Uyabuqonda ububanzi bokusebenza bokubekezelelana kwejometri kumishini ye-CNC?

Ukucaciswa kokubekezelelana kwejometri kuyisici esibalulekile somshini we-CNC, njengoba kuqinisekisa ukukhiqizwa okunembile kwezingxenye. Ukubekezelelwa kwejiyomethri ukuhlukahluka okungenziwa ngosayizi, umumo, umumo kanye nendawo yesici esiqeshini. Lezi zinhlobonhlobo zibalulekile ekusebenzeni okusebenzayo kwengxenye.

Ukubekezelelana kweJiyomethri kusetshenziswa kumishini ye-CNC yezinhlelo zokusebenza ezahlukahlukene.

Ukulawula ubukhulu:

Ukubekezelelwa kwejiyomethri kuvumela ukulawula okunembile kosayizi nobukhulu bezici ezenziwe ngomshini. Iqinisekisa ukuthi zonke izingxenye ziqondaniswe ngokuphelele futhi zenza umsebenzi wazo ohlosiwe.

Ukulawula Ifomu:

Ukubekezelelwa Kwejiyomethri kuqinisekisa ukuthi ukwakheka okufiswayo kanye nekhonsathi kuyafinyelelwa ezicini zomshini. Kubalulekile ezingxenyeni ezidinga ukuqoqwa, noma ezinezidingo ezithile zokukhwelana.

Ukulawula Ukuqondisa:

Ukubekezelela kwejiyomethri kusetshenziselwa ukulawula ukuqondanisa kwe-angular kwezici ezifana nezimbobo, izikhala nezindawo. Kubaluleke kakhulu ezingxenyeni ezidinga ukuqondanisa okunembile noma okufanele zilingane ngokunembile kwezinye izingxenye.

Ukubekezelela Kwejiyomethri:

Ukubekezelelwa kwejiyomethri ukuchezuka okungenziwa endaweni yezici entweni. Iqinisekisa ukuthi izici ezibucayi zengxenye zibekwe ngokunembile maqondana nenye, okwenza ukusebenza kahle nokuhlanganisa.

Ukulawulwa Kwephrofayela:

Ukubekezelela Kwejiyomethri kusetshenziselwa ukulawula ukuma okuphelele kanye nephrofayili yezici eziyinkimbinkimbi njengamajika, amakhonsathi nezindawo. Lokhu kuqinisekisa ukuthi izingxenye zomshini ziyahlangabezana nezidingo zephrofayili.

Ukulawulwa kwe-Concentricity & Symmetry:

Ukubekezelelwa kwejiyomethri kudlala indima ebalulekile ekuzuzeni ukugxila kanye nokulinganisa kwezici zomshini. Kubaluleke kakhulu uma uqondanisa izingxenye ezijikelezayo njengama-shafts, amagiya nama-bearings.

Ukulawula ukuphuma:

Ukubekezelelana kweJiyomethri kucacisa ukuhluka okuvunyelwe ekuqondeni nasekuyindilinga kokujikelezai-cnc iphendule izingxenye. Iklanyelwe ukuqinisekisa ukusebenza kahle nokunciphisa ukudlidliza namaphutha.

