Wazi kangakanani ngokuklama komshini?

Idizayini yemishini igatsha lobunjiniyela elisebenzisa izimiso namasu ahlukahlukene ukuklama, ukuhlaziya kanye nokwenza kahle amasistimu nezingxenye zemishini. Idizayini yemishini ihlanganisa ukuqonda inhloso ehlosiwe yengxenye noma isistimu, ukukhetha izinto ezisetshenziswayo ezifanele, kucatshangelwa izici ezihlukahlukene, ezifana nezingcindezi namandla, kanye nokuqinisekisa ukusebenza okuthembekile nokusebenza kahle.

Idizayini yemishini ihlanganisa ukuklanywa komshini, ukwakheka kwesakhiwo, ukwakheka kwemishini kanye nokwakhiwa komkhiqizo. Idizayini yomkhiqizo iphathelene nokuklanywa kwemikhiqizo ebonakalayo efana nempahla yabathengi, okokusebenza kwasembonini nokunye okubambekayo. Ukwakhiwa komshini, ngakolunye uhlangothi, kugxile ekwakhiweni kwemishini efana nezinjini, izinjini zomoya kanye nemishini yokukhiqiza. Idizayini ye-Mechanism iphathelene nokuklama izindlela eziguqula okokufaka kube okokukhiphayo okufunayo. Ukuklama kwesakhiwo kuyisinyathelo sokugcina. Kubandakanya ukuhlaziywa nokuklanywa kwezakhiwo ezinjengamabhuloho, izakhiwo, namafreyimu ukuze zibe namandla, ukuzinza, ukuphepha, nokuqina kwazo.

Injani inqubo yokuklama ethile?

Inqubo yokuklama ngokuvamile ihilela izinyathelo ezihlukahlukene, njengokuhlonza ucwaningo lwenkinga nokuhlaziywa, ukukhiqizwa kombono kanye nomklamo onemininingwane eminingi kanye ne-prototyping, kanye nokuhlola nokuchazwa. Kulezi zigaba onjiniyela basebenzisa amasu namathuluzi ahlukene njengesofthiwe ye-computer-aid design (CAD), ukuhlaziya isici esinqunyiwe (FEA) kanye nokulingisa ukuze kuqinisekiswe futhi kuthuthukiswe umklamo.

Yiziphi izici okufanele abaklami bazicabangele?

Idizayini yemishini ngokuvamile ihlanganisa izinto ezifana nokwenza, i-ergonomics, ukonga kwezindleko kanye nokusimama. Onjiniyela bazama ukwakha amamodeli angagcini nje ngokusebenza futhi asebenza kahle kodwa, kufanele futhi bacabangele izimfuno zabasebenzisi, umthelela wendawo kanye nemikhawulo yezomnotho.

Kubalulekile ukukhumbula ukuthi umkhakha wokuklama ngomshini inkambu ebanzi neqhubekayo eguquguqukayo enezimpahla ezintsha, ubuchwepheshe kanye nezindlela ezithuthukiswa njalo. Ngakho-ke, abaklami bemishini kufanele bahlale bevuselela amakhono abo nolwazi ukuze bahlale bephambili ekuthuthukeni kwezobuchwepheshe.

Okulandelayo amaphuzu olwazi mayelana ne-mechanical design eqoqwe futhi yahlelwa ithimba lonjiniyela be-Anebon ukuze wabelane nozakwabo.

1. Izimbangela zokwehluleka ezingxenyeni eziwumshini yilezi: ukuphuka okujwayelekile noma ukulimala okungaphezulu kwensalela yokuguqulwaukunemba waphenduka izingxenye(ukugqwala, ukukhathala nokuguga) Ukwehluleka ngenxa yemiphumela yezimo ezijwayelekile zokusebenza.

