Ukulungiselela umsebenzi wesikole

(1) Idatha yokusebenza:

Kubandakanya imidwebo yomhlangano ojwayelekile, imidwebo yomhlangano wengxenye, imidwebo yezingxenye, i-BOM yezinto ezibonakalayo, njll., kuze kube sekupheleni kwephrojekthi, ubuqotho nokuhlanzeka kwemidwebo kanye nobuqotho benqubo yolwazi lwamarekhodi kumele kuqinisekiswe.

(2) Indawo yokusebenza:

Ukubekwa kwezingxenye kanye nokuhlanganiswa kwengxenye kufanele kwenziwe endaweni ethile yokusebenza. Indawo lapho umshini ophelele ubekwe futhi uhlanganiswe khona kufanele ihlelwe ngokucacile. Kuze kube sekupheleni kwawo wonke umsebenzi, zonke izindawo zokusebenza kufanele zigcinwe zicocekile, zilinganiselwe futhi zihlelekile.

(3) Izinto zokuhlanganisa:

Ngaphambi kokusebenza, izinto zokuhlanganisa ezibalulwe enqubweni yokuhlanganisa kufanele zibe endaweni ngesikhathi. Uma ezinye izinto ezingahlangani zingekho, ukulandelana kokusebenza kungashintshwa, bese ugcwalisa ifomu lesikhumbuzo lezinto ezibonakalayo bese ulithumela emnyangweni wokuthenga.

(4) Isakhiwo, ubuchwepheshe bokuhlanganisa kanye nezidingo zenqubo yemishini kufanele ziqondwe ngaphambi kokuhlanganiswa.

Izinto ezidingekayo:

Imidwebo yedizayini:

Ukucaciswa kobuchwepheshe bokuhlanganiswa kwemishini ngokuvamile kufaka phakathi imidwebo yedizayini ebonisa izingxenye okufanele zihlanganiswe, ubukhulu bazo, ukubekezelela, nanoma yiziphi izici ezikhethekile noma izidingo.

I-Bill of Materials (BOM):

Lolu uhlu oluphelele lwazo zonke izingxenye ezidingekayo ukuze kuhlanganiswe imishini, kuhlanganise nenani lazo kanye nezingxenye zezinombolo.

Ukucaciswa kwezinto:

Ukucaciswa kobuchwepheshe bokuhlanganiswa komshini kungase futhi kubandakanye ukucaciswa kwempahla, njengohlobo lwempahla okufanele isetshenziselwe ingxenye ngayinye, ubulukhuni bayo, ukuminyana, nezinye izakhiwo.

Izinqubo zokuhlanganisa:

Lena imiyalelo yesinyathelo ngesinyathelo yokuhlanganisa izingxenye, kuhlanganise nanoma imaphi amathuluzi akhethekile noma amasu adingekayo.

Amazinga okulawula ikhwalithi:

Ukucaciswa kobuchwepheshe bokuhlanganiswa komshini kungase futhi kuhlanganise namazinga okulawula ikhwalithi, njengezidingo zokuhlola kanye nemibandela yokwamukela.

Ukupakishwa nokucaciswa kokuthumela:

Ukucaciswa kobuchwepheshe bomhlangano wemishini kungase futhi kubandakanye ukucaciswa kokupakisha nokuthumela, njengohlobo lwezinto zokupakisha ezizosetshenziswa kanye nendlela yokuthunyelwa.

Ukucaciswa okuyisisekelo

(1) Ukuhlanganiswa kwemishini kufanele kuhlanganiswe ngokuhambisana ngokuqinile nemidwebo yomhlangano kanye nezidingo zenqubo ezinikezwe umnyango wokuklama, futhi kwenqatshelwe ngokuphelele ukuguqula okuqukethwe komsebenzi noma ukushintsha izingxenye ngendlela engavamile.

(2) Icnc machining izingxenye zensimbiezizohlanganiswa kumele kube yizo eziphumelela ukuhlolwa komnyango wokuhlola izinga. Uma kukhona izingxenye ezingafanelekile ezitholakala ngesikhathi somhlangano, kufanele zibikwe ngesikhathi.

(3) Indawo yokuhlanganisa idingeka ukuthi ihlanzeke ngaphandle kothuli noma okunye ukungcola, futhi izingxenye kufanele zigcinwe endaweni eyomile, engenalo uthuli enamaphedi okuzivikela.

(4) Phakathi nenqubo yokuhlanganisa, izingxenye ngeke zishaywe, zisikwe, noma ingaphezulu lezingxenye ngeke lonakale, noma izingxenye ngokusobala zizogotshwa, zisontekile noma zikhubazekile, futhi indawo yokuhlangana yezingxenye ngeke yonakale. .

