Iphutha lomshini lisho izinga lokuchezuka phakathi kwamapharamitha wejiyomethri wengxenye wangempela (usayizi wejiyomethri, umumo wejiyomethri, nokuma okuhlangene) ngemva komshini kanye namapharamitha afanelekile wejiyomethri.

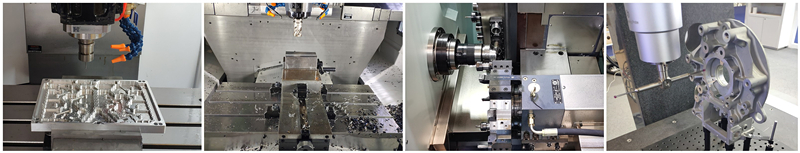

Izinga lesivumelwano phakathi kwamapharamitha wejiyomethri angempela namahle ngemva komshini wokusebenza kwengxenye ukunemba komshini. Iphutha lomshini lincane, izinga lokuvumelana nokunemba liyanda.7075 aluminium machining

Ukunemba komshini kanye nephutha lomshini kuyizindlela ezimbili zenkinga. Ngakho-ke, usayizi wephutha lomshini ubonisa ileveli yokunemba komshini. Izizathu eziyinhloko zamaphutha omshini yilezi ezilandelayo:

1. Iphutha lokukhiqiza lethuluzi lomshini

Iphutha lokukhiqiza ithuluzi lomshini ikakhulukazi lihlanganisa iphutha lokuzungezisa i-spindle, iphutha lesitimela esiqondisayo, kanye nephutha leketango lokudlulisela.

Iphutha lokuzungezisa i-spindle libhekisela ekuhlukeni kwe-eksisi yangempela yokuzungezisa ye-spindle ngokuhlobene ne-axis yayo yokuzungezisa okumaphakathi ngesikhathi esisheshayo ngasinye, okuzothinta ngokuqondile ukunemba kocezu lokusebenza oluzocutshungulwa. Izizathu eziyinhloko zephutha lokuzungezisa i-spindle yiphutha le-spindle's coaxiality, iphutha lokuthwala ngokwalo, iphutha le-coaxiality phakathi kwama-bearings, kanye nokuzungezisa kwe-spindle. Umzila wesitimela uwuphawu lokunquma ubudlelwano bendawo obuhlobene bengxenye yethuluzi ngalinye lomshini ethuluzini lomshini, futhi liwuphawu lokuma kokunyakaza kwethuluzi lomshini.Aluminium CNC machining

Iphutha lokukhiqiza lesitimela esiqondisayo, ukuguga okungalingani kwesitimela esiqondisayo, kanye nekhwalithi yokufaka izinto ezibalulekile ezidala iphutha. Iphutha lochungechunge lokudlulisela libhekisela iphutha elihlobene nokunyakaza phakathi kwezinto zokudlulisela ekuqaleni nasekupheleni kochungechunge lokudlulisela. Kubangelwa amaphutha okukhiqiza kanye nokuhlanganisa ingxenye ngayinye kuchungechunge lokudlulisela nokuguga ngesikhathi sokusetshenziswa.

2. Iphutha lejiyomethri lethuluzi

Noma yiliphi ithuluzi lizogqoka nakanjani phakathi nenqubo yokusika, okuzodala izinguquko kusayizi nokuma kwe-workpiece. Umthelela wephutha lejiyomethri yethuluzi kuphutha lomshini uyahlukahluka ngohlobo lwethuluzi: lapho ithuluzi losayizi ongashintshi lisetshenziselwa umshini, iphutha lokukhiqiza ithuluzi lizothinta ngokuqondile ukunemba komshini we-workpiece; kumathuluzi ajwayelekile (njengamathuluzi okuguqula, njll.), iphutha layo lokukhiqiza Alinawo umthelela oqondile emaphutheni omshini.

3. Iphutha lejometri yesakhiwo

Umsebenzi we-fixture ukwenza i-workpiece ilingane nethuluzi, futhi ithuluzi lomshini linendawo efanele, ngakho-ke iphutha lejiyomethri le-fixture lithonya kakhulu iphutha lomshini (ikakhulukazi iphutha lendawo).

4. Iphutha lokuma

Iphutha lokuma ngokuyinhloko lihlanganisa iphutha lereferensi yokuqondisa kabi kanye nephutha lokukhiqiza elingalungile lepheya yokuma. Lapho ucubungula i-workpiece ethuluzini lomshini, izakhi zejometri ezimbalwa ku-workpiece kufanele zikhethwe njengedatha yokubeka ngesikhathi sokucubungula. datum) ayihlangani, kuzokwenzeka iphutha lokungaqondani kahle kwedatha.

