Uyazi ukuthi zingaki izindlela ezikhona zokusetha ithuluzi okunembile kumalebula e-CNC?

I-Touch Probe Method: - Le ndlela isebenzisa i-probe ethinta ithuluzi ukukala indawo yalo uma iqhathaniswa nendawo eyireferensi yomshini. Inikeza idatha enembile ngobubanzi bethuluzi nobude.

Ithuluzi Lokusetha ngaphambilini:Ithuluzi le-pre-setter lisetshenziselwa ukukala ubukhulu bethuluzi ngaphandle komshini. Le ndlela ivumela ukusethwa okusheshayo nokunembile kwethuluzi.

Indlela ye-Offset yethuluzi:– Ngale ndlela, u-opharetha ukala ubude nobubanzi bethuluzi esebenzisa amathuluzi afana nama-caliper nama-micrometer. Amanani abe esefakwa ohlelweni lokulawula lomshini.

I-Laser Tool Measurement:Amasistimu e-laser asetshenziselwa ukusetha nokulinganisa ubukhulu bamathuluzi. Ngokuveza umsebe wokukhanya kwe-laser onqenqemeni lwethuluzi, bahlinzeka ngedatha yamathuluzi enembile nesheshayo.

Indlela Yokuqaphela Isithombe:Amasistimu ekhompyutha athuthukisiwe angasebenzisa ubuchwepheshe bokubona isithombe ukuze abale ngokuzenzakalelayo ubukhulu bamathuluzi. Lokhu bakwenza ngokuthatha izithombe zethuluzi, bahlaziye izici zalo bese bebala izilinganiso.

Lesi isihloko esiwusizo kakhulu. I-athikili yethula kuqala izimiso nemibono ngemuva “kwendlela yokumisa ithuluzi lokusika isilingo” evame ukusetshenziswa ngezinsimbi ze-CNC. Ibe sethula izindlela ezine zamanuwali zezilungiselelo zamathuluzi okusika isilingo zezinhlelo zokuphendula ze-CNC. Ukuze kuthuthukiswe ukunemba kwezilungiselelo zayo zamathuluzi, kwasungulwa uhlelo olulawula indlela yokusika isilingo esizenzakalelayo esekelwe “ekunqumeni okuzenzakalelayo – ukukala – ukunxeshezelwa kwamaphutha”. Izindlela ezine ezinembile zokusetha amathuluzi nazo zifinyeziwe.

1. Isimiso nemibono ngemuva kwendlela yokusethwa kwamathuluzi yezintambo ze-CNC

Ukuqonda izimiso zokusethwa kwamathuluzi e-CNC lathe kubalulekile kubaqhubi abafuna ukugcina imibono ecacile mayelana nokusethwa kwamathuluzi, ukusebenza kahle kokusetha amathuluzi, nokuphakamisa izindlela ezintsha. Ukulungiselelwa kwethuluzi ukunquma indawo yomsuka yesistimu yokuxhumanisa ucezu lokusebenza, olushintshayo lapho kuhlelwa uhlelo lwethuluzi lomshini lokuxhumanisa. Ukulungiselelwa kwethuluzi kuhilela ukuthola izixhumanisi zomshini lapho kuqalwa khona uhlelo lwethuluzi eliyinkomba, nokunquma i-offset yamathuluzi ngokuhlobene nalelo thuluzi.

Izimiso ezilandelayo zisetshenziselwa ukukhombisa imiqondo nemibono ngemuva kokuhlelwa kwethuluzi kusetshenziswa indlela yokusika isilingo. Sebenzisa i-Hua Medieval Star Teaching Turning System (inguqulo engu-5.30 yesofthiwe yohlelo lokusebenza); sebenzisa isikhungo sobuso bokuphela kwesokudla kucezu lokusebenza ukuze uthole imvelaphi yohlelo bese ulumisa ngomyalo we-G92. Ukuhlelwa kobubanzi, izixhumanisi ze-workpiece yephoyinti lokuqala lohlelo ngu- (100,50); faka amathuluzi amane kwisibambi samathuluzi. Ithuluzi elingu-No.1 liyithuluzi elishintshashintshayo elingu-90deg futhi ithuluzi elingu-No. Reference 2 liyithuluzi lokuphendula kahle lendingilizi elingu-90deg. ummese, No. No. Ummese wesi-4 umbese onentambo engunxantathu one-engeli engu-60deg (izibonelo eziku-athikili ziyafana).

