Lesi isifinyezo sabantu embonini lapho sifingqa ukwakheka kwesakhiwo, kodwa akulula neze. Enqubweni yokuxhumana nezikimu ezehlukene, sithole ukuthi kuhlala kunezinkinga zokubeka kanye nokubopha ekwakhiweni kokuqala. Ngale ndlela, noma yiluphi uhlelo olusha luzolahlekelwa ukubaluleka kwalo okungokoqobo. Ngokuqonda kuphela ulwazi oluyisisekelo lokubeka indawo kanye nokuhlanganisa lapho singaqinisekisa ngokuyisisekelo ubuqotho bedizayini yesakhiwo nesikimu sokucubungula.

Ulwazi lwendawo

1, Isimiso esiyisisekelo sokuma ohlangothini lwe-workpiece

Uma ubeka eceleni kwendawo yokusebenza, isimiso samaphuzu amathathu siyisisekelo esiyisisekelo, njengoba kunjalo nokusekelwa. Lokhu kufana nesimiso sokusekela, esibizwa ngokuthi isimiso samaphuzu amathathu, esivela kumgomo othi "amaphuzu amathathu angekho emgqeni ofanayo anquma indiza". Amaphuzu amathathu kwamane anganquma ubuso, ngakho-ke ingqikithi yobuso obune inganqunywa. Nokho, kungakhathaliseki ukuthi utholakala kanjani, kunzima kakhulu ukwenza iphuzu lesine endizeni efanayo.

▲ Umgomo wamaphuzu amathathu

Isibonelo, uma usebenzisa ama-positioners angu-4 okuphakama okungaguquki, amaphuzu angu-3 kuphela endaweni eyodwa angathinta ucezu lokusebenza, futhi amaphuzu angu-4 asele kusengenzeka kakhulu ukuthi angaxhumani nomsebenzisi.

Ngakho-ke, lapho ulungiselela isibonisi, ngokuvamile sisekelwe kumaphuzu amathathu, futhi ibanga phakathi kwalawa maphuzu amathathu kufanele linyuswe ngangokunokwenzeka.

Ngaphezu kwalokho, lapho ulungiselela i-positioner, kuyadingeka ukuqinisekisa isiqondiso somthwalo wokucubungula osetshenzisiwe kusengaphambili. Isiqondiso somthwalo wokucubungula futhi isiqondiso sesibambo samathuluzi/uhambo lwamathuluzi. I-positioner ilungiswa ekugcineni kwesikhombisi-ndlela sokuphakelayo, esingathinta ngokuqondile ukunemba kukonke kwe-workpiece.

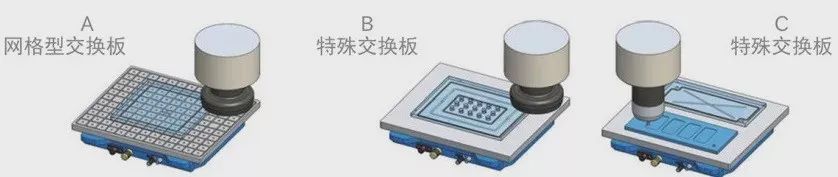

Ngokuvamile, uhlobo lwebhawodi olulungisekayo lusetshenziselwa ukubeka indawo engenalutho ye-workpiece, kanye nohlobo olungaguquki (i-Izingxenye Zokuguqula ze-CNCindawo yokuxhumana iphansi) i-positioner isetshenziselwa ukubeka indawo yomshini womsebenzi wokusebenza.

2. Isimiso esiyisisekelo sokuma kusuka emgodini wokusebenza

Uma usebenzisa imbobo ecutshungulwe kwinqubo yangaphambilini ye-workpiece yokubeka, kuyadingeka ukusebenzisa iphini lokubekezelela ukubeka. Ngokufanisa ukunemba kwembobo ye-workpiece nokunemba kwephrofayili yephinikhodi nokuhlanganisa ngokuvumelana nokubekezelelana okufanele, ukunemba kokumisa kungahlangabezana nezidingo zangempela.

