Ukuthuthukiswa kwezinto zamathuluzi ngokuvamile kwenzeka ngokuhambisana nezidingo ezithile zenqubo enikeziwe, uma inqubo yezingxenye zemishini isisunguliwe. Kubalulekile ukucabangela ngokugcwele ukuba nokwenzeka kokuqaliswa kokusebenza ngenkathi kwakhiwa inqubo. Lapho udala ama-tooling fixtures, ukulungiswa kwenqubo kufanele kuphakanyiswe uma kunesidingo.

Ikhwalithi yomklamo wezinto zamathuluzi kufanele ihlolwe ngokusekelwe ekhonweni layo lokuqinisekisa ngokungaguquguquki ikhwalithi yokucubungula yesiqeshana sokusebenza, ukufeza ukusebenza kahle kokukhiqiza okuphezulu, ukunciphisa izindleko, ukunika amandla ukususwa kwe-chip okulungile, ukuqinisekisa ukusebenza okuphephile, ukonga emisebenzini, kanye nokwenza lula ukukhiqiza nokukhiqiza. ukunakekela. Imingcele yokuhlola ihlanganisa lezi zici.

1. Imihlahlandlela eyisisekelo yokuklama izinto zamathuluzi

1) Qinisekisa ukuzinza nokuthembeka kokuma kwengcezu yokusebenza ngesikhathi sokusetshenziswa;

2) Nikeza amandla anele okuthwala noma okubamba ukuze uqinisekise ukucutshungulwa kwengcezu yokusebenza endaweni;

3) Nika amandla ukusebenza okulula nokusheshayo ngesikhathi senqubo yokuhlanganisa;

4)Faka izingxenye ezigqokekayo ezinesakhiwo esishintshayo, ukugwema kahle ukusetshenziswa kwamanye amathuluzi uma izimo zivuma;

5) Misa ukwethembeka ekumisweni okuphindaphindiwe kwesakhiwo ngesikhathi sokulungiswa noma ukushintshwa;

6) Nciphisa ubunkimbinkimbi nezindleko ngokugwema izakhiwo eziyinkimbinkimbi noma nini lapho kungenzeka;

7) Sebenzisa izingxenye ezijwayelekile njengezingxenye zengxenye ngezinga elikhulu ngangokunokwenzeka;

8) Sungula ukuhlelwa komkhiqizo wangaphakathi kanye nokumiswa ngaphakathi kwenkampani.

2. Ulwazi oluyisisekelo lwe-tooling kanye ne-fixture design

Ithuluzi lomshini elihle kakhulu kufanele lihlangabezane nezidingo eziyisisekelo ezilandelayo:

1) Ukuqinisekisa ukunemba komshini wokusebenza kudinga ukukhetha idatha yokuma efanele, indlela, nezingxenye, kanye nokwenza ukuhlaziya iphutha lokuma uma kudingeka. Kufanele futhi kuqashelwe umthelela wezakhi zesakhiwo ekucutshungulweni ukuze kuqinisekiswe ukuthi into elungiswayo ihlangabezana nokucaciswa kokunemba kocezu lokusebenza.

2) Ukuze kuthuthukiswe ukusebenza kahle kokukhiqiza, lungisa inkimbinkimbi yezinto ezikhethekile ukuze zifane namandla okukhiqiza. Sebenzisa izindlela zokubopha ezisheshayo nezisebenzayo noma nini uma kunokwenzeka ukuze wenze imisebenzi ibe lula, unciphise isikhathi esiyisizayo, futhi uthuthukise ukusebenza kahle kokukhiqiza.

3)Khetha izakhiwo ezilula nezinengqondo zokulungiswa okukhethekile nokusebenza okuhle kakhulu ukuze wenze lula ukukhiqiza, ukuhlanganisa, ukulungisa, ukuhlola, nezinqubo zokulungisa.

4)Izinto zokusebenza ezisebenza kahle kakhulu kufanele zibe namandla anele nokuqina, kuhlanganiswe nokusebenza okulula, okuphumelelayo, okuphephile, nokuthembekile. Noma nini lapho kungenzeka futhi kungabizi kakhulu, sebenzisa i-pneumatic, hydraulic, nezinye izinsimbi zokubopha ezenziwe ngomshini ukuze unciphise amandla okusebenza komsebenzisi. Ukwengeza, ukulungiswa kwamathuluzi kufanele kusize ukukhishwa kwe-chip futhi kuqalise izakhiwo, uma kunesidingo, ukuvimbela ama-chips ukuthi angafaki engcupheni indawo yocezu lokusebenza, ukulimala kwamathuluzi, noma ukubangela ukunqwabelana kokushisa nokucubungula ukuguqulwa kwesistimu.

