Isikhungo somshini, esaziwa nangokuthi isikhungo semishini ye-CNC, iyithuluzi lomshini elizenzakalelayo neliguquguqukayo elisetshenziswa embonini yokukhiqiza ukwenza imisebenzi ehlukahlukene yokwenza imishini.

-

Uhlolojikelele: Isikhungo somshini sihlanganisa imisebenzi eminingana ibe yiyunithi eyodwa, okuhlanganisa ukugaya, ukubhola, ukuthepha, ukubhora, futhi ngezinye izikhathi ukuphenduka. Ihlanganisa ithuluzi lomshini, isishintshi samathuluzi, kanye nesistimu yokulawula ibe yisistimu eyodwa yokwandisa ukusebenza kahle nokukhiqiza.

-

Izinhlobo: Izikhungo zomshini ziza ngezinhlobo ezahlukene, njengezikhungo zokumayini eziqondile (VMC) kanye nezikhungo zokumachine ezivundlile (HMC). Ama-VMC ane-spindle eqondile eqondile, kuyilapho ama-HMC ane-spindle eqondile eqondile. Uhlobo ngalunye lunezinzuzo zalo futhi lufanele izicelo ezithile.

-

Izimbazo: Izikhungo zomshini ngokuvamile ziba nezimbazo ezintathu noma ngaphezulu zokunyakaza. Okuvame kakhulu imishini ye-axis emithathu, enezimbazo ezingu-X, Y, kanye no-Z zokunyakaza komugqa. Amamodeli athuthukile angase abe nezimbazo ezijikelezayo ezengeziwe (isb, A, B, C) zomshini we-multi-axis.

-

Ukulawulwa kwe-CNC: Izikhungo zomshini zilawulwa yizinhlelo zokulawula izinombolo zekhompyutha (CNC). Uhlelo lwe-CNC luvumela ukulawula okunembile kwenqubo yokwenza imishini, okuhlanganisa ukunyakaza kwamathuluzi, amanani okuphakelayo, isivinini sokupholisa, nokugeleza kokupholisa.

-

Ukushintsha Ithuluzi: Izikhungo zomshini zifakwe iziguquli zamathuluzi ezizenzakalelayo (i-ATC) ezivumela ukushintshaniswa okusheshayo nokuzenzakalelayo kwamathuluzi okusika ngesikhathi senqubo yokwenza imishini. Lokhu kunika amandla ukukhiqiza okusebenzayo nokungaphazamiseki.

-

Ukusebenza: Izinto zokusebenza zigcinwe ngokuvikelekile etafuleni noma endaweni yesikhungo somshini ngesikhathi sokusebenza komshini. Kusetshenziswa izindlela ezahlukahlukene zokubamba, njengama-vises, ama-clamp, ama-fixtures, kanye nezinhlelo ze-pallet, kuye ngokuthi isicelo kanye nezidingo.

-

Izicelo: Izikhungo zomshini zisetshenziswa kakhulu ezimbonini ezifana ne-aerospace, ezezimoto, ezokwelashwa, nezokukhiqiza jikelele. Baqashelwa imisebenzi efana nokugaya izingxenye eziyinkimbinkimbi, izimbobo zokumba, ukudala amaphrofayili anembile, kanye nokuzuza ukubekezelelana okuqinile.

-

Intuthuko: Umkhakha wezikhungo zemishini uthuthuka ngokuqhubekayo ngokuthuthuka kwezobuchwepheshe. Lokhu kubandakanya ukuthuthukiswa komklamo womshini, amasistimu okulawula, ubuchwepheshe bamathuluzi okusika, ukuzenzekelayo, nokuhlanganiswa nezinye izinqubo zokukhiqiza.