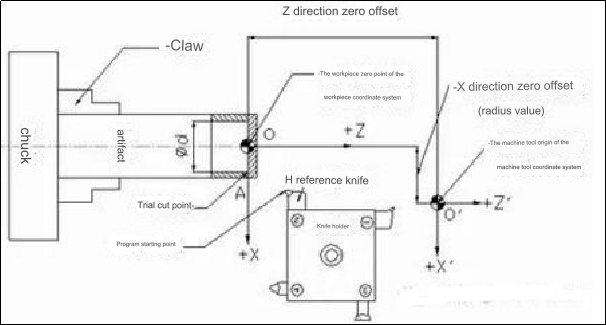

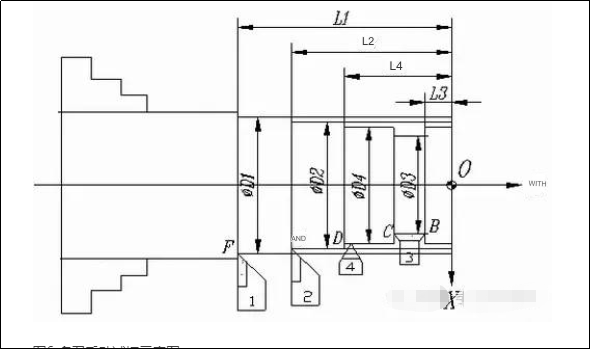

Izixhumanisi "zethuluzi lomshini" zisetshenziselwa ukulungiselelwa kwamathuluzi. Njengoba kuboniswe emfanekisweni 1, ithuluzi lereferensi “ukuhlola mathupha kusika indingilizi yangaphandle kanye nobuso bokugcina bocezu lokusebenza futhi kurekhode izixhumanisi zethuluzi lomshini we-XZ esibonisini. Izixhumanisi zethuluzi lomshini zomsuka wohlelo O zithathwe ebudlelwaneni obuphakathi kwezixhumanisi zethuluzi lomshini endaweni ethi A ne-O: XO=XA – Phd, ZO=ZA. Ngokusebenzisa izixhumanisi ze-workpiece ka-H ngokuphathelene nephoyinti u-O (100,50), ekugcineni singakwazi ukuthola izixhumanisi zamathuluzi omshini zephoyinti H: XH=100 – Phd, ZH=ZA+50. Lolu hlelo lokuxhumanisa ucezu lokusebenza lusekelwe endaweni yethiphu yethuluzi ethuluzini lereferensi.

Umfanekiso 1 Umdwebo weSkimu wokusika isilingo sesandla kanye nezilungiselelo zamathuluzi

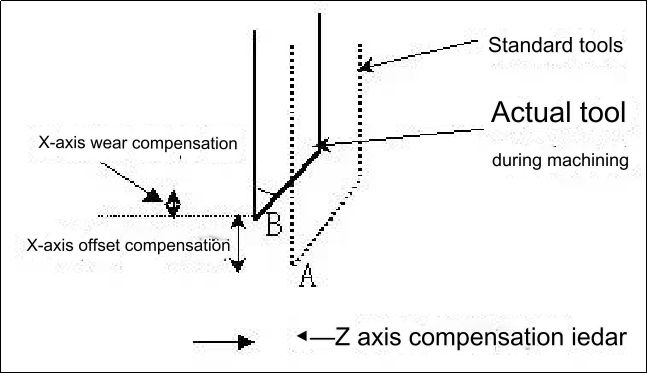

Emfanekisweni 2, ukulinganisa phakathi kwephoyinti A kanye nethiphu yethuluzi B kwenzeka ngenxa yokuhluka kwezandiso nezikhundla kusiqondisindlela sika-X no-Z samathuluzi aboshelwe kumphathi wamathuluzi. Isistimu yokudidiyela yasekuqaleni yocezu lokusebenza ayisasebenzi. Ithuluzi ngalinye lizophinde ligqoke ngenani elihlukile ngesikhathi lisetshenziswa. Ngakho-ke, ithuluzi linciphisa futhi amanani okugqoka ethuluzi ngalinye kufanele anxeshezelwe.

Ukuze unqume i-offset yethuluzi, ithuluzi ngalinye kufanele liqondaniswe nendawo ethile yokubhekisela (iphuzu A noma B ku-Figure 1) ku-workpiece. I-CRT ibonisa izixhumanisi zamathuluzi omshini ahlukile kumathuluzi angasetshenziswa amathuluzi angewona amareferensi. Ngakho-ke, zibekwe endaweni efanayo. Ngokusebenzisa izibalo mathupha noma izibalo zesofthiwe, izixhumanisi zethuluzi lomshini zikhishwa kulezo zethuluzi lereferensi. I-offset yamathuluzi ibe isibalelwa idivayisi ngayinye engajwayelekile.

