1. Thola ngobuhlakani amanani amancane okudla futhi usebenzise imisebenzi ye-trigonometric ngobuhlakani

Thola ukudla okuncane ngobuhlakani futhi usebenzise imisebenzi ye-trigonometric ngempumelelo.Ngesikhathi sokujika, ama-workpiece anemibuthano yangaphakathi nangaphandle edinga ukunemba okuphezulu avame ukucutshungulwa. Izinselele ezifana nokusika ukushisa, ukuguga okubangela ukuguga kwamathuluzi, kanye nokunemba okuphindaphindiwe kwesibambi sethuluzi lesikwele kwenza kube nzima ukuqinisekisa ikhwalithi.

Ukuze sibhekane nokujula okunembile kokuthatha okuncane, silungisa isibambi sethuluzi le-longitudinal nge-engeli esekelwe ebudlelwaneni obuphakathi kwezinhlangothi eziphambene kanye ne-hypotenuse kanxantathu, okuvumela ukujula okuqondile okuphambene phakathi nenqubo yokujika. Le ndlela ihlose ukonga isikhathi nomsebenzi, ukugcina ikhwalithi yomkhiqizo, nokuthuthukisa ukusebenza kahle komsebenzi.

Ivelu yesikali esijwayelekile yesibambi sethuluzi le-lathe le-C620 ngu-0.05mm isigaba ngasinye. Ukuze kuzuzwe ukujula kwe-lateral okungu-0.005mm, kubhekiselwa kuthebula lomsebenzi we-sine trigonometric:sinα=0.005/0.05=0.1 α=5º44′Ngakho-ke, ukulungisa isibambi sethuluzi sibe ngu-5º44′ kwenza ithuluzi lokujika likwazi ukuzuza ukujula okuncane okungu-0.005mm endaweni isiqondiso esiphambene nokunyakaza ngakunye kohlaka lwe-longitudinal.

2. Amakesi amathathu obuchwepheshe bokushayela emuva

Umuzwa obanzi wokukhiqiza ukhombisile ukuthi ukusebenzisa ubuchwepheshe bokusika okubuyela emuva ezinqubweni ezithile zokuguqula kungaveza imiphumela emihle. Izehlakalo zamanje zifaka:

(1) Izingxenye zensimbi engagqwali ye-Martensitic zisetshenziswa njengento yokuhlehla izintambo zokusika.

Uma usebenza kuma-workpieces anemicu engu-1.25 kanye no-1.75mm, kuvamile ukuhlangabezana nezinkinga ezihlobene nokuhoxiswa kwamathuluzi nokubopha. Ama-lathes ajwayelekile avame ukuntula idivayisi ye-buckling disk, edinga izixazululo zangokwezifiso ezidla isikhathi. Ngenxa yalokho, ukucubungula imicu enalawa ma-pitches athile kungadla isikhathi futhi ukuphenduka okunesivinini esiphansi kungaba ukuphela kwendlela esebenzayo.

Kodwa-ke, ukusika ngesivinini esiphansi kungaholela ekulumeni kwamathuluzi kanye nokuba mahhadlahhadla kahle kwendawo, ikakhulukazi uma usebenzisana nezinto zensimbi engagqwali ye-martensitic efana no-1Crl3 no-2 Crl3. Ukuze kubhekwane nalezi zinselele, indlela yokusika "emihlehla emithathu" yathuthukiswa ekusebenzeni komshini.

Le ndlela, ebandakanya ukulayisha ithuluzi okuhlanekezelwe, ukuhlehla ukusika, nezikhombisi-ndlela zokusika eziphambene, ifakazele ukuthi iyasebenza ekuzuzeni ukusika intambo enesivinini esikhulu ngokuhlehlisa ithuluzi elibushelelezi. Le ndlela inenzuzo ikakhulukazi njengoba ivumela ukusika okuphumelelayo futhi igwema izinkinga ezingase zibe khona zokuququda ithuluzi ezihlobene nokujika kwesivinini esiphansi.

