Kungakanani okwaziyo mayelana nokubeka kanye nokuhlanganisa emishinini?

Ukuze uthole imiphumela enembayo nenembayo, ukubeka indawo kanye nokubopha kuyizici ezibalulekile zomshini.

Funda ngokubaluleka kokubeka kanye nokubopha lapho kwenziwa imishini:

Ukuma: Lokhu ukubekwa okunembile kwe-workpiece ehlobene nethuluzi lokusika. Ukuqondanisa umsebenzi ohambisana nezimbazo ezintathu eziyinhloko (X, Y, Z) kuyadingeka ukuze uthole ubukhulu obufunekayo nendlela yokusika.

Ukuqondanisa kubalulekile ekwenzeni imishini enembile:Ukuqondanisa ama-workpieces ngokunembile kungenzeka ngamasu afana nezitholi zonqenqema, izinkomba kanye nomshini wokulinganisa wokudidiyela (CMM).

Kubalulekile ukusungula indawo yedatha noma iphoyinti lokuma okungaguquki:Lokhu kuvumela yonke imishini elandelayo ukuthi isekelwe endaweni evamile noma indawo eyireferensi.

I-clamping iyinqubo yokuvikela i-workpiece emshinini:Ihlinzeka ngokuzinza futhi ivimbele ukudlidliza noma ukunyakaza okungaholela emishinini engalungile.