2. Izingxenye zedizayini kufanele zikwazi ukuhlangabezana: nezimfuneko zokugwema ukwehluleka phakathi nesikhathi esibekiwe (amandla noma ukuqina, isikhathi) kanye nezimfuneko zezinqubo zesakhiwo, izidingo zomnotho, izidingo zekhwalithi ephansi, nezimfuneko zokwethembeka.

3. Imibandela yokuklama ingxenye ihlanganisa imibandela yamandla, imibandela yokuphila yokuqina, imibandela yokuzinza kokudlidliza namazinga okwethembeka.

4. Izindlela zokuklama ingxenye: idizayini yethiyori, idizayini ye-empirical, idizayini yokuhlola imodeli.

5. Okuvame ukusetshenziselwa izingxenye zemishini Izinto zezingxenye zemishini zihlanganisa izinto ze-ceramic, izinto ze-polymer kanye nezinto eziyinhlanganisela.

6. Amandla weizingxenye ezenziwe ngomshiniihlukaniswa ibe amandla okucindezeleka okuqinile kanye namandla okucindezeleka okuguquguqukayo.

7. Isilinganiso sokucindezeleka r = -1 i-asymmetrical cyclic stress. isilinganiso r = 0 sibonisa ingcindezi emide yomjikelezo.

8. Kukholakala ukuthi isigaba se-BC saziwa njengokukhathala kobunzima (ukukhathala komjikelezo ophansi); I-CD iyisigaba sokugcina sokukhathala kwempilo. ingxenye yomugqa elandela iphoyinti elingu-D imelela ileveli yokwehluleka kwempilo engapheli yesifanekiso. D umkhawulo unomphela wokukhathala.

9. Amasu okuthuthukisa amandla ezingxenye uma ukhathele Yehlisa umthelela wokugxilisa ingqondo ekucindezelekenicnc izingxenye ezigayiwengokwezinga elikhulu ngangokunokwenzeka (ukunciphisa umthwalo umsele ovulekile) Khetha izinto ezinamandla okukhathala okuqinile futhi ucacise izindlela zokwelapha ukushisa nezindlela zokuqinisa ezandisa amandla ezinto ezikhathele.

10. Ukungqubuzana kwamaslayidi: Ukungqubuzana kwemingcele yokungqubuzana okomile, ukungqubuzana koketshezi, nokungqubuzana okuxubile.

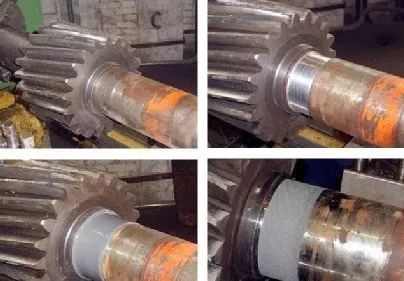

11. Inqubo yokugqoka yezingxenye ihlanganisa isiteji sokugijima kanye nesiteji sokugqoka esizinzile kanye nesiteji sokugqoka esinzima. Kufanele kwenziwe imizamo yokunciphisa isikhathi sokugijima, ukwelula isikhathi sokuguga okuzinzile futhi kubambezele ukubukeka kokugqoka okunzima kakhulu.

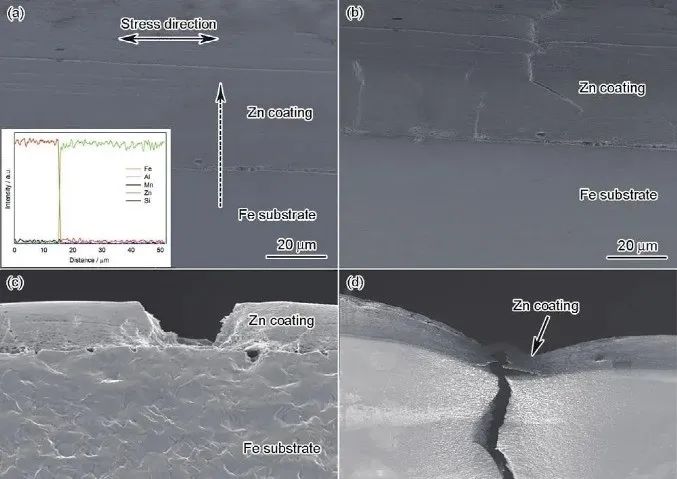

12. Isigaba sokugqokwa ukuguga kwe-Abrasive, i-adhesive wear kanye nokugqwala kokukhathala, ukuguguleka kokuguga nokuguga okukhathazayo.