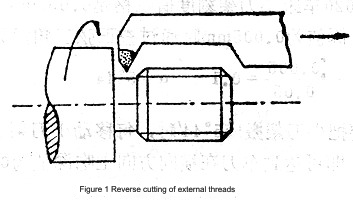

Lapho ingaphandle yemoto, gaya isibambo esifana nentambo yangaphakathi yommese wemoto (Umfanekiso 1);

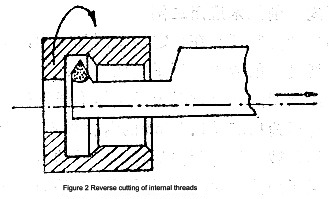

Lapho intambo yangaphakathi yemoto igaya, ummese ongaphakathi ongemuva ongemuva (Umfanekiso 2).

Ngaphambi kokuqala inqubo, lungisa i-spindle ye-counter-rotation disc spindle ukuze uqinisekise isivinini sokuzungezisa uma uqalisa ukuzungezisa okuphikisayo. Okulandelayo, beka futhi uvikele i-thread cutter, qalisa ukuzungezisa phambili ngesivinini esiphansi, futhi uye endaweni engenalutho yamathuluzi. Bese, qhubeka nokufaka ithuluzi lokujika intambo ekujuleni okufanelekile kokusika ngaphambi kokushintshela ekuzungekiseni emuva. Phakathi nalesi sigaba, ithuluzi lokuguqula kufanele lijikeleze ukusuka kwesokunxele liye kwesokudla ngesivinini esikhulu. Ngemva kokusikeka okuningana kulandela le ndlela, kungenzeka ukufeza intambo enobulukhuni obuphezulu kanye nokunemba okuphezulu.

(2) Izimbali eziginqika ezimelene nezimoto

Uma usebenzisa i-lathe yokugoqa yendabuko, kuvamile ukuthi izinhlayiya zensimbi nemfucumfucu kungene ucezu lokusebenza nethuluzi lokusika. Ukusebenzisa indlela entsha yokusebenza nge-spindle ye-lathe kunganciphisa ngempumelelo izingqinamba okuhlangatshezwane nazo ngesikhathi sokusebenza okujwayelekile futhi kuholele emiphumeleni emihle iyonke.

(3) Ukuhlehla ukujika kwemicu yepayipi ecishiwe yangaphakathi neyangaphandle

Lapho usebenza emicu yepayipi ecijile yangaphakathi nengaphandle enezidingo ezinembayo eziphansi kanye namaqoqo amancane, ungasebenzisa ngokuqondile indlela entsha yokuhlehla yokusika nokufaka ithuluzi lokuhlehla ngaphandle kwesidingo sedivayisi yesifanekiso, ukugcina izinqubo zokusika eziqhubekayo.

Ukusebenza kahle kommese wokuswayipha ongemuva kwemanuwali, oshanela ukusuka kwesokunxele kuye kwesokudla lapho uphendula intambo yepayipi le-taper yangaphandle, kusemandleni awo okulawula ngempumelelo ukujula kommese wokusika ukusuka kububanzi obukhudlwana kuye kububanzi obuncane ngenxa yengcindezi yangaphambili ngesikhathi. inqubo yokusika. Ukusetshenziswa kwalobu buchwepheshe obusha bokubuyela emuva ekuguquleni kuyaqhubeka nokukhula futhi kungashintshwa kalula ukuze kuhambisane nezimo ezithile ezihlukile.

3. Ukusebenza okusha kanye nokusungulwa kwethuluzi lokumba izimbobo ezincane

Ngesikhathi sokuvula, lapho izimbobo zokumba ezincane kuno-0.6mm, ububanzi obulinganiselwe kanye nokungaqinile kahle kwe-drill bit kuvimbela ukwanda kwejubane lokusika. I-workpiece material, i-alloy ukumelana nokushisa nensimbi engagqwali, ibonisa ukumelana nokusika okuphezulu. Ngenxa yalokho, ukusebenzisa indlela yokudla ngokudlulisa ngomshini ngesikhathi sokumba kunganqamula i-drill bit. Isixazululo esilula nesisebenzayo siwukusebenzisa indlela yokudla okwenziwa ngesandla kanye nethuluzi elikhethekile.

