela kushiwo kwezinye izincwadi zesakhiwo sensimbi ukuthi ama-bolts anamandla aphezulu abhekisela kumabhawodi amandla awo adlula amamaki angu-8.8. Kuleli phuzu lokubuka, okokuqala, izindinganiso ze-Anglo-American aziyisekeli, futhi akukho ncazelo "eqinile" futhi "ebuthakathaka" ngezinga elithile lamandla. Okwesibili, ayihlangabezani “namabhawodi anamandla” okukhulunywe ngawo emsebenzini wethu.

I-2) Ukuze kube lula ukuqhathanisa, ukucindezeleka kwamaqembu e-bolt ayinkimbinkimbi akubhekwa lapha.

I-3) Amandla okucindezela i-screw aphinde acatshangelwe ekwakhiweni kwe-bolt high-strength bolt ene-pressure, ezokwethulwa ngokuningiliziwe kulokhu okulandelayo "Ukuqhathaniswa kwe-pressure-bearing kanye ne-friction-type high-strength bolts".

Kungakanani okwaziyo ngamabhawodi anamandla aphezulu?

Igama eligcwele lamabholithi anamandla aphezulu ekukhiqizeni libizwa ngokuthi i-high-strength bolt connection pair, futhi ngokuvamile alibhekiseli kuwo njengamabhawodi anamandla amakhulu ngamafuphi.

Ngokwezici zokuyifaka, ihlukaniswe yaba: amabhawodi amakhulu amaheksagoni ekhanda namabhawudi okugunda okugunda. Phakathi kwazo, uhlobo lwe-shear torsional lusetshenziswa kuphela ezingeni 10.9.

Ngokwezinga lokusebenza lamabhawodi anamandla amakhulu, ihlukaniswe yaba: 8.8 no-10.9. Phakathi kwazo, kukhona kuphela amabhawodi amakhulu anama-hexagonal anamandla aphezulu ebangeni lesi-8.8. Endleleni yokumaka, inombolo engaphambi kwephuzu ledesimali ikhombisa amandla okuqina ngemva kokwelashwa kokushisa; inombolo engemuva kwephoyinti ledesimali ikhombisa isilinganiso sesivuno, okungukuthi, isilinganiso senani elilinganisiwe lamandla esivuno kuya kunani elilinganiselwe lamandla okuqina okugcina. . IBanga lesi-8.8 lisho ukuthi amandla aqinile we-bolt shaft awekho ngaphansi kuka-800MPa, kanti isilinganiso sesivuno singu-0.8; Ibanga le-10.9 lisho ukuthi amandla aqinile we-bolt shaft awekho ngaphansi kuka-1000MPa, kanti isilinganiso sesivuno singu-0.9.

Amadayamitha amabhawodi anamandla aphezulu ekwakhiweni kwesakhiwo ngokuvamile ahlanganisa i-M16/M20/M22/M24/M27/M30, kodwa i-M22/M27 iwuchungechunge lwesibili lokukhetha, futhi i-M16/M20/M24/M30 iyisinqumo esiyinhloko ngaphansi kwezimo ezivamile.

Ngokuphathelene nokuklama kwe-shear, ama-bolts anamandla aphezulu ahlukaniswe abe: uhlobo olunengcindezi ye-bolt high-strength kanye nohlobo lwe-high-strength bolt friction ngokusho kwezidingo zokuklama.

Amandla okuthwala ohlobo lokungqubuzana ancike ku-anti-slip coefficient yendawo yokushayisana yokudlulisa amandla kanye nenani lezindawo zokungqubuzana. I-coefficient ye-friction yokugqwala okubomvu ngemva kwe-sandblasting (edutshulwa) iphezulu kakhulu, kodwa ithintwa kakhulu izinga lokwakha mayelana nokusebenza kwangempela. Amayunithi amaningi okugada Wonke aphakamisa ukuthi izinga lingehliswa yini ukuze kuqinisekiswe ikhwalithi yephrojekthi.

