Kungakanani okwaziyo ngayo yonke inqubo yokuhlanganisa imishini?

Ukuhlanganiswa komshini kuyinqubo yokuhlanganisa izingxenye ezihlukahlukene ukuze zakhe uhlelo olusebenzayo lwemishini noma umkhiqizo. Lokhu kuhlanganisa ukufunda nokuqonda imidwebo yobunjiniyela, ukukhetha nokusebenzisa amathuluzi afanelekile nezinto zokusebenza ukuze kulingane futhi kuqondiswe izingxenye, ukunamathisela izingxenye ngamasu ahlukahlukene (okufana nokufaka ibhawudi, okunamathelisa, noma ukushisela), kanye nokwenza izivivinyo zekhwalithi ukuze kuqinisekiswe ukusebenza okufanele. Izinqubo zokuhlanganisa zingahlelwa ngokwezidingo kanye nobunkimbinkimbi bomkhiqizo ngamunye.

Ukulungiselela umsebenzi wesikole

(1)Idatha Yokusebenza: ihlanganisa imidwebo yomhlangano ojwayelekile (GA), imidwebo yengxenye yomhlangano (CA), imidwebo yezingxenye (PD), izinhlu zezinto ze-BOM njll. Ukuphelela, ukuhlanzeka, nobuqotho bayo yonke inqubo yolwazi nemidwebo kufanele kugcinwe kuze kuphele ukwakhiwa iphrojekthi.

(2)Indawo yokusebenza: Indawo lapho izingxenye zibekwe khona futhi izingxenye zihlanganiswe kufanele zicaciswe. Kubalulekile ukuhlela indawo lapho uzohlangana khona futhi ubeke umshini wakho. Zonke izindawo zokusebenza kufanele zicoceke, zifane futhi zi-odwe kuze kube yilapho umsebenzi usuphothuliwe.

(3)Izinto zomhlangano. Izinto zokuhlanganisa kumele zibe sezilungile ngaphambi kokuhlinzwa. Uhlelo lwemisebenzi lungashintshwa uma izinto ezithile ezinganqunyelwe zingatholakali. Ifomu lokusheshisa impahla kufanele ligcwaliswe bese lithunyelwa emnyangweni wokuthenga.

(4)Ngaphambi komhlangano, kubalulekile ukuqonda isakhiwo, inqubo yokuhlanganisa kanye nezidingo zobuchwepheshe zemishini.

Ukucaciswa okuyisisekelo

(1) Umhlangano wemishini kufanele wenziwe ngokuhambisana ngokuqinile nemidwebo yomhlangano, izidingo zenqubo kanye nemiyalelo enikezwe ithimba lokuklama. Akuvunyelwe ukushintsha okuqukethwe komsebenzi ngaphandle kwemvume, noma ukushintsha izingxenye ngendlela engavamile.

(2) Izingxenye ezihlanganisiwe kufanele zibe izingxenye eziphumelele ukuhlolwa nokugunyazwa umnyango wokuqinisekisa ikhwalithi. Bika noma yiziphi izingxenye ezingafanelekile ezitholwe ngesikhathi somhlangano.

(3) Indawo yokuhlangana kufanele ingabi nothuli nokunye ukungcola. Izingxenye kufanele zigcinwe endaweni engenalo uthuli, eyomile futhi ivikelwe ngamaphedi.

(4) Izingxenye kumele zihlanganiswe ngaphandle kokungqubuzana, ukusikwa noma ukulinyazwa phezulu. Nokho, zingase zigobe, zisonteke noma zikhubazeke ngendlela ephawulekayo. Izindawo zokukhwelana nazo akumele zonakaliswe.

(5) Lapho uhlanganisa izingxenye ezihamba kancane, kuyalulekwa ukuthi wengeze amafutha okugcoba (amafutha) phakathi kwezindawo zokuthintana.

(6) Ubukhulu bezingxenye ezihambisanayo kufanele bube ncamashi.