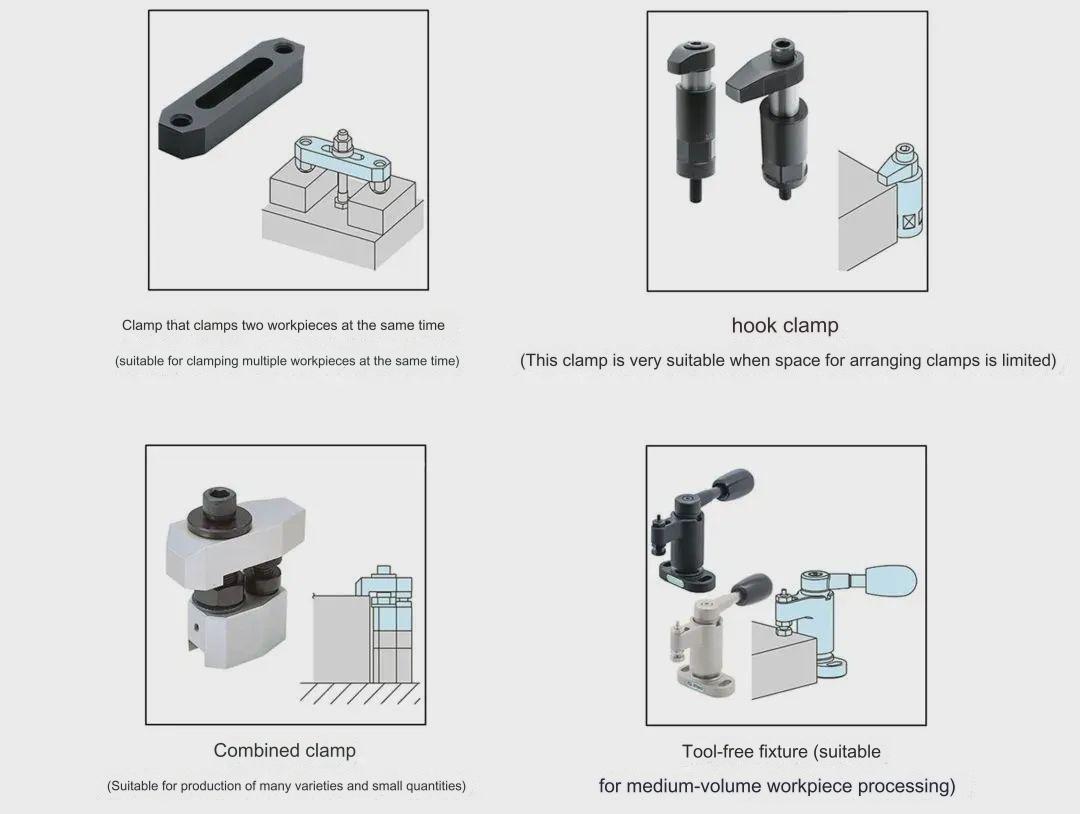

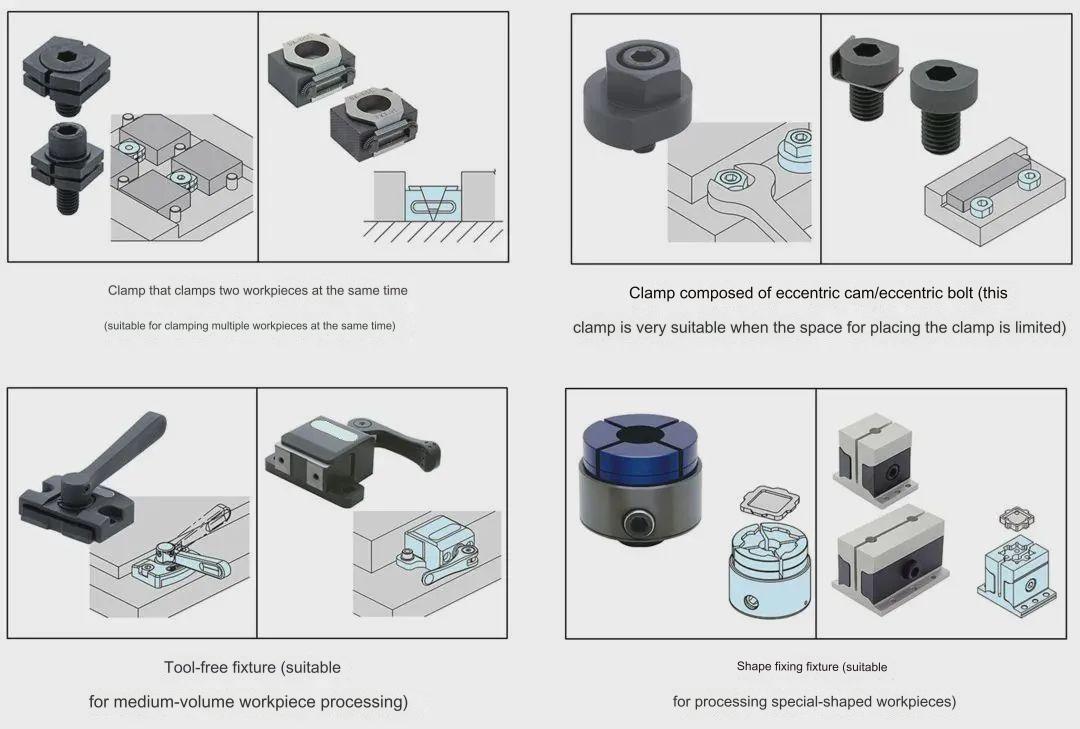

Izinhlobo zama-clamps:Kunezinhlobo eziningi zama-clamps ezingasetshenziselwa ukukhanda. Lezi zihlanganisa izinsimbi zikazibuthe kanye nezinsimbi zomoya, ezisebenza ngogesi, noma ze-hydraulic-pneumatic. Ukukhethwa kwezindlela zokubopha kusekelwe ezintweni ezifana nosayizi nokuma, amandla omshini, kanye nezidingo ezithile.

Amasu Okuqinisa:Ukubamba okufanele kuhilela ukusabalalisa amandla okubamba ngokulinganayo, ukugcina ingcindezi engaguquki kucezu lokusebenza nokugwema ukuhlanekezela. Ukuze uvimbele ukulimala kwe-workpiece ngenkathi ugcina ukuzinza, kubalulekile ukusebenzisa ukucindezela okulungile kwe-clamping.

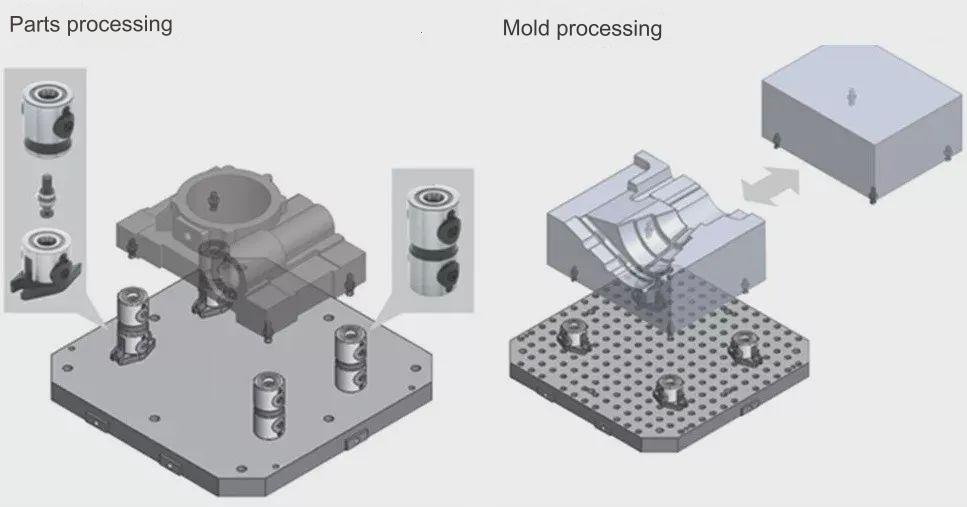

Izinto ezilungiswayo zingamathuluzi akhethekile abambayo futhi amise izinto zokusebenza:Banikeza ukwesekwa, ukuqondanisa nokuzinza kwemisebenzi yomshini. Lokhu kunciphisa ingozi yephutha futhi kuthuthukisa ukukhiqiza.

