Isikhungo somshini sihlanganisa uwoyela, igesi, ugesi, nokulawula izinombolo, futhi singakwazi ukubona ukuboshelwa kanyekanye kwezingxenye ezihlukahlukene eziyinkimbinkimbi njengamadiski, amapuleti, amagobolondo, amakhamera, isikhunta, njll., futhi singaqedela ukubhola, ukugaya, ukubhora, ukwandisa. , ukubuyisela kabusha, ukuthepha okuqinile nezinye izinqubo ziyacutshungulwa, ngakho-ke iyimishini efanelekileukunemba okuphezulu kwemishini. Lesi sihloko sizokwabelana ngokusetshenziswa kwezikhungo zemishini kusuka kulezi zici ezilandelayo:

Isikhungo somshini silibeka kanjani ithuluzi?

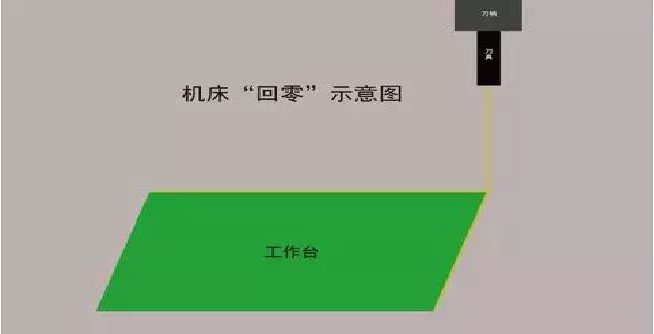

1. Buyela kuziro (buyela kumsuka womshini)

Ngaphambi kokusetha ithuluzi, qiniseka ukwenza umsebenzi wokubuyela kuziro (ubuyela kumsuka wethuluzi lomshini) ukuze usule idatha yokuxhumanisa yokusebenza kokugcina. Qaphela ukuthi izimbazo X, Y, kanye no-Z zonke zidinga ukubuyela kuqanda.

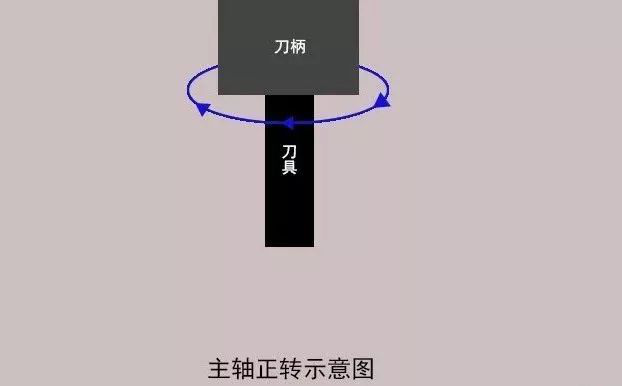

2. I-spindle izungeza phambili

Kumodi ye-"MDI", i-spindle izungeziswa phambili ngokufaka ikhodi yomyalo, futhi igcina isivinini sokuzungezisa esimaphakathi. Bese ushintshela kumodi "yesondo lesandla", bese uhambisa ithuluzi lomshini ngokushintsha izinga lokulungisa.