Isikhungo somshini sihlanganisa uwoyela, igesi, ugesi, nokulawula izinombolo, futhi singakwazi ukubona ukugoqa ngesikhathi esisodwa kwamadiski ahlukahlukene, amapuleti, amagobolondo, amakhamera, isikhunta nezinye izingxenye eziyinkimbinkimbi kanye nezinto zokusebenza, futhi singaqedela ukubhoboza, ukugaya, ukubhora, ukwandisa, ukubuyisela kabusha, ukuthepha okuqinile nezinye izinqubo ziyacutshungulwa, ngakho-ke kuyithuluzi elifanele lemishini enembayo ephezulu. Lesi sihloko sizokwabelana ngamakhono okusebenzisa izikhungo zemishini kusuka kulezi zici ezilandelayo:

Isikhungo somshini silibeka kanjani ithuluzi?

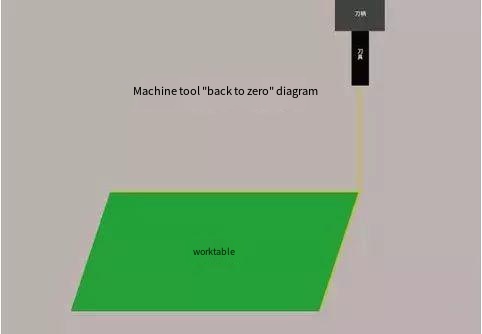

1. Buyela kuziro (buyela kumsuka wethuluzi lomshini)

Ngaphambi kokusetha ithuluzi, kuyadingeka ukuthi ubuyele ku-zero (ubuyele kumsuka wethuluzi lomshini) ukuze usule idatha yokuxhumanisa yokusebenza kokugcina. Qaphela ukuthi izimbazo X, Y, kanye no-Z zonke zidinga ukubuyela kuqanda.

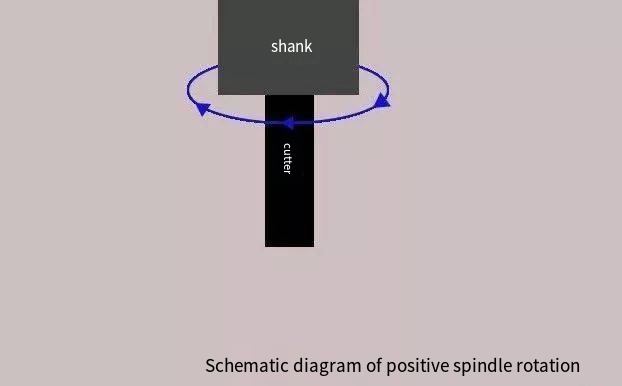

2. I-spindle izungeza phambili

Kumodi ye-"MDI", i-spindle izungeziswa phambili ngokufaka amakhodi womyalo, futhi isivinini sokuzungezisa sigcinwa ezingeni eliphakathi. Bese ushintshela kumodi "yesondo", futhi wenze ukusebenza kokunyakaza kwethuluzi lomshini ngokushintsha nokulungisa isivinini.

