Kungakanani okwaziyo mayelana nendlela yokucubungula intambo kumishini ye-CNC?

Emishinini ye-CNC, imicu ivamise ukudalwa ngokusika noma ukwenza imisebenzi. Nazi izindlela ezimbalwa ezivame ukusetshenziswa ezisetshenziswa yiqembu le-Anebon:

Ukuthepha:Le ndlela ihlanganisa ukusika izintambo kusetshenziswa umpompi, okuyithuluzi elinemijondolo ye-helical. Ukuthepha kungenziwa ngesandla noma ngokusebenzisa umshini, futhi kulungele ukudala izintambo zangaphakathi.

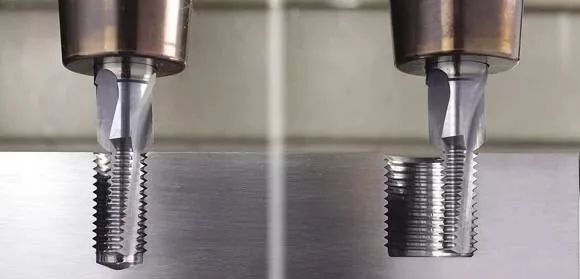

I-Thread Milling: Ukugaya intambo kusebenzisa ithuluzi lokusika elizungezayo elinemitshingo eminingi ukwenza imicu. Kuyindlela eguquguqukayo engasetshenziswa kokubili imicu yangaphakathi neyangaphandle. Ukugaya intambo kuvame ukuncanyelwa emicu emikhulu noma lapho kudingeka amasayizi ahlukahlukene nezinhlobo zentambo.

Ukuphenduka kochungechunge:Le ndlela ihilela ukusebenzisa ithuluzi lokusika lephuzu elilodwa elifakwe ku-lathe ukuze kwakhiwe imicu yangaphandle. Ukuguqula intambo kuvame ukusetshenziselwa imicu emikhulu noma emide futhi kulungele yomibili imicu eqondile kanye ne-tapered.

I-Tread Rolling:Ekugingqeni intambo, insimbi eqinile ifaka ingcindezi kucezu lokusebenza ukuguqula izinto bese kwakheka imicu. Le ndlela iyasebenza futhi ikhiqiza imicu yekhwalithi ephezulu, iyenze ifanelekele ukukhiqizwa kwevolumu ephezulu.

Ukugaya Intambo:Ukugaya uchungechunge kuyinqubo yomshini enembayo esebenzisa isondo lokugaya ukuze kudaleke imicu. Ivamise ukusetshenziselwa ukukhiqizwa kwentambo okunembayo okuphezulu kanye nekhwalithi ephezulu, ikakhulukazi emicu eyinkimbinkimbi noma ekhethekile.

Lapho ukhetha indlela yokucubungula uchungechunge, izici ezifana nosayizi wentambo, izidingo zokunemba, izakhiwo zezinto ezibonakalayo, umthamo wokukhiqiza, nokucatshangelwa kwezindleko kufanele kucatshangelwe.

Umlando

Igama lesiNgisi elihambisana nesikulufi lithi Isikulufa. Incazelo yaleli gama ishintshe kakhulu emakhulwini eminyaka amuva nje. Okungenani ngo-1725, kusho "ukukhwelana".

Ukusetshenziswa komgomo wentambo kungalandelelwa emuva ethuluzini lokuphakamisa amanzi elijikelezayo elakhiwa isazi esingumGreki u-Archimedes ngo-220 BC.

Ngekhulu lesi-4 AD, amazwe agudle uLwandle iMedithera aqala ukusebenzisa umgomo wamabhawudi namantongomane emikhakheni yokunyathelisa esetshenziselwa ukuphisa iwayini. Ngaleso sikhathi, izintambo zangaphandle zaziboshwe zonke ngentambo emgqeni we-cylindrical, bese ziqoshwa ngokwalolu phawu, kuyilapho imicu yangaphakathi yayivame ukwakhiwa ngokushaya ngesando ezungeze imicu yangaphandle ngezinto ezithambile.