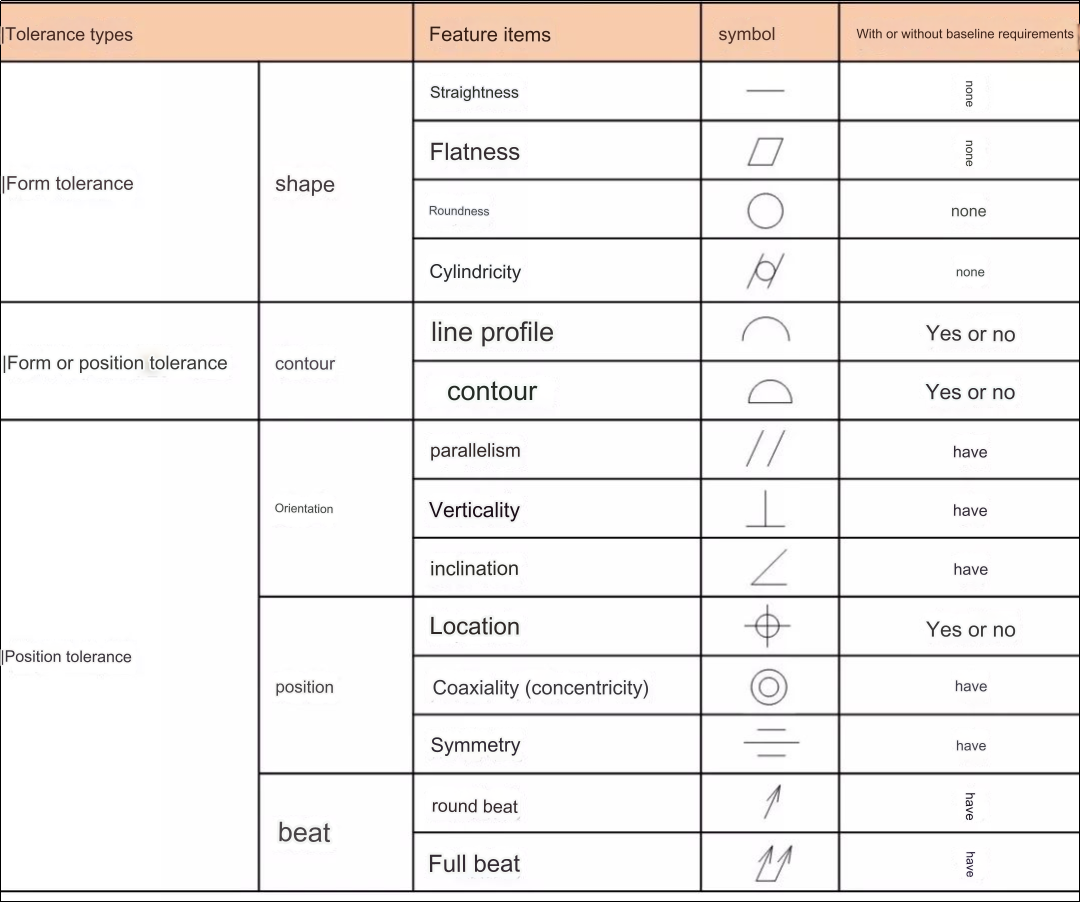

Uma singakuqondi ukubekezelelana kwejometri emidwebeni ekukhiqizeni, khona-ke ukuhlaziywa kokucubungula kuzovalwa futhi imiphumela yokucubungula ingase ibe yingozi nakakhulu. Leli thebula liqukethe uphawu lokubekezelela lwejiyomethri olujwayelekile lwezinto eziyi-14.

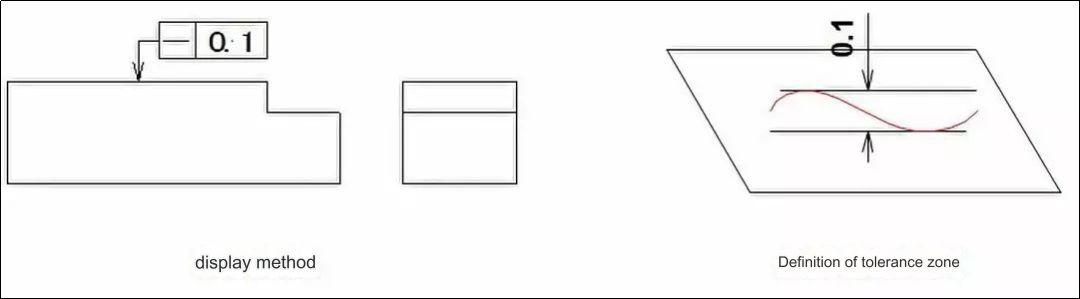

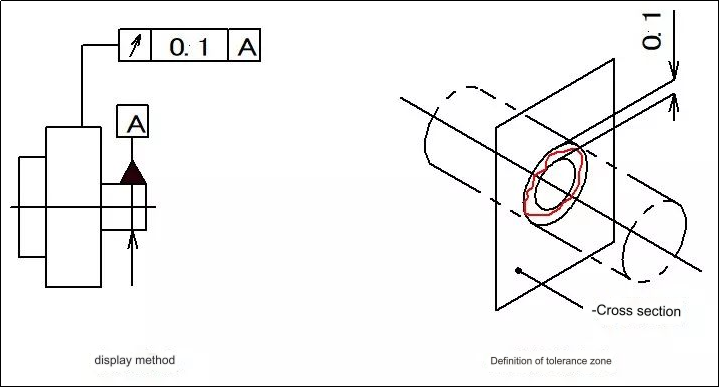

1. Ukuqondisa

Ukuqondile yikhono lengxenye ukugcina umugqa oqondile ofanelekile. Ukubekezelela ukuqondisa kuchazwa njengokuchezuka okukhulu komugqa wangempela oqondile usuka emugqeni okahle.

Isibonelo 1:Indawo yokubekezelela endizeni kufanele ibe phakathi kwemigqa emibili eqondile nebanga elingu-0.1mm.

Isibonelo sesi-2:Uma wengeza uphawu lwe-P enanini lokubekezelela kufanele libe sendaweni yesilinda esinobubanzi obungu-0.08mm.

