Ukubhoboza, ukudonsa, ukulungisa kabusha, ukudinwa... Basho ukuthini? Okulandelayo kuzokufundisa ukuthi uqonde kalula umehluko phakathi kwale miqondo.

Uma kuqhathaniswa nokucutshungulwa kwendawo yangaphandle, izimo zokucubungula imbobo zimbi kakhulu, futhi kunzima kakhulu ukucubungula izimbobo kunokucubungula imibuthano yangaphandle. Lokhu kungenxa yokuthi:

I-1) Ubukhulu bethuluzi elisetshenziselwa ukukhanda imbobo bunqunyelwe ubukhulu bembobo okufanele yenziwe ngomshini, futhi ukuqina akulungile, okujwayele ukugoba ukuguquguquka nokudlidliza;

2) Lapho machining imbobo ngeithuluzi losayizi ongashintshi, ubukhulu bembobo ngokuvamile bunqunywa ngokuqondile ubukhulu obuhambisanayo bethuluzi, futhi iphutha lokukhiqiza nokugqoka kwethuluzi kuzothinta ngokuqondile ukunemba komshini wembobo;

I-3) Lapho izimbobo zomshini, indawo yokusika ingaphakathi kwendawo yokusebenza, ukukhishwa kwe-chip kanye nezimo zokushisa ukushisa zimpofu, futhi ukunemba kwemishini kanye nekhwalithi yendawo akulula ukuyilawula.

1. Ukumba nokulungisa kabusha

1. Ukubhoboza

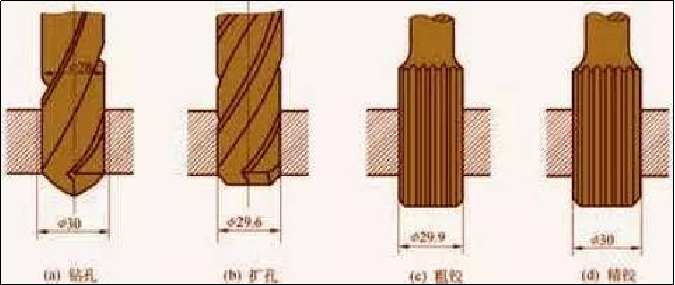

Ukubhoboza kuyinqubo yokuqala yokugaya izimbobo ezintweni eziqinile, kanti ububanzi bezimbobo ngokuvamile bungaphansi kuka-80mm. Kunezindlela ezimbili zokumba: enye iwukuzungezisa umshini wokubhola; enye iwukuzungezisa isiqeshana sokusebenza. Amaphutha akhiwe yizindlela ezimbili zokumba ezingenhla ahlukene. Endleleni yokubhoboza nge-drill bit ejikelezayo, lapho i-drill bit ihlukanisiwe ngenxa ye-asymmetry yonqenqema lokusika kanye nokuqina okunganele kwe-drill bit, umugqa ophakathi womgodi owenziwe ngomshini uzosonteka noma uhlanekezelwe. Ayiqondile, kodwa ububanzi bembobo abushintshile; ngokuphambene nalokho, endleleni yokubhoboza lapho i-workpiece ijikeleziswa khona, ukuphambuka kwe-drill bit kuyokwenza ukuthi ububanzi bembobo bushintshe, kuyilapho i-centerline yembobo isaqondile.

Amathuluzi okumba asetshenziswa ngokuvamile ahlanganisa: i-twist drill, i-centre drill, i-deep hole drill, njll. Phakathi kwazo, okuvame ukusetshenziswa kakhulu i-twist drill, ububanzi bayo Φ0.1-80mm.