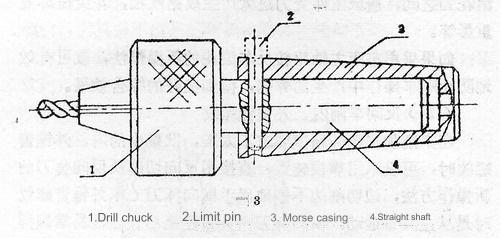

Isinyathelo sokuqala sibandakanya ukuguqula i-drill chuck ibe uhlobo oluntantayo lwe-straight-shank. Ngokubophela i-drill bit encane ku-drill chuck entantayo, ukubhola okubushelelezi kufinyelelwa. Ingxenye engemuva yebhithi yokubhoboza ihlanganisa isibambo esiqondile kanye nokulingana okuslayidayo, okuvumela ukunyakaza kwamahhala ngaphakathi komdonsi. Khonamanjalo, lapho ubhoboza imbobo encane, ukuphakela okuncane ngesandla okuthambile nge-drill chuck kusiza ukubhola okusheshayo, ukugcina ikhwalithi nokwelula impilo yesevisi yezingcezu ezincane zokubhoboza.

Ukwengeza, i-chuck ye-drill eguquliwe enezinjongo eziningi ingasetshenziselwa ukuthepha intambo yangaphakathi enobubanzi obuncane, ukubuyisela kabusha, kanye nemisebenzi efanayo. Ngezimbobo ezinkulu, kunconywa ukufaka iphinikhodi phakathi komkhono wokudonsa nesibambo esiqondile. Bheka Umfanekiso 3 ukuze uthole imininingwane ebonakalayo.

4. I-Shockproof yokucubungula imbobo ejulile

Ngesikhathi sokucutshungulwa kwembobo ejulile, inhlanganisela yobubanzi bembobo encane kanye ne-shank yethuluzi eliyisicefe encane ingaholela ekudlidlizeni okungenakugwenywa lapho uguqula izingxenye ezinobubanzi bembobo obusuka ku-Φ30 ukuya ku-Φ50mm kanye nokujula okungaba ngu-1000mm. Ukunciphisa ukudlidliza nokuqinisekisa ukucutshungulwa kwembobo ejulile yekhwalithi ephezulu, indlela eqondile nephumelelayo ihlanganisa ukunamathisela izisekelo ezimbili, ezakhiwe ngezinto ezifana nendwangu ne-bakelite, emzimbeni wenduku.

Lezi zisekelo kufanele zifane nosayizi wobubanzi bembobo ngokunembile. Ngokusebenzisa ibhulokhi ye-bakelite ehlanganiswe ngendwangu njengokweseka indawo phakathi kwenqubo yokusika, ibha yamathuluzi iyasimama, kunciphisa kakhulu amathuba okudlidliza futhi yenze ukukhiqizwa kwezingxenye zembobo ejulile yekhwalithi ephezulu.

5. Ukuvimbela ukuphuka kwama-drill amancane aphakathi nendawo

Ngesikhathi sokujika, ukubhoboza imbobo ephakathi nendawo encane kuno-Φ1.5mm kubeka engcupheni enkulu yokubhodloza imbobo emaphakathi. Indlela ephumelelayo yokuvimbela ukuphuka ukugwema ukukhiya isigxobo somsila ngenkathi ubhoboza imbobo ephakathi. Lokhu kuvumela isisindo esifile se-tailstock namandla okushayisana phakathi kwawo nombhede wethuluzi lomshini ukuthi kusetshenziselwe ukumba. Ezimweni lapho ukumelana nokusika kudlulele, i-tailstock izohoxisa ngokuzenzakalelayo, ngaleyo ndlela ivikele i-drill ephakathi.