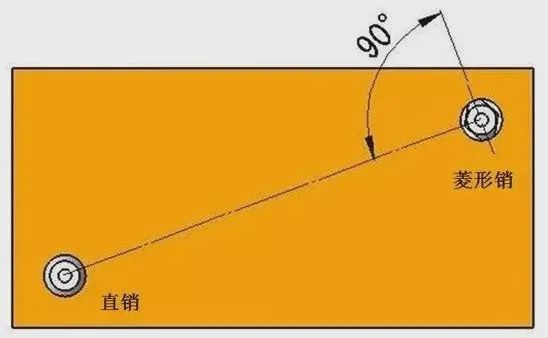

Ngaphezu kwalokho, lapho usebenzisa iphinikhodi yokubeka, ngokuvamile eyodwa isebenzisa iphinikhodi eqondile kanti enye isebenzisa iphinikhodi yedayimane, ngakho-ke kuzoba lula kakhulu ukuhlanganisa nokuqaqa ucezu lokusebenza. Akuvamile ukuthi i-workpiece ibambeke ngephini.

▲ Ukuma ngophini

Yebo, kungenzeka futhi ukusebenzisa iphinikhodi eqondile kuzo zombili izikhonkwane ngokulungisa ukubekezelela okufanelekile. Ukuze uthole ukuma okunembe kakhudlwana, kuvame ukusebenza kahle kakhulu ukusebenzisa iphinikhodi eqondile kanye nephinikhodi yedayimane.

Uma kusetshenziswa iphinikhodi eqondile kanye nephinikhodi yedayimane, umugqa wokuxhuma endaweni yokumisa (lapho iphinikhodi yedayimane ithinta ucezu lokusebenza) wephinikhodi yedayimane ngokuvamile iba ngu-90 ° perpendicular kumugqa wokuxhuma phakathi kwephinikhodi eqondile nephinikhodi yedayimane. Lokhu kulungiselelwa okokumisa kwe-angular (isiqondiso sokuzungezisa se-workpiece).