5) Izakhiwo ezikhethekile ezisebenza kahle ngokomnotho kufanele zisebenzise izingxenye nezakhiwo ezijwayelekile ngangokunokwenzeka. Lwela imiklamo elula nokukhiqiza okulula ukuze unciphise izindleko zokukhiqiza. Ngakho-ke, yenza ukuhlaziya okudingekile kwezobuchwepheshe nezomnotho kwesixazululo sokuhlanganisa phakathi nesigaba sokuklama ngokusekelwe ekuhlelekeni nasemandleni okukhiqiza ukuze kuthuthukiswe izinzuzo zezomnotho zale ngxenye ngesikhathi sokukhiqiza.

3. Uhlolojikelele lokumiswa kwamathuluzi nokuklanywa kwesakhiwo

1. Izindlela eziyisisekelo kanye nezinyathelo zokusebenzisa amathuluzi nokuklama kwesakhiwo

Ukulungiselela ngaphambi kokuklama Idatha yasekuqaleni yamathuluzi nesakhiwo sesakhiwo ihlanganisa lokhu okulandelayo:

a)Nikeza izaziso zedizayini, ingxenye yemidwebo eqediwe, imidwebo yokuqala, nezindlela zokucubungula, kanye neminye imininingwane yobuchwepheshe. Thola ukuqonda ngezidingo zobuchwepheshe zenqubo ngayinye, okuhlanganisa izindlela zokumisa nokubopha, imininingwane yokucubungula kusukela esigabeni esandulele, izimo ezingaphezulu, amathuluzi omshini asetshenziswayo, amathuluzi, okokusebenza kokuhlola, ukubekezelelwa kwemishini, kanye nenani lokusika.

b)Qonda usayizi weqoqo lokukhiqiza kanye nezidingo zokulungisa.

c)Zijwayeze namapharamitha okusebenza ayinhloko, ukusebenza, ukucaciswa, ukunemba, nobukhulu obuhlotshaniswa nesakhiwo sengxenye yokuxhumanisa ingxenye yethuluzi lomshini elisetshenzisiwe.

d)Gcina i-inventory evamile yezinto zokulungisa.

2. Izinkinga okufanele zicatshangelwe ekwakhiweni kwezinto zamathuluzi

I-clamp design ngokuvamile inesakhiwo esisodwa, esinikeza umbono wokuthi isakhiwo asiyinkimbinkimbi kakhulu. Ikakhulukazi manje ukuthandwa kwe-hydraulic clamps kwenze kwaba lula kakhulu ukwakheka komshini wokuqala. Kodwa-ke, uma ukucatshangelwa okuningiliziwe kungathathwa ngesikhathi senqubo yokuklama, izinkinga ezingadingekile zizokwenzeka nakanjani:

a)Lapho uklama, qiniseka ukuthi imajini engenalutho ye-workpiece ibhekwa ngokunembile ukuvimbela ukuphazamiseka ngenxa yobukhulu obukhulu. Lungiselela umdwebo ongenalutho ngaphambi kokuqhubeka nenqubo yokuklama ukuze uvumele isikhala esanele.

b)Ukuqinisekisa ukusebenza kahle kanye nokususwa kwe-chip okushelelayo kwe-fixture, kubalulekile ukubhekana nezinkinga ezingaba khona njengokunqwabelana kwamafayili ensimbi kanye nokuphuma kahle koketshezi olusikiwe ekuqaleni kwesigaba sokuklama. Ukulindela nokuxazulula izinkinga zokucubungula kusukela ekuqaleni kubalulekile ukuze kuthuthukiswe inhloso yokulungisa ukuze kuthuthukiswe ukusebenza kahle kanye nokusebenza kalula.

c)Gcizelela ukuvuleka sekukonke kwesakhiwo ukuze kube lula inqubo yokufaka kubaqhubi, ukugwema imisebenzi edla isikhathi nedinga abasebenzi. Ukudebeselela ukuvuleka kwesakhiwo akulungile ekwakhiweni.