(7) Izingxenye namathuluzi kufanele kubekwe ngendlela ekhethekile ngesikhathi sokuhlanganisa. Izingxenye namathuluzi akufanele kubekwe ngqo phezu noma phezu komshini. Uma kwenzeka ukuthi amacansi okuzivikela noma amakhaphethi adingekayo, kufanele abekwe endaweni yokubeka.

Eqinisweni, akuvunyelwe ukunyathela umshini ngesikhathi somhlangano. Uma kwenzeka kudingekile ukuhamba emshinini, amakhaphethi noma amacansi kufanele abekwe phezulu. Ukunyathela izingxenye ezibalulekile noma izingxenye ezingezona ezensimbi ezinamandla aphansi kwenqatshelwe ngokuphelele.

Joyina indlela

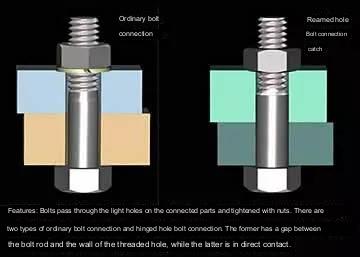

(1) Ukuxhumeka kwe-Bolt

A. Sebenzisa iwasha eyodwa kuphela inadi ngalinye lapho uqinisa amabhawodi. Amakhanda ezinzipho kufanele ashunyekwe ezingxenyeni zomshini ngemva kokuba isikulufu se-countersunk siqinisiwe.

B. Ngokuvamile ukuxhumana okunentambo kudinga amawasha alwa nokuxega. Indlela yokuqinisa amabhawodi amaningi alinganayo ukuwaqinisa kancane kancane futhi ngendlela elinganayo. Izixhumi ze-strip nazo ziqiniswa kancane kancane futhi ngokulinganayo ukusuka maphakathi kuya ngaphandle.

C. Uma izikulufo zingadingeki ukuba zihlakazwe ngesikhathi sokuqiniswa noma ukunakekelwa kwedivayisi ehambayo, kufanele ziboshwe nge-glue yentambo ngaphambi kokuhlanganiswa.

D. I-torque wrench isetshenziselwa ukuqinisa izinsimbi ezinezidingo zetorque ezicacisiwe. Ama-bolts ngaphandle kwe-torque ecacisiwe kufanele aqiniswe ngokuvumelana nemithetho "Isithasiselo".

(2) Phina uxhumano

A. Ngokuvamile, ubuso bokugcina bephinikhodi kufanele bube phezulu kancane kunobuso bephinikhodiizingxenye zokugaya. Isiphetho esikhulu sephinikhodi e-screw-tail tapered kufanele icwiliswe embobeni ngemva kokufakwa engxenyeni.

B. Imisila yephinikhodi ye-cotter kufanele ihlukane ngo-60deg kuya ku-90deg ngemva kokuba ilayishwe ezingxenyeni ezifanele.

(3) Ukuxhumana okubalulekile

A. Akumele kube negebe phakathi kwezindawo zokukhwelana zokhiye abayisicaba kanye nabagxilile.

B. Uma izingxenye ezihambayo zikakhiye noma i-spline zihanjiswa ohlangothini lwe-axial ngemva kokuhlanganisa, akufanele kube khona ukungalingani.

C. Ukhiye we-hook kanye nokhiye be-wedge kufanele bahlanganiswe ukuze indawo yabo yokuxhumana ingabi ngaphansi kuka-70% wendawo yonke yokusebenza. Izingxenye okungaxhunywana nazo akumele zihlanganiswe ndawonye, futhi ingxenye eveziwe akufanele ibe ngaphezu kuka-10% -15% ubude.

(4) Ukuhleka

A. Izinto kanye nokucaciswa kwe-riveting kufanele kuhambisane nezidingo zedizayini. Ukucutshungulwa kwezimbobo zama-rivets kufanele futhi kuhlangabezane nezindinganiso ezifanele.