Cishe ngo-1500, emdwebeni wensiza yokucubungula intambo edwetshwe uLeonardo da Vinci ongumNtaliyane, kwase kunombono wokusebenzisa isikulufu sowesifazane kanye negiya lokushintshana ukuze kucutshungulwe imicu yemibala ehlukene. Kusukela ngaleso sikhathi, indlela yokusika intambo iye yathuthukiswa embonini yokwenza amawashi yaseYurophu.

Ngo-1760, izelamani zaseBrithani u-J. Wyatt noW. Wyatt bathola ilungelo lobunikazi lokusika izikulufu zokhuni ngomshini okhethekile. Ngo-1778, u-J. Ramsden waseBrithani wake wenza ithuluzi lokusika intambo eliqhutshwa yipheya legiya lezikelemu, elalikwazi ukucubungula imicu emide ngokunemba okuphezulu. Ngo-1797, u-H. Mozley waseBrithani wasebenzisa isikulufu sokuhola sowesifazane kanye negiya lokushintshanisa ukuze aguqule imicu yensimbi ngezingqimba ezihlukene ku-lathe athuthukiswe nguye, futhi yasungula indlela eyisisekelo yokuphendula izintambo.

Ngawo-1820, uMaudsley wakhiqiza iqoqo lokuqala lompompi futhi uyafa ngokucutshungulwa kwentambo.

Ekuqaleni kwekhulu lama-20, ukuthuthukiswa kwemboni yezimoto kwaphinde kwakhuthaza ukumiswa kwemicu kanye nokuthuthukiswa kwezindlela ezihlukahlukene zokunemba nezindlela eziphumelelayo zokucubungula intambo. Amakhanda okuvula okuzenzakalelayo okuvula okuzenzakalelayo kanye nompompi abawa ngokuzenzekelayo abanciphayo kwasungulwa ngokulandelana, futhi ukugaya intambo kwaqala ukusetshenziswa.

Ekuqaleni kwawo-1930, kwavela ukugaya intambo.

Nakuba ubuchwepheshe bokugoqa intambo babunelungelo lobunikazi ekuqaleni kwekhulu le-19, ngenxa yobunzima bokukhiqiza isikhunta, ukuthuthukiswa kwakuhamba kancane kakhulu. Kwaze kwaba yiMpi Yezwe Yesibili (1942-1945) lapho ngenxa yezidingo zokukhiqizwa kwezikhali kanye nokuthuthukiswa kobuchwepheshe bokugaya intambo, inkinga yaxazululwa. Inkinga yokunemba yokukhiqiza isikhunta izuze ukuthuthukiswa okusheshayo.

Intambo ihlukaniswe ngokuyinhloko ibe intambo yokuxhuma kanye nentambo yokudlulisela

Ukuxhuma izintambo, izindlela zokucubungula ikakhulukazi: ukuthepha, ukuthunga, ukuthunga, ukugoqa, ukugoqa, njll.

Ngentambo yokudlulisela, izindlela eziyinhloko zokucubungula yilezi: ukuphenduka okumaholo nokucolisa - ukugaya, ukugaya isivunguvungu - ukuphenduka okungalungile nokuhle, njll.

Isigaba sokuqala: ukusika intambo

Ngokujwayelekile kubhekiselwa endleleni yokucubungula izintambo ezintweni zokusebenza ngamathuluzi okwakha noma amathuluzi abrasive, ikakhulukazi okuhlanganisa ukuphenduka, ukugaya, ukuthepha nokugaya intambo, ukugaya nokusika isivunguvungu. Lapho uguqula, ukugaya nokugaya izintambo, njalo lapho umshini wokusebenza uzungeza, uchungechunge lokudlulisela lwethuluzi lomshini luqinisekisa ukuthi ithuluzi lokuguqula, i-milling cutter noma isondo lokugaya lihambisa umthofu ngokunembile nangokulinganayo eduze kwe-axis ye-workpiece. Uma uthepha noma ucucuza, ithuluzi (thepha noma ufe) kanye nocezu lokusebenza kwenza umnyakazo ozungezayo ohlobene, futhi i-groove yentambo yokuqala eyakhiwe iqondisa ithuluzi (noma ucezu lokusebenza) ukuhamba nge-axially.