Indawo yokuma yesiqeshana sokusebenza kanye nesici sokuma sendawo yakha ipheya yokuma. Ukuhluka okukhulu kwendawo yokusebenza okubangelwa ukwenziwa okungalungile kwepheya yokuma kanye negebe elihambisanayo phakathi kwamapheya okumisa kubizwa ngokuthi iphutha lokukhiqiza elinganembi lokuma kwepheya. Iphutha lokukhiqiza elingalungile lepheya yokumisa lizokwenzeka kuphela lapho indlela yokulungisa isetshenziselwa ukucubungula futhi ngeke yenzeke endleleni yokusika isilingo.

5. Iphutha elibangelwa ukuguqulwa kwamandla kwesistimu yenqubo

Ukuqina kwengcezu yokusebenza: Uma ukuqina kwengcezu yokusebenza ohlelweni lokucubungula kuphansi uma kuqhathaniswa namathuluzi omshini, amathuluzi, nezinto ezilungiswayo, ngaphansi kwesenzo samandla okusika, ukuwohloka kwendawo yokusebenza ngenxa yokuqina okunganele kuzoba nomthelela obaluleke kakhulu emaphutheni omshini.

Ukuqina kwethuluzi: Ukuqina kwethuluzi eliphendukayo eliyisilinda endaweni emaphakathi emshinini (y) bukhulu kakhulu, futhi ukuguqulwa kwalo kunganakwa. Lapho imbobo yangaphakathi ibhonsa ngobubanzi obuncane, ukuqina kwebha yamathuluzi kubi kakhulu, futhi ukuguqulwa kwamandla ebha yamathuluzi kuthonya kakhulu ukunemba komshini wembobo.

Ukuqina kwezingxenye zamathuluzi omshini: Izingxenye zamathuluzi omshini zakhiwe izingxenye eziningi. Ayikho indlela yokubala elula efanelekile yokuqina kwezingxenye zamathuluzi omshini. Izindlela zokuhlola zinquma ngokuyinhloko ukuqina kwezingxenye zamathuluzi omshini. Izici ezithinta ukuqina kwezingxenye zamathuluzi omshini zifaka umthelela wokuwohloka kokuxhumana kwendawo ehlanganyelwe, umthelela wokungqubuzana, umthelela wezingxenye eziqinile kancane, kanye nomthelela wokususwa.Izingxenye zemishini ye-Aluminium CNC

6. Amaphutha abangelwa ukuguqulwa okushisayo kwesistimu yenqubo

Ukuwohloka kokushisa kwesistimu yenqubo kuthinta kakhulu amaphutha omshini, ikakhulukazi ngokunemba kanye nokwenza imishini emikhulu. Amaphutha e-machuring abangelwa ukuwohloka kwe-thermal kwesinye isikhathi angadala u-50% wephutha eliphelele le-workpiece.

7. Iphutha lokulungisa

Enqubweni ngayinye yokwenza imishini, kuhlale kunendlela eyodwa noma enye ukulungiswa ohlelweni lwenqubo. Njengoba ukulungiswa kungenakunemba, kwenzeka iphutha lokulungisa. Kuhlelo lokucutshungulwa, ukunemba kwesikhundla okuhambisanayo kwe-workpiece kanye nethuluzi elisethuluzini lomshini liqinisekiswa ngokulungisa ithuluzi lomshini, ithuluzi, isihluthulelo, noma ucezu lomsebenzi. Uma ukunemba kwasekuqaleni kwamathuluzi omshini, amathuluzi, okokulungisa, nezikhala zengcezu yokusebenza zihlangabezana nezimfuneko zobuchwepheshe ngaphandle kokucabangela izici eziguqukayo, amaphutha okulungisa adlala indima ebalulekile kumaphutha omshini.

8. Iphutha lokulinganisa

Uma ingxenye ilinganiswa ngesikhathi noma ngemva kokucubungula, ukunemba kokulinganisa kuthintwa ngokuqondile indlela yokulinganisa, ukunemba kwethuluzi lokulinganisa, ucezu lokusebenza, kanye nezici ezizimele nezinjongo.

9. Ukucindezeleka kwangaphakathi

Ukucindezeleka okukhona ngaphakathi kwengxenye ngaphandle kwamandla angaphandle kubizwa ngokuthi ukucindezeleka kwangaphakathi. Uma ukucindezeleka kwangaphakathi kukhiqizwa ku-workpiece, insimbi izobe ingazinzile futhi ibe nezinga eliphezulu lamandla. Izoshintsha ngokuzenzekelayo ibe yisimo esizinzile sezinga eliphansi lamandla, ehambisana nokuguqulwa, ngakho-ke i-workpiece ilahlekelwa ukunemba kwayo kwasekuqaleni.

I-Anebon Metal Products Limited inganikeza i-CNC Machining, i-Die Casting, isevisi yokwenziwa kwe-Sheet Metal, sicela ukhululeke ukuxhumana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Isikhathi sokuthumela: Jan-11-2022