Isifinyezo sezindlela eziyisishiyagalombili zokucubungula intambo okufanele wazi lapho wenza imishini.

.Igama lesiNgisi elihambisana nelithi Screw is Screw. Incazelo yaleli gama ishintshe kakhulu emakhulwini eminyaka amuva nje. Okungenani ngo-1725, kusho "ukukhwelana".

Ukusetshenziswa komgomo wentambo kungalandelelwa emuva ethuluzini lokuphakamisa amanzi elijikelezayo elakhiwa isazi esingumGreki u-Archimedes ngo-220 BC.

Ngekhulu lesi-4 AD, amazwe aseMedithera aqala ukusebenzisa isimiso samabhawudi namantongomane emishinini yokunyathelisa esetshenziswa ekwenzeni iwayini. Ngaleso sikhathi, intambo yangaphandle yayiphonswa ngentambo ibe isiyingi bese ibazwa ngokwalolu phawu, kuyilapho intambo yangaphakathi yayivame ukwakhiwa ngokushaya intambo yangaphandle ngento ethambile.

Cishe ngo-1500, emdwebeni wedivaysi yokucubungula intambo edwetshwe uLeonardo da Vinci ongumNtaliyane, kwakukhona umqondo wokusebenzisa i-Screw yesifazane kanye negiya lokushintshanisa ukucubungula imicu enamagqabha ahlukene. Kusukela ngaleso sikhathi, indlela yokusika intambo iye yathuthukiswa embonini yokwenza amawashi yaseYurophu.

Ngo-1760, izelamani zaseBrithani u-J. Wyatt noW. Wyatt bathola ilungelo lobunikazi lokusika izikulufu zokhuni ngomshini othile. Ngo-1778, u-J. Ramsden waseBrithani wake wenza ithuluzi lokusika intambo eliqhutshwa igiya lezikelemu, elikwazi ukucubungula imicu emide ngokunemba okuphezulu. Ngo-1797, indoda eyiNgisi u-H. Maudsley yasebenzisa i-Screw yesifazane kanye negiya lokushintshanisa ukuze iguqule imicu yensimbi yezingqimba ezihlukene ku-lathe yakhe ethuthukisiwe, eyabeka indlela eyinhloko yokuphendula izintambo.

Ngawo-1820, uMaudsley wakhiqiza ompompi bokuqala futhi wafa ngenxa yokulutha.

Ekuqaleni kwekhulu lama-20, ukuthuthukiswa kwemboni yezimoto kwaphinde kwakhuthaza ukumiswa kwemicu kanye nokuthuthukiswa kwezindlela ezihlukahlukene ezinembile neziphumelelayo zokucutshungulwa kwentambo. Amakhanda okuvula okuzenzakalelayo okuvula okuzenzakalelayo kanye nompompi abawa ngokuzenzekelayo abanciphayo kwasungulwa ngokulandelana, futhi ukugaya intambo kwaqala ukusetshenziswa.

Ekuqaleni kwawo-1930, kwavela ukugaya intambo.

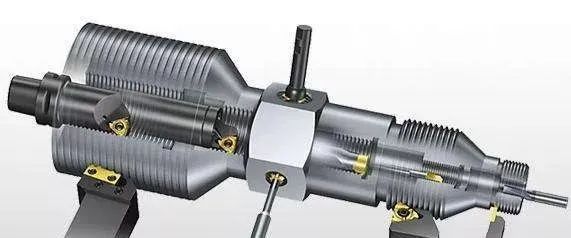

Nakuba ubuchwepheshe bokugoqa intambo babunelungelo lobunikazi ekuqaleni kwekhulu le-19, ngenxa yobunzima bokukhiqiza isikhunta, ukuthuthukiswa kwandiswa kwaze kwaba yiMpi Yezwe Yesibili (1942-1945) ngenxa yesidingo sokukhiqizwa kwezikhali kanye nokuthuthukiswa kobuchwepheshe bokugaya intambo. Inkinga yokunemba yokukhiqiza isikhunta ithuthuke ngokushesha.Ingxenye yokujika ye-CNC

Imicu ihlukaniswa ngokuyinhloko ibe imicu yokuxhuma kanye nemicu yokudlulisela.

Izindlela zokucubungula ezimaphakathi zokuxhuma izintambo ukuthepha, ukuthunga, ukuthunga, ukugoqa intambo, ukugingqa intambo, njll.