(5) Ezingxenyeni ezihamba kancane, amafutha okugcoba (amafutha) kufanele afakwe phakathi kwezindawo zokuthintana ngesikhathi sokuhlanganisa.

(6) Ubukhulu obuhambisanayo bezingxenye ezifanayo kufanele bube nembayo.

(7) Lapho kuhlanganiswa, izingxenye namathuluzi kufanele kube nezindawo ezikhethekile zokubeka. Ngokuyisisekelo, izingxenye namathuluzi akuvunyelwe ukubekwa emshinini noma ngqo phansi. Uma kunesidingo, amacansi okuzivikela noma amakhaphethi kufanele abekwe endaweni lapho abekwe khona.

(8) Empeleni, ukunyathela umshini akuvunyelwe ngesikhathi somhlangano. Uma kudingeka ukunyathela, amacansi okuzivikela noma okhaphethi kufanele babekwe emshinini. Ukunyathela izingxenye ezibalulekile kanye nezingxenye ezingezona ezensimbi ezinamandla aphansi akuvunyelwe ngokuqinile.

Joyina indlela

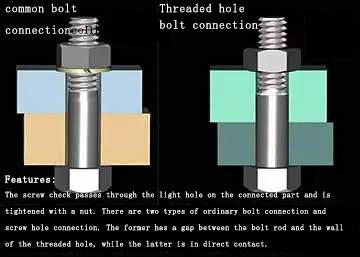

(1) Ukuxhumeka kwe-Bolt

A. Uma uqinisa ama-bolts, ungasebenzisi ama-wrenches aguquguqukayo, futhi ungasebenzisi i-washer eyodwa efanayo ngaphansi kwamantongomane. Ngemuva kokuthi izikulufo ze-countersunk ziqinisiwe, izinhloko ze-nail kufanele zifakwe emshininiinsimbi engagqwali cnc izingxenyefuthi akufanele adalulwe.

B. Ngokuvamile, ukuxhuma okunentambo kufanele kube namawasha asentwasahlobo alwa nokuxega, futhi indlela yokuqinisa amabhawodi amaningi alinganayo kufanele iqiniswe kancane kancane ngokulandelana, futhi izixhumi ze-strip kufanele ziqiniswe ngokulinganayo futhi kancane kancane ukusuka phakathi kuya kuzo zombili izinkomba.

C. Ngemuva kokuthi ama-bolts namantongomane eqinisiwe, ama-bolts kufanele adalule izigxobo ezingu-1-2 zamantongomane; lapho izikulufa zingadingi ukuqaqa izingxenye ngesikhathi sokuqina kwedivayisi ehambayo noma ukulungiswa, izikulufa kufanele ziboshwe nge-glue yentambo ngaphambi kokuhlanganiswa.

D. Kuma-fasteners anezidingo ze-torque ezibaluliwe, i-torque wrench kufanele isetshenziselwe ukuziqinisa ngokuya nge-torque ecacisiwe yokuqinisa. Ngamabhawodi angenayo i-torque eqinisiwe ecacisiwe, i-torque eqinisayo ingabhekisela kumithethonqubo "ku-Appendix".

(2) Phina uxhumano

A. Ubuso bokugcina bephinikhodi yokumisa ngokuvamile kufanele bube phezulu kancane kunobuso bengxenye. Ngemuva kokuthi iphinikhodi ecijile enomsila oyisikulufa efakwe ezingxenyeni ezifanele, ukuphela kwayo okukhulu kufanele kucwile emgodini.

B. Ngemuva kokuthi iphinikhodi ye-cotter ilayishwe endaweni efaneleizingxenye ezigayiwe, imisila yayo kufanele ihlukaniswe ngo-60°-90°.

(3) Ukuxhumana okubalulekile

A. Izinhlangothi ezimbili zokhiye ongukhiye wokhiye oyisicaba kanye nokhiye ogxilile kufanele zithintane ngokufanayo, futhi akumele kube negebe phakathi kwezindawo zokukhwelana.

B. Ngemva kokuba isihluthulelo (noma i-spline) esine-clearance fit siqoqwe, lapho izingxenye ezihambayo ezihambisanayo zihamba ngendlela ye-axial, akumele kube khona ukungalingani ekuqineni.