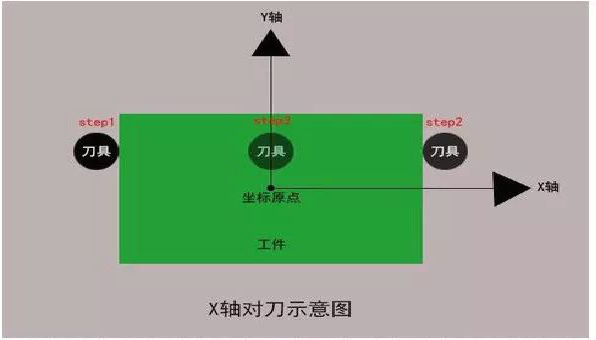

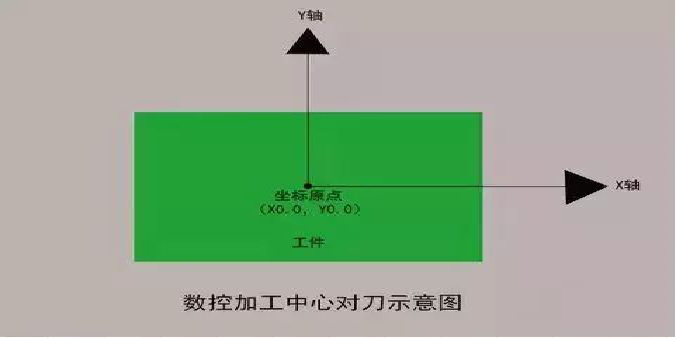

3. Ukulungiselelwa kwethuluzi le-X-direction

Thinta ngobumnene ithuluzi elingakwesokudla se-workpiece ukuze usule izixhumanisi ezihlobene zethuluzi lomshini; phakamisa ithuluzi ngendlela engu-Z, bese uhambisa ithuluzi ohlangothini lwesobunxele lwe-workpiece, wehle ufike ekuphakameni okufanayo nangaphambili, hambisa ithuluzi kanye ne-workpiece Thinta kancane, phakamisa ithuluzi, bhala inani le-X le-coordinate ehlobene wethuluzi lomshini, hambisa ithuluzi kuhhafu wesixhumanisi esihlobene X, bhala inani le-X lokuxhumanisa okuphelele kwethuluzi lomshini, bese ucindezela (INPUT) ukuze ufake isistimu yokuxhumanisa.

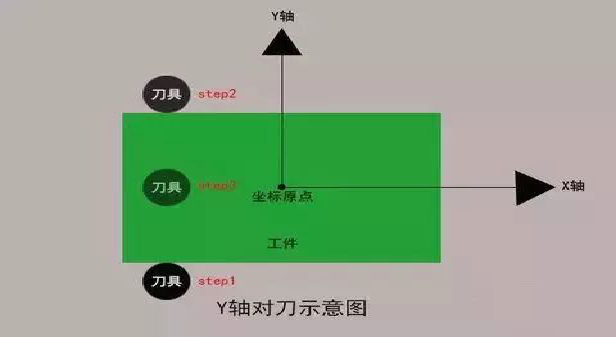

4.Y-isilungiselelo sethuluzi lesiqondiso

Thinta ngobumnene ithuluzi eliphambi kwendawo yokusebenza ukuze usule izixhumanisi ezihlobene zethuluzi lomshini; phakamisa ithuluzi ngendlela engu-Z, bese uhambisa ithuluzi ngemuva kwe-workpiece, wehlele ekuphakameni okufanayo nangaphambili, hambisa ithuluzi kanye nendawo yokusebenza Thinta kancane, phakamisa ithuluzi, bhala inani elingu-Y le-coordinate ehlobene ithuluzi lomshini, hambisa ithuluzi kuhhafu wesixhumanisi esihlobene esingu-Y, bhala phansi inani elingu-Y lokuxhumanisa okuphelele kwethuluzi lomshini, bese ucindezela (INPUT) ukuze ufake isistimu yokuxhumanisa.

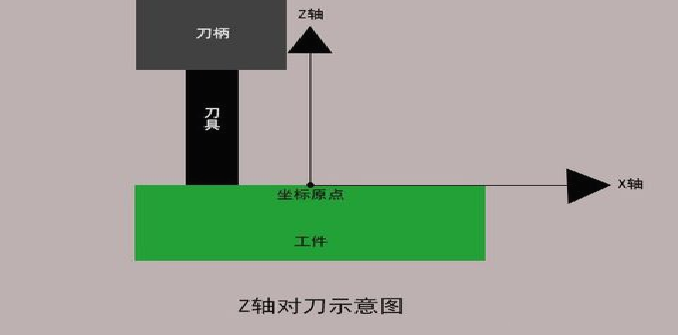

5. Ukulungiselelwa kwethuluzi le-Z-direction

Hambisa ithuluzi phezu kwendawo yokusebenza edinga ukubhekana nephoyinti elinguziro lesiqondiso sika-Z, hambisa kancane ithuluzi ukuze lithinte kancane indawo engaphezulu yendawo yokusebenza, qopha inani lika-Z ohlelweni lokuxhumanisa lwethuluzi lomshini ngalesi sikhathi. , bese ucindezela (INPUT) ukuze ufake ohlelweni lokuxhumanisa.