Umfanekiso 2 Isinxephezelo sokususwa kwamathuluzi nokuguga

Ukunemba kwezilungiselelo zamathuluzi okusika isilingo okwenziwa ngesandla kunomkhawulo. Lokhu kwaziwa ngokuthi ukusebenzisa ama-rough tooling. Njengoba kukhonjisiwe kuMfanekiso 3, ukuze kuzuzwe imiphumela enembe kakhudlwana ngaphakathi kwezibonelelo zomshini wecnc ingxenye ye-auto, uhlelo olulula lokusika isilingo esizenzakalelayo lungaklanywa. Ummese wereferensi ulungiswa ngokuqhubekayo kusetshenziswa umqondo "wesinxephezelo sephutha lokusika-othomathikhi". I-offset yamathuluzi nendawo yokuqala yohlelo yethuluzi elingelona ireferensi kusetshenziselwa ukwenza isiqiniseko sokuthi umehluko phakathi kwevelu yomyalelo wokucubungula kanye nevelu elilinganisiwe langempela lihlangabezana nezidingo zokunemba. Ukusetha ithuluzi lokunemba kuyilungiselelo lethuluzi elenzeka kulesi sigaba.

Kuvamile ukulungisa ama-offset angajwayelekile ngemva kokulungiswa kokuqala. Lokhu kungenxa yokuthi ukuqinisekisa ukuthi indawo lapho ithuluzi eliyinkomba iqala khona inembile kuyimfuneko yokulungisa amathuluzi anembile.

Le nqubo yokusetha ithuluzi eliyisisekelo ifinyelelwa ngokuhlanganisa lezi zigaba ezimbili: ukuhlola mathupha ukusika ummese ngereferensi ukuze uthole izixhumanisi zamathuluzi omshini wenkomba yesilungiselelo samathuluzi. - Bala noma ubale ngokuzenzakalelayo ama-offset amathuluzi ethuluzi ngalinye elingelona ireferensi. - Ummese wereferensi utholakala ekuqaleni kohlelo. - Ummese wereferensi ubiza ngokuphindaphindiwe uhlelo lokusika ukuhlolwa. Isiphathi samathuluzi sizohanjiswa nge-MDI noma kumodi yesinyathelo ukuze kunxeshezelwe amaphutha futhi kulungiswe indawo lapho kuqalwa khona. Ngemva kokulinganisa usayizi ummese ongeyona isisekelo uzobiza ngokuphindaphindiwe uhlelo lokusika ukuhlolwa. I-offset yamathuluzi iyalungiswa ngokusekelwe kulokhu. Lokhu kusho ukuthi ithuluzi lereferensi lizobe limile ekuqaleni kohlelo.

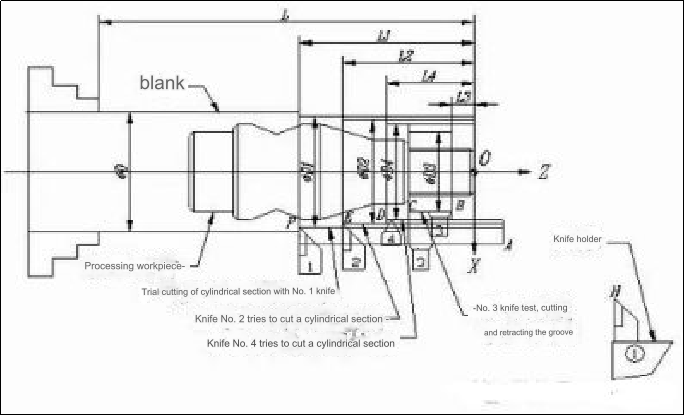

Umfanekiso wesi-3 Umdwebo Wezinhlelo Zokusethwa Kwethuluzi Lokusika Isivivinyo Semimese Eminingi