Ngenxa yemikhawulo yesakhiwo, ukugoba kokugoba kanye nokuqina kwe-torsional ye-drill bit kokubili kuphansi, kuhlanganiswe nokugxila okuphansi, ukunemba kokubhola kuphansi, ngokuvamile kufinyelela kuphela ku-IT13 ~ IT11; ubuhhadlahhadla obungaphezulu bubuye bube bukhulu, futhi uRa ngokuvamile ungu-50 ~ 12.5μm; kodwa izinga lokukhishwa kwensimbi lokumba likhulu, futhi ukusebenza kahle kokusika kuphezulu. Ukubhoboza kusetshenziswa kakhulu ukucubungula izimbobo ezinezidingo zekhwalithi ephansi, njengezimbobo zebhawodi, izimbobo ezinentambo engezansi, izimbobo zikawoyela, njll. Ezimbobeni ezinokunemba okuphezulu komshini kanye nezidingo zekhwalithi engaphezulu, kufanele zifinyelelwe ngokuvuselela kabusha, ukuphinda kwenziwe kabusha, ukucikeka noma ukugaya ngaphakathi. imishini elandelayo. 2. Ukuhlaziya

I-Reaming iwukucutshungulwa okuqhubekayo kwezimbobo eziboshiwe, zaphonswa noma zakhiwe ngomshini wokubuyisela kabusha ukuze kwandiswe imbobo futhi kuthuthukiswe izinga lokucutshungulwa kwezimbobo.Ukwenza imishini yokugcinawemigodi engafuneki kangako. I-drill yokubuyisela kabusha ifana ne-twist drill, kodwa enamazinyo engeziwe futhi ayinakho unqenqema lweshizolo.

Uma kuqhathaniswa nokubhoboza, ukubuyisela kabusha kunezici ezilandelayo: (1) inani lamazinyo okugaya likhulu (amazinyo angu-3 ~ 8), isiqondiso sihle, futhi ukusika kuzinzile; (2) i-drill yokuvuselela ayinawo umphetho weshizolo, futhi izimo zokusika zinhle; (3) Isibonelelo somshini sincane, iphakethe le-chip lingenziwa lingashoni, i-drill core ingenziwa ibe mkhulu, futhi amandla nokuqina komzimba womsiki kungcono. Ukunemba kokuphinda kwenziwe kabusha imbobo kuvame ukuthi yi-IT11~IT10, futhi ubulukhuni bendawo u-Ra bungu-12.5~6.3μm. Ukubuyisela kabusha kuvame ukusetshenziselwa izimbobo zomshini ezinobubanzi obuncane kuno-. Lapho ubhoboza imbobo enobubanzi obukhulu (D ≥ 30mm), i-drill bit encane (ububanzi buyizikhathi ezingu-0.5~0.7 ububanzi bembobo) kuvame ukusetshenziselwa ukubhoboza ngaphambili, bese kuba nosayizi ohambisanayo wokubhoboza kabusha. isetshenziselwa ukukhipha kabusha imbobo, okungathuthukisa ikhwalithi yembobo. Ikhwalithi yokucubungula nokusebenza kahle kokukhiqiza.

Ngokungeziwe ekucubunguleni izimbobo eziyisilinda, ukwenza kabusha kungase futhi kusebenzise izimbobo zokuphinda ezimise okukhethekile (okubuye kwaziwe ngokuthi osinki) ukuze kucutshungulwe izimbobo zezihlalo ezishoniwe ezihlukahlukene kanye nokucwila. Ingxenye engaphambili ye-countersink ngokuvamile inekholomu yomhlahlandlela, eqondiswa imbobo eyenziwe ngomshini.

2. Ukuhlaziya

I-Reaming ingenye yezindlela zokuqeda izimbobo, ezisetshenziswa kakhulu ekukhiqizeni. Emigodini emincane, ukubuyisela kabusha kuyindlela eyonga kakhulu futhi esebenzayo kunokugaya kwangaphakathi kanye nesicefe esihle.

1. Abahlaziyi

Ama-Reamers ngokuvamile ahlukaniswe abe izinhlobo ezimbili: ama-hand reamers nama-reamers omshini. Isibambo se-remer yesandla siyisibambo esiqondile, ingxenye esebenzayo yinde, futhi umsebenzi oqondisayo ungcono. Isivuseleli sesandla sinezakhiwo ezimbili zohlobo olubalulekile kanye nobubanzi obungalungiseka bangaphandle. Kunezinhlobo ezimbili zama-reamers omshini, uhlobo lwe-shank kanye nohlobo lwemikhono. Ama-Reamers awakwazi ukucubungula izimbobo eziyindilinga kuphela, kodwa futhi nezimbobo ze-taper zingacutshungulwa ngama-taper reamer. 2. Inqubo yokubuyisela kabusha kanye nokusetshenziswa kwayo