B. Ingaphezulu le-rivetedizingxenye ze-aluminiumakumele ilimale noma ikhubazekile lapho i-riveting.

C. Akufanele kube nokuxega engxenyeni egobile, ngaphandle uma kunezidingo ezithile. Inhloko yama-rivets kumele ixhumane nengxenye e-riveted futhi ibushelelezi futhi iyindilinga.

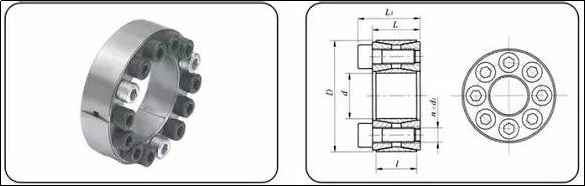

(5) Ukuxhumeka kwemikhono yokwandisa

Umhlangano womkhono wokunweba: Faka amafutha okugcoba kumkhono wokunweba, faka umkhono wokunweba embotsheni yehabhu ehlanganisiwe, faka umshini wokufaka, ulungise indawo yomhlangano, bese uqinisa amabhawodi. I-oda lokuqiniswa liboshwe ngokusikeka, futhi kwesokunxele nesokudla kuyaphambana futhi kuqiniswe ngokulinganayo ngokulandelana ukuze kuqinisekiswe ukuthi inani letorque elilinganiselwe liyafinyelelwa.

(6) Ukuxhumana okuqinile

Setha izikulufu ezinemiphetho eyikhonikhi kufanele zibe nesiphetho esicijile esingu-90-degree. Umgodi kufanele ube ngama-degree angama-90.

Ukufakwa kweziqondiso zomugqa

(1) Indawo yokufaka ujantshi womhlahlandlela kumele ibe isicaba futhi ingabi nokungcola.

(2) Uma umzila wesitimela unomkhawulo wereferensi, isitimela kufanele sifakwe eduze komkhawulo. Uma lungekho unqenqema lwereferensi, khona-ke isiqondiso sokuslayida kufanele sifane nezidingo zedizayini. Hlola isiqondiso sesilayidi ngemva kokuqinisa izikulufu kumzila wesitimela. Uma kungenjalo, izodinga ukulungiswa.

(3) Uma isilayidi siqhutshwa amabhande okudlulisa, khona-ke amabhande kufanele alungiswe futhi agxilwe ngaphambi kokuba ibhande lidonswe ngendlela ye-oblique. Uma kungenjalo, i-pulley kufanele ilungiswe ukuze kuqinisekiswe ukuthi indlela yokushayela yebhande ihambisana nomzila wesitimela.

Ukuhlanganiswa kwamaketanga e-sprocket

(1) I-sprocket kufanele yakhelwe ukusebenzisana ne-shaft.

(2) Amazinyo egiye kokubili ama-sprockets okushayela noma ashayelwa kufanele abe nendiza ephakathi nendawo yejiyomethri, futhi ama-offset awo angeqi izimfuneko zokuklama. Kufanele ibe ngaphansi noma ilingane no-2%0, uma ingacacisiwe ngomklamo.

(3) Uhlangothi olusebenzayo lweketango kufanele luqiniswe lapho luxhunywa nge-sprocket.

(4) Ukuhlehla kweketango ohlangothini olungasetshenziswa kufanele kube ngaphakathi kwemingcele yomklamo. Kufanele ilungiswe uma ingacacisiwe kumklamo.

Ukuhlanganiswa kwegiya

(1) Uma i-rimu yegiya ingu-20mm noma ngaphansi, ukungahambi kahle kwe-axial akumele kudlule ku-1mm. Uma ububanzi begiya bungaphezu kuka-20mm ukungahambi kahle angeke kweqe u-5%.

(1) I-JB180-60 “I-Bevel Gear transmission Tolerance”, i-JB162 ne-JB162 kufanele icacise izidingo zokunemba kokufakwa kwamagiya angama-cylindrical namagiya e-bevel.