1. Ukuphenduka kwentambo

Ukuvula izintambo ku-lathe kungasebenzisa ithuluzi elijikayo noma ikamu lentambo. Ukuguqula intambo ngethuluzi lokuguqula ukwakha kuyindlela evamile yokukhiqizwa kwesiqephu esisodwa kanye neqoqo elincane lama-workpieces anezintambo ngenxa yesakhiwo esilula sethuluzi; intambo ephendulayo ngethuluzi lokuhlanganisa intambo inezinga eliphezulu lokukhiqiza, kodwa isakhiwo samathuluzi siyinkimbinkimbi futhi sifaneleka kuphela ukukhiqizwa okuphakathi nendawo nokukhulu. Ukunemba kwephimbo kwentambo ye-trapezoidal evula ama-lathes ajwayelekile ngokuvamile ingafinyelela kumabanga 8 kuya ku-9 (JB2886-81, okufanayo ngezansi); ukucubungula izintambo kuma-lathes ezintambo ezikhethekile kungathuthukisa kakhulu ukukhiqiza noma ukunemba.

2. Ukugaya intambo

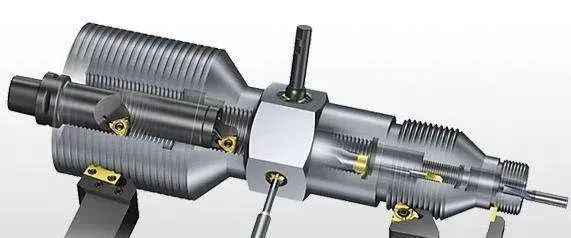

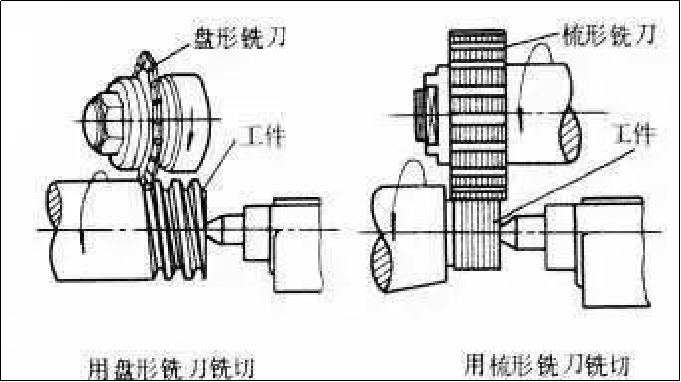

I-Prototype cnc millingnge-disc cutter noma i-comb cutter emshinini wokugaya intambo.

Abasiki be-disc milling basetshenziswa kakhulu ekugayeni imicu yangaphandle ye-trapezoidal kuma-workpiece afana nezikulufu nezikelemu. I-milling cutter emise okwekama isetshenziselwa ukugaya imicu evamile yangaphakathi neyangaphandle kanye nemicu ye-taper. Njengoba igaywe nge-milling cutter enemiphetho eminingi futhi ubude bengxenye yayo yokusebenza bukhulu kunobude bentambo ecutshunguliwe, i-workpiece idinga kuphela ukujikeleziswa ngama-1.25 kuya ku-1.5 ukuphenduka ukuze kucutshungulwe. Sekwenziwe, ukukhiqiza kuphezulu. Ukunemba kwephimbo lokugaywa kwentambo ngokuvamile kungafinyelela amabanga ayi-8-9, futhi ubulukhuni obungaphezulu bungama-microns angu-R5-0.63. Le ndlela ilungele ukukhiqizwa kwenqwaba yama-workpieces anemicu ngokunemba okuvamile noma ukugaywa okungalungile ngaphambi kokugaya.

Umsiki wokugaya uchungechunge wenza intambo yangaphakathi

3. Ukugaya intambo

Isetshenziswa kakhulu ukucubungula izintambo ezinembayo zezinto zokusebenza eziqinile emishinini yokugaya intambo. Ngokwesimo sesigaba esiphambanayo sesondo lokugaya, singahlukaniswa ngezinhlobo ezimbili: isondo lokugaya elinomugqa owodwa kanye nesondo lokugaya elinemigqa eminingi. Ukunemba kwephimbo lokugaya isondo lomugqa owodwa kungaba amamaki angu-5-6, ubulukhuni obungaphezulu bungama-microns angu-R1.25-0.08, futhi ukugqoka kwesondo lokugaya kulula kakhulu. Le ndlela ilungele ukugaya izikulufu zokuhola ezinembayo, amageji entambo, izikelemu, amaqoqo amancane ezinto zokusebenza ezinentambo nokugaya impumuzo.ukunemba okuphendulwe ingxenye.