d)Hlala unamathela ezimisweni zetiyori eziyisisekelo ekwakhiweni kwesakhiwo ukuze ugcine ukunemba nokuphila isikhathi eside. Imiklamo akufanele ibeke engcupheni le migomo, ngisho noma ibonakala ihlangabezana nezidingo zabasebenzisi bokuqala, njengoba idizayini enhle kufanele imelane nokuhlolwa kwesikhathi.

e)Cabangela ukushintshwa okusheshayo nokulula kwezingxenye zokumisa ukuze ubhekane nokuguga okunzima futhi ugweme ukudizayina izingxenye ezinkulu, eziyinkimbinkimbi. Ukushintshwa kalula kufanele kube isici esibalulekile ekwakhiweni kwengxenye.

Ukuqoqwa kokuhlangenwe nakho komklamo wesakhiwo kubaluleke kakhulu. Ngezinye izikhathi ukuklama kuyinto eyodwa futhi ukusetshenziswa okusebenzayo kungenye, ngakho-ke ukuklama okuhle kuyinqubo yokuqongelela okuqhubekayo kanye nesifinyezo.

Izinto ezisetshenziswayo ezisetshenziswa kakhulu zihlukaniswe ikakhulukazi izigaba ezilandelayo ngokuya ngokusebenza kwazo:

01 isikhunta se-clamp

02 Ukubhoboza nokugaya amathuluzi

03 CNC, insimbi chuck

04 Ukuhlola igesi kanye namathuluzi okuhlola amanzi

05 Ukunquma nokushaya amathuluzi

06 Ukushisela amathuluzi

07 Ukupholisha i-jig

08 Amathuluzi womhlangano

09 Ukuphrinta kwephedi, ithuluzi lokuqopha nge-laser

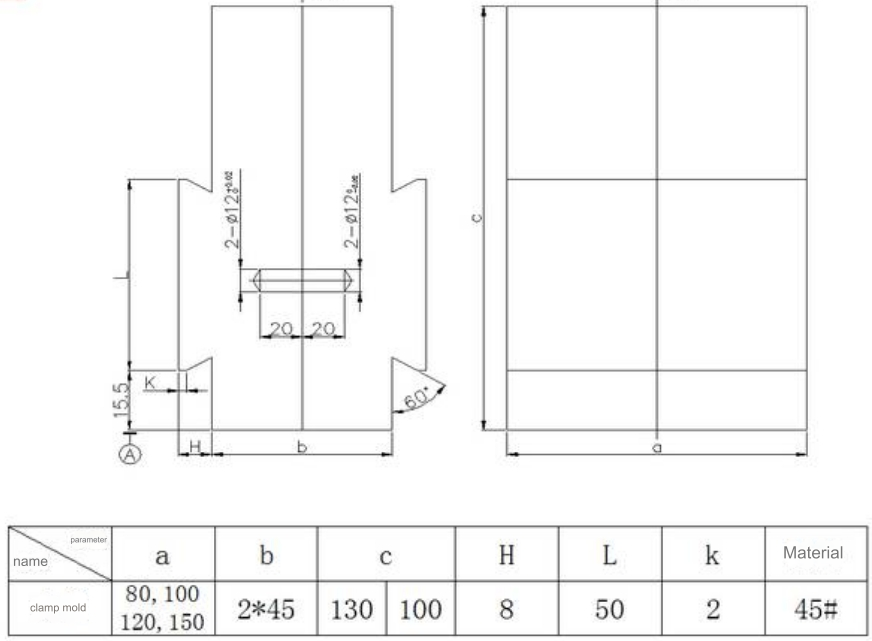

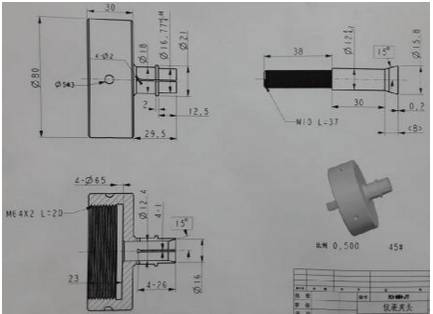

01 isikhunta se-clamp

Incazelo: Ithuluzi lokubeka kanye nokuhlanganisa ngokusekelwe kumumo womkhiqizo

Amaphuzu Wokuklama:

1)Lolu hlobo lwe-clamp luthola ukusebenza kwalo okuyinhloko ku-vise, futhi lunikeza ukuguquguquka kokusikwa ngokwezidingo.

