I-fixture design ngokuvamile yenziwa ngokuvumelana nezidingo ezithile zenqubo ethile ngemva kwenqubo yokwenza imishiniizingxenye zemishini ye-cncfuthiizingxenye eziphendukayo ze-cnckwakhiwa. Lapho kwenziwa inqubo, ukuthi kungenzeka yini ukufezeka kwesakhiwo kufanele kucatshangelwe ngokugcwele, futhi lapho uklama izakhiwo, uma kunesidingo, iziphakamiso zokuguqulwa kwenqubo nazo zingaphakanyiswa. Ikhwalithi yomklamo wesakhiwo kufanele ikalwe ngokuthi ingabe ingaqinisekisa ngokuzinzile ikhwalithi yokucubungula yesiqeshana sokusebenza, ukusebenza kahle kokukhiqiza okuphezulu, izindleko eziphansi, ukususwa kwe-chip okulungile, ukusebenza okuphephile, ukonga abasebenzi, kanye nokukhiqiza nokugcinwa okulula.

1. Izimiso eziyisisekelo zomklamo wesakhiwo

1. Ukwanelisa ukuzinza nokuthembeka kokuma kwe-workpiece ngesikhathi sokusetshenziswa;

2. Kukhona amandla anele okuthwala noma okubamba ukuze kuqinisekiswe ukucutshungulwa kwe-workpiece endaweni;

3. Hlangana nokusebenza okulula nokusheshayo kunqubo yokuhlanganisa;

4. Izingxenye ezisengozini kufanele zibe nesakhiwo esingashintshwa ngokushesha, futhi kungcono ukungasebenzisi amanye amathuluzi uma izimo zanele;

5. Ukwanelisa ukwethembeka kokumiswa okuphindaphindiwe kwesakhiwo ngesikhathi sokulungiswa noma ukushintshwa;

6. Gwema isakhiwo esiyinkimbinkimbi kanye nezindleko eziphezulu ngangokunokwenzeka;

7. Khetha izingxenye ezijwayelekile njengezingxenye zengxenye ngangokunokwenzeka;

8. Yakha i-systematization kanye nokumiswa kwemikhiqizo yangaphakathi yenkampani.

2. Ulwazi oluyisisekelo lokuklama kwesakhiwo

Ithuluzi lomshini elihle kakhulu kufanele lihlangabezane nezidingo eziyisisekelo ezilandelayo:

1. Ukuqinisekisa ukunemba komshini we-workpiece, isihluthulelo sokuqinisekisa ukunemba komshini ukukhetha kahle i-datum yokubeka, indlela yokubeka kanye nezingxenye zokubeka. Uma kunesidingo, kuyadingeka ukuhlaziya iphutha lokubeka. Kuyadingeka futhi ukunaka umthelela wesakhiwo sezinye izingxenye ku-fixture ekunembeni komshini. Ukuqinisekisa ukuthi i-fixture ingahlangabezana nezidingo zokunemba komshini we-workpiece.

2. Ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza, ubunkimbinkimbi bezinto ezikhethekile kufanele buvumelane nomthamo wokukhiqiza, futhi izindlela ezihlukahlukene zokubopha ezisheshayo neziphumelelayo kufanele zisetshenziswe ngangokunokwenzeka ukuze kuqinisekiswe ukusebenza okulula, kufinyezwe isikhathi esiyisizayo, nokuthuthukisa ukusebenza kahle kokukhiqiza.

3. Isakhiwo sesakhiwo esikhethekile esinomsebenzi omuhle wenqubo kufanele sibe lula futhi sinengqondo, esilungele ukukhiqiza, ukuhlanganiswa, ukulungiswa, ukuhlolwa nokugcinwa.