6. Isitobhi se-spindle

Qala ngokumisa i-spindle, hambisa i-spindle endaweni efanelekile, ubize uhlelo lokucubungula, futhi ulungiselele ukucutshungulwa okusemthethweni.

Isikhungo somshini sikhiqiza futhi sicubungule kanjani izingxenye ezigogeke kalula?

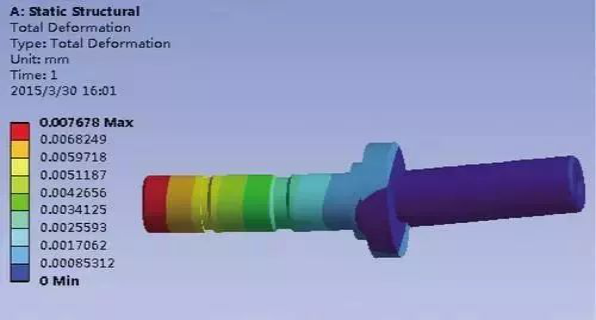

Ezingxenyeni ezinesisindo esincane, ukuqina okubuthakathaka namandla abuthakathaka, zikhubazeka kalula ngamandla nokushisa ngesikhathi sokucubungula, futhi izinga eliphezulu le-scrap yokucubungula liholela ekwenyukeni okukhulu kwezindleko. Ezingxenyeni ezinjalo, kufanele siqale siqonde izimbangela ze-deformation:

Phoqa ukuguqulwa:

Izingxenye ezinjalo zinezindonga ezincane, futhi ngaphansi kwesenzo samandla okubamba, kulula ukuba nobukhulu obuhlukahlukene enkambweni yomshini nokusika, futhi ukunwebeka kumpofu, futhi ukuma kwezingxenye kunzima ukuzibuyisela ngokwakho.

I-Thermal deformation:

I-workpiece ilula futhi incane, futhi amandla e-radial phakathi nenqubo yokusika azokwenza ukuthi umsebenzi womsebenzi ukhubazeke ngokushisa, ngaleyo ndlela wenze ubukhulu bomsebenzi wokusebenza bungalungile.

Ukuguqulwa kokudlidliza:

Ngaphansi kwesenzo samandla okusika ama-radial, izingxenye zijwayele ukudlidliza kanye nokuguqulwa, okuthinta ukunemba kwe-dimensional, ukwakheka, ukunemba kwendawo kanye nokuqina kwendawo yokusebenza.

Indlela yokucubungula yezingxenye ezikhubazekile kalula:

Izingxenye eziguga kalula ezimelelwe izingxenye ezinodonga oluncane zingasebenzisa uhlobo lwemishini yesivinini esikhulu enezinga elincane lokuphakelayo kanye nesivinini esikhulu sokusika ukuze kuncishiswe amandla okusika endaweni yokusebenza ngesikhathi sokucutshungulwa, futhi ngesikhathi esifanayo zenze iningi lokushisa kokusika lindiza. kude nama-chips ocezu lokusebenza ngesivinini esikhulu. Thatha, ngaleyo ndlela unciphise izinga lokushisa le-workpiece futhi unciphise ukuguqulwa okushisayo kwe-workpiece.

Kungani amathuluzi esikhungo somshini kufanele asuswe?