Uhlolojikelele lwamasu okusetha ummese omangelengele

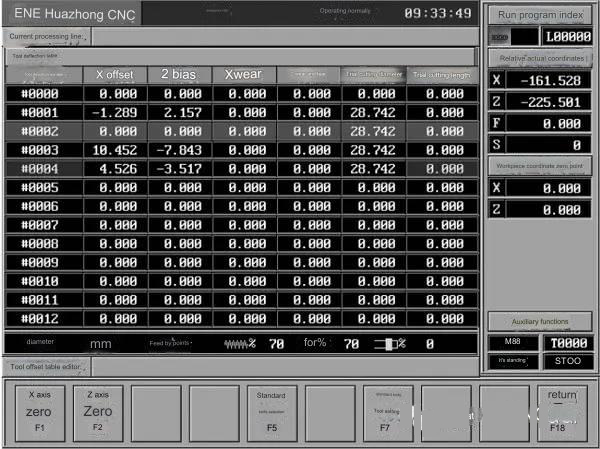

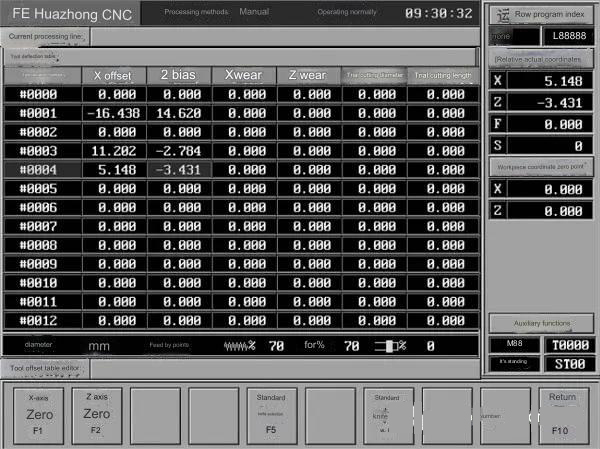

Ukuze ulungiselele ukusethwa kwamathuluzi, ungasebenzisa noma iyiphi kulezi zindlela ezilandelayo: cindezela ukhiye F2 kumenyu engaphansi ye-MDI yohlelo ukuze ufinyelele ithebula le-tool offset. Sebenzisa izinkinobho ukuhambisa ibha yokugqamisa endaweni yenombolo yethuluzi ehambisana nethuluzi ngalinye bese ucindezela inkinobho ethi F5. Shintsha amanani e-offset X kanye no-Z ezinombolo ze-offset zethuluzi #0000 kanye ne-#0001, bese ucindezela inkinobho ethi F5.

1) Setha ngokuzenzakalelayo indlela yokusetha ithuluzi ngokukhetha ithuluzi lereferensi.

Izinyathelo zokusetha ithuluzi ziboniswa kuMfanekiso 1 no-4.

Ibha eluhlaza okwesibhakabhaka egqanyiswe ngokhiye inganyakaziswa ukuze iqondanise ithuluzi le-offset #0002 lethuluzi lesithenjwa elingunombolo 2. Ithuluzi lereferensi 2. Ukusetha uNo.2, cindezela inkinobho ethi F5. Ithuluzi le-2 lizosethwa njengethuluzi elizenzakalelayo.

2) Sika umbuthano wangaphandle ngethuluzi lereferensi futhi uqaphele izixhumanisi zethuluzi lomshini we-X. Ngemva kokuhoxisa ithuluzi, misa umshini bese ukala ububanzi bangaphandle bengxenye ye-shaft.

3) I-reference blade ibuyela endaweni A eqoshwe indlela "yokugijima+isinyathelo". Faka i-PhD kanye noziro kumakholomu wobubanzi obunqunyiwe bokuhlolwa kanye nobude bokusika bokuhlolwa ngokulandelana.

4) Hoxisa ithuluzi elijwayelekile bese ukhetha inombolo yethuluzi elingajwayelekile. Bese, shintsha ithuluzi ngesandla. Ithiphu yethuluzi yethuluzi ngalinye elingajwayelekile kufanele liqondaniswe ngokubukeka nephuzu A kusetshenziswa indlela “yokugijima+isinyathelo”. Lungisa i-offset ehambisanayo ngemuva kokuthi ithuluzi liqondaniswe ngokubonakalayo. Uma ufaka uziro kanye ne-PhD kumakholomu obude nobubanzi bokusika kwesilingo, ama- knife offset ayo yonke imimese engeyona ireferensi azovezwa ngokuzenzakalelayo kukholamu ye-X offset kanye no-Z.

5) Uma ithuluzi lesithenjwa selibuyele endaweni A, i-MDI izosebenzisa i-“G91 G00/noma” G01 X[100 PhD] Z50 ukuze ifike lapho uhlelo luqala khona.

Umfanekiso 4 Umdwebo weSkimu wethuluzi lereferensi usetha ngokuzenzakalela i-offset yethuluzi lethuluzi elijwayelekile

2. Setha izixhumanisi zethuluzi lereferensi zibe ziro endaweni yereferensi yokusetha ithuluzi futhi ubonise ngokuzenzakalelayo indlela yokususa ithuluzi.

Njengoba kukhonjisiwe kuMfanekiso 1 nakuMdwebo 5, izinyathelo zokusetha ithuluzi zimi kanje:

1) Ngokufanayo nesinyathelo (2) ngenhla.