2) Izinsiza zokubeka ezengeziwe zingahlanganiswa kusikhunta sokubopha, ngokuvamile esivikelwe ngokushisela.

3)Umdwebo ongenhla uwumfanekiso owenziwe lula, futhi ubukhulu besakhiwo somgodi wokukhunta buncike ezimweni ezithile.

4)Beka kahle iphinikhodi yokubeka ububanzi obungu-12mm kusikhunta esisusekayo, kuyilapho imbobo ehambisanayo ekubunjweni okungashintshi idizayinelwe ukuthwala kahle iphinikhodi.

5) Phakathi nesigaba sokuklama, umgodi wokuhlanganisa kufanele ulungiswe futhi ukhuliswe ngo-0.1mm, kucatshangelwa indawo yohlaka yomdwebo ongenalutho ongancibilikisiwe.

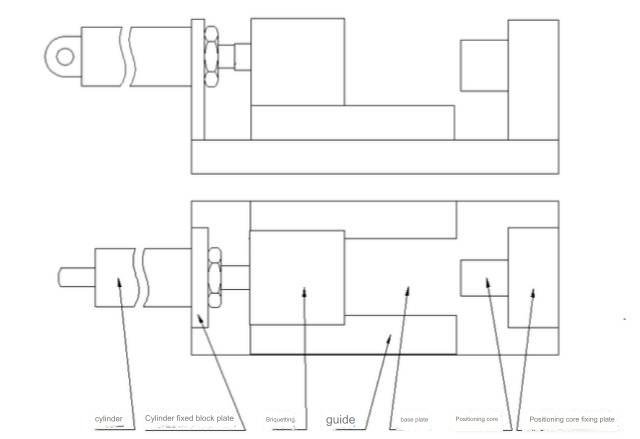

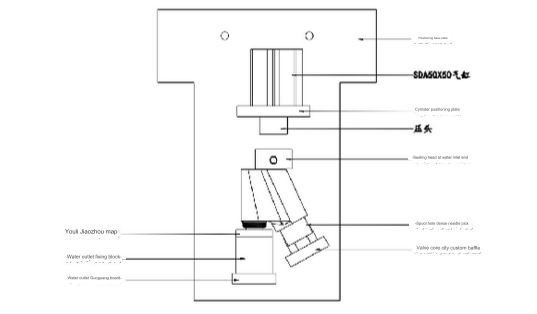

02 Ukubhoboza nokugaya amathuluzi

Amaphuzu Wokuklama:

1) Uma kudingekile, izindlela zokubeka ezengeziwe zingafakwa kumongo ongashintshi kanye nepuleti lawo elingashintshi elihambisanayo.

2)Isithombe esiveziwe siwuhlaka oluyisisekelo lwesakhiwo. Izimo zangempela zenza kudingeke umklamo owenziwe ngokuvumelana nesakhiwo somkhiqizo.

3)Ukukhethwa kwesilinda kuthonywa ubukhulu bomkhiqizo kanye nengcindezi oyitholayo phakathi nokucubungula. I-SDA50X50 iwukukhetha okukhona kulezi zimo.