6. Ubunzima bokucubungula isicelo sezinto ezibonakalayo

Uma sinobunzima bokucubungula izinto ezifana ne-high-temperature alloy nensimbi yokucisha, ubulukhuni obungaphezulu bomsebenzi womsebenzi kudingeka ukuthi bube ku-RA0.20 kuya ku-0.05 μm, nokunemba kosayizi nakho kuphezulu. Ekugcineni, ukucubungula okuhle kuvame ukwenziwa embhedeni wokugaya.

7. Ukulayisha okusheshayo nokuthulula i-spindle

Phakathi nezinqubo zokuphenduka, sivamise ukuhlangana nezinhlobonhlobo zamakhithi ama-bearing abonisa imibuthano yangaphandle ephendulwe kahle kanye nama-engeli e-taper kagayidi ahlanekezelwe. Ngenxa yobukhulu bawo benqwaba, adinga ukulayishwa nokulayishwa ngesikhathi sokucubungula. Isikhathi esidingekayo sokushintsha ithuluzi side kunesikhathi sangempela sokusika, okuholela ekunciphiseni ukusebenza kahle kokukhiqiza.

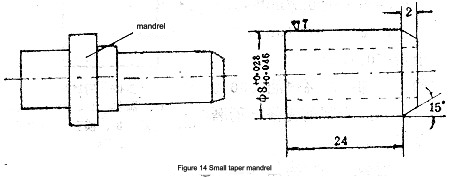

Ukulayisha okusheshayo nokukhipha i-mandrel, kanye nethuluzi lokujika le-single-blade (i-tungsten carbide) elichazwe ngezansi, linganciphisa isikhathi esiyisizayo futhi liqinisekise ikhwalithi yemikhiqizo lapho kucutshungulwa izingxenye zemikhono yokuthwala ehlukahlukene. Indlela yokukhiqiza imi kanje: Ukwakha i-mandrel encane-taper elula, i-taper encane ye-0.02mm isetshenziswa ngemuva.

Uma i-bearing isifakiwe, izingxenye zivikeleka ku-mandrel ngokusebenzisa ukungqubuzana, bese kusetshenziswa ithuluzi lokujika eline-blade elinemiphetho eminingi ukuze lisebenze ngaphezulu. Ngemva kokuzungezisa, i-engeli yekhoni iphendulelwa ku-15°, ngaleso sikhathi isikrufu sisetshenziselwa ukukhipha izingxenye ngokushesha nangempumelelo, njengoba kuboniswe kuMfanekiso 14.

8. Ukushayela kwezingxenye zensimbi ezicishayo

(1) Esinye sezibonelo eziyinhloko zokucishacnc imikhiqizo ngomshini

①I-high-speed steel W18CR4V ukuhlelwa kabusha kanye nokwenza kabusha (ukulungisa ngemva kwekhefu)

② Amazinga E-Slocculus Engajwayelekile Enziwe Ekhaya (Ukuqothulwa Kanzima)

③ Ukushayela kwezingxenyekazi zehadiwe nezingxenye zokufafaza

④ Ishayelwa ubuso obukhanyayo behadiwe

⑤ Kampompi okhanyayo onentambo ecolisisiwe ngommese wensimbi onesivinini esikhulu

Lapho sisebenzelana ne-hardware eqinile kanye nezingxenye zezinto ezibonakalayo eziyinselele emshinini ekukhiqizeni kwethu, ukukhethwa ngokucophelela kwezinto ezisetshenziswayo ezifanele kanye nenani lokusika, kanye nama-engeli ejiyomethri amathuluzi nezindlela zokusebenza, kungaletha izinzuzo ezibalulekile zezomnotho. Ngokwesibonelo, lapho i-square-mouth broach iphuka futhi ivuselelwa ukuze isetshenziswe ekukhiqizeni enye i-square-mouth broach, ayigcini nje ukwandisa umjikelezo wokukhiqiza kodwa futhi iholela ezindlekweni eziphezulu.