Izindlela zokucubungula ezimaphakathi zezintambo zokudlulisa ziwukuphenduka okumahhadlahhadla nokuhle ---ukugaya, ukugaya i-whirl---amaholoholo nokujika kahle, njll.

Isigaba sokuqala ukusika intambo

Ngokuvamile kubhekiselwa ekwenziweni kochungechunge lwezintambo zokusebenza ngamathuluzi okwakha noma abrasive, ikakhulukazi ahlanganisa ukuphenduka, ukugaya, ukuthepha kanye nokugaya intambo, ukugaya, nokusika okuvunguzayo. Lapho ujika, ugaywa, futhi ugaya izintambo, uchungechunge lokushayela lwethuluzi lomshini luqinisekisa ukuthi ithuluzi elijikayo, i-milling cutter, noma isondo lokugaya lihamba ngokunembile nangokulinganayo okukodwa okuholela e-eksisi yocezu lokusebenza ekuphendukeni ngakunye kwendawo yokusebenza. Uma uthepha noma uhlanganisa, ithuluzi (thepha noma ufe) kanye nocezu lokusebenza kuyazungezisa ngokuhlobene, futhi i-groove yentambo eyakhiwe ngaphambilini iqondisa ithuluzi (noma ucezu lokusebenza) ukuhamba nge-axially.

1. Ukuphenduka kwentambo

Ukuvula intambo ku-lathe kungenziwa ngethuluzi lokuphehla noma ikamu lentambo. Ukuguqula izintambo ngethuluzi lokuguqula ukwakha kuyindlela evamile yokukhiqizwa kwesiqephu esisodwa kanye neqoqo elincane lezinto zokusebenza ezinezintambo ngenxa yesakhiwo samathuluzi esilula; ukuguqula izintambo ngethuluzi lokuhlanganisa intambo kunokukhiqiza okuphezulu, kodwa isakhiwo samathuluzi siyinkimbinkimbi, sifanele kuphela ukukhiqizwa kwe-batch ephakathi nendawo enkulu. Baphendula izintambo zokusebenza zentambo emifushane enephimbo elihle. Ukunemba kwe-pitch kwama-lathes ajwayelekile okuguqula imicu ye-trapezoidal ngokuvamile ingafinyelela kumabanga angu-8 kuye kwayi-9 (JB2886-81, okufanayo ngezansi); ukwenza imicu kuma-lathes entambo akhethekile kungathuthukisa kakhulu ukukhiqiza noma ukunemba.

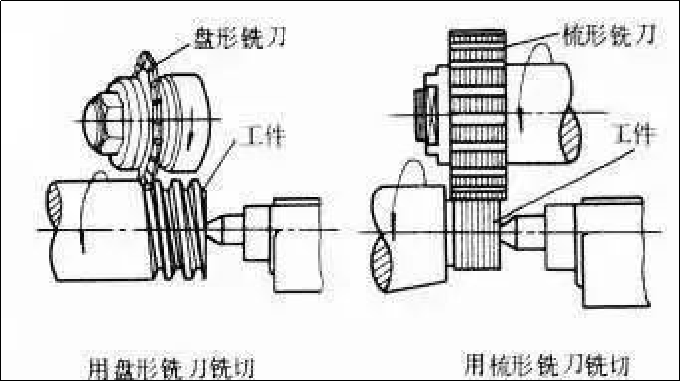

2. Ukugaya intambo

Bengigaya ngediski noma ikamu lokusika emshinini wokugaya.

Ama-disc milling cutter asetshenziselwa kakhulu ukugaya imicu yangaphandle ye-trapezoidal kuma-workpieces njengezikulufu kanye ne-worms i-milling cutter emise okwekamu isetshenziselwa ukugaya izintambo ezivamile zangaphakathi nangaphandle kanye nemicu ecijile. Njengoba igaywe nge-multi-blade milling cutter futhi ubude bengxenye yayo yokusebenza bukhulu kunobude bentambo, i-workpiece idinga kuphela ukujikeleza 1.25 kuya ku-1.5 ukuphenduka ukuze kucutshungulwe futhi kwenziwe ngokukhiqiza okuphezulu. Ukunemba kwephimbo lokugaywa kwentambo ngokuvamile kungafinyelela kumabanga ayi-8 kuya kwayi-9, futhi ubulukhuni obungaphezulu bungama-microns angama-R5 kuya ku-0.63. Le ndlela ilungele ama-workpieces akhiqiza ngobuningi wokunemba okuvamile noma ukugoqa ngaphambi kokugaya.