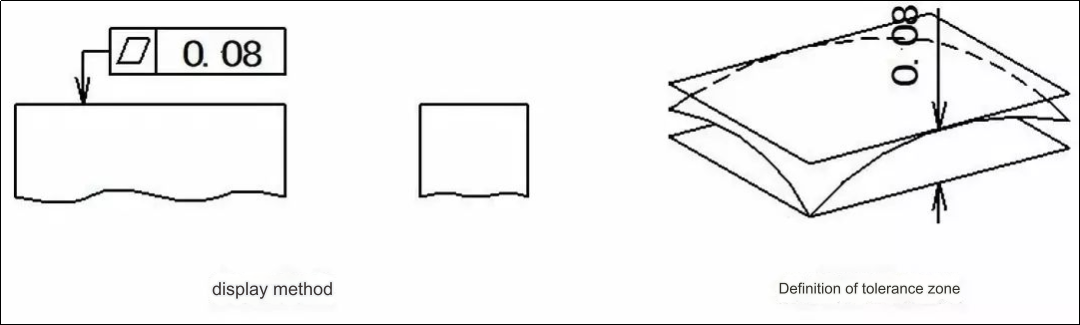

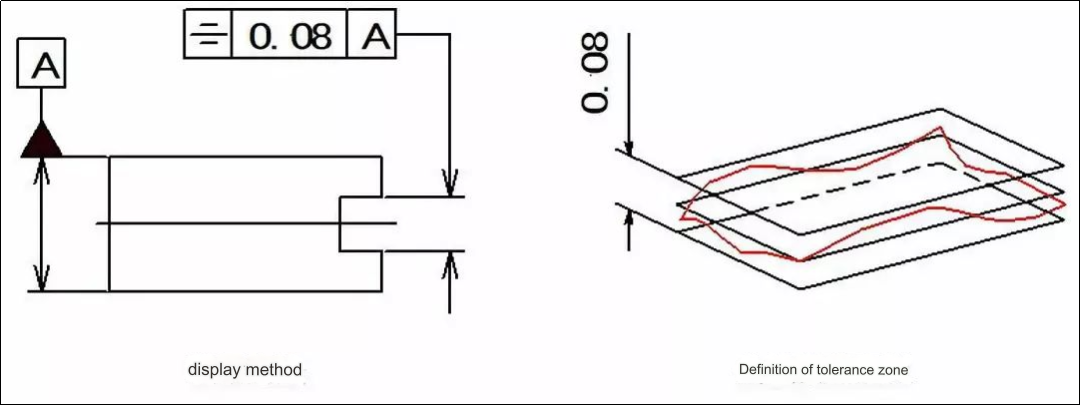

2. Ukucaba

Ukucaba (okubuye kwaziwe ngokuthi flatness) yisimo lapho ingxenye igcina indiza ekahle. Ukubekezelelana kwe-flatness kuyisilinganiso sokuchezuka okukhulu okungenziwa phakathi kwendawo ekahle kanye nendawo yangempela.

Isibonelo, indawo yokubekezelelana ichazwa njengesikhala phakathi kwezindiza ezihambisanayo ezihlukene ngo-0.08mm.

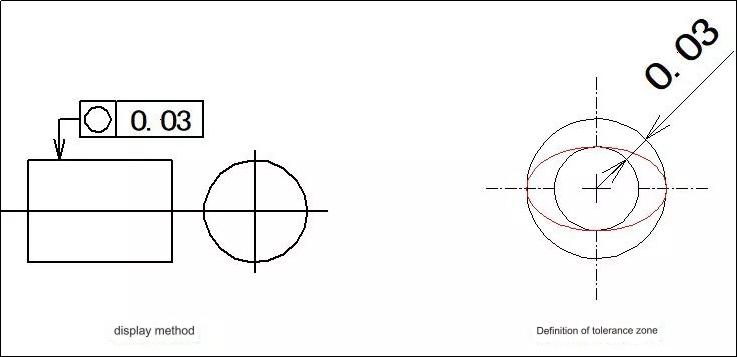

3. Ukujikeleza

Ukuyindilinga kwengxenye yibanga eliphakathi nendawo kanye nomumo wangempela. Ukubekezelelana kokuyindilinga kuchazwa njengokuphambuka okukhulu kwesimo esiyindilinga sangempela ukusuka kusimo esiyindilinga esifanelekile esigabeni esifanayo.

Isibonelo:Indawo yokubekezelela kufanele ibekwe endaweni efanayo evamile. Umehluko werediyasi uchazwa njengebanga phakathi kwamasongo amabili agxilile anokubekezela okungu-0.03mm.