Ukulungiswa kuza ngezinhlobo eziningi ezahlukene, njengama-V-blocks nama-engeli plate. Zingabuye zenziwe ngokwezifiso. Ukukhethwa kwesakhiwo esifanele kunqunywa ubunzima besiqephu kanye nezidingo zomshini.

I-Fixture Design ihlanganisa ukucatshangelwa ngokucophelela kwezintonjengobukhulu, isisindo, impahla kanye nezidingo zokufinyelela. Idizayini yesimo esihle izoqinisekisa ukugoqa okufanelekile kanye nokuma kokusebenza kahle kwemishini.

Ukubekezelela Nokunemba:Ukuma okunembile nokubopha kubalulekile ukuze uthole ukubekezelelana okuqinile kanye nokunemba lapho kwenziwa imishini. Iphutha elincane ekubambeni noma ekumiseni lingaholela ekuhlukeni kobukhulu kanye nekhwalithi yokwehlisa.

Ukuhlola Nokuqinisekisa:Ukuhlolwa okuvamile nokuqinisekiswa kokunemba kokugoqa nokubeka indawo kubalulekile ukuze kuqinisekiswe ukuhambisana kwekhwalithi. Ukuze uqinisekise ukunemba kwezingxenye eziwumshini, amadivayisi wokulinganisa afana nama-caliper nama-micrometer kanye nama-CMM angasetshenziswa.

Akulula njengalokhu. Sithole ukuthi umklamo wokuqala uhlala unezinkinga ezithile ngokucindezela nokubeka. Izixazululo ezintsha zilahlekelwa ukuhambisana kwazo. Singaqinisekisa kuphela ubuqotho kanye nekhwalithi yedizayini yesakhiwo ngokuqonda ukuma okuyisisekelo nolwazi lokuhlanganisa.

Ulwazi lwendawo

1. Ukubeka i-workpiece kusuka ohlangothini kuyisimiso esiyisisekelo.

Umgomo wamaphuzu angu-3, njengokwesekwa, umgomo oyisisekelo wokubeka ucezu lomsebenzi ohlangothini. Isimiso esinamaphuzu angu-3 siyefana nesokusekelwa. Lesi simiso sitholakala eqinisweni lokuthi “imigqa emithathu eqondile engaphambanisi inquma indiza.” Amaphuzu amathathu kwamane angasetshenziswa ukunquma indiza. Lokhu kusho ukuthi izindawo ezi-4 seziphelele zinganqunywa. Kunzima ukuthola iphuzu lesine endizeni efanayo, kungakhathaliseki ukuthi amaphuzu abekwe kanjani.

▲ umgomo wamaphoyinti angu-3

Isibonelo, esimweni sokusebenzisa izibeka-ndawo ezine ezinobude obungaguquki, amaphuzu amathathu kuphela akhethekile akwazi ukuxhumana nocezu lokusebenza, okushiya amathuba aphezulu okuthi iphuzu lesine elisele ngeke likwazi ukuxhumana.

Ngakho-ke, ngenkathi ulungisa indawo, umkhuba ojwayelekile uwukusekela kumaphuzu amathathu ngenkathi ukhulisa ibanga phakathi kwalawa maphuzu.

Ngaphezu kwalokho, ngesikhathi sokuhlelwa kwesimo, kubalulekile ukuthi uqinisekise kusengaphambili ukuqondiswa komthwalo wokucubungula osetshenzisiwe. Isiqondiso somthwalo womshini sihambisana nokunyakaza kwesibambi/ithuluzi. Ukubeka i-positioner ekugcineni kwesikhombisi-ndlela sokuphakelayo kuthinta ngokuqondile ukunemba kukonke kwe-workpiece.