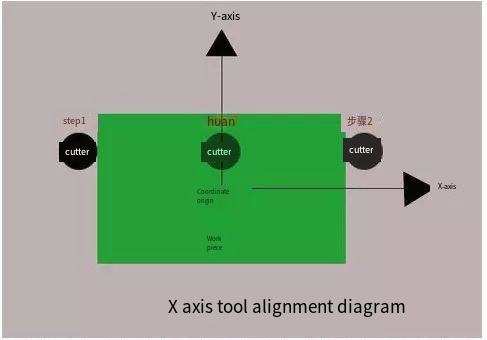

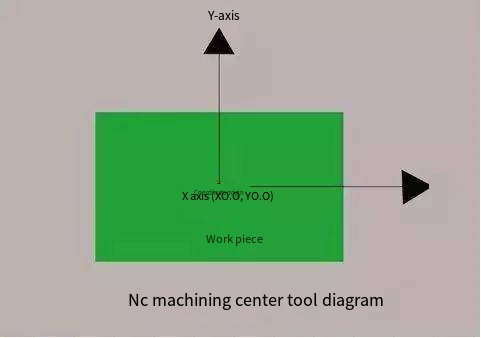

3. Ukulungiselelwa kwethuluzi lokuqondisa kwe-X

Sebenzisa ithuluzi ukuze uthinte kancane ohlangothini lwesokudla lwe-workpiece ukuze usule izixhumanisi ezihlobene zethuluzi lomshini; phakamisa ithuluzi ngendlela engu-Z, bese uhambisa ithuluzi kwesokunxele socezu lokusebenza, bese uhambisa ithuluzi nomsebenzi wehle uye phansi ekuphakameni okufanayo nangaphambili. Thinta kancane, phakamisa ithuluzi, bhala inani le-X lesixhumanisi esihlobene sethuluzi lomshini, hambisa ithuluzi kuhhafu wesixhumanisi esihlobene X, bhala inani elingu-X lokuxhumanisa okuphelele kwethuluzi lomshini, bese ucindezela (INPUT ) ukufaka isistimu yokuxhumanisa.

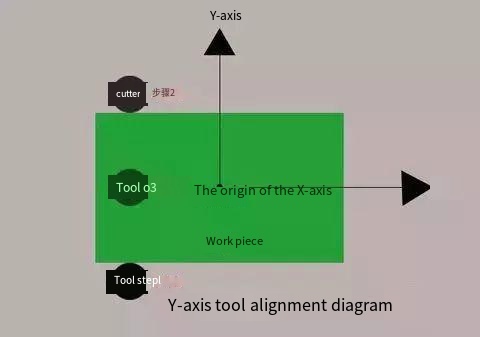

4. Isilungiselelo sethuluzi lesiqondiso sika-Y

Sebenzisa ithuluzi ukuthinta ngobumnene ingaphambili le-workpiece ukuze usule izixhumanisi ezihlobene zethuluzi lomshini; phakamisa ithuluzi ngendlela engu-Z, bese uyisa ithuluzi ngemuva kwendawo yokusebenza, bese uhambisa ithuluzi kanye nendawo yokusebenza phansi iye ekuphakameni okufanayo nangaphambili. Thinta kancane, phakamisa ithuluzi, bhala inani elingu-Y lesixhumanisi esihlobene sethuluzi lomshini, hambisa ithuluzi kuhhafu wesixhumanisi esihlobene esingu-Y, bhala inani elingu-Y lokuxhumanisa okuphelele kwethuluzi lomshini, bese ucindezela (INPUT ) ukufaka isistimu yokuxhumanisa.

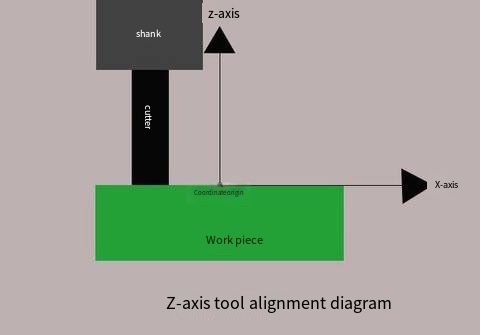

5. Isilungiselelo sethuluzi lesiqondiso se-Z

Hambisa ithuluzi phezu kwendawo yokusebenza ebheke endaweni eyiziro ohlangothini luka-Z, hambisa ithuluzi kancane kancane lize lithinte indawo engaphezulu yendawo yokusebenza kancane, qopha inani lika-Z ohlelweni lokuxhumanisa lwethuluzi lomshini ngalesi sikhathi. , bese ucindezela (INPUT) ukuze ufake ohlelweni lokuxhumanisa.

6. Isitobhi se-spindle

Misa i-spindle kuqala, hambisa i-spindle endaweni efanelekile, shayela uhlelo lokucubungula, futhi ulungiselele ukucutshungulwa okusemthethweni.

Isikhungo somshini sikhiqiza futhi sicubungule kanjani izingxenye ezikhubazekile?