Ulwazi olufanele lwe-clamp

1. Ukuhlukaniswa kwama-grippers

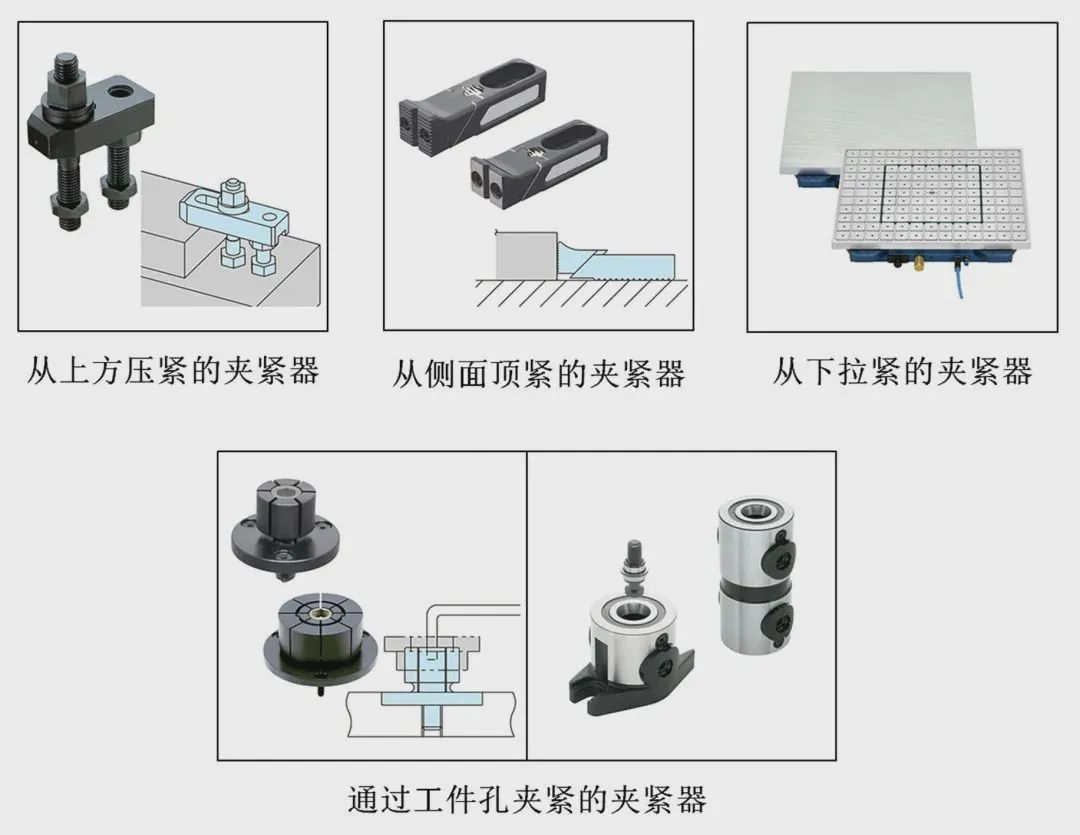

Ngokusho kwe-clamping direction, ngokuvamile ihlukaniswa ngezigaba ezilandelayo:

Okulandelayo, ake sibheke izici zama-clamp ahlukahlukene.