Indlela yethu ihlanganisa ukusebenzisa i-carbide YM052 namanye amathiphu e-blade ukuze kucwengwe impande ephukile ye-broach yasekuqaleni ibe i-engeli yangaphambili eyi-negative r. = -6°~ -8°, okuvumela ukuthi unqenqema lokusika lubuyiselwe ngemva kokugaya ngokucophelela nge-whetstone. Ijubane lokusika libekwe ku-V = 10~15m/min. Ngemuva kokuguqula umbuthano wangaphandle, i-groove engenalutho iyasikwa, bese intambo iphendulwa (ehlanganisa ukujika okunamandla nokuhle). Ukulandela ukuphenduka okulukhuni, ithuluzi kufanele lilolwe futhi ligaywe ngaphambi kokuqedela intambo yangaphandle, futhi ngemva kwalokho, ingxenye yentambo yangaphakathi ilungiselelwa ukuxhuma intambo yokubopha, ebuye inqunywe ngemva kokuxhuma. Ngenxa yalezi zinqubo zokuguqula, i-broach yesikwele ephukile nelahliwe yalungiswa futhi yabuyiselwa esimweni sayo sokuqala.

(2) Ukukhethwa kwezinto ezisetshenziswayo zomshini wehardware eqinile

① Amabanga amasha okufakwa kwe-carbide afana ne-YM052, YM053, ne-YT05 ngokuvamile asetshenziswa ekusikeni isivinini esingaphansi kuka-18m/min, kuzuzwe ubulukhuni bendawo yokusebenza obungu-Ra1.6~0.80μm.

②Ithuluzi le-FD cubic boron nitride liyakwazi ukucubungula uhla lwensimbi ecishiwe kanye nezingxenye ezimbozwe ngesifutho ngesivinini sokusika esingafika ku-100m/min, okuholela ekuqineni komhlaba okungu-Ra0.80~0.20μm. Ithuluzi le-DCS-F eliyinhlanganisela ye-cubic boron nitride elivela ku-Capital Machinery Factory kanye ne-Guizhou No. 6 Grinding Wheel Factory yabelana ngalokhu kusebenza. Nakuba umphumela wayo wokucubungula ungewona ophakeme njenge-carbide ehlanganisiwe, ayinawo amandla afanayo nokujula kokungena, futhi iza ngezindleko eziphakeme kanye nengozi yokulimala kwekhanda lomsiki uma isetshenziswe ngendlela engafanele.

③Amathuluzi okusika othayela asebenza ngesivinini sokusika esingu-40-60m/min kodwa anamandla aphansi.Ithuluzi ngalinye kulawa libonisa izici ezihlukile zomshini wezingxenye ezicishiwe futhi kufanele zikhethwe ngokusekelwe ezimeni ezithile ezihlanganisa ukuhluka kwempahla nobulukhuni.

(3) Izidingo Zokusebenza Kwamathuluzi Ezimpahleni Ezihlukene Zezingxenye Zensimbi Ecishiwe Izingxenye zensimbi ezicishiwe zezinto ezihlukahlukene zidinga ukusebenza kwamathuluzi okuhlukile ngaphansi kokuqina okufanayo futhi zingahlukaniswa ngezigaba ezintathu ezilandelayo:

Insimbi ephezulu ye-alloy:Lokhu kuphathelene nensimbi yamathuluzi ne-die steel (ikakhulukazi izinsimbi ezihlukahlukene ezinesivinini esikhulu) ezinokuqukethwe kwento eyingxube yengxubevange engaphezu kuka-10%.

Insimbi ye-alloy:Lokhu kuhlanganisa insimbi yamathuluzi ne-die steel enokuqukethwe kwe-alloy element esukela ku-2 kuya ku-9%, isibonelo, i-9SiCr, i-CrWMn, nensimbi yesakhiwo esinamandla amakhulu.