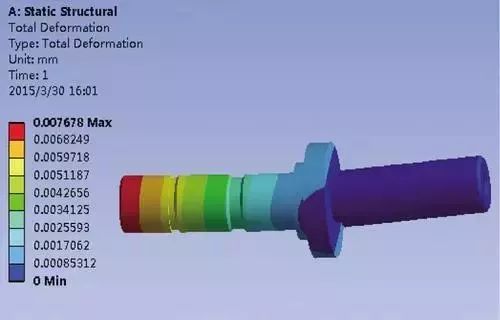

Ngobai-axis cnc machiningizingxenye ezinesisindo esilula, ukungaqini kahle, namandla abuthakathaka, zikhubazeka kalula ngamandla nokushisa ngesikhathi sokucutshungulwa, futhi izinga eliphezulu lokucutshungulwa kwezinsalela liholela ekwenyukeni okukhulu kwezindleko. Ezingxenyeni ezinjalo, kufanele siqale siqonde izimbangela ze-deformation:

I-Deformation ngaphansi kwamandla:

Udonga lwalolu hlobo lwezingxenye luncane, futhi ngaphansi kwesenzo se-clamping force, kulula ukuba nobukhulu obungalingani ngesikhathi somshini nokusika, futhi ukunwebeka kumpofu, futhi ukuma kwezingxenye kunzima ukuzibuyisela ngokwakho.

Ukushintsha kokushisa:

I-workpiece ilula futhi incane, futhi ngenxa yamandla e-radial phakathi nenqubo yokusika, izobangela ukuguqulwa okushisayo kwe-workpiece, ngaleyo ndlela yenza ubukhulu bomsebenzi wokusebenza bungalungile.

Ukuguqulwa kokudlidliza:

Ngaphansi kwesenzo samandla okusika ama-radial, izingxenye zijwayele ukudlidliza kanye nokuguqulwa, okuzothinta ukunemba kwe-dimensional, ukwakheka, ukunemba kwesikhundla kanye nokuqina kwendawo yokusebenza.

Indlela yokucubungula yezingxenye ezikhubazeka kalula:

Ezingxenyeni ezikhubazekile kalula ezimelelwe izingxenye ezinodonga oluncane, umshini wejubane eliphezulu kanye nokusika ngesilinganiso esincane sokuphakelayo kanye nesivinini esikhulu sokusika kungasetshenziswa ukunciphisa amandla okusika ku-workpiece ngesikhathi sokucubungula, futhi ngesikhathi esifanayo, ukushisa okuningi kokusika. ichithwa ama-chips endizela kude nendawo yokusebenza ngesivinini esikhulu. Thatha, ngaleyo ndlela unciphise izinga lokushisa le-workpiece futhi unciphise ukuguqulwa okushisayo kwe-workpiece.

Kungani amathuluzi esikhungo somshini kufanele asuswe?

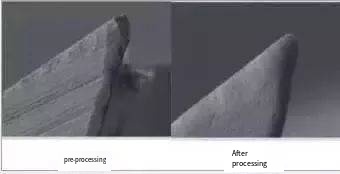

Amathuluzi e-CNC awasheshi ngangokunokwenzeka, kungani ukwelashwa kwe-passivation? Eqinisweni, ukudlula ithuluzi akukhona lokho wonke umuntu akuqonda ngokoqobo, kodwa indlela yokuthuthukisa impilo yesevisi yamathuluzi. Thuthukisa ikhwalithi yamathuluzi ngokushelela, ukupholishela, ukudiliza nezinye izinqubo. Lokhu empeleni kuyinqubo evamile ngemva kokuba ithuluzi seligaywe kahle nangaphambi kokumbozwa.