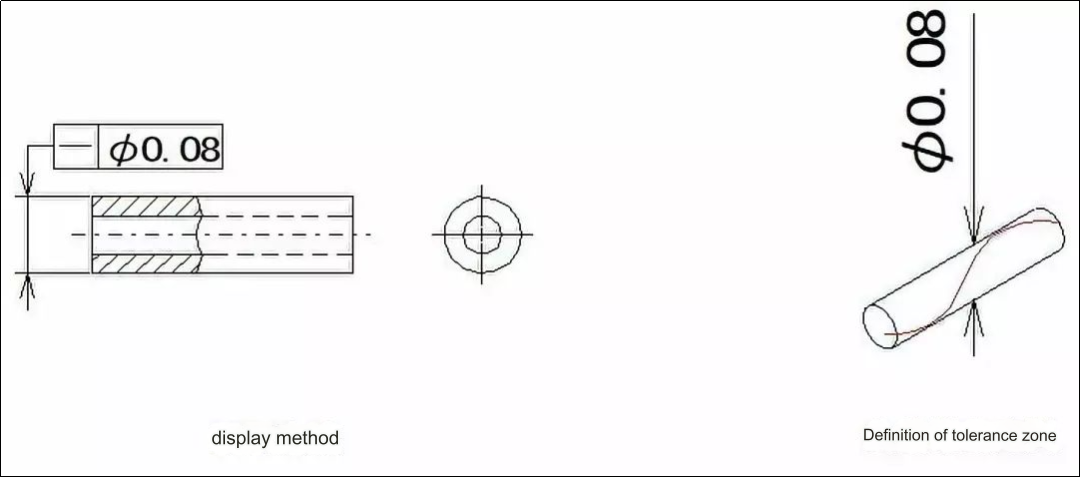

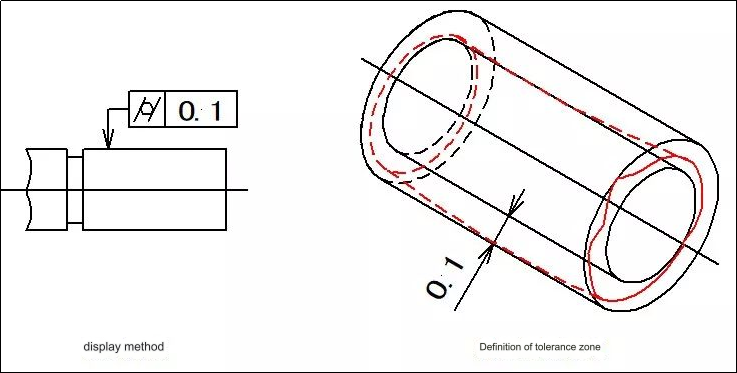

4. I-Cylindricity

Igama elithi 'Cylindricity' lisho ukuthi amaphuzu obuso obuyisilinda bengxenye aqhelelene ngokulinganayo ne-eksisi yayo. Ukuhluka okuphezulu okuvunyelwe phakathi kwendawo eyi-cylindrical yangempela kanye ne-cylindrical ekahle kubizwa ngokuthi ukubekezelelana kwe-cylinderricity.

Isibonelo:Indawo yokubekezelela ichazwa njengendawo ephakathi kwezindawo eziyi-coaxial cylindrical ezinomehluko ku-radius ongu-0.1mm.

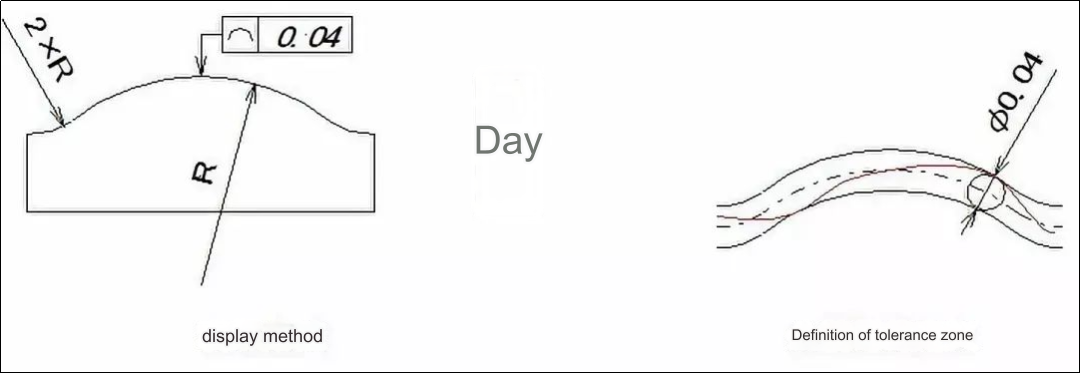

5. Ikhontatha yomugqa

Iphrofayili yomugqa yisimo lapho noma yiliphi ijika, kungakhathaliseki ukuthi umumo walo, ligcina umumo okahle endizeni ethile yengxenye. Ukubekezelela iphrofayili yomugqa ukuhluka okungenziwa ku-contour yamajika angewona ayindilinga.

Ngokwesibonelo, indawo yokubekezelela ichazwa njengesikhala phakathi kwezimvilophu ezimbili eziqukethe imibuthano yochungechunge yobubanzi obungu-0.04mm. Izikhungo zemibuthano zisemigqeni enomumo olungile ngokwejometri.

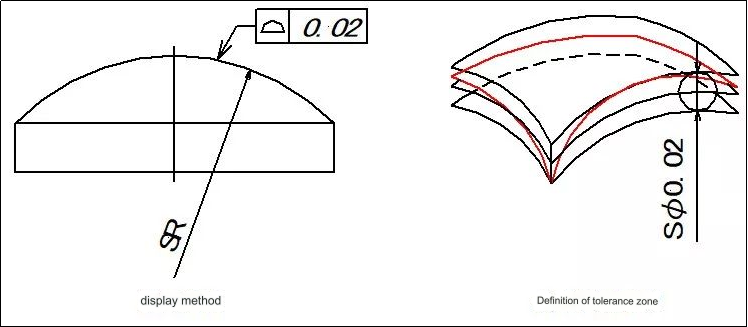

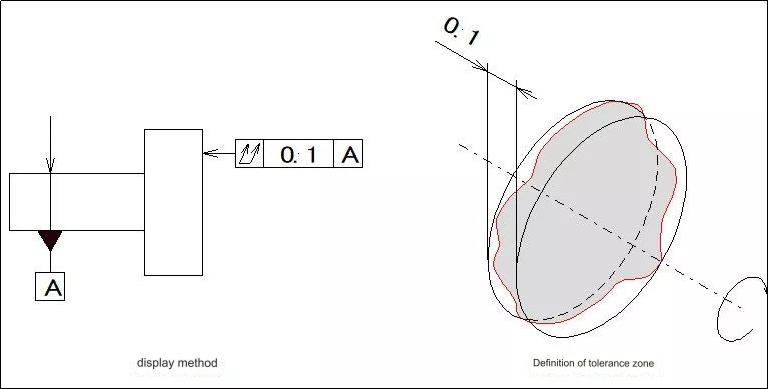

6. Surface contour

Ikhonta engaphezulu yisimo lapho indawo emise okwedlulele engxenyeni ethile igcina isimo sayo esihle. Ukubekezelelwa kwekhonta engaphezulu kuwumehluko phakathi komugqa wekhonta kanye nendawo eyikhonta efanelekile yendawo engayisiyingi.