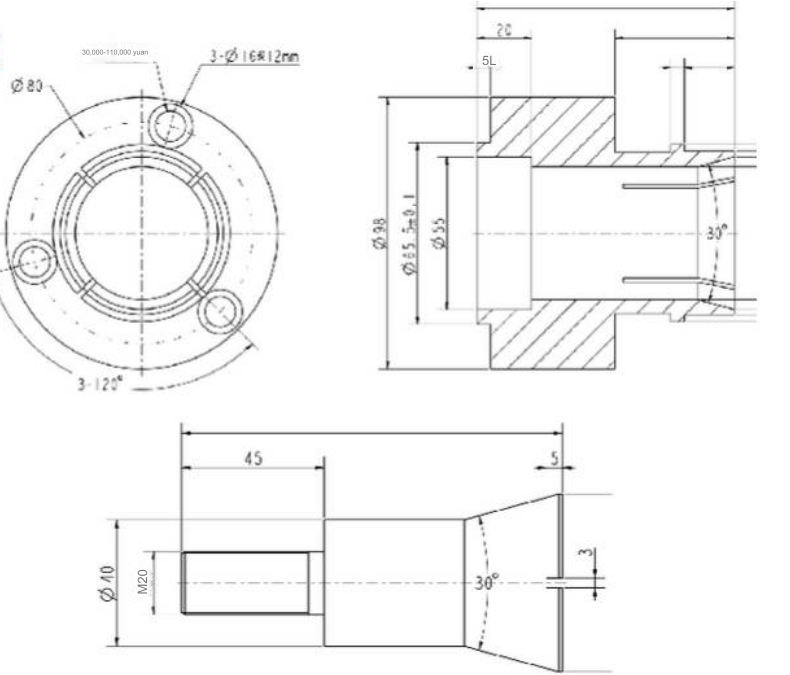

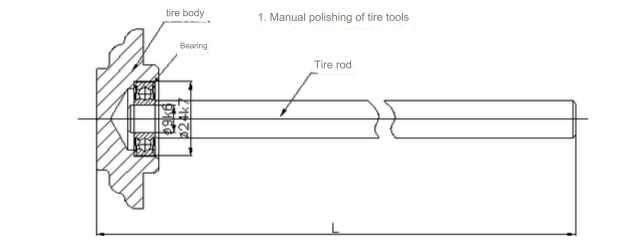

03 CNC, insimbi chuck

Inani eliphakeme kakhulu lama-CNC

I-toe-in chuck

Amaphuzu Wokuklama:

1. Ubukhulu obungaphawuliwe esithombeni esingenhla busekelwe kusayizi wembobo engaphakathi yomkhiqizo wangempela;

2. Indilinga yangaphandle esendaweni ethintana nembobo yangaphakathi yomkhiqizo idinga ukushiya umkhawulo ongu-0.5mm ohlangothini olulodwa ngesikhathi sokukhiqiza, futhi ekugcineni ifakwe ethuluzini lomshini we-CNC bese iphendulwa kahle ibe usayizi ukuvimbela ukuwohloka nokushintshashintsha. i-eccentricity ebangelwa inqubo yokucisha;

3. Kunconywa ukusebenzisa insimbi yasentwasahlobo njengento yengxenye yomhlangano kanye ne-45 # yengxenye ye-tie rod;

4. Intambo engu-M20 engxenyeni yenduku yokubopha iyintambo evame ukusetshenziswa, engalungiswa ngokuvumelana nesimo sangempela.

I-Instrument toe-in chuck

Amaphuzu Wokuklama:

1. Isithombe esingenhla siwumdwebo wereferensi, futhi ubukhulu bomhlangano nesakhiwo kusekelwe kubukhulu nokwakheka komkhiqizo wangempela;

2. Impahla ingu-45# futhi yacinywa.

Insimbi yangaphandle yokuqinisa

Amaphuzu Wokuklama:

1. Isithombe esingenhla siwumdwebo wereferensi, futhi usayizi wangempela uncike esakhiweni sosayizi wembobo yangaphakathi yomkhiqizo;

2. Indilinga yangaphandle esendaweni ethintana nembobo engaphakathi yomkhiqizo idinga ukushiya imajini engu-0.5mm ohlangothini olulodwa ngesikhathi sokukhiqiza, futhi ekugcineni ifakwe emshinini wensimbi bese iphendulwa kahle ibe usayizi ukuze kuvinjelwe ukuwohloka nokugqama. okubangelwa inqubo yokucisha;

3. Impahla ingu-45# futhi yacinywa.

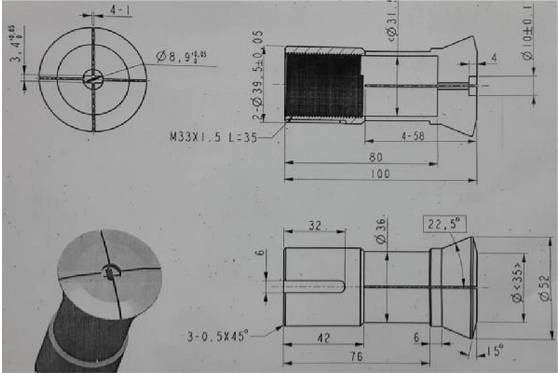

04 Amathuluzi okuhlola igesi

Amaphuzu Wokuklama:

1) Isithombe esinikeziwe sisebenza njengomhlahlandlela wamathuluzi okuhlola igesi. Isakhiwo sesakhiwo esithile kufanele sihambisane nomkhiqizo wangempela. Umgomo uwukwenza indlela yokuvala eqondile yokuhlola igesi nokuqinisekisa ubuqotho bomkhiqizo.