▲Ukuqhathaniswa kokwenziwa kwethuluzi

Imimese ilolwa ngesondo lokugaya ngaphambi komkhiqizo oqediwe, kodwa inqubo yokulola izobangela izikhala ezincanyana zibe ngamazinga ahlukahlukene. Lapho isikhungo somshini senza ukusika ngesivinini esikhulu, igebe le-microscopic lizokhula kalula, elizosheshisa ukuguga nokulimala kwethuluzi. Ubuchwepheshe bokusika besimanje bunezidingo eziqinile zokuzinza nokunemba kwethuluzi, ngakho-ke ithuluzi le-CNC kufanele lidluliselwe ngaphambi kokumbozwa ukuze kuqinisekiswe ukuqina nempilo yesevisi ye-coating. Izinzuzo ze-passivation yamathuluzi yilezi:

1. Melana nokugqokwa kwethuluzi

Ngesikhathi sokusika, ubuso bethuluzi buzogugiswa kancane kancane yi-i-workpiece ye-cnc yangokwezifiso, futhi umkhawulo wokusika ubuye uthambekele ekuguqulweni kwepulasitiki ngaphansi kokushisa okuphezulu nokucindezela okukhulu ngesikhathi sokusika. Ukwelashwa kwe-passivation kwethuluzi kungasiza ithuluzi ukuthi lithuthukise ukuqina kwalo futhi livimbele ithuluzi ukuthi lingalahlekelwa ukusebenza kwalo kokusika ngaphambi kwesikhathi.

2. Gcina isiphetho se-workpiece

Ama-Burrs onqenqemeni lwethuluzi azodala ukuguga kwamathuluzi futhi ingaphezulu le-workpiece eyenziwe ngomshini lizoba lukhuni. Ngemuva kokwelashwa kwe-passivation, umkhawulo wokusika wethuluzi uzoba bushelelezi kakhulu, ukusika kuzoncishiswa ngokufanele, futhi ukuqedwa okungaphezulu kwendawo yokusebenza kuzothuthukiswa.

3. Ukususwa kwe-chip ye-groove elula

Ukupholisha imitshingo yethuluzi kungathuthukisa ikhwalithi yendawo kanye nokusebenza kokukhipha ama-chip. Ukushelela komtshingo, kungcono ukuphuma kwe-chip, kanye nenqubo yokusika engaguquki ingafinyelelwa. Ngemuva kokudlula nokupholishwa kwethuluzi le-CNC esikhungweni somshini, izimbobo eziningi ezincane zizoshiywa phezulu. Lezi zimbobo ezincane zingakwazi ukumunca uketshezi oluningi lokusika ngesikhathi sokucubungula, okunciphisa kakhulu ukushisa okukhiqizwa ngesikhathi sokusika futhi kuthuthukisa kakhulu isivinini sokusebenza kahle kwemishini.

Isikhungo somshini sibunciphisa kanjani ubulukhuni bomsebenzi?

Ubulukhuni obungaphezulu bezingxenye bungenye yezinkinga ezivamile zeCNC imishiniizikhungo, ezibonisa ngokuqondile ikhwalithi yokucubungula. Indlela yokulawula ubulukhuni obungaphezulu bokucutshungulwa kwezingxenye, kufanele siqale sihlaziye ngokujulile izimbangela zokuqina kwendawo, ikakhulukazi okuhlanganisa: izimpawu zamathuluzi ezibangelwa ngesikhathi sokugaya; ukuguqulwa okushisayo noma ukuguqulwa kwepulasitiki okubangelwa ukuhlukaniswa kokusika; ithuluzi kanye machined surface ukungqubuzana phakathi.

Uma ukhetha ukukhahlamezeka kwendawo yokusebenza, akufanele nje kuhlangabezane nezidingo zokusebenza kwendawo yengxenye, kodwa futhi kucabangele ukucabangela kwezomnotho. Ngaphansi kwesisekelo sokuhlangabezana nomsebenzi wokusika, inani elikhulu eliyireferensi lokumahhadla kwendawo kufanele likhethwe ngangokunokwenzeka ukuze kwehliswe izindleko zokukhiqiza. Njengomabi wesikhungo sokusika imishini, ithuluzi kufanele linake ukugcinwa kwansuku zonke nokugaya okufika ngesikhathi ukuze kugwenywe ubulukhuni obungafanelekile obubangelwa ithuluzi elibuthuntu kakhulu.