4. Ithuluzi lamathuluzi elisebenza kahle kufanele libe namandla anele kanye nokuqina, futhi ukusebenza kufanele kube lula, konga abasebenzi, kuphephe futhi kuthembeke. Ngaphansi kwesisekelo sokuthi izimo zenhloso ziyakuvumela futhi zingokonga futhi ziyasebenza, amathuluzi okubamba imishini afana ne-pneumatic kanye ne-hydraulic pressure kufanele asetshenziswe ngangokunokwenzeka ukuze kwehliswe umfutho wokusebenza komsebenzisi. I-fixture kufanele futhi yenze kube lula ukukhishwa kwe-chip. Uma kunesidingo, isakhiwo sokususwa kwe-chip singasethwa ukuze kuvinjelwe i-chip ekulimazeni ukuma kwe-workpiece futhi ilimaze ithuluzi, futhi kuvimbele ukuqoqwa kwama-chips ekuletheni ukushisa okukhulu futhi kubangele ukuwohloka kwesistimu yenqubo.

5. Isakhiwo esikhethekile esinomnotho omuhle kufanele sisebenzise izingxenye ezijwayelekile kanye nesakhiwo esijwayelekile ngangokunokwenzeka, futhi silwele ukuba nesakhiwo esilula nokwenziwa okulula ukuze kuncishiswe izindleko zokukhiqiza. Ngakho-ke, ukuhlaziya okudingekile kwezobuchwepheshe nokwezomnotho kohlelo lokuhlanganisa kufanele kwenziwe ngokuya nge-oda namandla okukhiqiza ngesikhathi sokuklama, ukuze kuthuthukiswe izinzuzo zezomnotho zesakhiwo ekukhiqizeni.

3. Uhlolojikelele lokumiswa kwamathuluzi nokuklanywa kwesakhiwo

1. Izindlela eziyisisekelo kanye nezinyathelo zokwakheka kwesakhiwo

Amalungiselelo ngaphambi kokuklama Izinto zoqobo zokwakheka kwesakhiwo zifaka lokhu okulandelayo:

a) Ulwazi lobuchwepheshe olufana nesaziso sokuklama, ingxenye yomdwebo oqediwe womkhiqizo, umdwebo ongenalutho nomzila wokucubungula, ukuqonda izidingo zobuchwepheshe zokucubungula zenqubo ngayinye, uhlelo lokumisa nokuhlanganisa, ukucubungula okuqukethwe kwenqubo yangaphambilini, isimo esingenalutho, amathuluzi omshini namathuluzi asetshenziswe ukucubungula, amathuluzi okulinganisa okuhlola, isibonelelo somshini kanye nenani lokusika, njll.;

b) Ukuqonda iqoqo lokukhiqiza kanye nesidingo sezinto ezilungiswayo;

c) Qonda amapharamitha wobuchwepheshe abalulekile, ukusebenza, ukucaciswa, ukunemba kanye nobukhulu bokuxhumana besakhiwo esixhunywe nendawo, njll. yethuluzi lomshini elisetshenzisiwe;

d) Uhlu lwezinto ezijwayelekile zokulungisa izinto.

2. Izinkinga ezicatshangelwayo ekwakhiweni kwezakhiwo

I-fixture design ngokuvamile inesakhiwo esisodwa, enikeza abantu umuzwa wokuthi isakhiwo asiyinkimbinkimbi kakhulu, ikakhulukazi manje njengoba ukuthandwa kwe-hydraulic fixtures kwenza kube lula ukwakheka kwemishini yasekuqaleni, kodwa uma kungekho ukucatshangelwa okuningiliziwe okunikezwayo phakathi nenqubo yokuklama, izinkinga ezingadingekile ziyoba lula. kwenzeka ngokungenakugwenywa:

a) Isibonelelo esingenalutho se-workpiece ezosetshenzwa. Usayizi wokungenalutho mkhulu kakhulu, okubangela ukuphazamiseka. Ngakho-ke, kuyadingeka ukulungisa umdwebo onzima ngaphambi kokuklama. Shiya isikhala esanele.