Ngokwesibonelo:Indawo yokubekezelelana iphakathi kwemigqa yezimvilophu ezimbili ehlanganisa amabhola ochungechunge anobubanzi obungu-0.02mm. Isikhungo sebhola ngalinye kufanele sibe phezu komumo olungile wejometri.

7. Ukufana

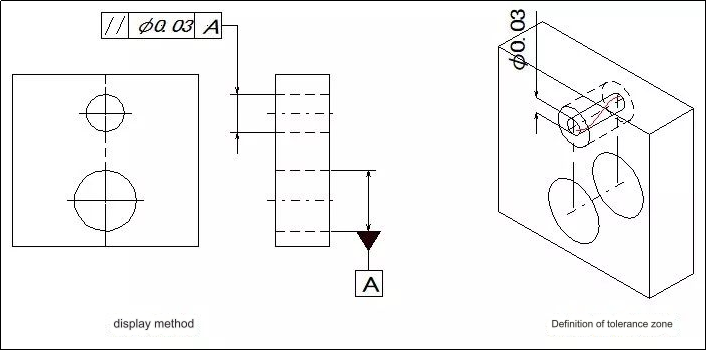

Izinga lokufana igama elisetshenziselwa ukuchaza iqiniso lokuthi ama-elementi engxenyeni ethile aqhelelene nedatha. Ukubekezelela ukufana kuchazwa njengokwehluka okukhulu okungenziwa phakathi kwendawo lapho into elinganiswayo ilele khona kanye nendlela efanelekile, ehambisana nedatha.

Isibonelo:Uma wengeza uphawu lwe-Ph ngaphambi kwevelu yokubekezelelana lapho-ke indawo yokubekezelela izoba ngaphakathi kwendawo yesilinda enobubanzi bereferensi obungu-Ph0.03mm.

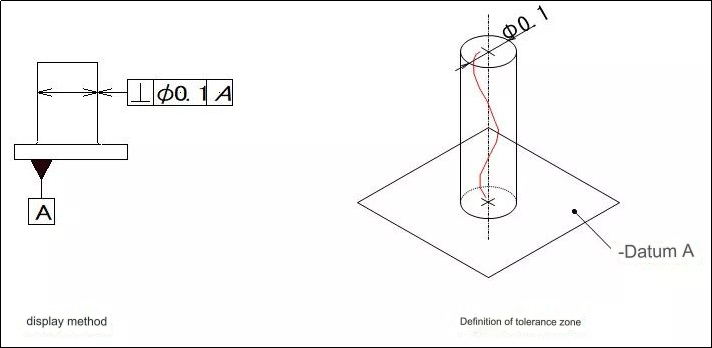

Izinga le-orthogonality, elaziwa nangokuthi i-perpendicularity phakathi kwama-elementi amabili libonisa ukuthi i-elementi elinganiselwe engxenyeni igcina u-90deg olungile ohlobene nedatha. Ukubekezelela ukuqina ukuhluka okukhulu phakathi kwendawo lapho isici esikalwa khona ngempela kanye naleyo ngokwedatha yedatha.

Isibonelo 1:Indawo yokubekezelelana izoba yi-perpendicular ne-cylindrical surface kanye nedatha engu-0.1mm uma umaka Ph uvela ngaphambi kwayo.

Isibonelo sesi-2:Indawo yokubekezelela kufanele ibe phakathi kwezindiza ezimbili ezifanayo, ziqhelelane ngo-0.08mm, kanye ne-perpendicular yomugqa wedatha.