13. Izinto zokugcoba zingahlukaniswa zibe izinhlobo ezine eziwuketshezi, igesi semi-solid, okuqinile kanye ne-liquid greases ahlukaniswa njengezigaba ezintathu: ama-calcium-based greases nano-based greases lithium-based grease, aluminium-based grease, kanye ne-aluminium-based.

14. Idizayini evamile yezinyo lentambo yokuxhuma ingunxantathu olinganayo onezinto ezinhle kakhulu zokuzikhiya kanye nokusebenza kokudlulisela kwentambo yokudlulisela engunxande kuphakeme kunezinye izintambo. Izintambo ze-trapezoidal ziyintambo yokudlulisela esetshenziswa kakhulu.

15. Iningi lezintambo ezixhumayo zinamandla okuzivalela, ngakho-ke imicu yochungechunge olulodwa ivame ukusetshenziswa. Imicu yokudlulisa idinga ukusebenza kahle okuphezulu kokudlulisa ngakho-ke imicu emithathu, noma imicu ekabili isetshenziswa kakhulu.

16. Ukuxhumeka kwebholidi kohlobo oluvamile (ngembobo noma izimbobo ezinamaphiko ezivulekile ezingxenyeni ezixhunyiwe) ukuxhumeka, uxhumano lwe-screw connections, setha uxhumano lwesikulufu.

17. Isizathu sokuxhuma okufakwe imicu ukuqinisa ngaphambilini ukuthuthukisa amandla nokuqina koxhumano. Kuyasiza futhi ukumisa izikhala nokushelela phakathi kwezingxenye ngemva kokulayisha. Inkinga eyinhloko yokuxegiswa koxhumano oluluchungechunge ukuvimbela ukunyakaza okujikelezayo kuzikulufu ngenkathi kulayishwa. (Ukungqubuzana ukuvimbela ukuxega, ukumelana nomshini ukuyeka ukuxega, ukuhlakaza ubudlelwano bokunyakaza kwesikulufa)

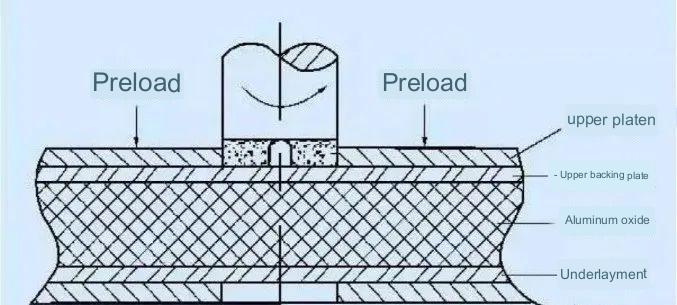

18. Izindlela zokwandisa amandla okuxhuma okunezintambo Nciphisa ukuphakama kokucindezeleka okuthinta amandla okukhathala ku-bolt (ukunciphisa ukuqina kwebhawodi kanye nokwandisa ukuqina kwezingxenye ezixhunyiwe) futhi uthuthukise ukusabalalisa okungalingani komthwalo phezu kwe-bolt. amazinyo emicu, yehlisa umphumela wokugxilisa ingqondo futhi usebenzise inqubo yokukhiqiza ephumelelayo.

19. Uhlobo lokhiye lokuxhuma Uhlobo lokhiye: isicaba (zombili izinhlangothi zinezindawo zokusebenza) ukhiye we-semicircular isixhumi sokhiye wedge uxhumano nokhiye we-tangential.