b) Ubushelelezi bokususwa kwe-chip ye-fixture. Ngenxa yesikhala sokucubungula esilinganiselwe sethuluzi lomshini ngesikhathi sokuklama, into elungiswayo ivamise ukuklanywa endaweni ehlangene. Ngalesi sikhathi, kuvame ukunganakwa ukuthi amafayili ensimbi akhiqizwa ngesikhathi senqubo yomshini aqoqa ekhoneni elifile le-fixture, kuhlanganise nokugeleza okungalungile kokusika uketshezi, okuzodala izinkinga zesikhathi esizayo. Ukucubungula kuletha izinkinga eziningi. Ngakho-ke, ekuqaleni kwenqubo yangempela, izinkinga ezivela ngesikhathi sokucubungula kufanele zicatshangelwe. Phela, ukulungiswa kusekelwe ekuthuthukiseni ukusebenza kahle kanye nokwenza lula ukusebenza.

c) Ukuvuleka okuphelele komdlalo. Ukuziba ukuvuleka kwenza kube nzima ku-opharetha ukufaka ikhadi, okudla isikhathi futhi kukhandla, futhi ukuklama akuvumelekile.

d) Izimiso zetiyetha eziyisisekelo zomklamo wesakhiwo. Isethi ngayinye yezinto ezilungiswayo kufanele idlule ezikhathini eziningi zokuphoqa nokukhulula izenzo, ngakho ingase ihlangabezane nezimfuneko zomsebenzisi ekuqaleni, kodwa okungeziwe okungeziwe kufanele kube nokugcinwa kokunemba kwakho, ngakho ungaklami okuthile okungqubuzana nomgomo. Ngisho noma ungakwenza manje ngenhlanhla, ngeke kuhlale isikhathi eside. Idizayini enhle kufanele ihambisane nesikhathi.

e) Ukushintshwa kwezinto ezibekwe endaweni. Isici sokuma siguge kakhulu, ngakho-ke ukushintshwa okusheshayo nokulula kufanele kucatshangelwe. Kungcono ukuthi ungayiklami njengengxenye enkulu.

Ukuqoqwa kokuhlangenwe nakho komklamo wesakhiwo kubaluleke kakhulu. Ngezinye izikhathi ukuklama kuyinto eyodwa, kodwa kungenye into ekusebenziseni okungokoqobo, ngakho-ke ukuklama okuhle kuyinqubo yokuqongelela okuqhubekayo nokufingqa.

Izinto ezisetshenziswayo ezisetshenziswa kakhulu zihlukaniswa ikakhulukazi zibe izinhlobo ezilandelayo ngokwemisebenzi yazo:

01 ukubopha isikhunta

02 Ukubhoboza nokugaya amathuluzi

03 CNC, insimbi chuck

04 Ukuhlolwa kwegesi, ithuluzi lokuhlola amanzi

05 Ukunquma nokushaya amathuluzi

06 ukushisela amathuluzi

07 Uhlelo lokupholisha

08 Amathuluzi womhlangano

09 pad ukuphrinta, laser engraving tooling

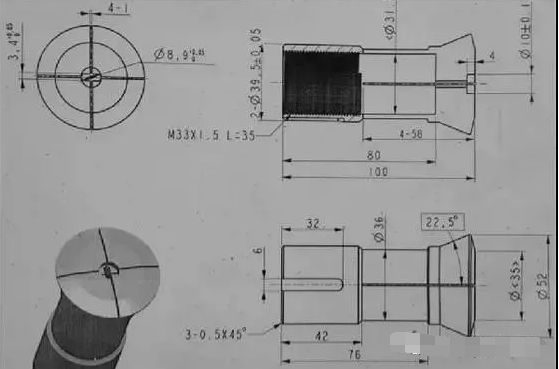

01 ukubopha isikhunta

Incazelo: Ithuluzi lokubeka indawo kanye nokubamba ngomumo womkhiqizo

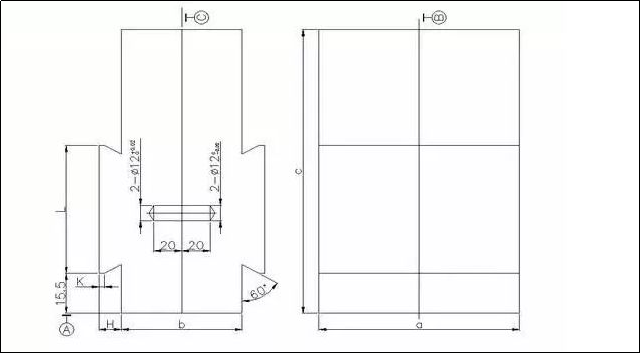

Amaphuzu Wokuklama:

1. Lolu hlobo lwesikhunta se-clamping lusetshenziselwa ikakhulukazi i-vise, futhi ubude balo bungasikwa ngokuvumelana nezidingo;

2. Amanye amadivaysi okumisa asizayo angaklanywa kusikhunta sokubopha, futhi isikhunta sokubopha ngokuvamile sixhunywa ngokushisela;

3. Isithombe esingenhla yisithombe esenziwe lula, futhi ubukhulu besakhiwo sesikhunta sinqunywa isimo esithile;

4. Qondanisa iphinikhodi yokumisa kahle enobubanzi obungu-12mm endaweni efanele esibukweni esinyakaziswayo, kanye nembobo yokubeka endaweni ehambisanayo yamaslayidi esikhunta esingashintshi ukuze kulingane iphini lokubeka;

5. Umgodi wokuhlanganisa udinga ukususwa futhi ukhuliswe ngo-0.1mm ngesisekelo sohlaka lomdwebo omangelengele ngaphandle kokushwabana phakathi nomklamo.

02 Ukubhoboza nokugaya amathuluzi

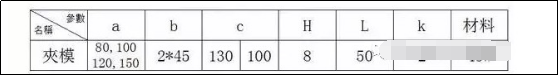

Amaphuzu Wokuklama:

1. Uma kunesidingo, ezinye izinto ezisizayo zokubeka zingaklanywa kumongo ongashintshi kanye nepuleti lawo elingashintshi;

2. Isithombe esingenhla siwumdwebo wesakhiwo esenziwe lula, futhi isimo sangempela sidinga ukuklanywa ngokuya ngesakhiwo somkhiqizo;

3. Isilinda sincike kusayizi womkhiqizo kanye nokucindezeleka ngesikhathi sokucubungula, futhi i-SDA50X50 ivame ukusetshenziswa;

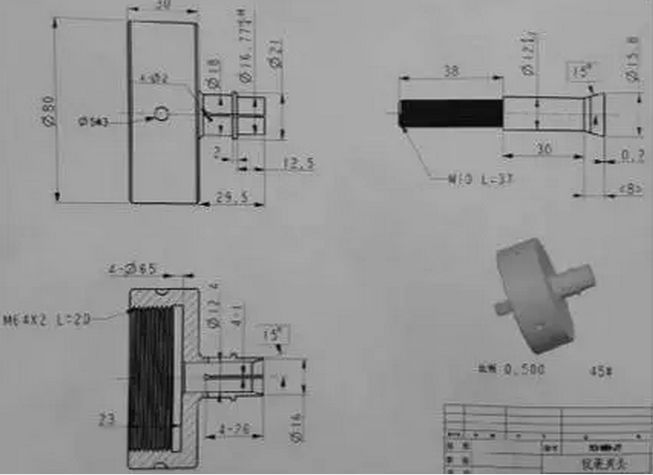

03 CNC, insimbi chuck

I-CNC Chuck

Ikholethi yangaphakathi

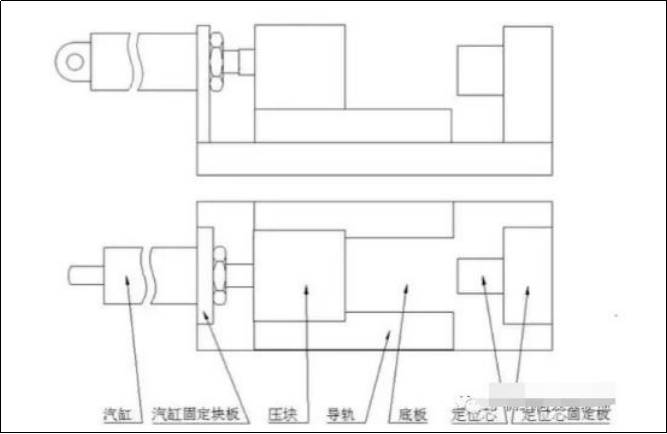

Amaphuzu Wokuklama:

1. Ubukhulu obungaphawuliwe emdwebeni ongenhla bunqunywa ngokwesakhiwo sosayizi wembobo engaphakathi yomkhiqizo wangempela;

2. Indilinga yangaphandle exhumene nembobo yangaphakathi yomkhiqizo idinga ukushiya umkhawulo ongu-0.5mm ohlangothini olulodwa ngesikhathi sokukhiqiza, futhi ekugcineni uyifake ethuluzini lomshini we-CNC bese uqeda ukuyishintsha ibe usayizi ukuze uvimbele ukuwohloka nokugqama. okubangelwa inqubo yokucisha;

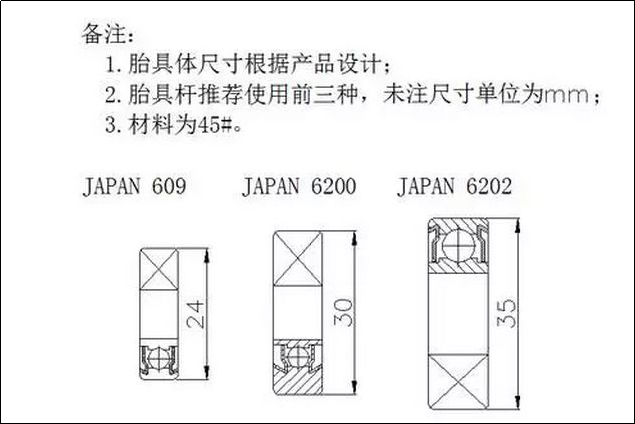

3. Impahla yengxenye yomhlangano inconywa ukusebenzisa insimbi yasentwasahlobo, futhi ingxenye yenduku ye-tie ingu-45 #;

4. Intambo engu-M20 yentambo yokubopha iyintambo evamile, engalungiswa ngokuvumelana nesimo sangempela.

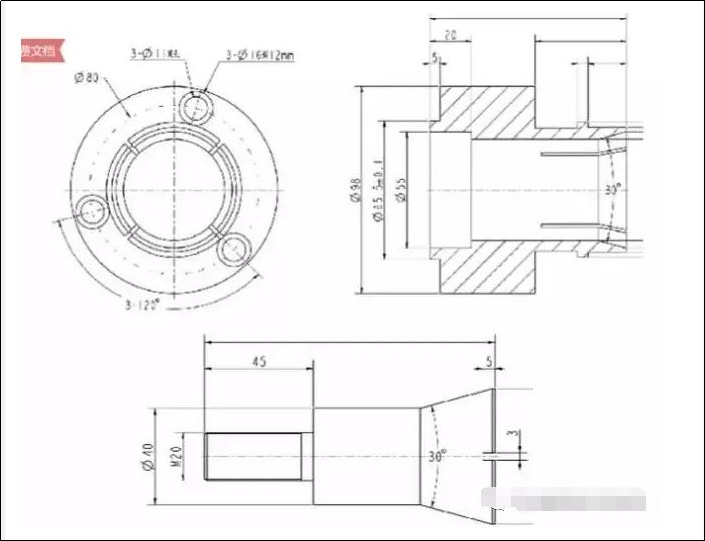

Instrument Inner Beam Chuck

Amaphuzu Wokuklama:

1. Isithombe esingenhla siwumfanekiso wereferensi, futhi usayizi womhlangano kanye nesakhiwo kunqunywa ngokwesilinganiso sangempela sangaphandle somkhiqizo kanye nesakhiwo;