C. Ngemuva kokuthi ukhiye we-hook kanye nokhiye we-wedge uhlangene, indawo yabo yokuxhumana akufanele ibe ngaphansi kuka-70% wendawo yokusebenza, futhi izingxenye ezingezona othintana nazo akufanele zigxilwe endaweni eyodwa; ubude bengxenye eveziwe kufanele bube ngu-10% -15% wobude bomthambeko.

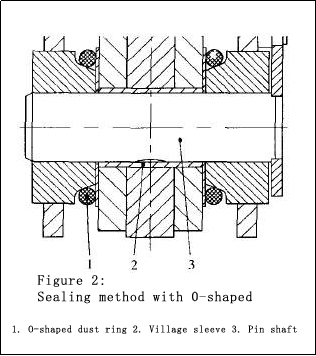

(4) Ukuhleka

A. Izinto zokwakha kanye nokucaciswa kwe-riveting kufanele kuhlangabezane nezidingo zedizayini, futhi ukucutshungulwa kwezimbobo ze-rivet kufanele kuhlangabezane nezindinganiso ezifanele.

B. Lapho i-riveting, ingaphezulu lezingxenye ezigoqiwe angeke lonakaliswe, noma ubuso bezingxenye ezigoqiwe ngeke bukhubazeke.

C. Ngaphandle uma kunezidingo ezikhethekile, akumele kube nokuxega ngemva kokugibela. Inhloko ye-rivet kumele ixhumane eduze nezingxenye eziboshwe futhi kufanele ibe bushelelezi futhi iyindilinga.

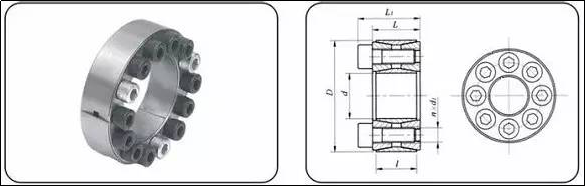

(5) Ukuxhumeka kwemikhono yokwandisa

Umhlangano womkhono wokunweba: Faka amafutha okugcoba kumkhono wokunweba, faka umkhono wokunweba embotsheni yehabhu ehlanganisiwe, faka umshini wokufaka, ulungise indawo yomhlangano, bese uqinisa amabhawodi. I-oda lokuqiniswa liboshwe ngokusikeka, futhi kwesokunxele nesokudla kuyaphambana futhi kuqiniswe ngokulinganayo ngokulandelana ukuze kuqinisekiswe ukuthi inani letorque elilinganiselwe liyafinyelelwa.

(6) ukuxhumana okuqinile

Ukuphela kwe-tapered kanye nembobo yesikulufu esisethiwe nge-conical end kufanele kube ngu-90 °, futhi isikulufu esisethiwe kufanele siqiniswe ngokuvumelana nembobo.

Ukuhlanganiswa kweziqondiso zomugqa

(1) Akumele kube khona ukungcola engxenyeni yokufaka ujantshi womhlahlandlela, futhi ukuvuleka kwendawo yokufaka kufanele kuhlangabezane nezidingo.

(2) Uma kukhona unqenqema lwereferensi ohlangothini lwesitimela somhlahlandlela, kufanele lufakwe eduze konqenqema lwereferensi. Uma lungekho unqenqema lwereferensi, isiqondiso sokuslayida sikajantshi womhlahlandlela kufanele sihambisane nezidingo zedizayini. Ngemva kokuqinisa izikulufo zokulungisa zesitimela somhlahlandlela, hlola ukuthi ingabe kukhona ukuchezuka endaweni eslayidayo yesilayidi. Uma kungenjalo kufanele ilungiswe.

(3) Uma isilayidi siqhutshwa ibhande lokudlulisela, ngemva kokuba ibhande lokudlulisela kanye nesilayidi zilungisiwe futhi ziqinisiwe, ibhande lokudlulisela akufanele lidonswe ngokukhululekile, ngaphandle kwalokho i-pulley kufanele ilungiswe ukuze isiqondiso sokushayela kwebhande lokudlulisela ihambisana nomzila wesitimela.

Ukuhlanganiswa kwe-sprocket chain

(1) Ukusebenzisana phakathi kwe-sprocket ne-shaft kumele kuhlangabezane nezidingo zokuklama.

(2) Izindiza ezimaphakathi zejiyomethri zamazinyo egiya le-sprocket yokushayela kanye ne-sprocket eshayelwa kufanele ziqondane, futhi i-offset akumele yeqe izimfuneko zokuklama. Uma kungacacisiwe ekwakhiweni, kufanele ngokuvamile kube ngaphansi noma kulingane no-2 ‰ webanga eliphakathi nendawo phakathi kwamasondo amabili.