Isibonelelo sokubuyisela kabusha sinethonya elikhulu kwikhwalithi yokuguqulwa kabusha. Uma isibonelelo sikhulu kakhulu, umthwalo we-reamer uzoba mkhulu, umkhawulo wokusika uzofiphazwa ngokushesha, akulula ukuthola indawo ebushelelezi eyenziwe ngomshini, futhi ukubekezelelana kwe-dimensional akulula ukuqinisekiswa; uma isibonelelo sincane kakhulu, Uma izimpawu zethuluzi ezishiywe inqubo yangaphambilini zingakwazi ukususwa, ngokwemvelo ngeke zithuthukise ikhwalithi yokucubungula imbobo. Ngokuvamile, i-hinge emangelengele i-0.35 ~ 0.15mm, futhi ihinge elihle lingu-01.5~0.05mm.

Ukuze ugweme ukwakheka konqenqema olwakhelwe phezulu, ukuphinda kwenziwe kabusha ngesivinini esiphansi sokusika (v <8m/min kuma-reamers ensimbi anesivinini esikhulu sensimbi nensimbi ekhonjiwe). Inani lokuphakelayo lihlobene nembobo okufanele icutshungulwe. Imbobo enkulu, likhulu inani lesiphakeli. Uma isivuseleli sensimbi enesivinini esikhulu sicubungula insimbi nensimbi ecijile, okuphakelayo kuvame ukuba ngu-0.3~1mm/r.

Lapho izimbobo zivuselelwa kabusha, kufanele zipholiswe, zigcotshwe futhi zihlanzwe ngoketshezi olufanele lokusika ukuze kuvinjelwe unqenqema olwakhiwe futhi kukhishwe ama-chips ngesikhathi. Uma kuqhathaniswa nokugaya kanye nesicefe, ukubuyisela kabusha kunokukhiqiza okuphezulu futhi kulula ukuqinisekisa ukunemba komgodi; kodwa-ke, ukubuyisela kabusha akukwazi ukulungisa iphutha lendawo ye-axis yembobo, futhi ukunemba kwendawo yembobo kufanele kuqinisekiswe inqubo yangaphambilini. Ukubuyisela kabusha akufanele kucubungule izimbobo ezinyathelwe kanye nezimbobo eziyimpumputhe.

Ukunemba kobukhulu bembobo yokubuyisela kabusha ngokuvamile i-IT9~IT7, futhi ubulukhuni obungaphezulu u-Ra ngokuvamile bungu-3.2~0.8 μm. Ngezimbobo ezinosayizi omaphakathi ezinezidingo zokunemba okuphezulu (ezifana nezimbobo zokunemba zezinga le-IT7), inqubo yokumba-enwebayo iwuhlelo lokucubungula olujwayelekile oluvame ukusetshenziswa ekukhiqizeni.

3. Kuyabhora

I-Boring iyindlela yokucubungula esebenzisa amathuluzi okusika ukuze kwandiswe izimbobo ezenziwe ngaphambili. Umsebenzi oyisicefe ungenziwa ngomshini oyisicefe noma i-lathe.

1. Indlela eyisicefe

Kunezindlela ezintathu ezahlukene zokusebenzisa imishini yokwenza isicefe.

(1) I-workpiece iyazungeza futhi ithuluzi liyaphakela. Okuningi okuyisicefe ku-lathe kungokwale ndlela eyisicefe. Izici zenqubo yilezi: umugqa we-axis wembobo ngemuva komshini uhambisana ne-axis yokuzungeza ye-workpiece, ukuzungeza komgodi kuncike ikakhulukazi ekunembeni kokujikeleza kwethuluzi lokuphotha lomshini, kanye nephutha le-axial geometry yembobo lincike ikakhulukazi. esiqondisweni sokuphakelayo kwethuluzi elihlobene ne-axis yokuzungeza ye-workpiece. ukunemba kwesikhundla. Le ndlela eyisicefe ilungele ukucubungula izimbobo ezinezidingo ze-coaxiality nengaphandle.