2. Impahla ingu-45#, icishiwe.

Insimbi yocingo yangaphandle chuck

Amaphuzu Wokuklama:

1. Isithombe esingenhla siwumfanekiso wereferensi, futhi usayizi wangempela uncike kusayizi nesakhiwo sembobo yangaphakathi yomkhiqizo;

2. Isiyingi esingaphandle esixhumene nembobo engaphakathi yomkhiqizo sidinga ukushiya umkhawulo ongu-0.5mm ohlangothini olulodwa ngesikhathi sokukhiqiza, bese ekugcineni siwufaka emshinini wokwenza izinto bese uqedela ukuwushintsha ube usayizi ukuze kuvinjelwe ukuwohloka nokungaqondile okubangelwa. ngenqubo yokucima;

3. Impahla ingu-45#, icishiwe.

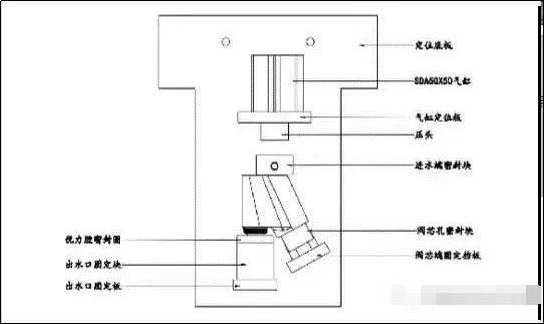

04 Ithuluzi lokuhlola igesi

Amaphuzu Wokuklama:

1. Isithombe esingenhla yisithombe esiyinkomba sethuluzi lokuhlola igesi. Isakhiwo esithile sidinga ukuklanywa ngokuya ngesakhiwo sangempela somkhiqizo. Umqondo uwukuvala umkhiqizo ngendlela elula, futhi uvumele ingxenye edinga ukuhlolwa igcwaliswe ngegesi ukuze kuqinisekiswe ukuqina kwayo;

2. Ubukhulu besilinda bungalungiswa ngokuhambisana nobukhulu bangempela bomkhiqizo, futhi kuyadingeka ukucabangela ukuthi ukushaywa kwe-cylinder kungahlangabezana nokulula kokukha nokubeka umkhiqizo;

3. Indawo yokuvala exhumene nomkhiqizo ngokuvamile yenziwa ngerabha enhle kakhulu, indandatho yerabha ye-NBR nezinye izinto ezicindezelwa kahle. Ngesikhathi esifanayo, kufanele kuqashelwe ukuthi uma kukhona ibhulokhi yokumisa ethintana nokubukeka komkhiqizo, zama ukusebenzisa amabhulokhi epulasitiki epulasitiki amhlophe futhi uwasebenzise ngesikhathi sokusebenzisa. Isembozo esiphakathi simbozwe ngendwangu yekotini ukuvimbela ukubonakala komkhiqizo ngokulimala;

4. Isiqondiso sokuma komkhiqizo kufanele sicatshangelwe ekwakhiweni, ukuze kuvinjwe ukuvuza kwegesi ekuvalelekeni ngaphakathi komgodi womkhiqizo futhi kubangele ukutholwa okungamanga.