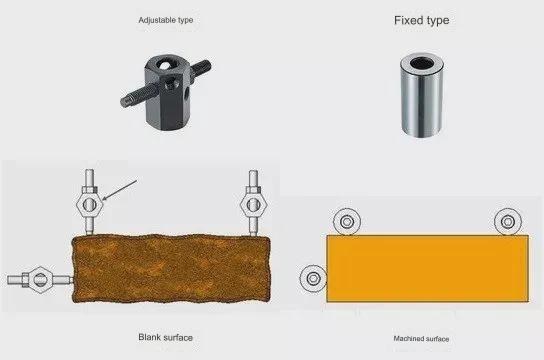

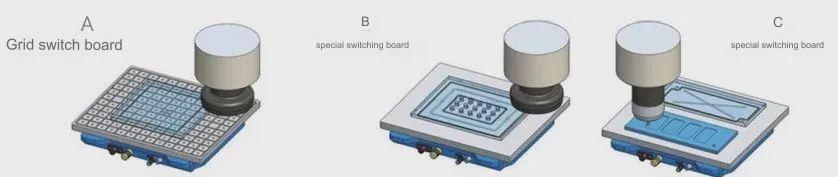

Imvamisa, ukuze kubekwe indawo emagebhugebhu yendawo yokusebenza, kusetshenziswa indawo elungisekayo yohlobo lwebhawodi, kuyilapho isihleli sohlobo olungaguquki (esinendawo yokuxhumana ye-workpiece yaphansi) sisetshenziselwa ukubeka indawo esebenza ngomshiniizingxenye zomshini.

2. Izimiso eziyisisekelo zokubeka ngokusebenzisa izimbobo ze-workpiece

Lapho ubeka indawo usebenzisa izimbobo ezidalwe ngesikhathi senqubo yomshini eyandulele, izikhonkwane ezinokubekezelela kufanele zisetshenziswe. Ngokuqondanisa ukunemba kwembobo ye-workpiece nokunemba komumo wephinikhodi, futhi uwahlanganise ngokusekelwe ekubekezeleleni okufanele, ukunemba kokuma kungahlangabezana nezidingo zangempela.

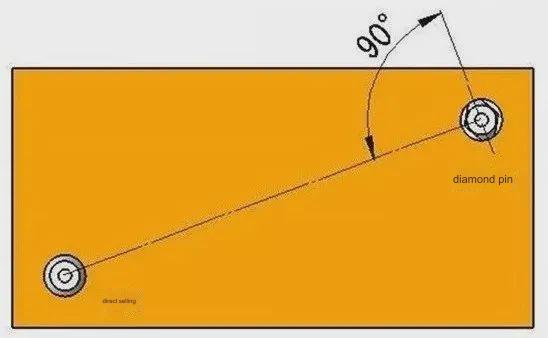

Ukwengeza, uma usebenzisa izikhonkwane ukuze umise, kuvamile ukusebenzisa iphinikhodi eqondile eduze kwephini ledayimane. Lokhu akusizi nje kuphela ukuhlanganiswa nokuhlakazwa kocezu lokusebenza kodwa futhi kunciphisa ithuba lokuthi ucezu lomsebenzi kanye nephinikhodi kunamathelane.

▲Sebenzisa ukubeka iphinikhodi

Impela, kuyasebenza ukuthola ukubekezelelana okufanele ngokusebenzisa izikhonkwane eziqondile kuzo zombili izikhundla. Nokho, ukuze kube nokunemba okukhulu ekumiseni, inhlanganisela yephinikhodi eqondile nephinikhodi yedayimane ibonakala iphumelela kakhulu.

Uma usebenzisa kokubili iphinikhodi eqondile kanye nephinikhodi ye-rhombus, ngokuvamile kuyanconywa ukuthi ubeke iphinikhodi ye-rhombus ngendlela lapho umugqa oxhumanisa isiqondiso sawo nendawo yokusebenza u-perpendicular (nge-engeli engu-90°) emgqeni oxhuma iphinikhodi eqondile kanye nephinikhodi eqondile. iphinikhodi ye-rhombus. Lolu hlelo oluthile lubalulekile ekunqumeni i-engeli yokuma kanye nesiqondiso sokuzungezisa ucezu lokusebenza.

