Intambo ihlukaniswe ngokuyinhloko ibe intambo yokuxhuma kanye nentambo yokudlulisela

Okwezintambo zokuxhuma zeCNC Machining izingxenyefuthiCNC Turning izingxenye, izindlela eziyinhloko zokucubungula yilezi: ukuthepha, ukucupha, ukuphenduka, ukugingqa, ukugingqa, njll. Okwentambo yokudlulisa, izindlela eziyinhloko zokucubungula yilezi: ukujika okumaholo nokucolekile---ukugaya, ukugaya isivunguvungu---ukuphenduka okungalungile, njll. .

Izindlela ezihlukahlukene zokucubungula zichazwe ngezansi:

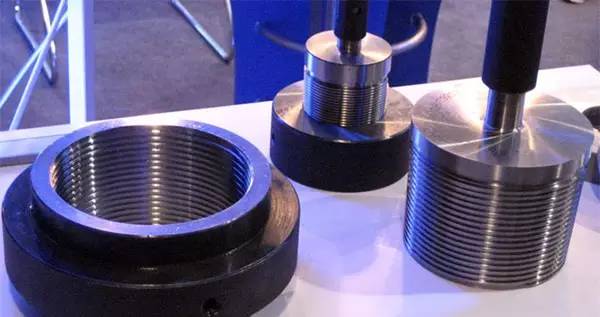

1. Ukusika intambo

Ngokuvamile ibhekisela endleleni yokucubungula imicuizingxenye eziphendukayo ze-cncngamathuluzi okwakha noma amathuluzi okugaya, ikakhulukazi ahlanganisa ukuphenduka, ukugaya, ukuthepha, ukuthunga, ukugaya, ukugaya nokusika isivunguvungu. Lapho ujika, ukugaya nokugaya izintambo, iketango lokudlulisela lethuluzi lomshini liqinisekisa ukuthi ithuluzi eliphendukayo, i-milling cutter noma isondo lokugaya lihambisa umthofu ngokunembile nangokulinganayo eduze kwe-eksisi ye-workpiece njalo lapho umsebenzi ujikeleza. Uma uthepha noma ucucuza, ithuluzi (thepha noma ufe) kanye nocezu lokusebenza kwenza umnyakazo ozungezayo ohlobene, futhi i-groove yentambo yokuqala eyakhiwe iqondisa ithuluzi (noma ucezu lokusebenza) ukuhamba nge-axially.

Ukuvula intambo kungasebenzisa ithuluzi lokujika lefomu noma ikama lentambo (bheka amathuluzi okuthunga). Ukuguqula izintambo ngamathuluzi okuguqula okwakha kuyindlela evamile yokukhiqizwa kwesiqephu esisodwa kanye neqoqo elincane lama-workpieces anentambo ngenxa yesakhiwo samathuluzi esilula; izintambo eziphendukayo ezinama-thread cutters zisebenza kahle kakhulu ekukhiqizeni, kodwa isakhiwo samathuluzi siyinkimbinkimbi futhi sifaneleka kuphela ukuguqulwa ekukhiqizeni okuphakathi nendawo nokukhulu Ama-workpieces amfishane ane-pitch enhle. Ukunemba kwe-pitch kwentambo ye-trapezoidal evula ama-lathes ajwayelekile ingafinyelela kuphela kumabanga 8 kuya ku-9 (JB2886-81, okufanayo ngezansi); ukucubungula izintambo kuma-lathes ezintambo ezikhethekile kungathuthukisa kakhulu ukukhiqiza noma ukunemba.