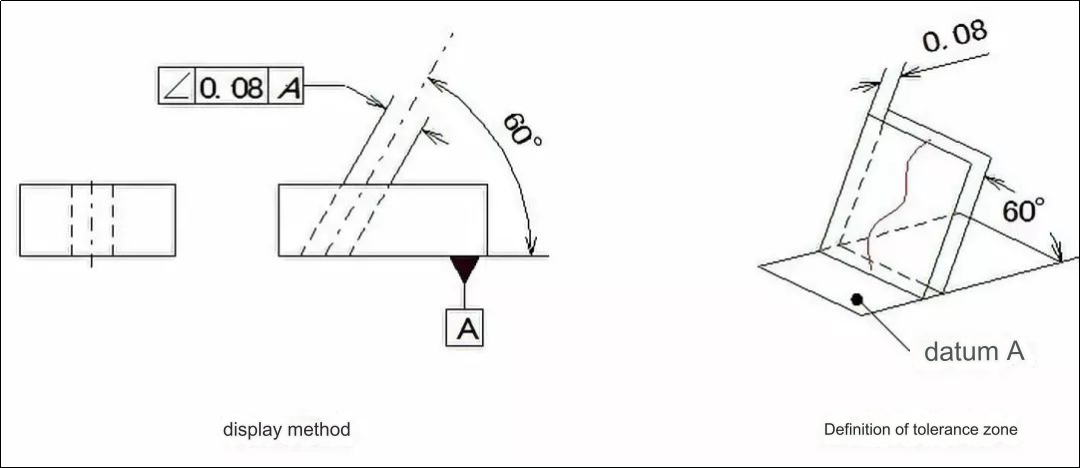

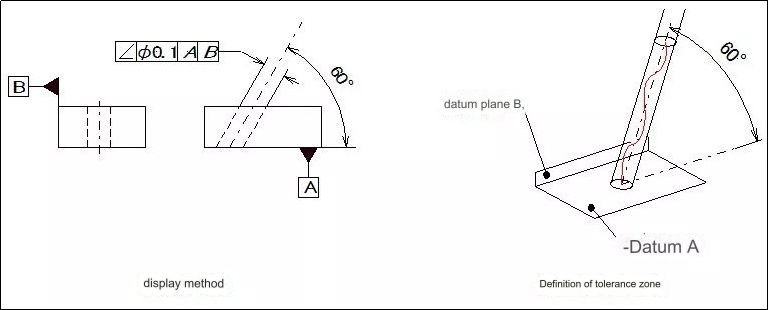

9. Ukuthambekela

Ukuthambekela kuyisimo sokuthi ama-elementi amabili kufanele agcine i-engeli ethile ekumukiseni kwawo okuhlobene. Ukubekezelelwa komthambeko inani lokuhluka okungavunyelwa phakathi kokuma kwesici okufanele silinganiswe nokuma okuhle, kunoma iyiphi i-engeli ehlobene nedatha.

Isibonelo 1:Indawo yokubekezelela yendiza elinganisiwe iyindawo ephakathi kwezindiza ezimbili ezihambisanayo ezinokubekezelela okungu-0.08mm, kanye ne-engeli yethiyori engu-60deg endizeni yedatha.

Isibonelo sesi-2:Uma wengeza uphawu lwe-P enanini lokubekezelelana khona-ke indawo yokubekezelelana kufanele ibe ngaphakathi kwesilinda onobubanzi obungu-0.1mm. Indawo yokubekezelela kufanele ihambisane nendiza A ngokuqondile ukuya ku-datum B kanye ne-engeli engu-60deg ukusuka ku-datum A.

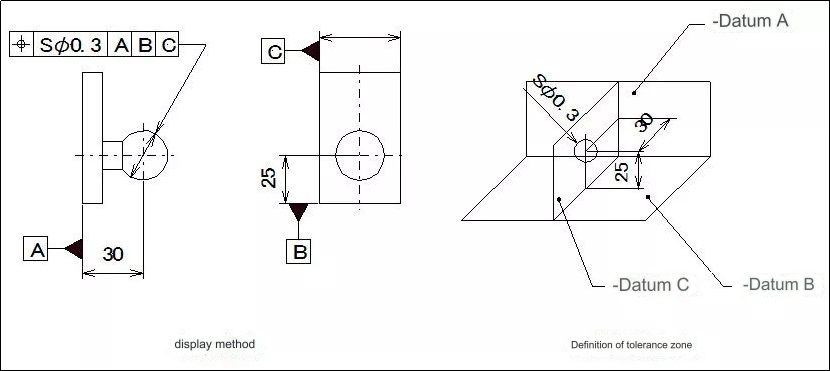

10. Indawo

Isikhundla ukunemba kwamaphoyinti, indawo engaphezulu, imigqa nezinye izakhi ezihlobene nendawo yazo efanelekile. Ukubekezelela isikhundla kuchazwa njengokuhluka okuphezulu okungavunyelwa endaweni yangempela ngokuhlobene nendawo ekahle.

Njengesibonelo, uma uphawu lwe-SPh lwengezwe endaweni yokubekezelelana, ukubekezelelana kungaphakathi kwebhola elinobubanzi obungu-0.3mm. Isikhungo sendawo yokubekezelelana yebhola siwusayizi olungile kuthiyori, uma kuqhathaniswa nedatha ka-A, B kanye no-C.