I-Multi-line grinding wheel grinding ihlukaniswe yaba izinhlobo ezimbili: indlela yokugaya i-longitudinal kanye nendlela yokugaya. Endleleni yokugaya i-longitudinal, ububanzi besondo lokugaya buncane kunobude bentambo okufanele igaywe, futhi intambo ingacolwa kuze kube usayizi wokugcina ngokunyakazisa isondo lokugaya ngobude kanye noma izikhathi eziningana. Endleleni yokugaya yokusika, ububanzi besondo lokugaya bukhulu kunobude bentambo okufanele igaywe.

Isondo lokugaya lisikeka ebusweni bomsebenzi wokusebenza ngokukhazimulayo, futhi ucezu lokusebenza lungagaywa ngemuva kokuphenduka okungaba ngu-1.25. Ukukhiqiza kuphezulu, kodwa ukunemba kuphansi kancane, futhi ukugqoka kwesondo lokugaya kuyinkimbinkimbi. Indlela yokugaya i-plunge ilungele ompompi bokugaya okusizayo ngamaqoqo amakhulu kanye nokugaya imicu ethile ukuze kuqiniswe.

4. Ukugaya intambo

I-nut-type noma i-screw-type thread grinder yenziwe ngezinto ezithambile ezifana ne-cast iron, kanyeizingxenye eziphendukayo ze-cncyochungechunge olucutshunguliwe kucezu lokusebenza olunephutha lephimbo lizungeziswa eziqondisweni eziya phambili nezihlehlayo ukuze kuthuthukiswe ukunemba kwephimbo. Imicu yangaphakathi eqinile ngokuvamile nayo iphansi ukuze isuse ukuguga nokuthuthukisa ukunemba.

5. Ukuthepha nokucupha

Ukuthepha

Iwukusebenzisa i-torque ethile ukujiya umpompi embobeni engaphansi ebhojwe ngaphambili endaweni yokusebenza ukuze kucutshungulwe intambo yangaphakathi.

Uchungechunge

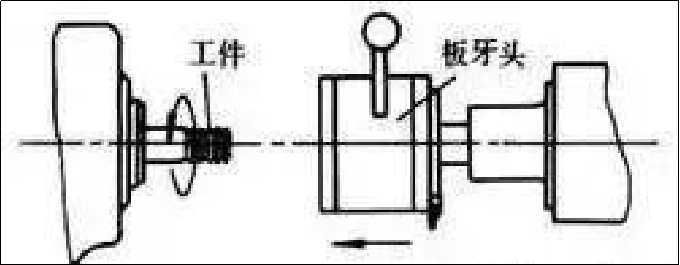

Kuwukusebenzisa idayi ukusika intambo yangaphandle kubha (noma ipayipi) workpiece. Ukunemba komshini wokuthepha noma ukuthunga kuncike ekunembeni kompompi noma ukufa.

Nakuba ziningi izindlela zokucubungula imicu yangaphakathi neyangaphandle, imicu yangaphakathi enobubanzi obuncane ingacutshungulwa kuphela ngompompi. Ukuthepha nokuhlanganisa kungenziwa ngesandla, noma ngezinsimbi, imishini yokubhoboza, imishini yokudonsa kanye nemishini yokulutha.