2) Ummese wereferensi ubuyela endaweni yokusika yesilingo A ngokusebenzisa indlela “ye-jog + step” ngokwenani elirekhodiwe.

3) Ku-interface eboniswe kuMfanekiso 4, cindezela ukhiye we-F1 ukuze "ukusetha i-X-axis ibe yiziro" bese ucindezela ukhiye we-F2 "ukusetha i-axis ku-zero". Bese “izixhumanisi zangempela ezihlobene” eziboniswa yi-CRT zithi (0, 0).

4) Guqula mathupha ithuluzi elingelona ireferensi ukuze ithiphu lethuluzi lalo liqondaniswe ngokubonakalayo nephoyinti A. Ngalesi sikhathi, inani "lezixhumanisi zangempela ezihlobene" eziboniswa ku-CRT liwukusuka kwethuluzi kwethuluzi elihlobene nethuluzi lereferensi. Sebenzisa u-▲ nezikhiye ukuze uhambise okuluhlaza okwesibhakabhaka Gqamisa inombolo yethuluzi elingelona ireferensi, ulirekhode bese ulifaka endaweni efanayo.

5) Ngokufanayo nesinyathelo sangaphambilini (5).

Umfanekiso 5 Umdwebo Weskimu We-offset Yethuluzi uboniswa ngokuzenzakalelayo lapho Ithuluzi Lereferensi lisethelwe kuqanda kumaphoyinti ereferensi wesethingi yamathuluzi.

3. Indlela yokususa ummese ibalwa ngokubala ngesandla ukusika kwesilingo ngemimese eminingi yengxenye ye-shaft eyindilinga yangaphandle.

Njengoba kuboniswe emfanekisweni wesi-6, uhlelo luqondanisa imimese 1, 2 kanye no-4 bese lusika i-eksisi. Ibe isirekhoda izixhumanisi zomshini zeziphetho zokusika zommese ngamunye. (Amaphuzu F, D, kanye no-E emfanekisweni wesi-6). Kala ububanzi nobude besegimenti ngayinye. Faka esikhundleni ummese wokusika ongu-1. Njengoba kuboniswe esithombeni, nqamula ikhefu lamathuluzi. Qondanisa i-blade yokusika nethiphu elifanele, rekhoda izixhumanisi zephuzu B bese ukala i-L3 ne-PhD3 ngokomfanekiso. Ubudlelwano obukhulayo bokuxhumanisa phakathi kwamaphoyinti ka-F, E kanye no-D ethuluzi ngalinye, kanye nomsuka we-O bunganqunywa ngokuqhathanisa idatha engenhla.

Kungase kubonakale ukuthi izixhumanisi zamathuluzi omshini yilezi (X2-PhD2+100 kanye ne-Z2-L2+50) kanye nezixhumanisi zamathuluzi omshini endaweni yokuqala yohlelo ehambisana nethuluzi eliyinkomba. Indlela yokubala ikhonjiswe kuthebula 1. Ezikhaleni, faka amanani abaliwe futhi aqoshiwe. Qaphela: Ibanga lokusika isilingo yibanga eliphakathi kwephoyinti lokuhlanganisa elinguziro lesiqephu sokusebenza kanye nendawo yokugcina yesilingo esisikwe ku-Z-direction. Izikhombisi-ndlela ezinhle nezingezinhle zinqunywa i-eksisi yokuxhumanisa.

Umfanekiso 6 Umdwebo ohleliwe wokusika isilingo sesandla semimese eminingi

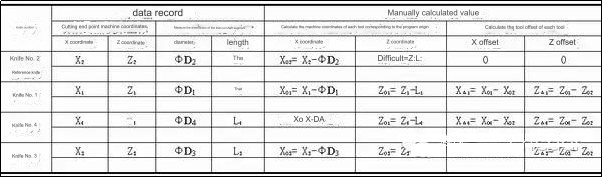

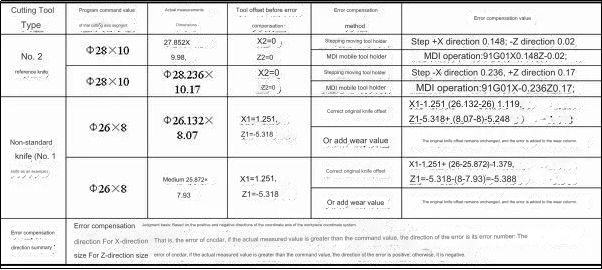

Ithebula 1 Ukubalwa kokususwa kwamathuluzi kumathuluzi angajwayelekile

Le ndlela ivumela inqubo yokusika yokuhlola elula, njengoba iqeda isidingo sokuvumelanisa ngokubonakalayo amaphuzu okusika ukuhlolwa. Nokho, i-offset yommese kufanele ibalwe ngesandla. Ungakwazi ukubala i-offset yethuluzi ngokushesha uma uphrinta ishidi ngefomula bese ugcwalisa izikhala.