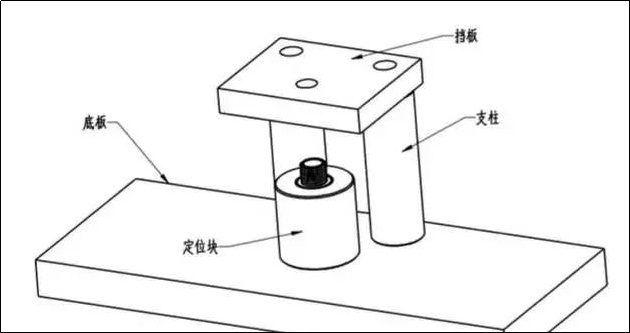

05 ukubhoboza amathuluzi

Amaphuzu okuklama: Isithombe esingenhla sibonisa isakhiwo esivamile samathuluzi okubhoboza. Umsebenzi wepuleti eliphansi ukwenza lula ukulungiswa ku-workbench yomshini wokubhoboza; umsebenzi webhulokhi yokumisa ukulungisa umkhiqizo, isakhiwo esithile siklanywe ngokuvumelana nesimo sangempela somkhiqizo, futhi indawo emaphakathi iseduze ukuze kube lula futhi ukukhetha nokubeka umkhiqizo ngokuphepha; umsebenzi we-baffle ukwenza lula umkhiqizo ukuba uhlukaniswe nommese wokubhoboza; Insika isebenza njengesiphithiphithi esingaguquki. Izikhundla zomhlangano kanye nobukhulu bezingxenye ezibalwe ngenhla zingaklanywa ngokuya ngesimo sangempela somkhiqizo.

06 ukushisela amathuluzi

I-Welding tooling isetshenziswa ngokuyinhloko ukulungisa indawo yengxenye ngayinye ekuhlanganiseni kokushisela nokulawula ubukhulu obuhlobene bengxenye ngayinye emhlanganweni wokushisela. Isakhiwo salo ngokuyinhloko ibhulokhi yokumisa, okudingeka iklanywe ngokuvumelana nesakhiwo sangempela seizingxenye ze-aluminium machiningfuthiizingxenye zethusi machining. Kuyaqapheleka ukuthi lapho umkhiqizo ubekwe ethuluzini lokushisela, akuvunyelwe ukudala isikhala esivaliwe phakathi kwamathuluzi ukuvimbela ukucindezela ngokweqile kwesikhala esivalekile ngesikhathi sokushisa kwe-welding kusuka ekuthinteni ubukhulu bezingxenye ngemuva kokushisela. .

07 Uhlelo lokupholisha

08 Amathuluzi womhlangano

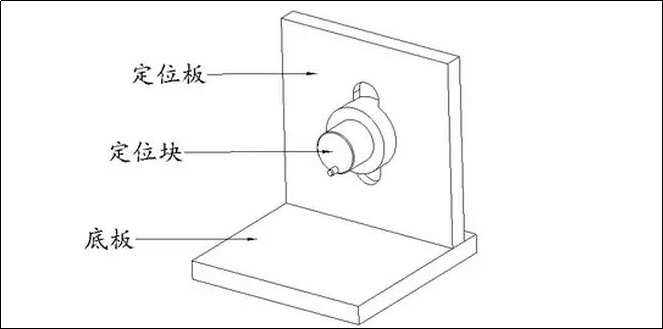

Amathuluzi womhlangano asetshenziswa ngokuyinhloko njengethuluzi lokubeka insiza ngesikhathi sokuhlanganisa izingxenye. Umqondo wawo wokuklama ukuthi umkhiqizo ungathathwa kalula futhi ubekwe ngokuvumelana nesakhiwo somhlangano wezingxenye, ukubukeka komkhiqizo akukwazi ukonakala ngesikhathi senqubo yokuhlanganisa, futhi umkhiqizo ungambozwa ngendwangu kakotini ukuze uvikele umkhiqizo ngesikhathi. sebenzisa. Ekukhetheni izinto zokwakha, zama ukusebenzisa izinto ezingezona ezensimbi njengeglue emhlophe.

09 pad ukuphrinta, laser engraving tooling

Amaphuzu okuklama: Dizayina isakhiwo sokuma samathuluzi ngokuya ngezidingo zokubhala zesimo sangempela somkhiqizo. Kufanele kuqashelwe ukuthi kulula ukuthatha nokubeka umkhiqizo kanye nokuvikelwa kokubukeka komkhiqizo. Ibhulokhi yokumisa kanye nensiza yedivayisi yokumisa lapho kuthintana nomkhiqizo kufanele kwenziwe ngezinto ezingezona ezensimbi njengeglue emhlophe. .

Isikhathi sokuthumela: Dec-26-2022