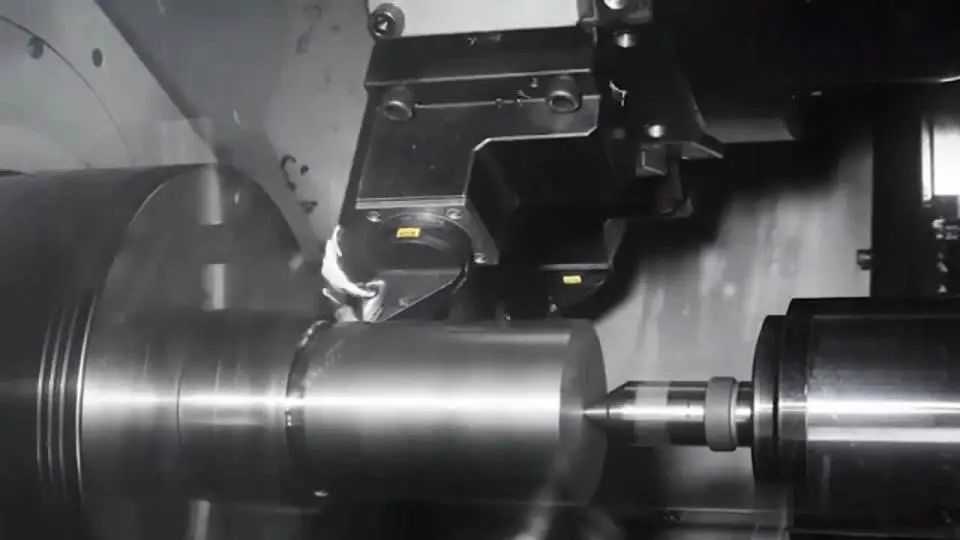

Imboni isebenzisa amathuluzi omshini we-CNC anembayo (isikhungo somshini, i-EDM, izintambo ezihamba kancane, namanye amathuluzi omshini) ukwenza imishini enembayo ephezulu. Ingabe unayo isipiliyoni esinjalo:ukuqala-upp ukucubungula njalo ekuseni, ukunemba machining ucezu lokuqala ngokuvamile akwanele; Ukunemba kwezingxenye zokuqala kuvame ukungazinzi kakhulu, futhi amathuba okwehluleka aphezulu kakhulu lapho kwenziwa imishini ngokunemba okuphezulu, ikakhulukazi ukunemba kwesikhundla.ingxenye eyenziwe ngomshini

Izimboni ezingenawo umuzwa wokwenza imishini onembayo zivame ukusola ikhwalithi yesisetshenziswa ngokunemba okungazinzile. Amafekthri anolwazi ekwenzeni machining ngokunemba azonamathisela ukubaluleka okukhulu kubhalansi yokushisa phakathi kwezinga lokushisa le-ambient nethuluzi lomshini. Kuyacaca ukuthi ngisho namathuluzi omshini anemba okuphezulu angathola kuphela ukunemba komshini ozinzile ngaphansi kwemvelo ezinzile yezinga lokushisa kanye nokulingana okushisayo. Ukushisa kuqala ithuluzi lomshini kuwumqondo ovamile ovamile wokwenza imishini enembayo lapho utshala imali ekumshinini onemba kakhulu ngemva kokuvulwa komshini.

1. Kungani ithuluzi lomshini kufanele lishiswe ngaphambili?aluminium CNC machining ingxenye

Izici ezishisayo zamathuluzi omshini we-CNC zinomthelela obalulekile ekunembeni komshini, okubala ngaphezu kwesigamu sokunemba komshini.

I-spindle yethuluzi lomshini, ama-rails omhlahlandlela, izikulufu zokuhola, nezinye izinto ezisetshenziswa ku-XYZ shaft ezinyakazayo zizoshisa futhi ziwohloke ngenxa yokulayisha nokushwiba ngesikhathi sokunyakaza. Noma kunjalo, iketango lephutha le-thermal deformation eligcina lithinta ukunemba kwemishini yi-spindle kanye ne-XYZ shaft yokunyakaza, okuwukususwa kwetafula.