(3) Lapho iketango lihlangana ne-sprocket, uhlangothi olusebenzayo kufanele luqiniswe ukuze kuqinisekiswe ukuhlangana okubushelelezi.

(4) I-sag yohlangothi olungasebenzi lweketango kufanele luhlangabezane nezidingo zokuklama. Uma kungacaciswanga ekwakhiweni, kufanele kulungiswe ngokuya ngo-1% kuya ku-2% webanga eliphakathi nendawo phakathi kwama-sprockets amabili.

Ukuhlanganiswa kwamagiya

(1) Ngemuva kokuthi amagiya ahlanganayo ahlanganiswa, lapho ububanzi berimu legiya bungaphansi noma bulingana no-20mm, ukungahambi kahle kwe-axial akumele kudlule ku-1mm; lapho ububanzi berimu legiya bukhulu kuno-20mm, ukungahambi kahle kwe-axial akufanele kudlule u-5% wobubanzi berimu.

(2) Izidingo zokunemba zokufakwa kwamagiya angama-cylindrical, amagiya e-bevel, namadrayivu e-worm kufanele zicaciswe kokuthi JB179-83 “Involute Cylindrical Gear Accuracy”, JB180-60 “Bevel Gear Transmission Tolerance” kanye ne-JB162 ngokulandelanayo ngokuya ngokunemba nosayizi we izingxenye zokudlulisela -60 "Ukubekezelelana kwe-Worm Drive" kuqinisekisiwe.

(3) Indawo enemeshing yamagiya kufanele igcotshwe ngokujwayelekile ngokwezidingo zobuchwepheshe, futhi i-gearbox izogcwaliswa ngamafutha okugcoba emgqeni wezinga likawoyela ngokwezidingo zobuchwepheshe.

(4) Umsindo webhokisi lika-gearbox uma ugcwala akumele udlule ku-80dB.

Ukulungiswa kwe-rack nokuxhumeka

(1) Ukulungiswa kokuphakama kwama-rack ezingxenye ezihlukene kufanele kulungiswe kubude obufanayo ngokuya ngendawo eyireferensi efanayo.

(2) Amaphaneli odonga awo wonke ama-rack kufanele alungiswe endizeni efanayo eqondile.

(3) Ngemuva kokuthi ama-racks esigaba ngasinye alungiswe endaweni futhi ahlangabezane nezidingo, amapuleti ahlanganisiwe ahlanganisiwe phakathi kwawo kufanele afakwe.

Ukuhlanganiswa kwezingxenye ze-pneumatic

(1) Ukumiswa kwesethi ngayinye yesisetshenziswa somshini womoya wokuphefumula kufanele kuxhunywe ngokuhambisana ngokuqinile nomdwebo wesekethe yomoya ohlinzekwe umnyango wokuklama, futhi ukuxhunywa komzimba wamavalvu, ijoyinti lepayipi, isilinda, njll. kumele kuhlolwe ngendlela efanele.

(2) I-inlet ne-outlet ye-valve yokunciphisa ingcindezi yokungenisa umoya iyonke ixhunywe ngalapho kumcibisholo khona, futhi inkomishi yamanzi nenkomishi kawoyela yesihlungi somoya kanye nokothambisa kufanele kufakwe ziqonde phansi.

(3) Ngaphambi kokufaka amapayipi, impushana yokusika nothuli olusepayipini kufanele kuqhunyiswe ngokuphelele.

(4) Ijoyinti yepayipi ifakwe ngesikulufi. Uma intambo yepayipi ingenayo ingcina yeglue, itheyiphu yempahla eluhlaza kufanele ilinyazwe. Indawo emazombezombe ihambisana newashi ukusuka phambili. Itheyiphu yempahla eluhlaza akumele ihlanganiswe nevalvu. Lapho ugoqa, intambo eyodwa kufanele igcinwe.

(5) Ukuhlelwa koqhoqhoqho kufanele kube kuhle futhi kube kuhle, zama ukungaweqi ukuhlelwa, futhi emakhoneni kufanele kusetshenziswe izindololwane ezingu-90°. Lapho i-trachea ilungisiwe, ungafaki amalunga ekucindezelekeni okwengeziwe, ngaphandle kwalokho kuzodala ukuvuza komoya.

(6) Lapho uxhuma i-valve ye-solenoid, naka indima yenombolo yembobo ngayinye kuvalvu: P: inani eliphelele; A: i-outlet 1; B: isitolo 2; R (EA): i-exhaust ehambisana no-A; S (EB) : I-Exhaust ehambisana no-B.