Umthamo wokuthwala umthwalo wohlobo oluthwala ingcindezi uncike enanini elincane lomthamo we-shear we-bolt kanye nomthamo wokucindezela we-bolt. Endabeni yendawo eyodwa kuphela exhumayo, umthamo othwala i-shear wohlobo lwe-M16 friction ngu-21.6-45.0 kN, kuyilapho umthamo wokugunda wohlobo lwe-M16 oluthwala ingcindezi ungama-39.2-48.6 kN, futhi ukusebenza kungcono kunokwe- uhlobo lokungqubuzana.

Mayelana nokufakwa, inqubo yohlobo oluthwala ingcindezi ilula, futhi indawo yokuxhuma idinga kuphela ukuhlanzwa ngamafutha kanye nokugqwala okuntantayo. Umthamo wokuthwala oqinile eduze kokuqondisa kwe-shaft uthakazelisa kakhulu kukhodi yesakhiwo sensimbi. Inani ledizayini lohlobo lokungqubuzana lilingana nezikhathi ezingu-0.8 zamandla angaphambi kokungezwani, futhi inani ledizayini lohlobo lokucindezela lilingana nendawo esebenzayo yesikulufu esiphindaphindwe ivelu yokuklama yamandla aqinile wento. Kubonakala sengathi Kunomehluko omkhulu, empeleni, amanani amabili ayafana ngokuyisisekelo.

Lapho uthwala amandla okugunda kanye namandla aqinile ekuqondeni kwe-eksisi yenduku ngesikhathi esifanayo, uhlobo lokungqubuzana ludinga ukuthi isilinganiso samandla okugunda athwalwe yibhawodi kumthamo wokugunda kanye nesamba sesilinganiso sokucindezeleka samandla athwalwa yi-axial. ngesikulufu kumthamo wokushesha singaphansi kuka-1.0, futhi uhlobo lokucindezela ludinga Isamba sesikwele sesilinganiso samandla okugunda kumthamo wokugunda webhawodi kanye nesikwele isilinganiso samandla e-axial kumthamo oqinile wesikulufu singaphansi kuka-1.0, okusho ukuthi, ngaphansi kwenhlanganisela yomthwalo ofanayo, ububanzi obufanayo bokuthwala Indawo yokuphepha yomklamo wamabhawudo anamandla aphezulu ingaphezulu kwalokho amabhawodi anamandla aphezulu ohlobo lwe-friction.

Uma kucatshangelwa ukuthi ngaphansi kwesenzo esiphindaphindiwe sokuzamazama komhlaba okunamandla, indawo yokungqubuzana yokuxhumana ingase ihluleke, futhi umthamo wokugunda ngalesi sikhathi usancike kumthamo wokugunda webhawodi kanye nomthamo wokucindezela wepuleti. Ngakho-ke, ikhodi yokuzamazama komhlaba ibeka umthamo wokugcina wokugunda wamabholithi anamandla amakhulu Aphethe ifomula yokubala yamandla.

Nakuba uhlobo oluthwele ingcindezi lunenzuzo enanini lokuklama, ngoba luyingxenye yokwehluleka kokucindezelwa kwe-shear, izimbobo zebholidi ziyizimbobo zohlobo lwe-pore ezifana namabhawodi ajwayelekile, futhi ukuwohloka ngaphansi komthwalo kukhulu kakhulu kunaleyo ye-bolt. uhlobo lokungqubuzana, ngakho-ke amabhawodi anamandla aphezulu athwala ingcindezi Uhlobo lusetshenziswa kakhulu ekuxhumekeni kwezingxenye ezingashukumi, uxhumo lwengxenye yomthwalo ongaguquguquki, kanye nokungaphindaphindi. izixhumanisi zengxenye.