(2) Ithuluzi liyazungeza futhi i-workpiece yenza ukunyakaza kokuphakelayo. I-spindle yomshini oyisicefe ishayela ithuluzi eliyisicefe ukuthi lijikeleze, futhi ithebula lokusebenza lishayela ucezu lokusebenza ukwenza ukunyakaza kokuphakelayo.

(3) Lapho ithuluzi lizungeza futhi lenza ukunyakaza kokuphakela, indlela eyisicefe isetshenziselwa isicefe. Ubude be-overhang bebha eyisicefe buyashintshwa, futhi ukuguqulwa kwamandla kwebha eyisicefe nakho kuyashintshwa. I-diameter yembobo incane, yenza imbobo ene-tapered. Ukwengeza, ubude be-overhang ye-bar eyisicefe buyanda, futhi ukuguquguquka kokugoba kwe-shaft eyinhloko ngenxa yesisindo sayo nakho kuyanda, futhi i-axis yomgodi owenziwe ngomshini izogotshwa ngokufanele. Le ndlela eyisicefe ifaneleka kuphela emigodini emifushane.

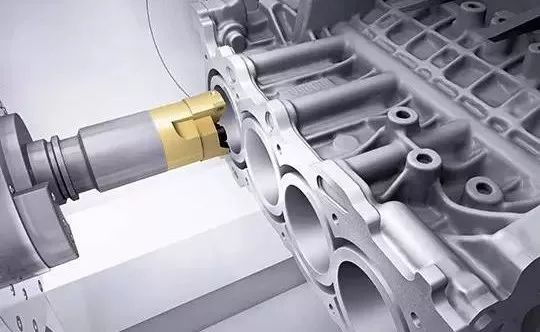

2. Idayimane eliyisicefe

Uma kuqhathaniswa ne-boring evamile, i-diamond boring ibonakala ngenani elincane lokusika emuva, ukudla okuncane, kanye nesivinini esikhulu sokusika. Ingathola ukunemba okuphezulu kwemishini (IT7~IT6) kanye nendawo ebushelelezi kakhulu (i-Ra ingu-0.4~ 0.05 μm). Idayimane eyisicefe ekuqaleni yayicutshungulwa ngamathuluzi ayisicefe wedayimane, futhi manje isivame ukucutshungulwa nge-carbide enosimende, i-CBN namathuluzi edayimane okwenziwa. Ikakhulukazi isetshenziselwa ukucubungula ama-workpieces ensimbi angeyona ayoni, kodwa futhi nokucubungula insimbi nensimbi.

Izilinganiso zokusika ezivame ukusetshenziselwa ukubhora kwedayimane yilezi: inani lokusikwa emuva kwe-pre-boring liyi-0.2 ~ 0.6mm, kanti ukubhoreka kokugcina kungu-0.1mm; isilinganiso sokuphakelayo singu-0.01~0.14mm/r; ijubane lokusika liyi-100 ~ 250m/min lapho kwenziwa insimbi ecijile, kanye nemishini engu-150 ~ 300m/min yensimbi, 300 ~ 2000m/min yokucubungula izinsimbi ezingenayo ayoni.

Ukuze uqinisekise ukuthi i-diamond boring ingafinyelela ukunemba okuphezulu kwe-machining kanye nekhwalithi ephezulu, ithuluzi lomshini (umshini we-Diamond boring) osetshenzisiwe kufanele ube nokunemba okuphezulu kwejometri kanye nokuqina. I-shaft eyinhloko yethuluzi lomshini ivame ukusekelwa ngokunemba kwama-angular amabhola okuxhumana noma ama-hydrostatic sliding bearings, kanye nezingxenye ezijikelezayo ezinesivinini esikhulu. Kumelwe ilinganisele ngokunembile; ngaphezu kwalokho, ukunyakaza kwendlela yokudla kufanele kuzinze kakhulu ukuze kuqinisekiswe ukuthi i-worktable ingenza ukunyakaza kokudla okuzinzile futhi okunejubane eliphansi.