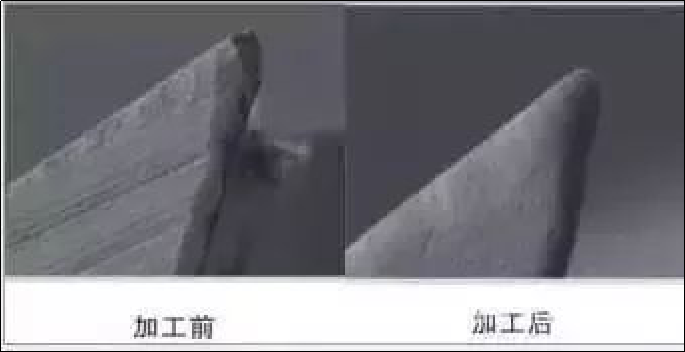

Amathuluzi e-CNC awasheshi ngangokunokwenzeka, ngakho kungani ungawadlulisi? Eqinisweni, ukudlula ithuluzi akukhona lokho wonke umuntu akuqonda ngokoqobo, kodwa indlela yokuthuthukisa impilo yesevisi yethuluzi. Thuthukisa ikhwalithi yamathuluzi ngokusebenzisa izinqubo ezifana nokuleveling, ukupholisha, nokususa amabhamu. Lokhu empeleni kuyinqubo evamile ngemva kokuba ithuluzi seligaywe kahle nangaphambi kokumbozwa.

▲Isiqhathaniso sokwenza ithuluzi

Ithuluzi lizocijwa isondo lokugaya ngaphambi komkhiqizo oqediwe, kodwa inqubo yokulola izobangela amazinga ahlukene wezikhala ezincane. Lapho isikhungo somshini senza ukusika ngesivinini esikhulu, i-micro-notch izokwandiswa kalula, okuzosheshisa ukuguga nokulimala kwethuluzi. Ubuchwepheshe bokusika besimanje bunezidingo eziqinile zokuzinza nokunemba kwethuluzi, ngakho-ke ithuluzi le-CNC kufanele lidluliselwe ngaphambi kokumbozwa ukuze kuqinisekiswe ukuqina nempilo yesevisi ye-coating. Izinzuzo ze-passivation yamathuluzi yilezi:

1. Gwema ukugqokwa kwamathuluzi aphathekayo

Phakathi nenqubo yokusika, ubuso bethuluzi buzogujwa kancane kancane yi-workpiece, futhi umkhawulo wokusika ubuye uthambekele ekuguqulweni kwepulasitiki ngaphansi kokushisa okuphezulu nokucindezela okukhulu ngesikhathi sokusika. Ukudlula ithuluzi kungasiza ukuthuthukisa ukuqina kwethuluzi futhi kuvimbele ithuluzi ukuthi lingalahlekelwa ukusebenza ngaphambi kwesikhathi.

2. Gcina isiphetho se-workpiece

Ama-Burrs onqenqemeni lwethuluzi azobangela ukuthi ithuluzi liguge futhi ingaphezulu le-workpiece eyenziwe ngomshini lizoba lukhuni. Ngemuva kokwelashwa kwe-passivation, unqenqema lokusika lwethuluzi luzoba bushelelezi kakhulu, i-chipping phenomenon izoncishiswa ngokufanele, futhi isiphetho esingaphezulu se-workpiece sizothuthukiswa.

3. Ukususwa kwe-chip ye-groove elula

Ukupholisha i-groove yethuluzi kungathuthukisa ikhwalithi yendawo kanye nokusebenza kokukhipha ama-chip. Uma i-groove ibushelelezi, kungcono ukuphuma kwe-chip, futhi ukusika okungaguquki kungafinyelelwa. Ngemuva kokuthi ithuluzi le-CNC lesikhungo somshini lidlulisiwe futhi lipholishwe, izimbobo eziningi ezincane zizosala phezulu. Lezi zimbobo ezincane zingakwazi ukudonsa uketshezi oluningi lokusika ngesikhathi sokucubungula, okunciphisa kakhulu ukushisa okukhiqizwa ngesikhathi sokusika futhi kuthuthukisa kakhulu ukusebenza kahle kokusika. isivinini.

Isikhungo somshini sibunciphisa kanjani ubulukhuni bomsebenzi?

Ubuso obumangelengele bezingxenye bungenye yezinkinga ezivamile zeCNC imishiniizikhungo, ezibonisa ngokuqondile ikhwalithi yokucubungula. Indlela yokulawula ubulukhuni obungaphezulu bokucutshungulwa kwezingxenye, kufanele siqale sihlaziye izimbangela zokuqina kwendawo, ikakhulukazi okuhlanganisa: izimpawu zamathuluzi ezibangelwa ukugaya; ukuguqulwa okushisayo noma ukuguqulwa kwepulasitiki okubangelwa ukuhlukaniswa kokusika; ithuluzi kanye machined surface ukungqubuzana phakathi.