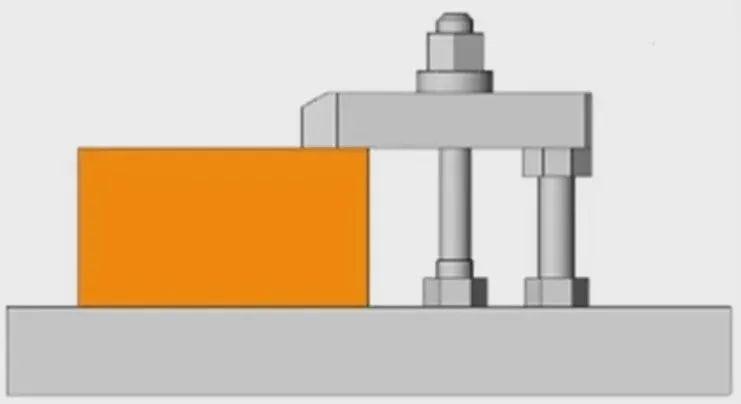

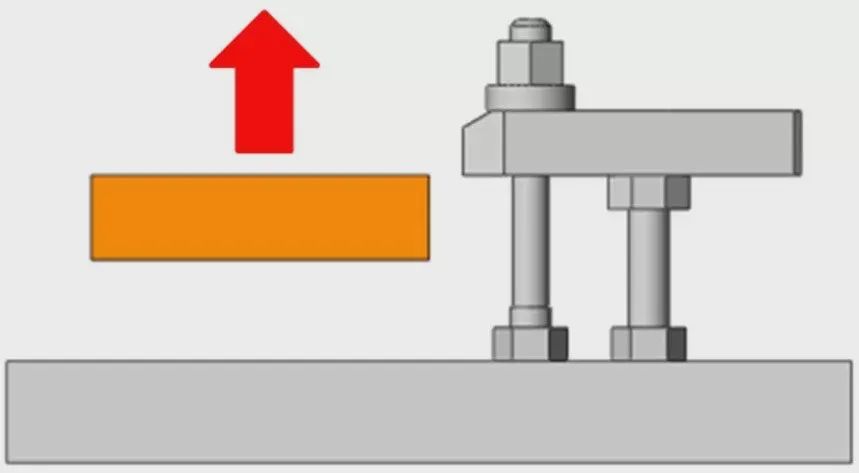

1. Izinsimbi ezicindezelwe ukusuka phezulu

Idivayisi yokubopha ecindezelwa ngaphezu kwendawo yokusebenza inokonakala okuncane kakhulu ngesikhathi sokubopha, futhi iyisimeme kakhulu ngesikhathi sokucutshungulwa kocezu lokusebenza. Ngakho-ke, ngokuvamile, ukucatshangelwa kokuqala ukubopha kusuka phezulu kwe-workpiece. Isici esivame kakhulu sokucindezela ukusuka ngenhla kwendawo yokusebenza wumshini owenziwe ngesandla. Isibonelo, isibalo esilandelayo sibizwa ngokuthi "uhlobo lwamaqabunga avulekile". I-clamp ehlanganiswe ngokucindezela ipuleti, i-stud bolt, ujeke kanye namantongomane ibizwa ngokuthi i-"loose leaf" clamp.

Ngaphezu kwalokho, amapuleti okucindezela anomumo ohlukile angakhethwa ngokuya ngokuma kwe-workpiece. NjengeIzingxenye ze-CNC Machining, Izingxenye Eziphendukayo Nezingxenye Zokugaya.

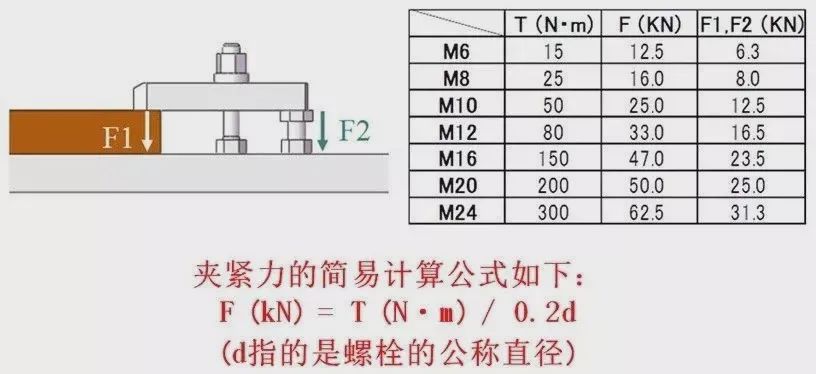

Ubudlelwano phakathi kwe-torque namandla okubamba we-clamp yohlobo lweqabunga elixegayo bungabalwa ngokuphusha kwamandla ebhawodi.

