Ekwenziweni komshini, ukuze ukwandise ikhwalithi yokucubungula nokuphinda ukunemba, kuyadingeka ukukhetha kahle nokunquma ithuluzi elifanele. Kweminye imishini eyinselele futhi enzima, ukukhetha ithuluzi kubaluleke kakhulu.

1. Indlela yamathuluzi enesivinini esikhulu

1. Indlela yamathuluzi enesivinini esikhulu

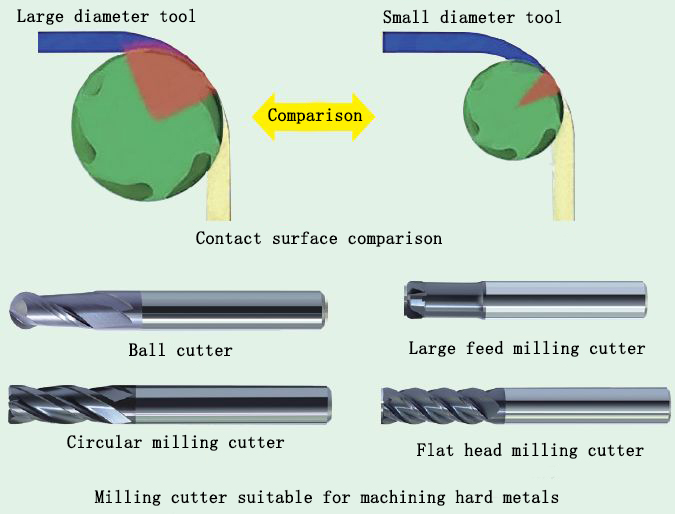

Uhlelo lwe-CAD/CAM lufinyelela ukunemba kokusika okuphezulu kakhulu ngokulawula ngokunembile ubude be-arc bethuluzi lokusika endleleni yamathuluzi e-cycloid enesivinini esikhulu. Lapho i-milling cutter isika ekhoneni noma kwezinye izimo zejometri eziyinkimbinkimbi, inani lokudla kommese ngeke likhuphuke. Ukuze basebenzise ngokugcwele le ntuthuko yezobuchwepheshe, abakhiqizi bamathuluzi baye baklama futhi bathuthukisa izisiki ezithuthukisiwe zokugaya ezinobubanzi obuncane. Izisiki zokugaya ezinobubanzi obuncane zingasika izinto zokusebenza ezengeziwe ngesikhathi seyunithi ngokusebenzisa izindlela zamathuluzi anesivinini esikhulu, futhi zithole izinga eliphezulu lokususa insimbi.

Ngesikhathi somshini, ukuthintana kakhulu phakathi kwethuluzi kanye nobuso be-workpiece kungabangela kalula ukuthi ithuluzi lihluleke ngokushesha. Umthetho osebenzayo wesithupha ukusebenzisa i-milling cutter enobubanzi obungaba ngu-1/2 wengxenye encane kakhulu yomsebenzi. Lapho i-radius ye-milling cutter incane kunosayizi wengxenye encane kakhulu yomsebenzi, kunendawo yokuthi ithuluzi lihambe kwesokunxele nakwesokudla, futhi i-engeli encane yokudla ingatholakala. Abasiki bokugaya bangasebenzisa amaphethelo amaningi kanye namazinga aphezulu okuphakelayo. Ngaphezu kwalokho, lapho i-milling cutter enobubanzi be-1/2 yengxenye encane kakhulu yomsebenzi isetshenziswa, i-angle yokusika ingagcinwa encane ngaphandle kokwandisa ukuphenduka komsiki.

Ukuqina komshini kusiza nokunquma ubukhulu bamathuluzi angasetshenziswa. Isibonelo, uma usikwa emshinini we-taper engu-40, ububanzi bomshini wokusika kufanele bube ngu-<12.7mm. Ukusetshenziswa kwesisiki esinobubanzi obukhulu kuzokhiqiza amandla amakhulu okusika angase adlule ikhono lomshini lokuthwala, okuholela engxoxweni, ukuwohloka, ukuqedwa kahle kwendawo, kanye nempilo yamathuluzi ibe mfushane.

Uma usebenzisa indlela entsha yamathuluzi enesivinini esiphezulu, umsindo wesisiki sokugaya ekhoneni uyafana nowokusika umugqa oqondile. Umsindo okhiqizwa umsiki wokugaya phakathi nenqubo yokusika uyafana, okubonisa ukuthi awuzange ubhekane nokushaqeka okukhulu okushisayo nokwemishini. I-milling cutter yenza umsindo omemezayo njalo lapho ijika noma isika ekhoneni, okubonisa ukuthi ububanzi bomshini wokusika kungase kudingeke buncishiswe ukuze kuncishiswe i-engeli yokudla. Umsindo wokusika uhlala ungashintshiwe, okubonisa ukuthi ingcindezi yokusika kumshini wokusika iyunifomu futhi ayiguquguquki phezulu naphansi ngokushintshwa kwejometri ye-workpiece. Lokhu kungenxa yokuthi i-engeli yommese ihlala njalo.