2. Ukugaya intambo

Ukugaya kwenziwa emshinini wokugaya intambo nge-disc cutter noma i-comb cutter. Abasiki be-disc milling basetshenziswa kakhulu ekugayeni imicu yangaphandle ye-trapezoidal kuma-workpiece afana nezikulufu nezikelemu. I-milling cutter emise okwekama isetshenziselwa ukugaya imicu evamile yangaphakathi neyangaphandle kanye nemicu ye-taper. Njengoba igaywe nge-multi-edged milling cutter, ubude bengxenye yayo yokusebenza bukhulu kunobude bentambo ecutshunguliwe, ngakho-ke i-workpiece idinga kuphela ukujikeleza 1.25 kuya ku-1.5 ukuphenduka ukuze kucutshungulwe. Ukukhiqiza okuphelele, okuphezulu. Ukunemba kwephimbo lokugaywa kwentambo ngokuvamile kungafinyelela ebangeni lesi-8-9, futhi ubulukhuni obungaphezulu bungama-microns angu-R 5-0.63. Le ndlela ilungele ukukhiqizwa kwenqwaba yama-workpieces anemicu ngokunemba okuvamile noma ukugaywa okungalungile ngaphambi kokugaya.

3. Ukugaya intambo

Isetshenziselwa ikakhulukazi ukwenza imicu yokunemba yezingxenye zokusebenza eziqinile kuma-grinders wentambo. Ngokwesimo sesigaba esiphambanayo sesondo lokugaya, singahlukaniswa ngezinhlobo ezimbili: isondo lokugaya elinomugqa owodwa kanye nesondo lokugaya elinemigqa eminingi. Ukunemba kwe-pitch yesondo lokugaya lomugqa owodwa ngamamaki angu-5-6, ubulukhuni obungaphezulu bungama-microns angu-R 1.25-0.08, futhi ukugqoka kwesondo lokugaya kulula kakhulu. Le ndlela ifanelekileukugaya izikulufu zokuhola eziqondile, ama-thread gauge, izikelemu, amaqoqo amancane ezinto zokusebenza ezinentambo kanye nezinsimbi zokunemba zokugaya. I-Multi-line grinding wheel grinding ihlukaniswe yaba izinhlobo ezimbili: indlela yokugaya i-longitudinal kanye nendlela yokugaya. Endleleni yokugaya i-longitudinal, ububanzi besondo lokugaya buncane kunobude bentambo okufanele igaywe, futhi intambo ingacolwa kuze kube usayizi wokugcina ngokunyakazisa isondo lokugaya ngobude kanye noma izikhathi eziningana. Endleleni yokugaya i-plunge, ububanzi besondo lokugaya bukhulu kunobude bentambo okufanele igaywe, futhi isondo lokugaya lisika ebusweni bomsebenzi wokusebenza nge-radially, futhi ucezu lokusebenza lungagaywa ngemuva kokuphenduka okungaba ngu-1.25. Ukukhiqiza kuphezulu, kodwa ukunemba kuphansi kancane, futhi ukugqoka kwesondo lokugaya kuyinkimbinkimbi. Indlela yokugaya i-plunge ilungele ompompi bokugaya okusizayo ngamaqoqo amakhulu kanye nokugaya imicu ethile ukuze kuqiniswe.

4. Ukugaya intambo

Igrinder yentambo yohlobo lwamantongomane noma isikulufu senziwe ngezinto ezithambile ezifana nensimbi ecijile, futhi izingxenye zezintambo ezicutshunguliwe ezinamaphutha ephimbo zigxilwa phambili neziqondiso ezihlehlayo ukuze kuthuthukiswe ukunemba kwephimbo. Intambo yangaphakathi eqinile ivame ukuqedwa ngokugaya ukuze kuthuthukiswe ukunemba.

5. Ukuthepha nokucupha

Ukuthepha kuwukusebenzisa i-torque ethile ukugoqa umpompi embobeni engaphansi ebhojwe ngaphambili endaweni yokusebenza ukuze kucutshungulwe umucu wangaphakathi. Intambo iwukusetshenziswa kwe-dies ukusika imicu yangaphandle kumabha (noma amapayipi) workpieces. Ukunemba komshini wokuthepha noma ukuthunga kuncike ekunembeni kompompi noma ukufa. Nakuba ziningi izindlela zokucubungula imicu yangaphakathi neyangaphandle, imicu yangaphakathi enobubanzi obuncane ingacutshungulwa kuphela ngompompi. Ukuthepha nokulutha kungenziwa ngesandla, noma ama-lathes, imishini yokumba, imishini yokudonsa kanye nemishini yokulutha.