I-thread milling cutter yokwenza imicu yangaphakathi

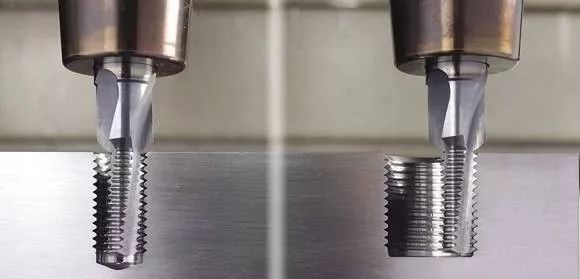

3. Ukugaya intambo

Isetshenziswa kakhulu ukucubungula izintambo ezinembayo zezinto zokusebenza eziqinile emishinini yokugaya intambo. Ukuma kwesigaba esiphambanayo sesondo lokugaya kungahlukaniswa ngezinhlobo ezimbili: isondo lokugaya elinomugqa owodwa kanye nesondo lokugaya elinemigqa eminingi. Ukunemba kwephimbo okutholwe ngokugaya kwesondo lomugqa owodwa kungamabanga ama-5 kuye kwasi-6, kanti ubulukhuni obungaphezulu bungama-microns angu-R1.25 kuya ku-0.08, okulungele kangcono ukugqoka isondo lokugaya. Le ndlela ilungele ukugaya izikulufu ezinembayo, izikali zentambo, izikelemu, amaqoqo amancane ezinto zokusebenza ezinentambo, kanye nezinsimbi zokunemba zokugaya. I-Multi-line grinding wheel grinding ihlukaniswe yaba izindlela zokugaya ze-longitudinal kanye ne-plunge. Endleleni yokugaya i-longitudinal, ububanzi besondo lokugaya buncane kunobude bentambo okufanele igaywe, futhi isondo lokugaya lihamba ngobude kanye noma izikhathi eziningana ukuze ligaye intambo ifinyelele ubukhulu bokugcina. Ububanzi besondo lokugaya lendlela yokugaya bukhulu kunobude bentambo okufanele igaywe. Isondo lokugaya lisikwa ngokukhazimulayo ebusweni bomsebenzi, futhi ucezu lokusebenzela lungagaywa kahle ngemuva kokuphenduka okungaba ngu-1.25. Ukukhiqiza kuphezulu, kodwa ukunemba kuphansi kancane, futhi ukugqoka kwamasondo okugaya kuyinkimbinkimbi. I-Plunge grinding ilungele ukugaya amaqoqo amakhulu ompompi kanye nokugaya imicu ethile ukuze kuqiniswe.izingxenye ze-aluminium extrusion

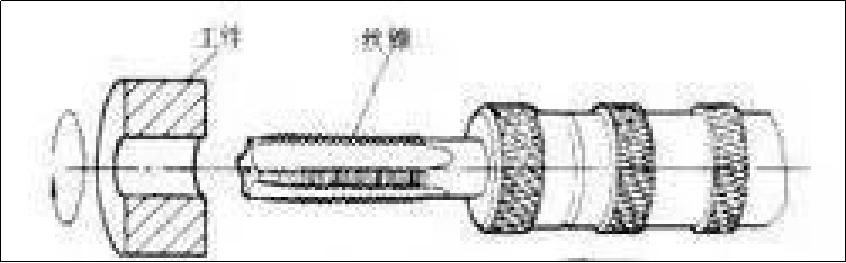

4. Ukugaya intambo

Igrinder yentambo yohlobo lwamantongomane noma isikulufu senziwe ngezinto ezithambile ezifana nensimbi ecijile, futhi izingxenye lapho intambo inephutha lephimbo kucezu lokusebenza zingaphansi kokugaya okuzungezisayo okuya phambili nokuhlehliswa ukuze kuthuthukiswe ukunemba kwephimbo. Imicu yangaphakathi eqinile ivamise ukuba phansi ukuze kuqedwe ukuwohloka nokuthuthukisa ukunemba.