20. Ukudluliswa kwebhande kungahlukaniswa ngezinhlobo ezimbili: uhlobo lwe-meshing kanye nohlobo lwe-friction.

21. Ukucindezeleka okukhulu kokuqala kwebhande kusendaweni lapho ukuphela okuqinile kwebhande kuqala ukujikeleza i-pulley encane. Ukungezwani kushintsha izikhathi ezi-4 phakathi nesifundo ebhandeni.

22. Ukuqina kokudluliswa kwebhande le-V: idivaysi evamile yokuqinisa amandla, idivaysi ecindezelayo ezenzakalelayo, idivayisi yokuqinisa amandla kusetshenziswa i-tensioning pulley.

23. Isibalo se-chain link ochungechungeni lwe-roller ngokuvamile silingana (inani lamazinyo ku-sprocket inombolo engaziwa) futhi ilinki yeketango enwetshiwe isetshenziswa uma inani lamaketango kuyinombolo eyinqaba.

24. Isizathu sokuqiniswa kwe-chain drive siwukuqinisekisa ukuthi i-meshing ayinaphutha futhi ugweme ukudlidliza kweketango uma ukuhlehla ekugcineni kukhulu kakhulu kanye nokwandisa ibanga le-meshing phakathi kweketango kanye ne-sprocket.

25. Imbangela yokwehluleka kwegiya ukuphuka kwamazinyo, ukugqokwa kwendawo yezinyo (igiya elivuliwe) ukugoba amazinyo (igiya elivaliwe) Ukunamathisela kwamazinyo nokuguqulwa kwepulasitiki (ama-ridge ayabonakala emigqeni yamasondo okushayela avela kuyo. isondo lokushayela).

26. Amagiya anobunzima obungaphezu kuka-350HBS no-38HRS aziwa ngokuthi anobuso obuqinile noma, uma engewona, anobuso obuthambile.

27. Ukuthuthukisa ukunemba kokukhiqiza nokunciphisa usayizi wegiya ukwehlisa isivinini elihamba ngaso kungehlisa umthwalo oguquguqukayo. Ukuze wehlise lo mthwalo ngamandla, idivayisi ingase ilungiswe phezulu. amazinyo egiya akhiwa abe isigubhu sokuthuthukisa ikhwalithi yamazinyo egiya. ukulayisha ukusatshalaliswa.

28. Uma i-engeli eholayo ye-coefficient yobubanzi iba nkulu, iba nkulu ukusebenza kahle, futhi ikhono lokuzivala livikeleke kancane.

29. Hambisa igiya lezikelemu. Ngemva kokugudluka uzobona ukuthi iziyingi ze-pitch circle kanye ne-pitch circle ziyadlulana, nokho-ke kusobala ukuthi i-pitch line worm yesibungu isishintshile, futhi ayisaqondani nendilinga yayo.

30. Imbangela yokwehluleka ekushayeleni izikelemu ukugqwala kwe-pitting kanye nokuphuka kwezimpande zezinyo, ukunamathiswa kwendawo yezinyo kanye nokuguga ngokweqile. Ukwehluleka ngokuvamile kubangelwa ukushayela kwezikelemu.

31. Ukuphelelwa amandla okuvela ku-closed worm drive meshing wear wear Ukulahlekelwa ama-bearings kanye nokulahlekelwa ama-splash kawoyela njengoba izingxenye zingena ethangini likawoyela zinyakazisa uwoyela.

32. Idrayivu yezikelemu kufanele ibale ibhalansi yokushisa ngokwemfuneko yokuqinisekisa ukuthi amanani ekhalori ngeyunithi ngayinye yesikhathi alingana nenani lokushisa elilahliwe ngesikhathi esifanayo.