Umgomo wokukhethwa kwenani lokujika kwentambo

Njengoba iphimbo (noma ukuhola) kwentambo kucaciswe iphethini, isihluthulelo sokukhetha inani lokusika lapho uphendula intambo ukucacisa isivinini sokuphotha n kanye nokujula kokusika.

1. Ukukhethwa kwejubane lokuphotha

Ngokomshini othi ukuphotha okuphothayo kuzungezisa ukuphenduka oku-1 futhi ithuluzi liphakela umthofi ongu-1 lapho liphendula uchungechunge, isivinini sokuphakelayo se-CNC lathe lapho uphendula intambo sinqunywa isivinini sokuphotha esikhethiwe. Intambo yokuhola eyalwe kubhlokhi yokucubungula intambo (iphimbo lochungechunge intambo yokuqala eyodwa), okulingana nezinga lokuphakelayo i-vf elimelwe inani lokuphakelayo u-f (mm/r)

vf = nf (1)

Kungabonakala kufomula ukuthi izinga lokuphakelayo vf lilingana nezinga lokuphakelayo f. Uma ijubane lokuphotha lethuluzi lomshini likhethwa liphezulu kakhulu, izinga lokuphakelayo eliguquliwe kufanele lidlule kakhulu izinga lokuphakelayo elilinganiselwe lethuluzi lomshini. Ngakho-ke, lapho kukhethwa isivinini sokuphotha ukuze siphendule intambo, ukulungiselelwa kwepharamitha yesistimu yokuphakelayo kanye nokucushwa kukagesi kwethuluzi lomshini kufanele kucatshangelwe ukuze kugwenywe into eyenzeka "yamazinyo esiphithiphithi" wentambo noma iphimbo eduze nendawo yokuqala/yokuphela. ukungahlangabezani nezidingo.

Ukwengeza, kubalulekile ukuqaphela ukuthi uma ukucutshungulwa kwentambo sekuqaliwe, inani lejubane lokuphotha ngokuvamile alikwazi ukushintshwa, futhi isivinini sokuphotha esihlanganisa ukuqedela imishini kufanele silandele inani elikhethiwe kokuphakelayo kokuqala. Uma kungenjalo, isistimu ye-CNC izobangela ukuthi uchungechunge lube "nesiphithiphithi" ngenxa yenani "lokudubula ngokweqile" lesignali ye-pulse yereferensi yesifaki khodi sokushaya kwenhliziyo.

2) Ukukhethwa kokujula kokusika

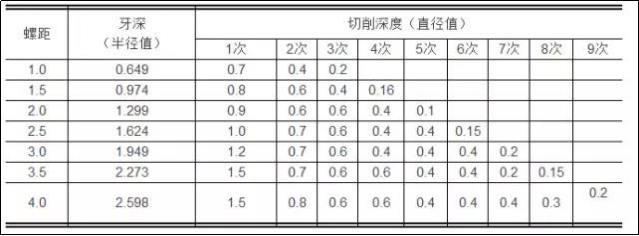

Njengoba inqubo yokuguqula intambo yenza ukuphenduka, amandla ethuluzi ampofu, futhi okuphakelayo kokusika kukhulu, futhi amandla okusika ethuluzini nawo makhulu. Ngakho-ke, ukucubungula okuphakelayo okuyingxenye ngokuvamile kuyadingeka, futhi ukujula kokusika okunengqondo kukhethwa ngokuya ngethrendi enciphayo. Ithebula 1 libala amanani ayireferensi ezikhathi zokuphakelayo nokujula kokusikwa kokusikwa kochungechunge lwemethrikhi evamile ukuze kusetshenziswe ireferensi yabafundi.

Ithebula 1 Izikhathi zokuphakelayo nokujula kokusikwa kokusika intambo yemethrikhi evamile

Isikhathi sokuthumela: Dec-10-2022