Izimo ezijwayelekile zomkhawulo wesevisi zalezi zinhlobo ezimbili nazo zihlukile:

Ukuxhumeka kohlobo lwe-Friction kubhekisela ekusheleleni okuhlobene kwendawo yokushayisana yokuxhumana ngaphansi kwenhlanganisela eyisisekelo yemithwalo;

Uxhumano oluthwala ukucindezela lubhekisela ekusheleleni okuhlobene phakathi kwezingxenye zokuxhuma ngaphansi kwenhlanganisela evamile yomthwalo;

Ibhawodi elivamile

1. Amabhawodi ajwayelekile ahlukaniswe abe yizinhlobo ezintathu: A, B, no-C. Amabili okuqala amabhawodi acwengisisiwe, asetshenziswa kancane. Ngokuvamile, amabhawodi ajwayelekile abhekisa kumabhawodi ajwayelekile ezinga le-C.

2. Kokunye ukuxhumana kwesikhashana nokuxhumana okudingeka kuhlakazwe, amabhawodi ajwayelekile asezingeni C asetshenziswa kakhulu. Amabhawodi ajwayelekile ajwayele ukusetshenziswa ezakhiweni zokwakha yi-M16, M20, M24. Amanye amabhawodi amaholoholo embonini yemishini angase abe nobubanzi obukhulu uma kuqhathaniswa futhi asetshenziselwa izinjongo ezikhethekile.

Amabhawodi anamandla aphezulu

3. Impahla yama-bolts anamandla aphezulu ihlukile kuma-bolts ajwayelekile. Amabhawodi anamandla aphezulu ajwayele ukusetshenziselwa ukuxhumana unomphela. Okuvame ukusetshenziswa yi-M16~M30. Ukusebenza kwama-bolts amakhulu kakhulu akuzinzile futhi kufanele kusetshenziswe ngokuqapha.

4. Uxhumo lwe-bolt lwezingxenye eziyinhloko zesakhiwo sokwakha ngokuvamile luxhunywe ngama-bolts aphezulu.

5. Amabhawodi anamandla aphezulu alethwa ifekthri awahlukaniswa abe yi-pressure-bearing noma uhlobo lwe-friction.

6. Ingabe angamabhawudi anamandla aphezulu ohlobo lwe-friction noma amabhawodi anamandla aphezulu athwala ukucindezela? Eqinisweni, kunomehluko endleleni yokubala yokuklama:

I-1) Ngohlobo lwe-friction-high-power bolts, ukushelela phakathi kwamapuleti kuthathwa njengesimo somkhawulo womthamo wokuthwala.

I-2) Ukuze uthole ama-bolts anamandla aphezulu, ukushelela phakathi kwamapuleti kuthathwa njengesimo somkhawulo wokusetshenziswa okujwayelekile, futhi ukuhluleka kokuxhumeka kuthathwa njengesimo somkhawulo wokuthwala umthamo.

7. Amabhawodi anamandla aphezulu ohlobo lwe-Friction awakwazi ukunikeza ukudlala okugcwele emandleni amabhawodi. Kuzinhlelo zokusebenza ezingokoqobo, amabhawodi anamandla aphezulu ohlobo lokungqubuzana kufanele asetshenziselwe izakhiwo ezibaluleke kakhulu noma izakhiwo ezingaphansi kwemithwalo eguquguqukayo, ikakhulukazi uma umthwalo ubangela ukuhlehla kwengcindezi. Ngalesi sikhathi, amandla ebhawodi angasetshenzisiwe angasetshenziswa njengendawo yokugcina ukuphepha. Kwezinye izindawo, amabhawodi anamandla aphezulu anengcindezi kufanele asetshenziselwe ukunciphisa izindleko.

Umehluko phakathi kwamabhawodi ajwayelekile namabhawodi anamandla aphezulu

8. Amabhawodi ajwayelekile angasetshenziswa kabusha, kodwa amabhawodi anamandla amakhulu awakwazi ukuphinda asetshenziswe.