2. Ukugaya izingxenye ezincane

I-feed cutter enkulu ifanele ukugaywa kwezingxenye ezincane, ezingaveza umphumela wokunciphisa i-chip, okwenza kube nokwenzeka ukugaya ngezinga eliphezulu lokuphakela.

Ekucubunguleni izimbobo zokugaya ezivunguzayo kanye nezimbambo zokugaya, ithuluzi nakanjani lizokwenza ukuthintana okwengeziwe nendawo yomshini, futhi ukusetshenziswa kwesisiki esikhulu sokugaya kunganciphisa ukuthintana kwendawo yokusebenza, ngaleyo ndlela kunciphise ukushisa okusika kanye nokuguqulwa kwamathuluzi .

Kulezi zinhlobo ezimbili zokucubungula, i-feed milling cutter enkulu ivamise ukuba sesimweni sokuvaleka kancane ngesikhathi sokusika. Ngakho-ke, isinyathelo esiphezulu sokusika i-radial kufanele sibe u-25% wobubanzi bomshini wokusika, futhi ukujula okuphezulu kokusika okungu-Z kokusikwa ngakunye kufanele kube Kungu-2% wobubanzi bomsiki wokugaya.cnc machining ingxenye

Emgodini wokugaya ovunguzayo, lapho umsiki wokugaya esika endaweni yokusebenza ngomzila wesitimela ovunguzayo, i-spiral cutting angle ingu-2 ° ~ 3 ° ize ifinyelele ekujuleni kuka-Z okungu-2% kobubanzi besisiki sokugaya.

Uma i-milling cutter enkulu isesimweni esivulekile ngesikhathi sokusika, isinyathelo sayo sokuhamba nge-radial sincike ebukhuni bempahla yokusebenza. Lapho kugaywa izinto zokusebenza ezinobulukhuni HRC30-50, isinyathelo esiphezulu sokusika i-radial kufanele sibe u-5% we-diameter ye-milling cutter; lapho ubulukhuni bezinto ezibonakalayo bungaphezu kwe-HRC50, isinyathelo esiphezulu sokusika i-radial kanye nobukhulu be-Z ngephasi ngayinye Ukujula kokusika kungu-2% wobubanzi bomsiki wokugaya.ingxenye ye-aluminium

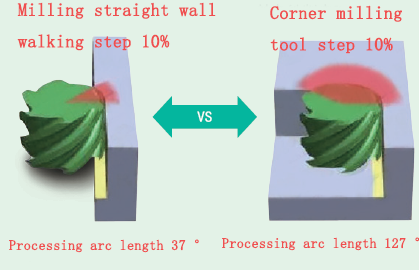

3. Ukugaya izindonga eziqondile

Uma ugaya ngezimbambo eziyisicaba noma izindonga eziqondile, kungcono ukusebenzisa i-arc cutter. Ama-arc cutter anemiphetho emi-4 kuye kwayi-6 afaneleka kakhulu ukugaya iphrofayili yezingxenye eziqondile noma ezivuleke kakhulu. Lapho inani lama-blades we-milling cutter likhula, likhulu izinga lokuphakela elingasetshenziswa. Kodwa-ke, umhleli womshini usadinga ukunciphisa ukuthintana phakathi kwethuluzi nendawo yokusebenza futhi asebenzise ububanzi bokusika be-radial obuncane. Uma umshini ethuluzi lomshini elinokuqina okungalungile, kunenzuzo ukusebenzisa i-milling cutter ene-diameter encane, enganciphisa ukuthintana nobuso be-workpiece.cnc ingxenye yokugaya

Isinyathelo sokusika kanye nokujula kokusika kwe-multi-edge arc milling cutter kuyafana naleyo ye-high-feed milling cutter. Umzila wamathuluzi we-cycloid ungasetshenziswa ukugoqa izinto eziqinile. Qinisekisa ukuthi ububanzi be-milling cutter cishe bungu-50% wobubanzi be-groove, ukuze i-milling cutter ibe nendawo eyanele yokuhamba, futhi uqinisekise ukuthi i-engeli yomsiki ngeke ande futhi ikhiqize ukushisa okusika ngokweqile.

Ithuluzi elingcono kakhulu lomshini othile alincikile kuphela ezintweni ezisikiwe, kodwa futhi ohlotsheni lwendlela yokusika nokugaya esetshenziswayo. Ngokulungiselela amathuluzi, isivinini sokusika, amanani okuphakelayo kanye namakhono wokuhlela ngomshini, izingxenye zingakhiqizwa ngokushesha nangcono ngezindleko eziphansi zokuwenza.

I-Anebon Metal Products Limited ingahlinzeka ngemishini ye-CNC, i-die casting, izinsizakalo zomshini wensimbi, sicela ukhululeke ukuxhumana nathi.

Tel: +86-769-89802722 Email: info@anebon.com Website : www.anebon.com

Isikhathi sokuthumela: Apr-28-2020