I-Diamond boring inekhwalithi enhle yokucubungula nokusebenza kahle kokukhiqiza okuphezulu, futhi isetshenziswa kabanzi ekucutshungulweni kokugcina kwezimbobo ezinembayo ekukhiqizeni ngobuningi, njengezimbobo zesilinda senjini, izimbobo zamaphini e-piston, nezimbobo zokuphotha emabhokisini okuphotha amathuluzi omshini. Kodwa-ke, kufanele kuqashelwe ukuthi uma usebenzisa i-diamond boring ukucubungula imikhiqizo yensimbi eyinsimbi, amathuluzi ayisicefe kuphela enziwe nge-carbide enosimende ne-CBN angasetshenziswa, futhi amathuluzi ayisicefe enziwe ngedayimane awakwazi ukusetshenziswa, ngoba ama-athomu e-carbon edayimane anobudlelwane obukhulu. ngezakhi zeqembu lensimbi. , impilo yamathuluzi iphansi.

3. Ithuluzi eliyisicefe

Amathuluzi ayisicefe angahlukaniswa abe ngamathuluzi ayisicefe onqenqemeni olulodwa namathuluzi ayisicefe onqenqema oluphindwe kabili.

4. Izici zobuchwepheshe kanye nesicelo uhla kuyisicefe

Uma kuqhathaniswa nenqubo yokubhoboza-yokwandisa-i-reaming, ububanzi bembobo abunqunyelwe ubukhulu bethuluzi, futhi okuyisicefe kunekhono elinamandla lokulungisa iphutha. Izindawo eziyisicefe nezibekayo zigcina ukunemba okuphezulu kokuma.

Uma kuqhathaniswa nendilinga yangaphandle yembobo eyisicefe, ngenxa yokuqina okungalungile kanye nokuguqulwa okukhulu kwesistimu yokuphatha ithuluzi, ukuchithwa kokushisa kanye nezimo zokususwa kwe-chip azilungile, futhi ukuguqulwa okushisayo kwe-workpiece kanye nethuluzi kukhulu kakhulu. Ikhwalithi yomshini kanye nokusebenza kahle kokukhiqiza kwembobo eyisicefe ayiphezulu njengendilinga yangaphandle yemoto. .

Ngokusekelwe ekuhlaziyweni okungenhla, kungabonakala ukuthi okuyisicefe kunobubanzi bokucubungula okubanzi, futhi kungacubungula izimbobo ezinosayizi abahlukahlukene kanye namazinga okunemba ahlukene. Ngezimbobo nezinhlelo zembobo ezinobubanzi obukhulu kanye nezidingo zokunemba ezisezingeni eliphezulu nezendawo, ukucikeka cishe ukuphela kokucubungula. indlela. Ukunemba komshini kokuyisicefe yi-IT9~IT7. Ukubhoka kungenziwa kumathuluzi omshini afana nemishini eyisicefe, ama-lathes, nemishini yokugaya. Inezinzuzo zokuguquguquka futhi isetshenziswa kabanzi ekukhiqizeni. Ekukhiqizeni ngobuningi, ukuze kuthuthukiswe ukusebenza kahle okuyisicefe, ukufa okuyisicefe kuvame ukusetshenziswa.

4. izimbobo zokucija

1. Isimiso sokucija nokucija ikhanda

Ukucija kuyindlela yokuqeda imbobo ngekhanda lokucija ngothi lokugaya (whitstone). Ngesikhathi sokucija, i-workpiece iyalungiswa, futhi i-honing head iqhutshwa yi-spindle yomshini ukuze ijikeleze futhi yenze ukunyakaza okuphindaphindiwe komugqa. Enkambweni yokugcoba, i-bar yokugaya isebenza ebusweni be-workpiece ngengcindezi ethile, futhi inqamula ungqimba omncane kakhulu wezinto ezivela ebusweni bomsebenzi wokusebenza, futhi i-trajectory yokusika iyi-mesh ewela. Ukuze wenze umzila wokunyakaza wezinhlamvu ezilumayo zebha yesihlabathi ungaphindi, ukuphenduka ngomzuzu wokunyakaza okujikelezayo kwekhanda elicijayo kanye nenani lemivimbo ephindaphindayo ngomzuzu wekhanda lokucija kufanele kube izinombolo eziyinhloko zomunye nomunye.