Ulwazi oluhlobene ne-clamp

1. Ukuhlukaniswa kwama-clamps

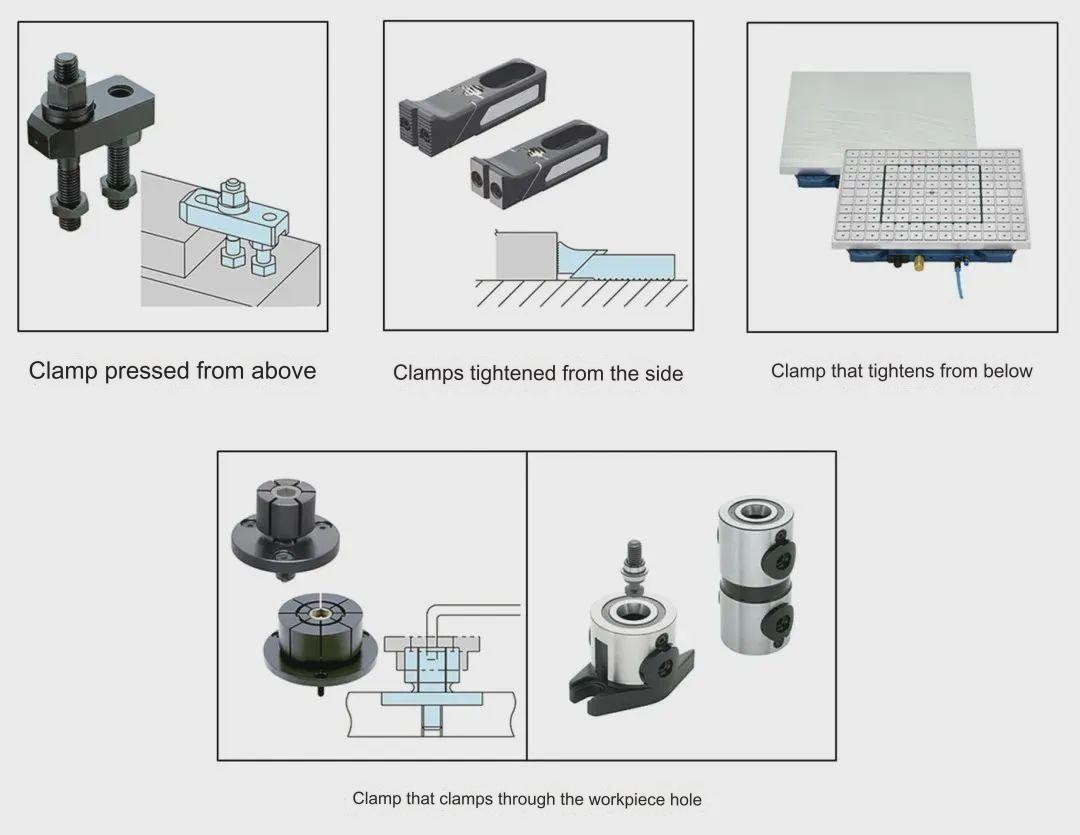

Ngokusho kwe-clamping direction, ngokuvamile ihlukaniswa ngezigaba ezilandelayo:

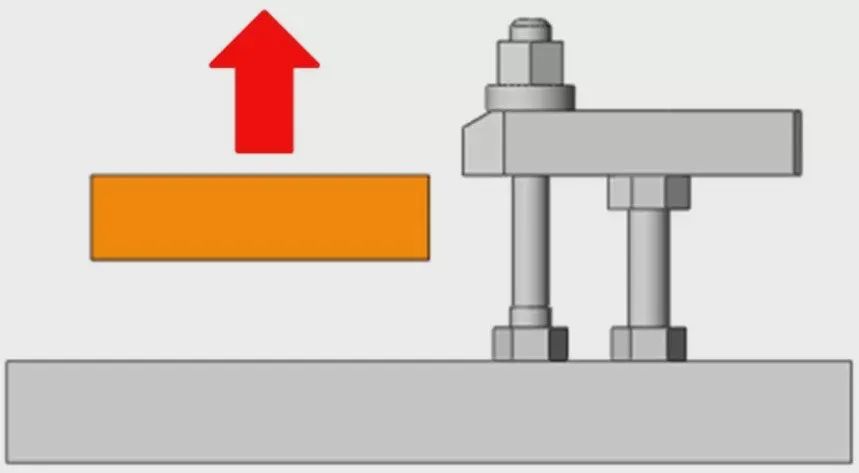

1. I-Overhead Compression Clamp

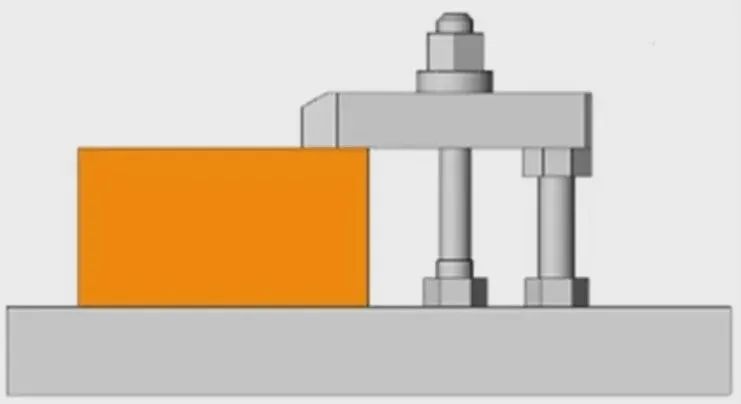

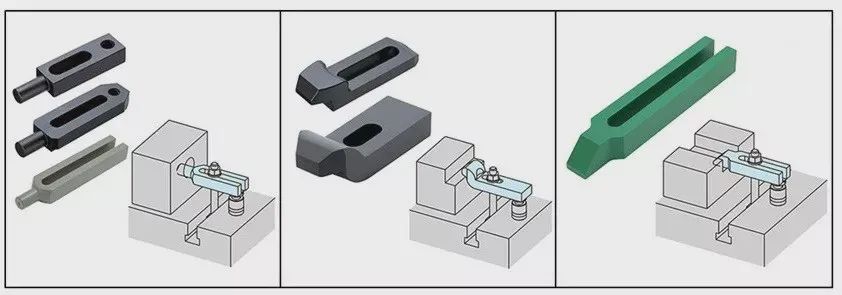

I-overhead compression clamp icindezela ngaphezulu kwendawo yokusebenza, okuholela ekuwohlokeni okuncane ngesikhathi sokugoqa kanye nokuzinza okuthuthukisiwe phakathi nokucutshungulwa kocezu lokusebenza. Ngenxa yalokho, ukubopha ucezu lokusebenza kusuka phezulu kuvame ukuba kuqala. Uhlobo oluvame kakhulu lwe-clamp esetshenziswa ngale ndlela i-manual mechanical clamp. Isibonelo, i-clamp eboniswe ngezansi ibizwa ngokuthi 'i-pine leaf clamp'. Okunye okuhlukile, okwaziwa ngele-'loose leaf clamp', kuhlanganisa i-pressure plate, ama-stud bolt, ojeke, namantongomane.”

Ngaphezu kwalokho, kuye ngokuma kwe-workpiece, unenketho yokukhetha ezinhlobonhlobo zamapuleti okucindezela aklanyelwe ngokuqondile ukufanisa ubujamo be-workpiece ehlukene.

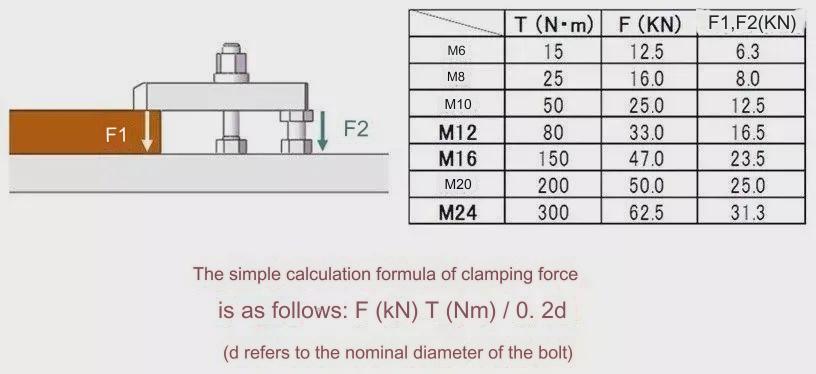

Kungenzeka ukunquma ukuhlobana phakathi kwetorque namandla okubamba ekubambeni kweqabunga okuxekethile ngokuhlaziya amandla okuphusha asetshenziswa ibholidi.

Ngaphandle kwe-clamp yohlobo lweqabunga elixegayo, kukhona nezinye izinsimbi ezitholakalayo ezivikela ucezu lokusebenza phezulu.

2. I-Side clamp ye-workpiece clamping

Indlela evamile yokubopha ihlanganisa ukuvikeleka kwe-workpiece kusuka phezulu, ukunikeza ukuzinza okuphakeme kanye nomthwalo omncane wokucubungula. Kodwa-ke, izimo zingase ziphakame lapho ukubamba phezulu kungafaneleki, njengalapho indawo engaphezulu idinga ukwenziwa ngomshini noma lapho ukubamba phezulu kungenzeki. Ezimweni ezinjalo, ukukhetha i-side clamping kuyadingeka.

Noma kunjalo, kubalulekile ukuqaphela ukuthi ukubopha ucezu lokusebenza ohlangothini kudala amandla antantayo. Kufanele kuqashelwe ukususa la mandla ngesikhathi sokuklanywa kwesakhiwo ukuze kuqinisekiswe ukusebenza kahle.

Ukucatshangelwa kungase kuhlanganise ukuhlanganisa izindlela eziphikisana nomthelela wamandla antantayo, njengokusebenzisa ukwesekwa okwengeziwe noma ingcindezi ukuze kuzinziswe ucezu lokusebenza. Ngokubhekana ngokuphumelelayo namandla antantayo, isisombululo se-clamping eseceleni esithembekile nesivikelekile singafinyelelwa, sandise ukuguquguquka kokucutshungulwa kwe-workpiece.