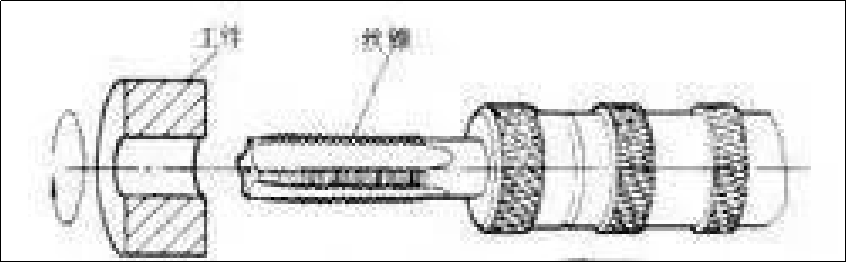

Isigaba sesibili: ukugoqa uchungechunge

Indlela yokucubungula lapho i-workpiece ikhubazeka ngokwepulasitiki ngokufa okugoqayo ukuze kutholwe imicu. Ukugingqa intambo ngokuvamile kwenziwa emshinini wokugoqa intambo noma i-lathe e-othomathikhi enekhanda eligoqekayo elivulekayo nelivalayo. Imicu yangaphandle yokukhiqiza ngobuningi bezibophelelo ezijwayelekile nokunye ukuxhuma okunentambo. Ububanzi bangaphandle bentambo egoqiwe ngokuvamile abukho ngaphezu kuka-25 mm, ubude abukho ngaphezu kwe-100 mm, ukunemba kwentambo kungafinyelela ezingeni 2 (GB197-63), futhi ububanzi bendawo engenalutho esetshenzisiwe cishe bulingana nephimbo. ububanzi bentambo ecutshunguliwe. Ukuginqika ngokuvamile akukwazi ukucubungula izintambo zangaphakathi, kodwa kuma-workpieces anezinto ezithambile, ompompi be-extrusion abangenawo ama-grooveless bangasetshenziswa ukuze bakhiphe izintambo zangaphakathi ezibandayo (ububanzi obukhulu bungafinyelela cishe ku-30 mm), futhi isimiso sokusebenza siyafana nokuthepha. I-torque edingekayo ku-extrusion ebandayo yemicu yangaphakathi imayelana

Okuphindwe kabili kwalokho kokuthepha, nokunemba komshini kanye nekhwalithi yangaphezulu kungaphezulu kancane kwalokho kokuthepha.

Izinzuzo zokugingqa intambo: ①Ubulukhuni bendawo buncane kunobo bokuphenduka, ukugaya nokugaya; ②Ingaphezulu lentambo ngemva kokugingqika lingakhuphula amandla nobulukhuni ngenxa yokuqina okubandayo; ③ Ukusetshenziswa okuphezulu kwempahla; ④Ukukhiqiza kuphindwe kabili uma kuqhathaniswa nokucutshungulwa , futhi kulula ukuzenzela; ⑤ Impilo ye-rolling die yinde kakhulu. Nokho, intambo egoqayo idinga ukuthi ubulukhuni bempahla yokusebenza bungeqi ku-HRC40; isidingo sokunemba kobukhulu bokungenalutho siphezulu; ukunemba nobulukhuni besikhunta esigoqayo nakho kuphezulu, futhi kunzima ukwenza isikhunta; ayifanele ukugoqa izintambo ezinezimo zamazinyo asymmetric.

Ngokusho kwe-rolling dies ehlukene, ukugoqa intambo kungahlukaniswa ngezinhlobo ezimbili: ukugoqa intambo nokugingqa intambo.

6. Ukuhlikihla

Amabhodi okugoqa intambo amabili anephrofayili yentambo ahlelwa ngokuphambana anephimbo elingu-1/2 elinyakazayo, ibhodi elimile lilungisiwe, futhi ibhodi elinyakazayo lenza ukunyakaza okuhambisanayo okuhambisanayo okuhambisana nebhodi elimile. Lapho i-izingxenye ezenziwe ngomshiniiphakelwa phakathi kwamapuleti amabili, ipuleti elinyakazayo liya phambili futhi lihlikihla ucezu lokusebenza, lenze indawo yalo ikhubazekile ngokwepulasitiki ukuze yakhe imicu (Umdwebo 6 [ukugoqeka kwentambo]).

7. Ukugingqa intambo

Kunezinhlobo ezi-3 zokugingqa intambo, intambo ejikelezayo, ukugingqa intambo eqinile kanye nokugingqa intambo yekhanda.

① Ukuginqika kwentambo ye-Radial: 2 (noma 3) amasondo okugoqa intambo anephrofayili yentambo afakwe kumashafu afanayo, i-workpiece ibekwe phezu kokusekelwa phakathi kwamasondo amabili, futhi amasondo amabili azungeza ngesivinini esifanayo ohlangothini olufanayo (Umdwebo 7 [Ukugoqeka kochungechunge lweradial]), enye yakho eyenza ukunyakaza kokuphakelayo kweradial. I-workpiece izungeza ngaphansi kokushayela kwesondo eligoqa intambo, futhi indawo engaphezulu ikhishwe ngomsakazo ukuze yenze imicu. Kwezinye izikulufu zokuhola ezingadingi ukunemba okuphezulu, indlela efanayo ingasetshenziswa futhi ekwenzeni umqulu.