Uma ukhetha ukukhahlamezeka kwendawo yokusebenza, akufanele nje kuhlangabezane nezidingo zokusebenza kwendawo yengxenye, kodwa futhi kucabangele ukucabangela kwezomnotho. Ngokwesisekelo sokwanelisa ukusebenza kokusika, inani elikhulu lereferensi elikhudlwana lokumahhadla kwendawo kufanele likhethwe ngangokunokwenzeka ukuze kwehliswe izindleko zokukhiqiza. Njengomabi wesikhungo sokusika, ithuluzi kufanele linake ukugcinwa kwansuku zonke kanye nokugaya okufika ngesikhathi ukuze kugwenywe ubulukhuni obungafanelekile obubangelwa ithuluzi elibuthuntu.

Yini okufanele ngiyenze ngemva kokuba isikhungo somshini sesiphelile?

Ngokuvamile, imithetho yenqubo yokwenza imishini yamathuluzi omshini wendabuko ezikhungweni zomshini icishe ifane. Umehluko omkhulu ukuthi izikhungo zomshini zenza umshini ozenzakalelayo oqhubekayo ukuze uqedele zonke izinqubo zokusika ngokusebenzisa i-clamping eyodwa. Ngakho-ke, izikhungo zemishini zidinga ukwenza "umsebenzi wangemuva".

1. Yenza ukwelashwa kokuhlanza. Ngemuva kokuthi isikhungo somshini siqedele umsebenzi wokusika, kuyadingeka ukususa ama-chips bese usula umshini ngesikhathi, futhi usebenzise ithuluzi lomshini kanye nemvelo ukuyigcina ihlanzekile.

2. Ukuze kuhlolwe futhi kushintshwe izesekeli, okokuqala, qaphela ukuhlola ipuleti lokusula uwoyela kumzila wesitimela, futhi ulishintshe ngesikhathi uma ligugile. Hlola isimo samafutha okugcoba nesipholile. Uma kwenzeka i-turbidity, kufanele ishintshwe ngesikhathi, futhi izinga lamanzi elingaphansi kwesilinganiso kufanele lengezwe.

3. Ukuze ulinganise inqubo yokuvala shaqa, ukunikezwa kwamandla namandla amakhulu kuphaneli yokusebenza yethuluzi lomshini kufanele kuvalwe ngokushintshana. Uma zingekho izimo ezikhethekile kanye nezidingo ezikhethekile, umgomo wokubuyela ku-zero kuqala, i-manual, i-jog, kanye ne-othomathikhi kufanele ilandelwe. Isikhungo somshini kufanele futhi sihambe ngesivinini esiphansi, isivinini esiphakathi, bese sihamba ngesivinini esikhulu. Isikhathi sokugijima esinesivinini esiphansi nesiphakathi akumele sibe ngaphansi kwamaminithi angu-2-3 ngaphambi kokuba kungabikho isimo esingavamile ngaphambi kokuqala ukusebenza.

4. Ukusebenza okujwayelekile, akukwazi ukushaya, ukulungisa noma ukulungisa i-workpiece ku-chuck noma phezulu, futhi ukusebenza okulandelayo kufanele kuqinisekiswe ngemuva kokuthi i-workpiece kanye nethuluzi liboshwe. Imishini yokuvikela nokuphepha emshinini akumele ihlakazwe futhi ihanjiswe ngokungafanele. Ukucubungula okusebenza kahle kakhulu empeleni ukucubungula okuphephile. Njengemishini yokucubungula ephumelelayo, ukusebenza kwesikhungo somshini lapho sivalwa kufanele kufaneke ngendlela efanele, okungeyona nje ukugcinwa kwenqubo eqediwe yamanje, kodwa futhi nokulungiselelwa kokuqala okulandelayo.

Isikhathi sokuthumela: Sep-19-2022