Ngokuvumelana nezidingo zobuchwepheshe, izindawo zokuhlanganisa amagiya kufanele zigcotshwe ngokuhambisana nokusebenza okujwayelekile. I-gearbox kufanele igcwaliswe kulayini wezinga ngamafutha okugcoba.

(4) Izinga lomsindo wokudluliswa komthwalo uma ugcwele akumele lidlule kuma-80dB.

Ukulungiswa kwe-rack nokuxhumeka

(1) Ama-rack ezingxenyeni ezihlukene zamarack kufanele wonke asethwe alingane ncamashi nobude, kusetshenziswa indawo eyireferensi efanayo.

(2) Wonke amaphaneli odonga ama-rack kufanele aqondaniswe endizeni efanayo eqondile.

(3) Amapuleti ahlanganisayo angaguquki kufanele afakwe phakathi kwezingxenye ngemva kokuba ama-rack elungiswe ukuze abe nobude nobukhulu obudingekayo.

Ukuhlanganiswa kwezingxenye ze-pneumatic

(1) Ukucushwa kwesethi ngayinye yamadivayisi okushayela umoya womoya kufanele kuxhunywe ngokuqinile ngokuhambisana nomdwebo wesifunda somoya onikezwe umnyango wokuklama. Umzimba we-valve, amalunga epayipi, amasilinda, njll. kumele axhunywe ngendlela efanele.

(2) I-inlet ne-outlet ye-valve yokunciphisa ingcindezi yokungenisa umoya iyonke ixhunywe ngalapho kumcibisholo khona, futhi inkomishi yamanzi nenkomishi kawoyela yesihlungi somoya kanye nokothambisa kufanele kufakwe ziqonde phansi.

(3) Ngaphambi kokufaka amapayipi, impushana yokusika nothuli olusepayipini kufanele kuqhunyiswe ngokuphelele.

(4) Ijoyinti yepayipi intambo. Uma intambo yepayipi ingenayo i-glue yentambo, i-tape yempahla eluhlaza kufanele isongwe. Indawo ejikajikayo ihambisana newashi uma ibukwa ngaphambili. Itheyiphu yempahla eluhlaza akumele ihlanganiswe nevalvu. I-tape yempahla eluhlaza akufanele ihlanganiswe ku-valve. Lapho ugoqa, intambo eyodwa kufanele igcinwe.

(5) Ukuhlelwa koqhoqhoqho kufanele kube kuhle futhi kube kuhle, futhi uzame ukungaweqi ukuhlelwa. Izindololwane ezingu-90deg kufanele zisetshenziswe emakhoneni. Lapho ulungisa i-trachea, ungafaki ukucindezeleka okwengeziwe kumalungu, ngaphandle kwalokho kuzodala ukuvuza komoya.

(6) Lapho uxhuma i-valve ye-solenoid, naka umsebenzi wenombolo yembobo yomoya ngayinye kuvalvu: P: ingqikithi yokungenisa umoya; A: i-air outlet 1; B: i-air outlet 2; R (EA): i-exhaust ehambisana no-A; S (EB) : I-Exhaust ehambisana no-B.

(7) Uma isilinda sihlanganiswa, i-axis ye-piston rod kanye nesiqondiso sokunyakaza komthwalo kufanele kuhambisane.

(8) Uma usebenzisa i-linear bearing guide, ngemva kokuba ingxenye engaphambili ye-cylinder piston rod ixhunywe emthwalweni, akumele kube khona amandla angavamile phakathi nayo yonke i-stroke, ngaphandle kwalokho isilinda sizolimala.

(9) Uma usebenzisa i-throttle valve, kufanele unake uhlobo lwe-throttle valve. Ngokuvamile, ihlukaniswa ngomcibisholo omkhulu omakwe emzimbeni we-valve. Umcibisholo omkhulu okhomba ekugcineni kwentambo usetshenziselwa isilinda; umcibisholo omkhulu okhomba ekugcineni kwepayipi usetshenziselwa i-valve ye-solenoid. .