2) Usayizi wesilinda ungafanelana nobukhulu bomkhiqizo, uqinisekise ukuthi i-cylinder stroke yenza kube lula ukuphathacnc machining umkhiqizo.

3) Ezindaweni zokuvala ezihlangana nomkhiqizo, izinto ezinamandla okucindezela aqinile njenge-Uni glue nezindandatho zenjoloba ze-NBR zivame ukusetshenziswa. Ukwengeza, lapho usebenzisa amabhulokhi okumisa athinta indawo engaphandle yomkhiqizo, kunconywa ukusebenzisa amabhulokhi epulasitiki eglue emhlophe ngesikhathi sokusebenza. Ngaphezu kwalokho, ukumboza isikhungo ngendwangu kakotini kusiza ukuvikela ukubukeka komkhiqizo.

4) Lapho uklama, kubalulekile ukucabangela ukuma komkhiqizo ukuvimbela ukuvuza kwegesi ngaphakathi komgodi womkhiqizo, okungaholela ekutholweni okungamanga.

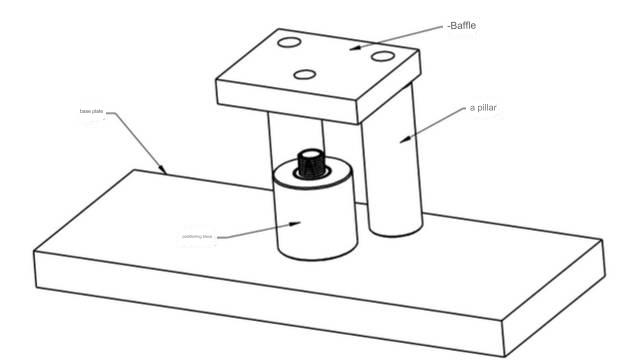

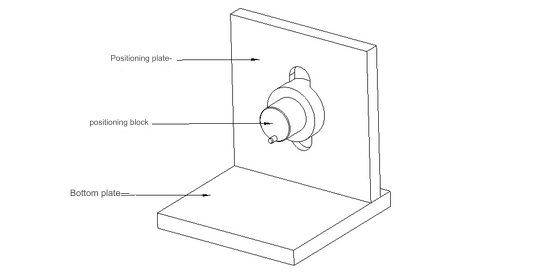

05 Ukubhoboza amathuluzi

Amaphuzu Wokuklama:

Isithombe esingenhla sibonisa ukwakheka okujwayelekile kwamathuluzi okubhoboza. I-base plate inamathela ngokuvikelekile ebhentshini lokusebenza lomshini we-punch, kuyilapho i-positioning block isetshenziswa ukuzinzisa umkhiqizo. Ukucushwa okunembayo kuhambisana nezidingo ezithile zomkhiqizo. Iphoyinti elimaphakathi livumela ukuphathwa okuphephile nokulula nokubeka umkhiqizo, kuyilapho i-baffle isiza ekuhlukaniseni umkhiqizo nombese wokubhoboza.

Izinsika zisebenzela ukuvikela i-baffle endaweni, futhi izindawo zokuhlangana nobukhulu balezi zingxenye zingenziwa ngendlela oyifisayo ukuze kuhambisane nezici ezihlukile zomkhiqizo.

06 Ukushisela amathuluzi

Umsebenzi oyinhloko we-welding tooling uwukuqinisekisa ukuma okunembile kwengxenye ngayinye ngaphakathi komhlangano wokushisela nokuqinisekisa ukulinganisa okungaguquguquki kwengxenye ngayinye. Isakhiwo esiyinhloko siqukethe ibhulokhi yokumisa, eklanywe ngokwezifiso ukuze ifane nesakhiwo esithile se-izingxenye ze-aluminium ezenziwe ngomshini we-cnc. Okubalulekile, lapho ubeka umkhiqizo ku-tooling ye-welding, kubalulekile ukugwema ukudala indawo evaliwe ukuvimbela noma yimuphi umthelela omubi kumasayizi wengxenye ngenxa yokucindezela okukhulu ngesikhathi sokushisela nokushisa.