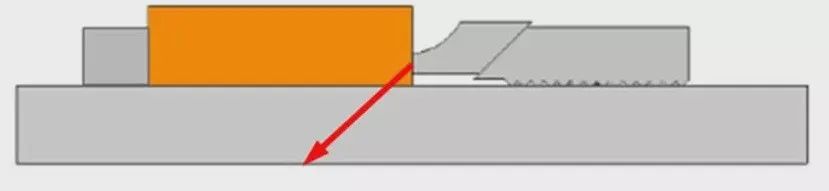

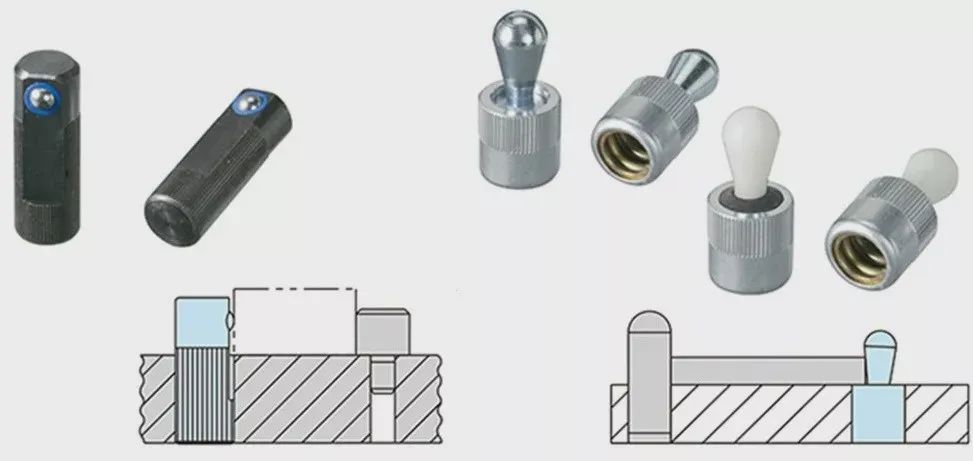

Kukhona futhi izinsimbi eziseceleni ezitholakalayo, njengoba kuboniswe esithombeni esingenhla. Lawa ma-clamp asebenzisa i-thrust force esuka ohlangothini, enze amandla atshekile abheke phansi. Lolu hlobo oluthile lwe-clamp lusebenza kahle kakhulu ekuvimbeleni ucezu lokusebenza ukuthi luntante luye phezulu.

Ngokufana nalezi zinsimbi eziseceleni, zikhona ezinye izinsimbi ezisebenza eceleni.

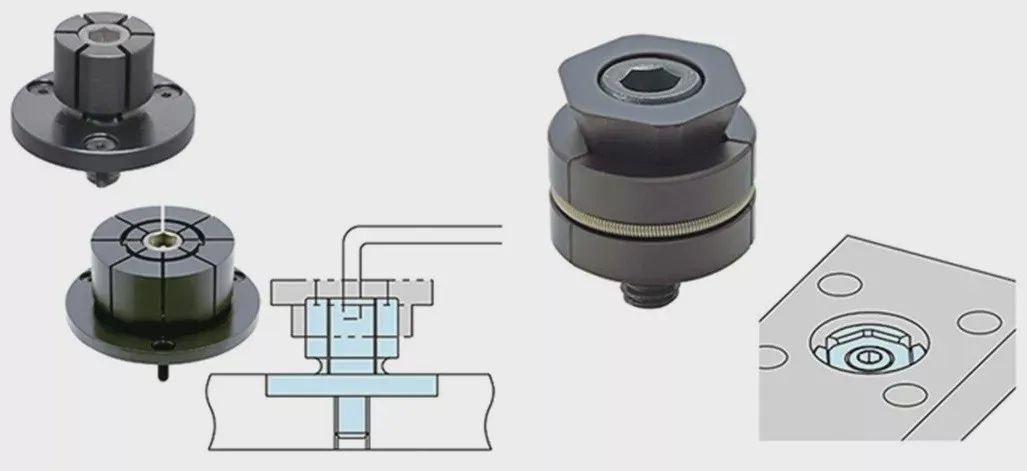

I-Workpiece Clamping kusukela Phansi

Lapho uphatha ucezu lokusebenzela lwepuleti elincanyana futhi udinga ukucubungula indawo yalo engaphezulu, izindlela zokubopha ezivamile ezivela phezulu noma ohlangothini zifakazela ukuthi azinakwenzeka. Ezimweni ezinjalo, isisombululo esisebenzayo ukubopha i-workpiece kusuka ngezansi. Ngezinto zokusebenza ezenziwe ngensimbi, i-clamp yohlobo lukazibuthe ivame ukufaneleka, kuyilapho ingeyona insimbiukugaya insimbi ngokwezifisoama-workpieces angavikelwa ngokusebenzisa izinkomishi zokumunca i-vacuum.

Kuzo zombili izimo ezibalulwe ngenhla, amandla okubamba ancike endaweni yokuxhumana phakathi kocezu lokusebenza kanye nezibuthe noma i-vacuum chuck. Kuyaqapheleka ukuthi uma umthwalo wokucubungula kuma-workpieces amancane uba ngokwedlulele, umphumela wokucubungula oyifunayo ungase ungafinyelelwa.