Izixazululo: Engeza amasinki okushisa ukwandisa indawo yokuqeda ukushisa. faka amafeni eduze kwe-shaft ukuze ukhulise ukugeleza komoya, bese ufaka osinki bokushisa ngaphakathi kwebhokisi lokudlulisela. Angaxhunywa epayipini lokupholisa elijikelezayo.

33. Izimfuneko zokwakhiwa kwe-hydrodynamic lubrication ukuthi izindawo ezimbili ezishelelayo kufanele zakhe igebe elimise okwe-wedge. Izindawo ezimbili ezihlukaniswe ifilimu kawoyela kufanele zibe nesivinini esanele sokushelela, futhi ukunyakaza kwayo kufanele kwenze amafutha okugcoba ageleze ngomlomo omkhulu aye emlonyeni omncane. kuyadingeka ukuze amafutha abe ne-viscosity ethile futhi ukunikezwa kwamafutha kuyadingeka ukuze kwanele.

34. Isakhiwo esiyisisekelo se-rolling bearings iyindandatho yangaphandle, umzimba we-Hydrodynamic wangaphakathi, ikheji.

35. Amabhere amathathu anama-tapered roller amabhere amahlanu amabhola ane-thrust deep groove amabhola ama-bearings angu-7 anama-angular contact cylindrical roller bearings 01, 02, 01 kanye no-02 kanye no-03 ngokulandelanayo. D=10mm, 12mm 15mm, 17,mm ibhekisela ku-20mm d=20mm futhi 12 ilingana no-60mm.

36. Impilo yesilinganiso esiyisisekelo: Amaphesenti angu-10 ama-bearings ngaphakathi kwenhlobonhlobo yamabheringi ahlushwa ukulimala kwemigodi, kuyilapho u-90% wamabheringi awathintwa ukulimala komgodi. Inani lamahora asetshenziwe liyisikhathi sokuphila esithwalayo.

37. Isilinganiso esiyisisekelo esiguqukayo: inani elikwazi ukulisekela uma isilinganiso esiyisisekelo somshini singama-revolution angu-106 ngokunembile.

38. Indlela yokunquma ukumiswa kokuthwala: ama-Fulcrum amabili agxilwe endaweni eyodwa ngayinye. Iphuzu elilodwa limiswe ngendlela ekabili, kuyilapho enye i-fulcrum igcina ibhukuda kuzo zombili izinhlangothi, kuyilapho enye igcina ngokubhukuda ukuze inikeze ukwesekwa.

39. Ama-bearings ahlukaniswa ngokwenani lomthwalo we-shaft (isikhathi sokugoba kanye ne-torque) i-mandrel (umzuzu wokugoba) kanye ne-Transmission shaft (torque).

I-Anebon ibambelela embonweni oyisisekelo wokuthi “Ikhwalithi iwumongo webhizinisi futhi isimo singaba ingqikithi yalo” Ukuze uthole isaphulelo esikhulu ku-Custom precision 5 Axis Lathecnc izingxenye zomshini, I-Anebon iyaqiniseka ukuthi sizohlinzeka ngemikhiqizo namasevisi asezingeni eliphezulu ngenani elithengekayo kanye nesevisi enhle kakhulu yangemva kokuthengisa kumakhasimende. Ukwengeza, i-Anebon izokwazi ukwakha ubudlelwano obuchumayo besikhathi eside nawe.

Ingxenye ye-Chinese Professional yaseChina CNC kanye Nezingxenye Zomshini Wensimbi, I-Anebon incike emikhiqizweni yekhwalithi ephezulu, idizayini ephelele, isevisi yamakhasimende eyingqayizivele kanye nezindleko ezithengekayo ukuze uthole ukwethenjwa inombolo enkulu yamakhasimende avela phesheya nase-US. Iningi lemikhiqizo ithunyelwa ezimakethe zaphesheya kwezilwandle.

Isikhathi sokuthumela: Aug-02-2023