Umfanekiso 7 Umdwebo weSchematic wokusetha ithuluzi elizenzakalelayo ohlelweni lwe-Century Star CNC

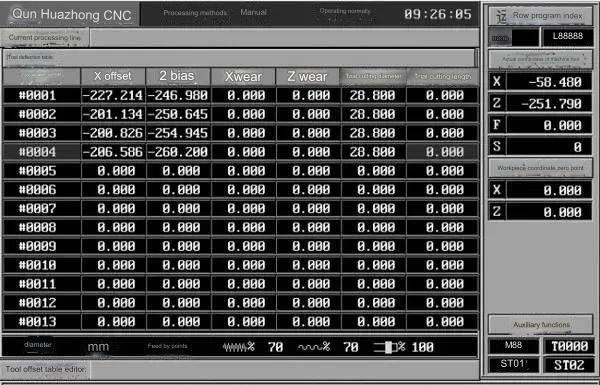

Indlela yokusetha ithuluzi elizenzakalelayo lamathuluzi amaningi wohlelo lwe-4th Century Star CNC

Zonke lezi zindlela ezibalulwe ngenhla ze-tool offset ziyizindlela ezihambisanayo. Ngemuva kokuthi abasebenzi abangochwepheshe benze ukulungiselelwa kwepharamitha kanye nokuhlola uhlelo, i-HNC-21T ivumela abasebenzisi ukuthi bakhethe "indlela yokuqeda ngokuphelele" lapho besetha amathuluzi. Ekuhlelweni komshini, i-offset yethuluzi eliphelele ihluke kancane kunendlela yokuvala ithuluzi elihlobene. Akudingekile ukusebenzisa i-G92 noma i-G54 kumasistimu wokuxhumanisa i-workpiece, futhi akudingekile ukukhansela isinxephezelo samathuluzi. Bheka uhlelo O1005 njengesibonelo. Njengoba kuboniswe kuMfanekiso 6, ngemva kokuba uhlelo lubuyela kuqanda, ummese ngamunye mawuzame mathupha ukusika ingxenye yesilinda.

Gcwalisa izinombolo ze-offset zamathuluzi zommese ngamunye ngemva kokukala ubude nobubanzi. Ubude bokusika kwesilingo bufakwe ohlwini lwekholomu yobubanzi bokusika kwesilingo. Isofthiwe yesistimu, isebenzisa indlela echazwe ku-"Multiknife Cutting of External Shaft Segment - Manual Calculation for Knife Offset", ingabala ngokuzenzakalelayo izixhumanisi zethuluzi lomshini lommese ngamunye ngokuya ngomsuka wohlelo. Le ndlela yokusetha ithuluzi ishesha kakhulu, futhi ifaneleka ngokukhethekile ukukhiqizwa kwezimboni.

Isifinyezo samasu amahlanu anembile wokusetha amathuluzi

Umgomo wokusetha ithuluzi okunembayo “ukulinganisa okuzenzakalelayo, ukusika okuzenzakalelayo kwesilingo kanye nesinxephezelo samaphutha”. Isinxephezelo sephutha singahlukaniswa ngezigaba ezimbili: Okokusebenza kwethuluzi lereferensi le-MDI, noma isinyathelo sokuthumela ithuluzi elinyakazayo ukuze kunxeshezelwe indawo yalo yokuqala yohlelo; kanye nethuluzi elingajwayelekile lokunxephezela amanani alo okunciphisa noma okugqoka. Ukuze kugwenywe ukudideka, Ithebula 2 lenzelwe ukubala futhi lirekhode amanani.

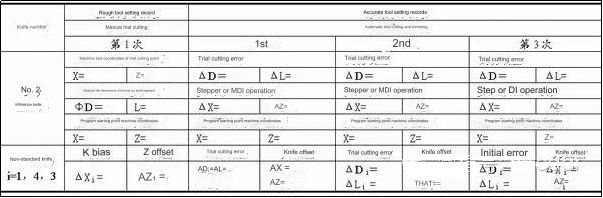

Ithebula 2 Ithebula Lokusetha Ithuluzi Lokuqopha Lendlela Yokusika Isilingo (Iyunithi: mm

1. Lungisa indlela ye-offset yethuluzi ngalinye elingajwayelekile ngemva kokuba ithuluzi eliyinkomba selilungise indawo yokuqala.