I-engeli ye-intersection yethrekhi yokucija ihlobene nesivinini esiphindaphindayo kanye nesivinini se-peripheral sekhanda lokucija. Ubukhulu be-engeli buthinta ikhwalithi yokucubungula nokusebenza kahle kokucija. Ngokujwayelekile, kuthathwa ngokuthi ngu-° ngokucisha okungalungile kanye nokucisha kahle. Ukuze kube lula ukukhishwa kwezinhlayiya ze-abrasive eziphukile kanye nama-chips, ukunciphisa izinga lokushisa lokusika futhi uthuthukise ikhwalithi yokucubungula, uketshezi olwanele lokusika kufanele lusetshenziswe ngesikhathi sokucija.

Ukuze wenze udonga lwembobo lucutshungulwe ngokulinganayo, ukushaywa kwe-sand bar kufanele kudlule inani elingaphezu kwesilinganiso kuzo zombili iziphetho zembobo. Ukuze kuqinisekiswe ukuvunyelwa kokucijwa okufanayo kanye nokunciphisa umthelela wephutha lokuzungezisa ithuluzi lomshini ekunembeni komshini, iningi lamakhanda okucija nama-spindle amathuluzi omshini axhunywa ngokuntanta.

Ukunwetshwa kwe-radial kanye nokulungiswa kokufinyezwa kwebha yokugaya ikhanda le-honing kunamafomu ahlukahlukene wesakhiwo njenge-manual, i-pneumatic kanye ne-hydraulic.

2. Izici zenqubo kanye nobubanzi besicelo sokucija

1) I-Honing ingathola ukunemba kwe-dimensional ephezulu kanye nokunemba komumo. Ukunemba komshini yi-IT7~IT6, futhi amaphutha ayindilinga kanye nesilinda emigodini angalawulwa ngaphakathi kobubanzi be-, kodwa ukucija akukwazi ukuthuthukisa ukunemba kwendawo yezimbobo ezenziwe ngomshini.

I-2) I-Honing ingathola ikhwalithi ephezulu, ubulukhuni be-Ra buyi-0.2 ~ 0.25μm, futhi ukujula kongqimba lwesici se-metamorphic sensimbi engaphezulu kuncane kakhulu 2.5 ~ 25μm.

3) Uma kuqhathaniswa nesivinini sokugaya, nakuba ijubane le-peripheral lekhanda lokucija lingekho phezulu (vc = 16 ~ 60m / min), kodwa ngenxa yendawo enkulu yokuxhumana phakathi kwe-sand bar kanye ne-workpiece, isivinini sokubuyisela siphezulu kakhulu. (va=8~20m/min). min), ngakho-ke ukucija kusenokukhiqiza okuphezulu.

I-Honing isetshenziswa kabanzi ekwenzeni izimbobo ze-cylinder zenjini kanye nezimbobo ezinembayo kumadivayisi ahlukahlukene we-hydraulic ekukhiqizeni ngobuningi. Kodwa-ke, ukucija akufanelekile ukucubungula izimbobo ezintweni zokusebenza zensimbi ezingenayo insimbi ezinepulasitiki enkulu, futhi ayikwazi ukucubungula izimbobo ezinemifantu eyisihluthulelo, izimbobo ze-spline, njll.

5. Donsa imbobo

1. Ukubhulabhula nokubhongoza

I-Hole broaching iyindlela yokuqeda ekhiqiza kakhulu eyenziwa emshinini wokugcoba nge-broach ekhethekile. Kunezinhlobo ezimbili zombhede wo-broaching: umbhede wo-broaching ovundlile kanye nombhede woku-broaching oqondile, onombhede ovundlile wokuthontelana ovame kakhulu.