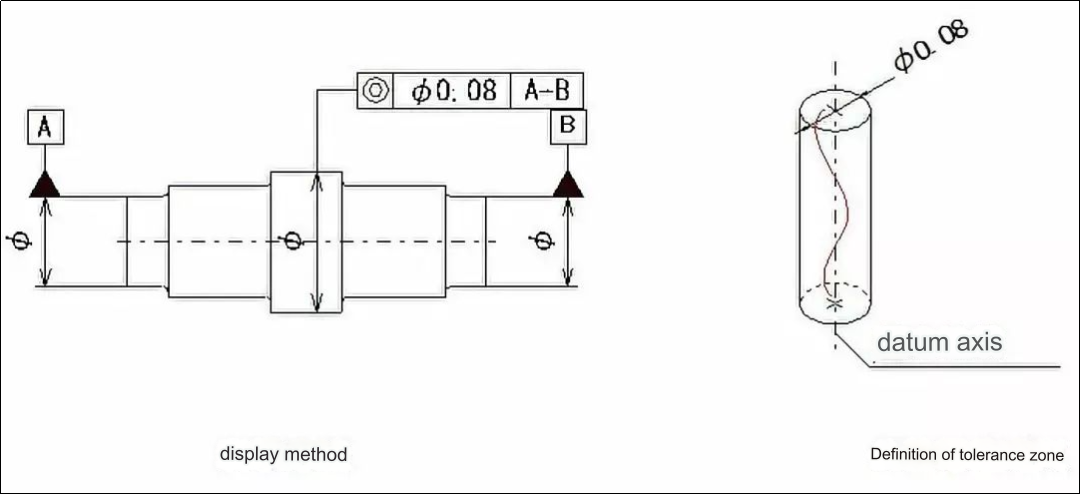

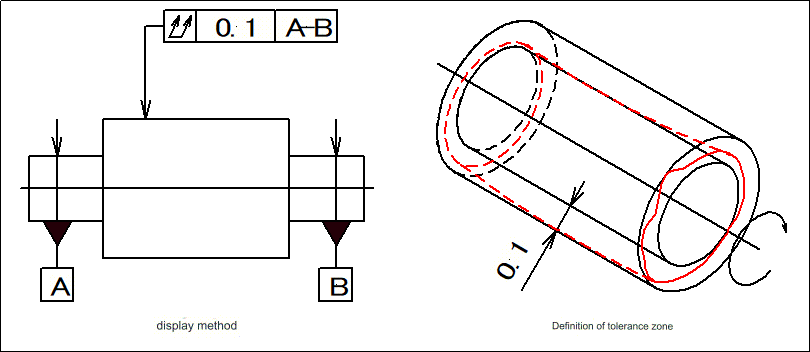

11. I-coaxiality (i-concentricity).

I-Coaxiality igama elisetshenziselwa ukuchaza iqiniso lokuthi i-eksisi elinganisiwe yengxenye ihlala kumugqa oqondile ofanayo ngokuhlobene ne-eksisi yesithenjwa. Ukubekezelela i-coaxiality ukuhluka okungenziwa phakathi kwe-eksisi yangempela kanye ne-reference axis.

Ngokwesibonelo:Indawo yokubekezelela, uma imakwe ngevelu yokubekezelelana, isikhala phakathi kwamasilinda amabili obubanzi obungu-0.08mm. I-eksisi yendawo yokubekezelela eyindilinga iqondana nedatum.

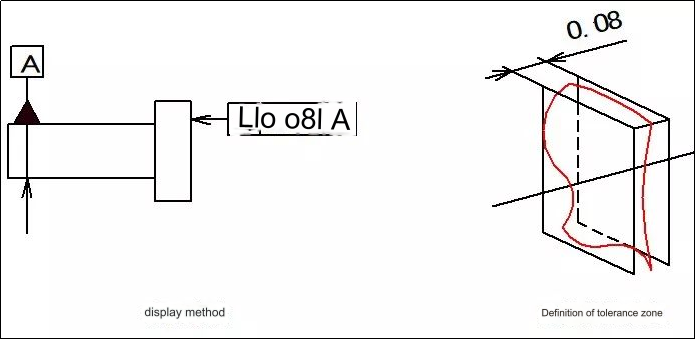

12. I-Symmetry

Ukubekezelelana kwe-symmetry ukuchezuka okukhulu kwendiza emaphakathi ye-symmetry (noma umugqa omaphakathi, i-eksisi) ukusuka endizeni efanelekile yokulinganisa. Ukubekezelelana kwe-symmetry kuchazwa njengokuchezuka okuphezulu kwendiza emaphakathi yesici sangempela, noma umugqa omaphakathi (i-eksisi), ukusuka endizeni efanelekile.

Isibonelo:Indawo yokubekezelela isikhala phakathi kwemigqa emibili ehambisanayo noma izindiza eziwu-0.08mm ukusuka kwenye futhi ziqondaniswe ngokulinganayo nendiza ye-datum noma umugqa omaphakathi.

13. I-Circle Beat

Igama elithi circular runout libhekisela eqinisweni lokuthi ingaphezulu lenguquko engxenyeni ihlala ingashintshile ngokuhlobene nendiza yedatha ngaphakathi kwendiza yokulinganisa ekhawulelwe. Ubukhulu bokubekezelela ukuphuma okuyisiyingi buvunyelwe ebangeni lokulinganisa elikhawulelwe, lapho into ezolinganiswa iqeda ukuzungezisa okugcwele eksisi yesithenjwa ngaphandle kwanoma yikuphi ukunyakaza kwe-axial.

Isibonelo 1:Indawo yokubekezelela ichazwa njengendawo ephakathi kwemibuthano egxilile enomehluko ku-radius engu-0.1mm nezikhungo zazo ezitholakala endizeni yedatha efanayo.

14. Ukushaya Okugcwele

Isamba esiphelile siyisamba sokuphuma esingaphezulu kwengxenye elinganisiwe lapho sizungeza ngokuqhubekayo ku-eksisi yesithenjwa. Isamba sokubekezelela ukuphuma siwukuphuma okuphezulu uma ukala i-elementi ngenkathi izungeza ngokuqhubekayo ku-axis yedatha.