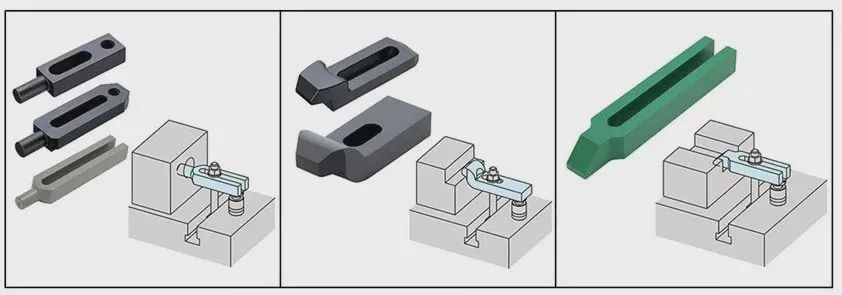

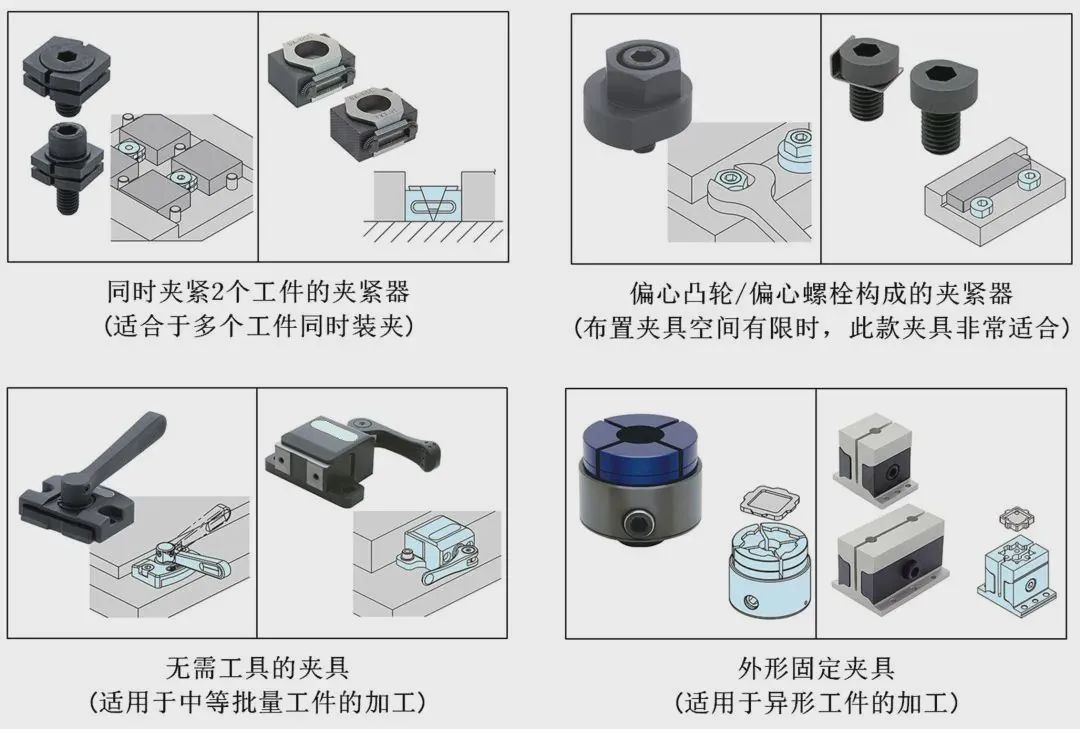

Ngaphezu kwe-clamp yeqabunga elixekethile, ama-clamp alandelayo afanayo ayatholakala ukuze abambe ngaphezulu kwe-workpiece.

2. I-clamping clamp ukusuka ohlangothini

Ekuqaleni, indlela yokubopha yokubopha ucezu lomsebenzi ukusuka phezulu iyona eqine kakhulu ngokunemba kanye nobuncane ekucubunguleni umthwalo womsebenzi. Kodwa-ke, uma kudingekile ukucubungula ngaphezu kwe-workpiece, noma akufanelekile ukubopha ngaphezu kwendawo yokusebenza, okwenza kube nzima ukubopha ngaphezu kwendawo yokusebenza, ungakhetha ukugoqa kusukela ohlangothini lwe-workpiece. Nokho, uma kuqhathaniswa, lapho umsebenzi wokusebenza uboshiwe ohlangothini, uzokhiqiza amandla antantayo. Indlela yokuqeda la mandla kufanele inakwe lapho uklama i-fixture.

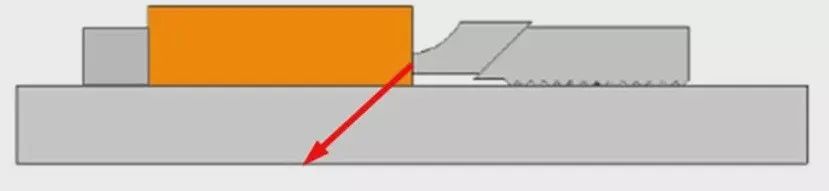

Njengoba kukhonjisiwe emfanekisweni ongenhla, i-clamp eseceleni nayo inamandla abheke phansi e-oblique ngenkathi ikhiqiza i-thrust, engavimbela ngempumelelo ucezu lokusebenza ukuthi luntante phezulu.