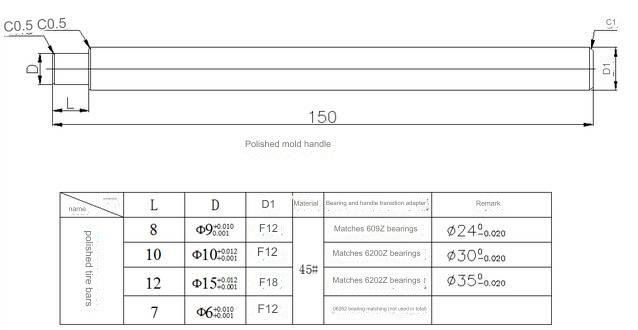

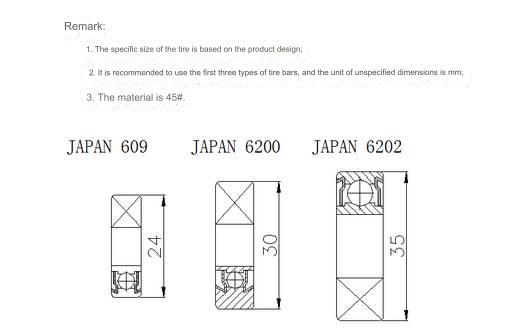

07 ukulungiswa kokupholisha

08 Amathuluzi womhlangano

Umsebenzi oyinhloko wamathuluzi womhlangano ukuhlinzeka ngokusekela ukuma ngesikhathi sokuhlanganiswa kwezingxenye. Umqondo wokuklama uwukuthuthukisa kalula ukucosha nokubeka imikhiqizo ngokusho kwesakhiwo somhlangano wezingxenye. Kubalulekile ukuqinisekisa ukuthi ukubukeka komkhiqizo kuhlala kungalimala ngesikhathi sokuhlanganiswa nokuthi ungambozwa ngesikhathi sokusetshenziswa. Vikela umkhiqizo ngokusebenzisa indwangu kakotini, futhi ucabange ukusebenzisa izinto ezingezona ezensimbi njengeglue emhlophe lapho ukhetha izinto.

09 Ukuphrinta kwephedi, ithuluzi lokuqopha nge-laser

Amaphuzu Wokuklama:

Dizayina isakhiwo sokuma samathuluzi ngokuya ngezidingo zokuqoshwa komkhiqizo wangempela. Naka ukuba lula kokukha nokubeka umkhiqizo, kanye nokuvikelwa kokubukeka komkhiqizo. Ibhulokhi yokumisa kanye nensiza yokubeka idivayisi ethintana nomkhiqizo kufanele yenziwe ngeglue emhlophe nezinye izinto ezingezona ezensimbi ngangokunokwenzeka.

I-Anebon inemishini yokukhiqiza ethuthuke kakhulu, onjiniyela abanolwazi nabaqeqeshiwe nabasebenzi, izinhlelo eziqashelwayo zokulawula ikhwalithi kanye neqembu elinobungane lokuthengisa elichwepheshile elisekela ngaphambi/ngemuva kokuthengisa le-OEM Plastic ABS/PA/POM yaseChina.I-CNC Metal LatheCNC Milling 4 Axis/5 Axis CNC izingxenye machining,Izingxenye zokuguqula ze-CNC. Njengamanje, i-Anebon ibheke phambili ekusebenzisaneni okukhulu nakakhulu namakhasimende aphesheya ngokuya ngezinzuzo ezifanayo. Sicela uzizwele mahhala ukuze uxhumane nathi ukuze uthole imininingwane eyengeziwe.

2022 Ikhwalithi ephezulu yaseChina CNC kanye Nemishini, Nethimba labasebenzi abanolwazi nabanolwazi, imakethe ye-Anebon ihlanganisa iNingizimu Melika, i-USA, Mid East, kanye neNyakatho Afrika. Amakhasimende amaningi abe ngabangane be-Anebon ngemuva kokubambisana okuhle ne-Anebon. Uma unesidingo sanoma yimiphi imikhiqizo yethu, khumbula ukusithinta manje. I-Anebon izolangazelela ukuzwa kuwe maduzane.

Isikhathi sokuthumela: Feb-26-2024