Insimbi ye-Carbon:Lokhu kuhlanganisa izinsimbi ezihlukahlukene zamathuluzi ekhabhoni nezinsimbi ezigayiwe ezifana ne-T8, T10, No. 15 steel noma No. 20 steel carburized steel, phakathi kokunye. Ngemva kokucisha, i-microstructure ye-carbon steel ihlanganisa i- tempered martensite kanye nenani elincane lama-carbides. Lokhu kuphumela kububanzi obuqinile be-HV800~1000, obuphezulu kunalelo lwe-WC ne-TiC ku-carbide enosimende kanye ne-A12D3 kumathuluzi e-ceramic.

Ukwengeza, ubulukhuni bayo obushisayo buphansi kunabo be-martensite engenazo izakhi zengxubevange, ngokuvamile abudluli ku-200°C.

Ukwandisa ubukhona bezakhi ze-alloying ensimbi kuholela ekwandeni okuhambisanayo kokuqukethwe kwe-carbide yensimbi ngemva kokucisha nokushisa, okuholela ekuxubeni okuyinkimbinkimbi kwezinhlobo ze-carbide. Insimbi enesivinini esiphezulu isebenza njengomfanekiso, lapho okuqukethwe kwe-carbide ku-microstructure ngemva kokucisha nokushisa kungafinyelela ku-10-15% (isilinganiso sevolumu). Lokhu kuhlanganisa izinhlobo ezahlukene zama-carbides njenge-MC, M2C, M6, M3, 2C, nezinye, ezine-VC ebonisa ubulukhuni obuphezulu (HV2800), obudlula kude ubulukhuni bezinto zamathuluzi ezijwayelekile.

Ngaphezu kwalokho, ukuqina okushisayo kwe-martensite equkethe izakhi eziningi ze-alloying kungakhushulwa cishe ku-600°C. Ngakho-ke, amandla okwenza insimbi ecishiwe enobunzima obukhulu obufanayo iyehluka kakhulu. Ngaphambi kokwenza ingxenye yensimbi ecishiwe, kubalulekile ukuthi uqale uhlaziye isigaba sayo, uqonde izici zayo, bese ukhetha izinto ezisetshenziswayo ezifanele, imingcele yokusika, nejometri yamathuluzi. Ngokucatshangelwa okufanele, ukuphenduka kwezingxenye zensimbi eziqinile kungenziwa ngama-engeli ahlukahlukene.

I-Anebon iyaziqhenya ngokugcwaliseka kwamakhasimende okuphezulu nokwamukelwa kabanzi ngenxa yokuphikelela kwe-Anebon kwekhwalithi ephezulu kokubili emkhiqizweni nasensizakalweni Yezici Zekhompyutha Zesitifiketi Se-CE Esenziwe Ngokwezifiso.CNC Izingxenye MillingI-Metal, i-Anebon ibilokhu ijaha isimo se-WIN-WIN nabathengi bethu. I-Anebon yamukele ngokufudumele amakhasimende avela emhlabeni wonke abeza ngaphezu kokuvakasha futhi amise ubudlelwano bothando obuhlala isikhathi eside.

CE Certificate China cnc machined aluminium izingxenye,Izingxenye ze-CNC eziphendukilekanye nezingxenye ze-cnc lathe. Bonke abasebenzi basefekthri, esitolo, nasehhovisi lase-Anebon balwela umgomo owodwa owodwa wokuhlinzeka ngekhwalithi engcono nesevisi. Ibhizinisi langempela ukuthola isimo sokuwina-win. Sithanda ukunikeza ukwesekwa okwengeziwe kumakhasimende. Yamukela bonke abathengi abahle ukuze baxhumane nathi imininingwane yemikhiqizo yethu nezisombululo!

Uma ufuna ukwazi okwengeziwe noma unemibuzo, sicela uxhumaneinfo@anebon.com.

Isikhathi sokuthumela: Feb-18-2024