Izinyathelo zokusetha ithuluzi ziboniswe kuMfanekiso 3.

Ngemuva kokulinganisa ithuluzi elinzima, ithuluzi lereferensi kufanele libe ekuqaleni kohlelo. Faka i-offset yawo wonke amathuluzi angajwayelekile endaweni efanele yethebula.

Sebenzisa uhlelo lwe-O1000 ukucubungula i-PhD2xL2 ukuze usike isilingo.

Khona-ke, linganisa ububanzi kanye nobude be-shaft yokusika ehlukanisiwe, uqhathanise nenani kuhlelo lomyalo, futhi unqume iphutha.

Shintsha indawo yokuqala yohlelo uma inani lephutha le-MDI noma ukunyakaza kwesinyathelo likhulu kunevelu yephutha le-MDI.

5) Shintsha inani lomyalo we-O1000 ngokuguquguqukayo ngokusekelwe kubukhulu obulinganisiwe futhi ulondoloze uhlelo. Phinda izinyathelo (2) kuze kube yilapho indawo yokuqala yethuluzi eliyinkomba isingaphakathi kwebanga lokunemba. Qaphela izixhumanisi zethuluzi lomshini endaweni yokuqala yohlelo olulungisiwe. Setha izixhumanisi kokuthi ziro.

6) Shayela i-O1001(ummese inombolo. 1, No. O1002 (ummese inombolo. 3) ukuze usike isilingo ngasinye, futhi ulinganise ubude u-Li (i=1, 2, 3) nobubanzi be-PhDi besigaba ngasinye.

7) Buyekeza amaphutha usebenzisa indlela yethebula 3.

Phinda izinyathelo 6 kuye ku-7 kuze kube yilapho amaphutha omshini engaphakathi kwebanga lokunemba futhi ithuluzi lesithenjwa limiswa ekuqaleni kohlelo futhi linganyakazi.

Ithebula 3 Isibonelo sesinxephezelo sephutha sokusikwa kwesilingo esizenzakalelayo sezingxenye ze-cylindrical shaft (iyunithi: mm).

2. Ukushintsha indawo yokuqala yethuluzi ngalinye

Umgomo wale ndlela wokusetha ithuluzi ukuthi ithuluzi ngalinye lilungisa indawo yalo yokuqala yohlelo, ngaleyo ndlela liqondaniswe ngokungaqondile nendawo efanayo yomsuka.

Izinyathelo zokusetha ithuluzi ziboniswe kuMfanekiso 3.

Ngemva kokulinganisa ithuluzi elimahhadlahhadla, inombolo. Ngemva kokulinganisa ithuluzi elinzima nokurekhoda ama-offset, ithuluzi lesithenjwa esingunombolo 2 kufanele libe ekuqaleni kohlelo.

Izinyathelo 2) ukuya ku-(5) zendlela yokuqala enembile yokusetha ithuluzi ziyefana.

Sebenzisa uhlelo lwe-O1000 ukwenza ukusika kwesilingo. Linganisa ubude be-Li kanye nobubanzi be-PhDi besigaba ngasinye.

Ithuluzi lokunyakaza kwesinyathelo noma isibambi sethuluzi le-MDI sinxephezela amaphutha futhi silungise indawo yokuqala yohlelo lwethuluzi ngalinye.

Phinda izinyathelo (6) kuze kube yilapho indawo yokuqala yethuluzi ngalinye lohlelo elingajwayelekile ingaphakathi kwebanga lokunemba elivunyelwe.

Ithebula le-offset lamathuluzi lingafinyelelwa ngokufaka izixhumanisi ezihlobene eziboniswe ku-CRT kokuthi X offset kanye nekholomu ye-Z offset ehambisana nenombolo ye-offset yethuluzi. Le ndlela ilula futhi ilula. Le ndlela ilula futhi ifanelekile.

3. Lungisa zonke izindlela ze-offset zamathuluzi angajwayelekile ngesikhathi esifanayo ngemva kokulungisa indawo yokuqala yohlelo lwereferensi yamathuluzi.

Indlela iyafana neyeyokuqala enembile yokusetha ithuluzi. Umehluko kuphela phakathi kwalokhu okubili ukuthi esinyathelweni sesi-7, uhlelo lwe-O1003 lubizwa, olubiza imimese emithathu ngesikhathi esisodwa (i-O1004 isusa i-No. Uhlelo lwe-O1003 luthatha indawo yesigaba se-2 sokucubungula ithuluzi. Izinyathelo ezisele ziyafana.