Ukunemba komshini wethuluzi lomshini esimweni sokusebenza kokuyeka isikhathi eside kanye nesimo sokulinganisa okushisayo kuhluke kakhulu. Isizathu siwukuthi izinga lokushisa le-spindle kanye ne-axis yokunyakaza ngayinye yethuluzi lomshini we-CNC kugcinwa ngokuqhathaniswa ezingeni elithile ngemva kokusebenza isikhathi esithile. Ngokushintsha kwesikhathi sokucubungula, ukunemba okushisayo kwamathuluzi omshini we-CNC kuvame ukuzinza, okubonisa ukuthi ukushisa kuqala i-spindle nezingxenye ezihambayo ngaphambi kokucubungula kubalulekile.

Kodwa-ke, "umsebenzi wokufudumala" wethuluzi lomshini awunakwa noma awaziwa amafektri amaningi.

2. Indlela yokushisa ithuluzi lomshini?

Uma ithuluzi lomshini ligcinwa isikhathi esingaphezu kwezinsuku ezimbalwa, kunconywa ukuthi ushise imizuzu engaphezu kwengu-30 ngaphambi komshini wokunemba okuphezulu; uma umshini ubanjwa amahora ambalwa kuphela, kunconywa ukuthi ushise imizuzu engu-5-10 ngaphambi komshini wokunemba okuphezulu.

Inqubo yokushisisa kwangaphambili ivumela ithuluzi lomshini ukuthi libambe iqhaza ekunyakazeni okuphindaphindiwe kwe-eksisi yokwenza imishini. Kungcono ukwenza ukuxhumana kwe-multi-eksisi. Isibonelo, vumela i-eksisi ye-XYZ isuke ekhoneni elingezansi kwesokunxele lesistimu yokuxhumanisa iye ekhoneni eliphezulu kwesokudla bese uphinda umugqa we-diagonal.cCNCmachining ingxenye

Lapho wenza, ungabhala uhlelo olukhulu ethuluzini lomshini ukuze uvumele ithuluzi lomshini liphindaphinde isenzo sokushisa. Isibonelo, uma ithuluzi lomshini we-CNC lima ukusebenza isikhathi eside noma ngaphambi kokucubungula izingxenye ezinemba okuphezulu, ngokuya ngejika lepharamitha yezibalo ye-3D ellipse kanye nebanga lesikhala lethuluzi lomshini oshisiwe ngaphambili, t isetshenziswa njengokuhluka okuzimele, kanye nezixhumanisi izimbazo ezintathu ezinyakazayo ze-XYZ zisetshenziswa njengamapharamitha. Ngebanga elithile lesinyathelo esikhuphukayo, ububanzi obubekiwe be-eksisi yokunyakaza ye-XYZ busetshenziswa njengesimo somngcele wepharamitha. Isivinini sokuphotha kanye nezinga lokuphakela kwe-eksisi enyakazayo ye-XYZ kuhlotshaniswa nokuguquguquka okuzimele kuka-t ukuze kuguquke ngokuqhubekayo phakathi kwebanga elishiwo, okukhiqiza Uhlelo lokulawula izinombolo olungabonwa ithuluzi lomshini wokulawula izinombolo lusetshenziselwa ukushayela ama-eksisi anyakazayo ithuluzi lomshini lokudala ukunyakaza okungalayishi okuvumelanisiwe, futhi kuhambisana nokuguqulwa kokulawula kwejubane lokuphotha kanye nezinga lokuphakela ngesikhathi sokunyakaza.

Ngemuva kokuthi umshini usufudunyezwe ngokugcwele, umshini oguqukayo ungafakwa ekukhiqizeni umshini wokunemba okuphezulu, futhi uzothola ukunemba komshini ozinzile nokungaguquguquki.

I-Anebon Metal Products Limited inganikeza i-CNC Machining, i-Die Casting, isevisi yokwenziwa kwe-Sheet Metal, sicela ukhululeke ukuxhumana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Isikhathi sokuthumela: Apr-21-2022