5. Ukuthepha nokucupha

Ukuthepha

Kuwukufifiyela umpompi embotsheni engaphansi ebhojwe ngaphambili endaweni yokusebenza ngetorque ethile ukuze kucutshungulwe umucu wangaphakathi.

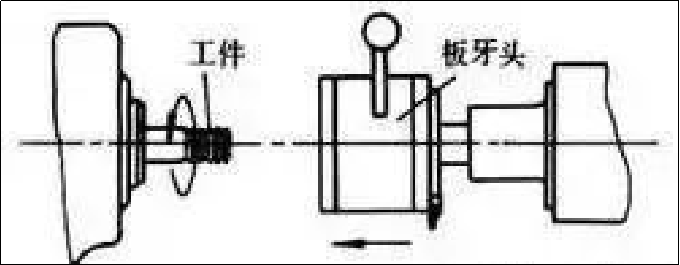

Uchungechunge

Sika intambo yangaphandle kubha (noma ipayipi) ucezu lokusebenzela ngedayizi. Ukunemba komshini wokuthepha noma ukuthunga kuncike ekunembeni kompompi noma ukufa.izingxenye ze-aluminium

Nakuba ziningi izindlela zokucubungula imicu yangaphakathi neyangaphandle, imicu yangaphakathi enobubanzi obuncane ingacutshungulwa kuphela ngompompi. Ukuthepha nokuhlanganisa kungenziwa ngesandla, nangezintambo, imishini yokubhoboza, imishini yokucofa, nemishini yokululela.

Isigaba sesibili: Ukugingqa uchungechunge

Indlela yokucubungula yokuguqula i-workpiece nge-plastically rolling die ukuze uthole intambo. Ukugingqa uchungechunge ngokuvamile kwenziwa emshinini wokugoqa Uchungechunge noma i-lathe ezenzakalelayo enekhanda eligoqayo elizenzakalelayo lokuvula nokuvala, intambo yangaphandle yokukhiqizwa ngobuningi kwezibophelelo ezijwayelekile, nokunye ukuhlanganisa okunentambo. Ububanzi bangaphandle bochungechunge olugoqiwe alukho ngaphezu kuka-25 mm, ubude abukho ngaphezu kwe-100 mm, ukunemba kwentambo kungafinyelela ezingeni 2 (GB197-63), futhi ububanzi bendawo engenalutho esetshenzisiwe bucishe bulingane nobubanzi bephimbo. Yochungechunge olucutshunguliwe. I-RTthread ngokuvamile ayikwazi ukucubungula imicu yangaphakathi, kodwa kuma-workpieces anezinto ezithambile, umpompi we-extrusion ongena-grooveless ungasetshenziswa ukukhipha izintambo zangaphakathi ezibandayo (ubukhulu bobukhulu bungafinyelela cishe ku-30 mm). Umgomo wokusebenza uyafana nowokucofa. I-torque edingekayo ekukhipheni okubandayo kwemicu yangaphakathi icishe ibe yinkulu ngokuphindwe ka-1 kunaleyo yokuthepha, futhi ukunemba komshini kanye nekhwalithi yendawo ephezulu iphakeme kancane kunaleyo yokuthepha.

Izinzuzo zokugoqa uchungechunge:

①Ubunzima obungaphezulu buncane kunobo bokuphenduka, ukugaya, nokugaya;

②Ingaphezulu le-Thread afThreadlling lingathuthukisa amandla nobulukhuni ngenxa yokuqina komsebenzi obandayo;

③Izinga lokusetshenziswa kwempahla liphezulu;

④Ukukhiqiza kuphindwe kabili uma kuqhathaniswa nokusika, futhi kulula ukuqaphela okuzenzakalelayo;

⑤ Impilo ye-rolling die yinde kakhulu. Nokho, i-Rolling Thread reThread ukuthi ubulukhuni bempahla yokusebenza abudluli i-HRC40; ukunemba kobukhulu bokungenalutho kuphezulu; ukunemba nobulukhuni befa eligoqayo nakho kuphezulu, futhi kunzima ukwenza idayizi; ayifanelekile ukugoqa izintambo ezine-asymmetric tooth shape.

Ngokusho kokufa okuhlukile, i-Thread ingahlukaniswa ngezinhlobo ezimbili: I-Thread rolling kanye ne-Threadthreadd.