6. Imimese emine ingalungiswa ngesikhathi esisodwa kusetshenziswa le ndlela

Ukuze uthole iphutha lomshini, kala ububanzi besigaba ngasinye, i-PhDi, nobude besigaba ngasinye, i-Li (i=2, 1, 4), usebenzisa indlela yokulinganisa ithuluzi. Sebenzisa i-MDI noma ukunyakaza okuhamba kancane uye kumphathi wamathuluzi wethuluzi lereferensi. Lungisa indawo yokuqala yohlelo. Ngamathuluzi angajwayelekile, qala ngokulungisa i-offset usebenzisa i-offset yoqobo. Bese, faka offset entsha. Iphutha lomshini wethuluzi lereferensi kufanele lifakwe kukholomu yokuguga. Shayela uhlelo lokusika isivivinyo lwe-O1005 uma ithuluzi eliphelele lisetshenziselwa ukulinganisa ithuluzi. Bese, unxephezela amaphutha omshini wamathuluzi kumakholomu okuguga wezinombolo zawo ezihlukene ze-offset.

Imuphi umthelela onawo ekukhetheni indlela yokusetha ithuluzi efanele ye-CNC lathes enakho kwikhwalithi yeIzingxenye zemishini ye-CNC?

Ukunemba nokunemba:

Amathuluzi okusika azoqondaniswa kahle uma ithuluzi lisethwe ngendlela efanele. Lokhu kuthinta ngokuqondile ukunemba nokunemba ekusebenzeni komshini. Ukulungiselelwa kwethuluzi okungalungile kungaholela kumaphutha obukhulu, ukuqedwa kwezindawo ezimbi, ngisho nokulahlwa.

Ukuvumelana:

Izilungiselelo zamathuluzi ezingaguquki ziqinisekisa ukufana kwemisebenzi yemishini kanye nekhwalithi engaguquki ezingxenyeni eziningi. Inciphisa ukuhlukahluka kokuphela kwendawo kanye nobukhulu, futhi isiza ukugcina ukubekezelelana okuqinile.

Impilo Yamathuluzi Nezingubo Zamathuluzi:

Ngokuqinisekisa ukuthi ithuluzi lisebenzisana kahle ne-workpiece, isilungiselelo esilungile samathuluzi singandisa impilo yamathuluzi. Izilungiselelo zamathuluzi ezingalungile zingabangela ukuguga ngokweqile nokuphuka kwamathuluzi, okuzonciphisa impilo yamathuluzi.

Ukukhiqiza kanye Nempumelelo

Amasu asebenzayo wokusetha amathuluzi anganciphisa isikhathi sokusetha umshini futhi andise isikhathi. Kwenyusa ukukhiqiza ngokunciphisa izikhathi zokungenzi lutho futhi kwandise isikhathi sokusika. Lokhu kuvumela izinguquko ezisheshayo zamathuluzi futhi kunciphisa isikhathi sokusebenza kwemishini.

Ukuphepha Komqhubi

Ukuphepha komsebenzisi kungathinteka ngokukhetha indlela efanele yokuhlela ithuluzi. Ezinye izindlela ezifana nokubonwa kwesithombe noma ukulinganisa ithuluzi le-laser ziqeda isidingo sokuphatha amathuluzi mathupha, kunciphisa amathuba okulimala.

Inhloso ye-Anebon ukuqonda ukonakala okuhle kakhulu okuvela embonini futhi inikeze ukusekelwa okuphezulu kumakhasimende asekhaya nawaphesheya ngenhliziyo yonke ngo-2022 Ikhwalithi Ephakeme Yensimbi Engagqwali Aluminium High Precision Custom MadeUkuphenduka kwe-CNC, Milling,cnc izingxenye eziseleye-Aerospace, Ukuze kwandiswe imakethe yethu yamazwe ngamazwe, i-Anebon ihlinzeka ngokuyinhloko amakhasimende ethu aphesheya kwezilwandle izingxenye zemishini ezisebenza kahle ezisezingeni eliphezulu, izingxenye ezigayiwe kanye nesevisi yokujika ye-cnc.

I-China wholesale China Machinery Parts kanye ne-CNC Machining Service, i-Anebon isekela umoya "wokusungula izinto ezintsha, ukuzwana, ukusebenza kweqembu nokwabelana, imikhondo, inqubekelaphambili ye-pragmatic". Sinike ithuba futhi sizobe sizokhombisa ikhono lethu. Ngosizo lwakho lomusa, i-Anebon ikholelwa ukuthi singakha ikusasa eliqhakazile nawe sindawonye.

Isikhathi sokuthumela: Oct-19-2023