②Ukugoqeka kwentambo ye-tangential: Okwaziwa nangokuthi intambo yeplanethi, ithuluzi eligoqayo liqukethe isondo elizungezayo eliphakathi nendawo elizungezayo kanye namapuleti ezintambo angu-3 amise okwe-arc (Umfanekiso 8 [uchungechunge lwe-tangential]). Ngesikhathi sokugoqa intambo, i-workpiece ingaphakelwa ngokuqhubekayo, ngakho-ke ukukhiqiza kuphezulu kunalowo wokugoqa intambo kanye ne-radial thread rolling.

③Ukugoqeka kwentambo yekhanda: Kwenziwa nge-lathe ezenzakalelayo, futhi ngokuvamile isetshenziselwa ukucubungula imicu emifushane ezintweni zokusebenza. Kunamasondo agoqayo angu-3 kuya ku-4 asakazwa ngokulinganayo endaweni engaphandle yendawo yokusebenza ekhanda eligoqayo (Umfanekiso 9 [ikhanda eligoqayo]). Ngesikhathi sokugoqa intambo, i-workpiece iyajikeleza, futhi ikhanda eligoqayo lidla nge-axially ukuze likhiphe umsebenzi ngaphandle kwentambo.

8. Ukucubungula intambo ye-EDM

Ukucutshungulwa kwentambo okujwayelekile kuvame ukusebenzisa izikhungo zokwenza imishini noma izisetshenziswa zokuthepha namathuluzi, futhi ngezinye izikhathi ukuthepha mathupha nakho kuyenzeka. Kodwa-ke, kwezinye izimo ezikhethekile, le ndlela engenhla akulula ukuthola imiphumela emihle yokucubungula, njengesidingo sokucubungula izintambo ngemva kokuphathwa kokushisa kwezingxenye ngenxa yokunganaki, noma ngenxa yezinkinga zezinto ezibonakalayo, njengokuthepha ngokuqondile ama-workpieces e-carbide enosimende. Ngalesi sikhathi, kuyadingeka ukucabangela indlela yomshini we-EDM.

Uma kuqhathaniswa nemetal cnc machiningindlela, ukuhleleka kwe-EDM kuyafana, futhi imbobo engezansi idinga ukubhobozwa kuqala, futhi ububanzi bomgodi ophansi kufanele bunqunywe ngokuvumelana nezimo zokusebenza. I-electrode idinga ukucutshungulwa ibe yisimo sentambo, futhi i-electrode idinga ukukwazi ukujikeleza ngesikhathi sokucubungula.

"Ikhwalithi yokuqala, Ukwethembeka njengesisekelo, inkampani eqotho kanye nenzuzo ehlangene" umqondo ka-Anebon, ukuze ukwazi ukudala ngokungaguquki futhi uphishekele ubuhle be-China Wholesale Custom Machining Part-Sheet Metal Part Factory-Auto Part, i-Anebon yakhula ngokushesha ngosayizi negama. ngenxa yokuzinikela okuphelele kwe-Anebon ekwenziweni kwekhwalithi ephezulu, inani elikhulu lezimpahla kanye nomhlinzeki omuhle wamakhasimende.

Umkhiqizi we-OEM China Ingxenye Yomshini Nengxenye Yesitembu, Uma kufanele ube nanoma yimiphi imikhiqizo ye-Anebon nezisombululo, noma ube nezinye izinto ezizokhiqizwa, qiniseka ukuthi usithumelela imibuzo yakho, amasampula noma imidwebo ejulile. Khonamanjalo, ihlose ukuthuthuka ibe yiqembu lebhizinisi lamazwe ngamazwe, i-Anebon izohlale ilapha ukuze ibheke ngabomvu ukuthola izipesheli zebhizinisi elihlanganyelwe namanye amaphrojekthi wokubambisana.

Isikhathi sokuthumela: Jun-19-2023