Umsebenzi wokuhlola umhlangano

(1) Ngaso sonke isikhathi lapho ukuhlanganiswa kwengxenye kuqedwa, kufanele kubhekwe ngokwalezi zinto ezilandelayo. Uma kutholakala inkinga yomhlangano, kufanele ihlaziywe futhi kubhekwane nayo kusenesikhathi.

A. Ubuqotho bomsebenzi wokuhlanganisa, hlola imidwebo yomhlangano, futhi uhlole ukuthi azikho yini izingxenye ezingekho.

B. Ukuze uthole ukunemba kwendawo yokufaka ingxenye ngayinye, hlola umdwebo womhlangano noma izidingo ezishiwo ekucacisweni okungenhla.

C. Ukuthembeka kwengxenye ngayinye exhumayo, noma isikulufu ngasinye sokubopha sifinyelela itorque edingekayo ukuze sihlanganiswe, nokuthi ingabe izibophelelo ezikhethekile ziyahlangabezana yini nezimfuneko zokuvimbela ukuxega.

D. Ukuguquguquka kokunyakaza kwezingxenye ezihambayo, njengokuthi ingabe kukhona ukuminyana noma ukuma, ukugqama noma ukugoba lapho uzungezisa noma uhambisa ama-conveyor roller, ama-pulley, ama-guide rails, njll.

(2) Ngemva komhlangano wokugcina, ukuhlola okuyinhloko ukuhlola ukuxhumana phakathi kwezingxenye zomhlangano. Okuqukethwe kokuhlola kusekelwe “ezimpahleni ezine” ezicaciswe ku-(1) njengezinga lokulinganisa.

(3) Ngemva komhlangano wokugcina, ukufakwa kwensimbi, udoti, uthuli, njll kuzo zonke izingxenye zomshini kufanele kuhlanzwe ukuze kuqinisekiswe ukuthi azikho izithiyo ezingxenyeni zokudlulisela.

(4) Lapho uhlola umshini, qapha ngokucophelela inqubo yokuqalisa. Ngemuva kokuthi umshini uqalisiwe, bheka ngokushesha imingcele yokusebenza eyinhloko nokuthi izingxenye ezihambayo zihamba ngokujwayelekile yini.

(5) Imingcele yokusebenza eyinhloko ihlanganisa isivinini sokunyakaza, ukushelela kokunyakaza, ukujikeleza kwe-shaft ngayinye yokudlulisela, izinga lokushisa, ukudlidliza nomsindo, njll.

I-Anebon izokwenza umsebenzi ngamunye onzima ube muhle kakhulu futhi ube muhle kakhulu, futhi isheshise izinyathelo zethu zokuma kusukela ezingeni lamabhizinisi aphezulu e-intercontinental asezingeni eliphezulu kanye nasezingeni eliphezulu e-China Gold Supplier ye-OEM, insizakalo yemishini ye-cnc yangokwezifiso, isevisi yokwenziwa kwe-Sheet Metal, ukugaya. amasevisi. I-Anebon izokwenza ukuthenga kwakho komuntu siqu ukuze uhlangabezane nokwanelisayo kwakho! Ibhizinisi le-Anebon limisa iminyango eminingana, okuhlanganisa umnyango wokuphumayo, umnyango wemali engenayo, umnyango wokulawula omuhle kakhulu kanye nesikhungo sesevisi, njll.

I-Factory Supply Chinaukunemba turning izingxenyekanye ne-Aluminium Part, Ungakwazi ukwazisa i-Anebon umbono wakho wokuthuthukisa umklamo oyingqayizivele wemodeli yakho siqu ukuze uvimbele izingxenye ezifanayo kakhulu emakethe! Sizonikeza isevisi yethu engcono kakhulu ukwanelisa zonke izidingo zakho! Khumbula ukuxhumana ne-Anebon ngokushesha!

Isikhathi sokuthumela: Sep-04-2023