9. Amabhawodi aqine kakhulu ngokuvamile enziwa ngensimbi yokuqina okuphezulu (No. 45 steel (8.8s), 20MmTiB (10.9S), okungamabhawudi acindezelwe. Uhlobo lokungqubuzana lisebenzisa isikrufu se-torque ukuze kufakwe i-prestress ecacisiwe, kanye uhlobo lokucindezela lukhulula ikhanda eliqhakaza iplamu Amabhawudo ajwayelekile enziwa ngensimbi evamile (Q235) futhi kuphela kudingeka kuqiniswe.

10. Amabhawodi ajwayelekile ngokuvamile eba grade 4.4, grade 4.8, grade 5.6 kanye grade 8.8. Amabhawodi aqine kakhulu ngokuvamile eba yibanga lesi-8.8 kanye nebanga le-10.9, okuyibanga le-10.9 elikhulu.

11. Izimbobo ezikulufi zamabhawudi ajwayelekile azikho zikhulu ngempela kunalezo zamabhawudi anamandla. Eqinisweni, amabhawodi ajwayelekile anezimbobo zezikulufo ezincane uma kuqhathaniswa.

12. Izimbobo ezikulufi zamabanga A no-B amabhawodi ajwayelekile ngokuvamile zinkulu ngo-0.3~0.5mm kuphela kunamabhawodi. Izimbobo zezikulufu zekilasi C ngokuvamile zinkulu ngo-1.0~1.5mm kunamabhawudi.

13. Amabhawodi anamandla aphezulu ohlobo lwefriction adlulisa imithwalo ngokungqubuzana, ukuze umehluko phakathi kwenduku yesikulufu nembobo yesikulufu ungafinyelela ku-1.5-2.0mm.

14. Izici zokudlulisa amandla okucindezelayo okuthwala amandla aphezulu ziqinisekisa ukuthi ngaphansi kokusetshenziswa okujwayelekile, amandla okugunda aweqeli amandla okungqubuzana, afana nalawo ohlobo lwe-friction-high-strength bolts. Lapho umthwalo ukhula futhi, ukushelela kwesihlobo kuzokwenzeka phakathi kwamapuleti axhumayo, futhi ukuxhumana kuncike ekuphikiseni kwe-shear kwesikulufu kanye nokucindezela kodonga lwembobo ukuze kudluliselwe amandla, afana nalawo amabhawodi ajwayelekile, ngakho-ke umehluko phakathi kwesikulufu kanye nembobo yesikulufu mncane kancane, 1.0-1.5mm.

I-Anebon ibambelela esimisweni esithi “Ithembekile, ikhuthele, iyathakazelisa, inobuhlakani obusha” ukuze ithole izixazululo ezintsha ngokuqhubekayo. I-Anebon ibheka amathemba, impumelelo njengempumelelo yayo yomuntu siqu. Vumela i-Anebon yakhe ikusasa eliphumelelayo ngesandla sezingxenye zomshini wethusi kanye nezingxenye ze-Complex titanium cnc / izinsimbi zokugxiviza. I-Anebon manje inokunikezwa kwezimpahla okuphelele kanye nentengo yokuthengisa kuyinzuzo yethu. Siyakwamukela ukubuza mayelana nemikhiqizo ye-Anebon.

Imikhiqizo Ethrendayo Yase-China CNC Machinging Ingxenye kanye Nengxenye Yokunemba, ngempela uma noma iyiphi yalezi zinto ingaba nesithakazelo kuwe, sicela usazise. I-Anebon izokujabulela ukukunikeza ikhotheshini lapho yathola imininingwane yomuntu. I-Anebon inonjiniyela bethu bomuntu siqu be-R&D ukuze bahlangabezane nanoma yiziphi izimfuneko. I-Anebon ibheke ngabomvu ukuthola imibuzo yakho maduze futhi inethemba lokuba nethuba lokusebenza nawe esikhathini esizayo. Siyakwamukela ukuze ubheke inhlangano ye-Anebon.

Isikhathi sokuthumela: Jun-01-2023