(7) Uma isilinda sihlanganiswa, i-axis ye-piston rod kanye nesiqondiso sokunyakaza komthwalo kufanele kuhambisane.

(8) Uma usebenzisa ama-linear bearings ukuqondisa, ngemva kokuba ingxenye yangaphambili ye-cylinder piston rod ixhunywe emthwalweni, akumele kube namandla angavamile ngesikhathi sonke sokushaywa, ngaphandle kwalokho isilinda sizolimala.

(9) Uma usebenzisa i-throttle valve, kufanele kuqashelwe uhlobo lwe-throttle valve. Ngokuvamile, ihlukaniswa ngomcibisholo omkhulu omakwe emzimbeni we-valve. Lona onomcibisholo omkhulu obheke ekugcineni okunentambo usetshenziselwa isilinda; lowo onomcibisholo omkhulu obheke ekugcineni kwepayipi usetshenziselwa i-valve ye-solenoid.

Umsebenzi wokuhlola umhlangano

(1) Ngaso sonke isikhathi lapho ukuhlanganiswa kwengxenye kuqedwa, kufanele kubhekwe ngokwalezi zinto ezilandelayo. Uma kutholakala inkinga yomhlangano, kufanele ihlaziywe futhi kubhekwane nayo kusenesikhathi.

A. Ubuqotho bomsebenzi wokuhlanganisa, hlola imidwebo yomhlangano, futhi uhlole ukuthi azikho yini izingxenye ezingekho.

B. Ukuze uthole ukunemba kwendawo yokufaka ingxenye ngayinye, hlola umdwebo womhlangano noma izidingo ezishiwo ekucacisweni okungenhla.

C. Ukwethembeka kwengxenye ngayinye yokuxhuma, noma isikulufu sokubopha ngasinye siyahlangabezana netorque edingekayo ukuze sihlanganiswe, nokuthi ingabe isibophelelo esikhethekile siyahlangabezana yini nemfuneko yokuvimbela ukuxega.

D. Ukuguquguquka kokunyakaza kwezingxenye ezihambayo, njengokuthi ingabe kukhona ukuma noma ukuma, ukucaca noma ukugoba lapho amarola, ama-pulley, ama-guide rails, njll. ezungeziswa noma enyakaziswa.

(2) Ngemva komhlangano wokugcina, ukuhlola okuyinhloko ukuhlola ukuxhumana phakathi kwezingxenye zomhlangano, futhi okuqukethwe kokuhlola kusekelwe “ezicini ezine” ezishiwo ku-(1) njengezinga lokulinganisa.

(3) Ngemva komhlangano wokugcina, izinsimbi zensimbi, udoti, uthuli, njll. engxenyeni ngayinye yomshini kufanele zihlanzwe ukuze kuqinisekiswe ukuthi azikho izithiyo ekudluliseni ngakunye.ukunemba waphenduka izingxenye.

(4) Lapho uhlola umshini, yenza umsebenzi omuhle wokuqapha inqubo yokuqalisa. Ngemuva kokuthi umshini uqale, kufanele ubheke ngokushesha ukuthi imingcele yokusebenza eyinhloko nezingxenye ezihambayo zihamba ngokujwayelekile.

(5) Imingcele yokusebenza eyinhloko ihlanganisa isivinini sokunyakaza, ukuzinza kokunyakaza, ukujikeleza kwe-shaft ngayinye yokudlulisela, izinga lokushisa, ukudlidliza nomsindo, njll.

I-Anebon inamathela esimisweni esiyisisekelo sokuthi "Ikhwalithi ngokuqinisekile iyimpilo yebhizinisi, futhi isimo singase sibe umphefumulo walo" ukuze uthole isaphulelo esikhulu sokunemba ngokwezifiso 5 I-Axis CNC Lathe CNC Machined Part, Anebon siyaqiniseka ukuthi singanikela ngemikhiqizo yekhwalithi ephezulu. nezisombululo ngentengo ephusile, ukwesekwa okuphezulu kwangemva kokuthengisa kubathengi. Futhi i-Anebon izokwakha isikhathi eside esinempilo.

Ingxenye ye-Chinese Professional yaseChina ye-CNC kanye nezingxenye ze-Metal Machining, i-Anebon ithembele ezintweni ezisezingeni eliphezulu, idizayini ephelele, isevisi yamakhasimende enhle kakhulu kanye nenani lokuncintisana ukuze lizuze ukwethenjwa kwamakhasimende amaningi ekhaya naphesheya. Imikhiqizo efika kuma-95% ithunyelwa ezimakethe zaphesheya.

Isikhathi sokuthumela: May-03-2023