Lapho i-broach, i-broach yenza kuphela ukunyakaza komugqa onesivinini esiphansi (ukunyakaza okuyinhloko). Inombolo yamazinyo e-broach esebenza ngesikhathi esifanayo akufanele ibe ngaphansi kuka-3, ngaphandle kwalokho i-broach ngeke isebenze kahle, futhi kulula ukukhiqiza ama-ripples annular ebusweni bomsebenzi. Ukuze uvimbele ukuthi i-broach ingaphuki ngenxa yamandla amakhulu okubhuqa, lapho i-broach isebenza, inani lamazinyo asebenzayo ngokuvamile akufanele lidlule ku-6 kuya ku-8.

Kunezindlela ezintathu ezihlukene zokuphequlula, ezichazwe ngale ndlela elandelayo:

1) I-Layered broaching Isici sale ndlela yokucubungula ukuthi i-broach isika isendlalelo semvume yomshini womsebenzi ngosendlalelo ngokulandelana. Ukuze kube lula ukuphuka kwe-chip, amazinyo okusika agaywe ngemisele yokuhlukanisa ama-chip. I-broach eklanywe ngokwendlela yokugcoba enezingqimba ibizwa ngokuthi i-broach evamile.

2) Ukubhulabhula kwebhulokhi Isici sale ndlela yokugaya ukuthi ungqimba ngalunye lwensimbi endaweni ewumshini luqukethe iqoqo lamazinyo anobukhulu obufanayo kodwa amazinyo anyakazayo (imvamisa iqembu ngalinye linamazinyo ama-2-3) akhishiwe. Izinyo ngalinye lisika kuphela ingxenye yongqimba lwensimbi. I-broach eklanywe ngokwendlela ye-block broaching ibizwa ngokuthi i-wheel-cut broach.

3) Ukubhulabhula Okubanzi Le ndlela igxilisa izinzuzo zokubhoboza okugqinsiwe kanye nezigaba. Ingxenye yezinyo eliqinile ithatha i-broaching ehlukene, futhi ingxenye yezinyo elicolile ithatha i-broaching egqinsiwe. Ngale ndlela, ubude be-broach bungafinyezwa, ukukhiqiza kungathuthukiswa, futhi izinga eliphezulu lendawo lingatholakala. I-broach eklanywe ngokwendlela ebanzi yokubhula ibizwa ngokuthi i-comprehensive broach.

2. Izici zenqubo kanye nobubanzi besicelo sokudonsa imbobo

I-1) I-broach iyithuluzi elinama-multi-blade, elingaqedela ngokulandelana ukugoqa, ukuqeda nokuqeda imbobo nge-stroke eyodwa yokubhoboza, ngokusebenza kahle kokukhiqiza okuphezulu.

I-2) Ukunemba kwe-broaching ikakhulukazi kuncike ekunembeni kwe-broach. Ngaphansi kwezimo ezijwayelekile, ukunemba kwe-broaching kungafinyelela ku-IT9~IT7, futhi ubulukhuni be-Ra bungafinyelela ku-6.3~1.6 μm.

I-3) Lapho udonsa umgodi, i-workpiece ibekwe ngumgodi owenziwe ngomshini ngokwawo (ingxenye ehamba phambili ye-broach iyisici sokumisa se-workpiece), futhi akulula ukuqinisekisa ukunemba kwe-mutual positional of the hole nezinye izindawo; Ekucutshungulweni kwezingxenye zomzimba, izimbobo zivame ukudwetshwa kuqala, bese ezinye izindawo zenziwe ngomshini kusetshenziswa izimbobo njengereferensi yokuma. 4) I-broach ayikwazi ukucubungula izimbobo eziyindilinga kuphela, kodwa futhi yakha izimbobo nezimbobo ze-spline.

I-5) I-broach iyithuluzi elilinganiselwe elinomumo oyinkimbinkimbi kanye nenani eliphakeme, elingafaneleki ukwenza izimbobo ezinkulu.

Izimbobo zokudonsa zivame ukusetshenziswa ekukhiqizeni ngobuningi ukuze kucutshungulwe emigodini ezingxenyeni ezincane neziphakathi nendawo ezinobubanzi obungu-Ф10 ~ 80mm kanye nokujula komgodi okungadluli izikhathi ezi-5 ububanzi bembobo.

Isikhathi sokuthumela: Aug-29-2022