6. Ukugingqa intambo

Amapuleti amabili okugoqa intambo anezimo zezinyo elinentambo ahlelwe ngokuphambene nomunye nge-pitch 1/2; ipuleti elimile lilungisiwe, futhi ipuleti elinyakazayo lihamba ngomugqa ophindaphindayo onyakazayo ngokuhambisana nepuleti elimile. Lapho i-workpiece ithunyelwa phakathi kwamapuleti amabili, ipuleti elinyakazayo liya phambili futhi lihlikihla isiqeshana sokusebenza ukuze siwohloke ngokwepulasitiki indawo engaphezulu ukuze yakhe intambo (Umfanekiso 6 [Isikulufa]).

7. Ukugingqa intambo

Kunezinhlobo ezintathu ze-radial Thread roThread, i-tangential Thread roThread, kanye ne-rolling head thread rolling.

①I-Radial Threathreadad 2 (noma 3) amasondo agoqa uchungechunge anamaphrofayili entambo afakwa kumashafti ahambisanayo; i-workpiece ibekwe ekusekelweni phakathi kwamasondo amabili, futhi amasondo amabili ajikeleza ngendlela efanayo nangesivinini esifanayo (Umfanekiso 7). [I-Radial Thread rolling]), enye yamarounds, futhi yenza ukunyakaza kokuphakelayo kwe-radial. Isondo eligoqa intambo lizungezisa ucezu lokusebenza, futhi indawo engaphezulu ikhishwe ngokukhanya ukuze kwakheke imicu. Kwezinye izikulufu zokuhola ezingadingi ukunemba okuphezulu, indlela efanayo ingasetshenziswa futhi ekwenzeni umqulu.

②I-Tangential Thread roThread Eyaziwa nangokuthi i-planetary Thread roThread, ithuluzi eligoqayo liqukethe isondo elijikelezayo elimaphakathi elizungezayo kanye namapuleti entambo amathathu amile amise okwe-arc (Fig. 8 [Tangential Thread rolling]). I-workpiece ingaphakelwa ngokuqhubekayo ngesikhathi sentambo ye-Thread, ngakho-ke ukukhiqiza kuphakeme kunaleyo ye-Thread roThreadand nentambo ye-radial Thread

③ Uchungechunge luphindwe kabusha: lwenziwa nge-automatic lathe futhi ngokuvamile lusetshenziselwa ukucubungula imicu emifushane endaweni yokusebenza. Kunamasondo aginqikayo angu-3 kuya ku-4 asakazwa ngokulinganayo endaweni engaphandle yendawo yokusebenza ekhanda eligoqayo (Fig. 9 [Uchungechunge oluphindwe kabusha lokugoqa]). Ngesikhathi sokugoqa intambo, i-workpiece iyazungeza, futhi ikhanda eligoqayo liphakela i-axially ukuze likhiphe ucezu lomsebenzi ku-Thread.

Ukuthunga intambo

Ukucutshungulwa kwemicu evamile ngokuvamile kusebenzisa izikhungo zomshini noma imishini yokuthepha namathuluzi; ngezinye izikhathi, ukuthepha ngesandla nakho kuyenzeka. Kodwa-ke, kwezinye izimo ezingavamile, le ndlela engenhla akulula ukuthola imiphumela emihle yokucubungula, njengesidingo somshini wezintambo ngemva kokwelashwa kokushisa kwezingxenye ngenxa yokunganaki noma ngenxa yezinkinga zezinto ezibonakalayo, njengesidingo sokuthinta ngokuqondile ama-workpieces e-carbide. . Ngalesi sikhathi, kuyadingeka ukucabangela indlela yokucubungula i-pEDM.

Uma kuqhathaniswa nendlela yomshini, inqubo ye-EDM ilandelana okufanayo: imbobo engezansi idinga ukubhobozwa kuqala, futhi ububanzi bomgodi ophansi kufanele bunqunywe ngokuvumelana nezimo zokusebenza. I-electrode idinga ukwenziwa ngomshini ibe umumo wentambo, futhi i-electrode idinga ukukwazi ukujikeleza phakathi nenqubo yomshini.

I-Anebon Metal Products Limited inganikeza i-CNC Machining, i-Die Casting, isevisi yokwenziwa kwe-Sheet Metal, sicela ukhululeke ukuxhumana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Isikhathi sokuthumela: Apr-15-2022