Isibonelo 1:Indawo yokubekezelela ichazwa njengendawo ephakathi kwezindawo ezimbili eziyisilinda ezinomehluko ku-radius ka-0.1mm, futhi ziyi-coaxial ku-datum.

Isibonelo sesi-2:Indawo yokubekezelela ichazwa njengendawo ephakathi kwezindiza ezihambisanayo ezinomehluko endaweni eyi-0.1mm, i-perpendicular nedatha.

Ukubekezelelana kwedijithali kunamuphi umthelela ezingxenyeni zomshini ze-CNC?

Ukunemba:

Ukubekezelelwa kwedijithali kuqinisekisa ukuthi ubukhulu bezingxenye ezimshinini bungaphakathi kwemikhawulo ethile. Ivumela ukuthi kukhiqizwe izingxenye ezihlangana kahle futhi zisebenze njengoba kuhlosiwe.

Ukuvumelana:

Ukubekezelelana kwedijithali kuvumela ukuvumelana phakathi kwezingxenye eziningi ngokulawula usayizi nokuhluka komumo. Lokhu kubaluleke kakhulu ezingxenyeni ezidinga ukushintshwa, noma ezisetshenziswa ezinqubweni ezifana nokuhlanganisa lapho kudingeka khona ukufana.

I-Fit and Assembly

Ukubekezelelana kwedijithali kusetshenziselwa ukuqinisekisa ukuthi izingxenye zingahlanganiswa ngendlela efanele futhi ngaphandle komthungo. Ivimbela izinkinga ezinjengokuphazamiseka, ukucaciswa okudlulele, ukungaboni ngaso linye kanye nokubopha phakathi kwezingxenye.

Ukusebenza:

Ukubekezelela idijithali kunembe futhi kuvumela izingxenye ukuthi zikhiqizwe ezihlangabezana namazinga okusebenza. Ukubekezelelana kwedijithali kubalulekile ezimbonini ezifana ne-aerospace nezimoto lapho ukubekezelelana okuqinile kubalulekile. Iqinisekisa ukuthi izingxenye zisebenza kahle futhi zihlangabezana nezindinganiso eziqinile zekhwalithi.

Ukuthuthukisa Izindleko

Ukubekezelelana kwedijithali kubalulekile ekutholeni ibhalansi efanele phakathi kokunemba, izindleko nokusebenza. Ngokuchaza ukubekezelelana ngokucophelela, abakhiqizi bangagwema ukunemba ngokweqile, okungakhuphula izindleko ngenkathi kugcinwa ukusebenza nokusebenza.

Ikhwalithi yokulawula:

Ukubekezelela idijithali kuvumela ukulawulwa kwekhwalithi okuqinile ngokunikeza imininingwane ecacile lapho kulinganiswa futhi kuhlolwa.izingxenye ezenziwe ngomshini. Ivumela ukutholwa kusenesikhathi kokuphambuka ekubekezeleleni. Lokhu kuqinisekisa ikhwalithi engaguquki kanye nezilungiso ezifika ngesikhathi.

Ukuvumelana nezimo

Abaklami banokuguquguquka okwengeziwe uma kuziwa ekuklameniizingxenye ezenziwe ngomshiningokubekezelelana kwedijithali. Abaklami bangacacisa ukubekezelelana ukuze banqume imikhawulo eyamukelekayo nokuhluka, kuyilapho beqinisekisa ukusebenza nokusebenza okudingekayo.

I-Anebon inganikeza kalula izixazululo zekhwalithi ephezulu, inani lokuncintisana kanye nenkampani yamaklayenti ehamba phambili. Indawo eya e-Anebon ithi “Uza lapha ngobunzima futhi sikunikeza ukumamatheka ongakukhipha” Ye-Good Wholesale Vendors Precision Part CNC Machining Hard Chrome Plating Gear, Ukunamathela kumgomo webhizinisi elincane lokuzuzisana, manje i-Anebon isizuze idumela elihle phakathi kwethu. abathengi ngenxa yezinkampani zethu ezihamba phambili, izimpahla zekhwalithi kanye nezigaba zamanani ezincintisanayo. I-Anebon yamukela ngokufudumele abathengi abavela ekhaya lakho naphesheya kwezilwandle ukuze basebenzisane nathi ukuze bathole imiphumela evamile.

Abathengisi Abahle I-Wholesale yase-China bakha insimbi engagqwali, okunembayo okuyingxenye ye-axis machining engu-5 kanyecnc ukugayaamasevisi. Izinjongo eziyinhloko ze-Anebon ukuhlinzeka amakhasimende ethu emhlabeni wonke ngekhwalithi enhle, amanani ancintisanayo, ukulethwa okwanelisayo kanye nezinsizakalo ezinhle kakhulu. Ukwaneliseka kwekhasimende kuwumgomo wethu oyinhloko. Siyakwamukela ukuthi uvakashele i-showroom yethu kanye nehhovisi. I-Anebon ibheke ngabomvu ukusungula ubudlelwano bebhizinisi nawe.

Uma ufuna ukwazi okwengeziwe, sicela uxhumaneinfo@anebon.com

Isikhathi sokuthumela: Nov-17-2023