Ukwengeza, kubalulekile ukuqinisekisa ukuthi izindawo zokuthintana zikazibuthe nezinkomishi zokumunca i-vacuum zibushelelezi ngokwanele ukuze zisetshenziswe ngendlela ephephile futhi efanele.

Ukusebenzisa i-Hole Clamping

Uma usebenzisa umshini womshini we-5-axis wemisebenzi efana nokucutshungulwa kobuso obuningi ngasikhathi sinye noma ukucubungula isikhunta, kuyancomeka ukuthi ukhethe ukugoqa izimbobo njengoba kusiza ekwehliseni umthelela wezinto ezilungiswayo namathuluzi enqubweni yokucubungula. Uma kuqhathaniswa nokubopha kusuka phezulu noma ohlangothini lwe-workpiece, ukubopha imbobo kusebenzisa ingcindezi encane futhi kunciphisa ngempumelelo ukuwohloka kocezu lokusebenza.

▲Sebenzisa izimbobo ngokucubungula okuqondile

▲Ukufakwa kwe-Rivet ye-Clamping

I-Pre-clamping

Ulwazi olwandulele ngokuyinhloko lugxile kuzinto zokuhlanganisa iziqeshana zokusebenza. Kubalulekile ukucabangela ukuthi ungathuthukisa kanjani ukusebenziseka futhi uthuthukise ukusebenza kahle ngokusebenzisa i-pre-clamping. Lapho ubeka ucezu lokusebenza ngokuqondile esisekelweni, amandla adonsela phansi angase abangele ucezu lokusebenza liwe phansi. Ezimweni ezinjalo, kubaluleka ukubamba ucezu lokusebenza mathupha ngenkathi usebenzisa i-clamp ukuze ugweme noma yikuphi ukususwa ngephutha.

▲Ukugoqa ngaphambili

Uma isiqeshana somsebenzi sisinda noma izingcezu eziningi ziboshiwe ngesikhathi esisodwa, zingaphazamisa kakhulu ukusebenza futhi zelule isikhathi sokubopha. Ukubhekana nalokhu, ukusebenzisa umkhiqizo wokugoqa wangaphambi kohlobo lwasentwasahlobo kuvumela umsebenzi ukuthi uboshwe ngenkathi umile, kuthuthukisa kakhulu ukusebenza futhi kunciphisa isikhathi sokubopha.

Ukucatshangelwa lapho ukhetha i-clamp

Uma usebenzisa izinhlobo eziningi zezimpimpi kumathuluzi afanayo, kubalulekile ukusebenzisa amathuluzi afanayo kukho kokubili ukubopha nokukhulula. Isibonelo, esithombeni esingakwesokunxele esingezansi, ukusebenzisa izikrufu zamathuluzi amaningi ukuze kuhlanganiswe imisebenzi kukhulisa umthwalo ophelele ku-opharetha futhi kunwebe isikhathi sokubopha. Ngakolunye uhlangothi, esithombeni esingakwesokudla esingezansi, ukuhlanganisa izikrufu zamathuluzi nosayizi bebhawodi kwenza inqubo yabasebenza kusayithi ibe lula.

▲Ukusebenza Kokubamba Ucwecwe

Ngaphezu kwalokho, lapho ulungisa idivayisi yokubopha, kubalulekile ukucabangela ukusebenza kokusebenza kwe-workpiece clamping. Uma i-workpiece idinga ukuboshelwa nge-engeli ethambekele, ingaphazamisa kakhulu ukusebenza. Ngakho-ke, kubalulekile ukugwema izimo ezinjalo lapho uklama amathuluzi okulungisa.

Ukuphishekela i-Anebon nenjongo yenkampani iwukuba njalo “ukwanelisa izidingo zethu zabathengi njalo”. I-Anebon iqhubeka nokuthola nesitayela futhi iklame imikhiqizo yekhwalithi ephezulu encomekayo kumakhasimende ethu aphelelwe yisikhathi namasha futhi ifinyelele ithemba lokuwina kubathengi be-Anebon kanye nathi nge-Original Factory Profile extrusions aluminium,i-cnc iphendule ingxenye, cnc yokugaya inayiloni. Samukela ngobuqotho abangani ukuthi bahwebe ngebhizinisi futhi baqale ukubambisana nathi. I-Anebon inethemba lokuthi izobambana ngezandla nabangani abasondelene ezimbonini ezehlukene ukuze ikhiqize ikusasa eliqhakazile.

Umkhiqizi wase-China we-China High Precision kanye ne-Metal Stainless Steel Foundry, i-Anebon ifuna amathuba okuhlangana nabo bonke abangani abavela ekhaya naphesheya ukuze kuzuze ukubambisana. I-Anebon inethemba lobuqotho lokuba nokubambisana kwesikhathi eside nani nonke ezisekelweni zenzuzo efanayo nentuthuko efanayo.

Isikhathi sokuthumela: Sep-25-2023