Ama-clamps abamba ohlangothini nawo anezinsimbi ezilandelayo ezifanayo.

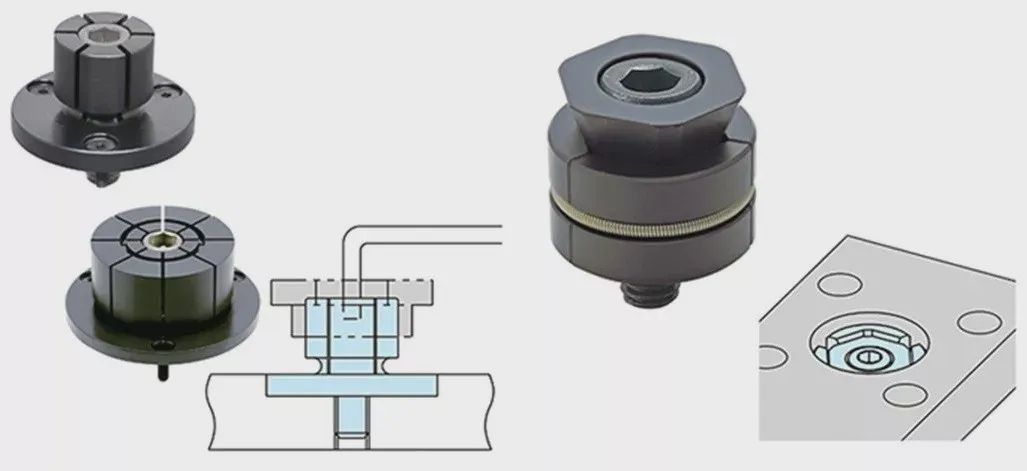

3. Idivayisi yokuhlanganisa ukuze uqinise i-workpiece kusukela ekudonseleni phansi

Lapho wenza indawo engaphezulu ye-workpiece yepuleti elincanyana, akunakwenzeka nje kuphela ukulibopha ukusuka phezulu, kodwa futhi kungenangqondo ukulicindezela ukusuka ohlangothini. Okuwukuphela kwendlela yokubopha enengqondo ukuqinisa i-workpiece kusuka phansi. Lapho i-workpiece igxilile kusuka ngezansi, uma yenziwe ngensimbi, i-clamp yohlobo lukazibuthe ivame ukusetshenziswa. Okwezinsimbi ezingenayo insimbi, izinkomishi zokumunca i-vacuum ngokuvamile zingasetshenziselwa ukucindezela.

Kulezi zimo ezimbili ezingenhla, amandla okubamba alingana nendawo yokuxhumana phakathi kwendawo yokusebenza kanye nozibuthe noma i-vacuum chuck. Uma umthwalo wokucubungula mkhulu kakhulu lapho ucubungula ama-workpiece amancane, umphumela wokucubungula ngeke ulunge.

Ukwengeza, lapho usebenzisa omazibuthe noma ama-vacuum suckers, izindawo zokuthintana ezinozibuthe nama-vacuum suckers zidinga ukwenziwa ezingeni elithile lokushelela ngaphambi kokuba zisetshenziswe ngokuphepha nangokujwayelekile.

4. Idivayisi yokuhlanganisa enezimbobo

Uma usebenzisa umshini womshini we-5-axis ukucubungula ubuso obuningi ngesikhathi esisodwa noma ukucubungula isikhunta, ukuze kuvinjelwe umthelela wezinto ezilungiswayo namathuluzi ekucutshungulweni, ngokuvamile kufanelekile ukusebenzisa indlela yokuhlanganisa imbobo. Uma kuqhathaniswa nendlela yokubopha kusuka phezulu kanye nohlangothi lwe-workpiece, indlela yokubopha imbobo inomthwalo omncane ku-workpiece futhi ingakhubaza ngempumelelo umsebenzi.

▲ Ukucubungula okuqondile ngezimbobo

▲ Setha i-rivet yokubopha

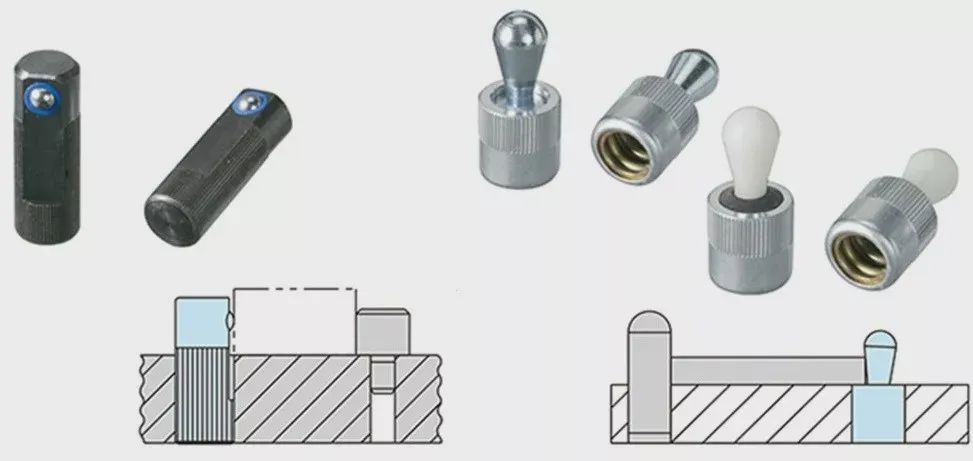

2. Ukugoqa ngaphambili

Okungenhla kumayelana ne-clamping fixture ye-workpiece. Indlela yokuthuthukisa ukusebenza nokusebenzisa i-pre clamping nayo ibalulekile. Lapho i-workpiece isethelwe phezulu esisekelweni, i-workpiece izowa ngenxa yamandla adonsela phansi. Ngalesi sikhathi, i-gripper kufanele isetshenziswe ngenkathi ibambe i-workpiece ngesandla.

▲ Ukubopha ngaphambili

Uma ama-workpieces esindayo noma iningi lazo liboshwe ngesikhathi esifanayo, ukusebenza kuzoncishiswa kakhulu futhi isikhathi sokubopha sizoba side kakhulu. Ngalesi sikhathi, ukusetshenziswa kwalolu hlobo lwe-spring pre clamping umkhiqizo kungenza i-workpiece isebenze i-gripper isesimweni esinganyakazi, ithuthukise kakhulu ukusebenza futhi inciphise isikhathi sokubopha indawo yokusebenza.

3, Izinyathelo zokuqapha lapho ukhetha i-gripper

Lapho kusetshenziswa izinhlobo eziningi zezinsimbi ekusetshenzisweni kwamathuluzi okufanayo, amathuluzi okubamba nokukhulula kufanele ahlanganiswe. Isibonelo, njengoba kukhonjisiwe esithombeni esingakwesokunxele, uma usebenzisa izinhlobonhlobo zamathuluzi okusebenza ngokucindezela, umthwalo ophelele womsebenzisi uzoba mkhulu, futhi isikhathi sokubopha sisonke se-workpiece sizoba side. Isibonelo, emfanekisweni ongakwesokudla ngezansi, izikrufu zamathuluzi namasayizi webhawodi kuhlanganiswe ukuze kube lula opharetha benkambu.

▲ Ukusebenza kokuqinisa ucwecwe

Ngaphezu kwalokho, lapho ulungiselela i-gripper, kubalulekile ukucabangela ukusebenza kwe-workpiece clamping ngangokunokwenzeka. Uma i-workpiece idinga ukutshekiswa ngesikhathi sokubopha, ukusebenza kuphazamisa kakhulu. Lesi simo sidinga ukugwenywa lapho uklama i-fixture.

Isikhathi sokuthumela: Oct-24-2022