Yini okufanele isikhungo somshini senze ngemva kokuqeda umsebenzi?

Ngokuvamile, izinqubo zokucubungula ithuluzi lomshini lezikhungo zemishini zicishe zifane. Umehluko omkhulu ukuthi isikhungo somshini siqedela zonke izinqubo zokusika ngokusebenzisa i-clamping yesikhathi esisodwa kanye nomshini ozenzakalelayo oqhubekayo. Ngakho-ke, isikhungo somshini sidinga ukwenza "umsebenzi wangemuva".

1. Yenza ukwelashwa kokuhlanza. Ngemuva kokuthi isikhungo somshini siqedele umsebenzi wokusika, kuyadingeka ukususa ama-chips ngesikhathi, sula unkulunkulu womshini, futhi ugcine ithuluzi lomshini nendawo ezungezile ihlanzekile.

2. Ukuze kuhlolwe futhi kushintshwe izesekeli, okokuqala, qaphela ukuhlola i-wiper yamafutha kumzila wesitimela, futhi uyishintshe ngesikhathi uma igugile. Hlola isimo samafutha okugcoba nesipholile. Uma kwenzeka i-turbidity, kufanele ishintshwe ngesikhathi. Uma izinga lamanzi liphansi kunesilinganiso, kufanele lifakwe.

3. Inqubo yokuvala shaqa kufanele ifane, futhi ukunikezwa kwamandla namandla amakhulu ephaneli yokusebenza kwethuluzi lomshini kufanele kuvalwe ngokushintshana. Uma zingekho izimo ezikhethekile kanye nezidingo ezikhethekile, umgomo wokubuyela ku-zero kuqala, i-manual, inching, kanye ne-othomathikhi kufanele ilandelwe. Isikhungo somshini kufanele futhi sihambe ngesivinini esiphansi, isivinini esiphakathi, bese sihamba ngesivinini esikhulu. Isikhathi sokugijima esinesivinini esiphansi nesiphakathi akufanele sibe ngaphansi kwamaminithi angu-2-3 ngaphambi kokuqala ukusebenza.

4. Hlela ukusebenza. Akuvunyelwe ukungqongqoza, ukuqondisa noma ukulungisa i-workpiece ku-chuck noma phezulu. Kuyadingeka ukuqinisekisa ukuthiizingxenye zokugaya ze-cncfuthi ithuluzi liyaboshelwa ngaphambi kokudlulela esinyathelweni esilandelayo. Umshwalense kanye nezisetshenziswa zokuvikela ukuphepha ethuluzini lomshini akufanele zihlakazwe futhi zihanjiswe ngokungafanele. Ukucubungula okusebenza kahle kakhulu empeleni ukucubungula okuphephile. Njengemishini esebenza kahle yokucubungula, ukusebenza kwesikhungo sokucubungula kumele kube okunengqondo futhi kufane uma kuvalwa. Lokhu akukhona nje ukugcinwa kwenqubo eqediwe yamanje, kodwa futhi ukulungiselela isiqalo esilandelayo.

I-Anebon inganikeza kalula izixazululo zekhwalithi ephezulu, inani lokuncintisana kanye nenkampani yamaklayenti ehamba phambili. Indawo eya e-Anebon ithi “Uza lapha ngobunzima futhi sikunikeza ukumamatheka ongakukhipha” Ye-Good Wholesale Vendors Precision Part CNC Machining Hard Chrome Plating Gear, Ukunamathela kumgomo webhizinisi elincane lokuzuzisana, manje i-Anebon isizuze idumela elihle phakathi kwethu. abathengi ngenxa yezinkampani zethu ezihamba phambili, izimpahla zekhwalithi kanye nezigaba zamanani ezincintisanayo. I-Anebon yamukela ngokufudumele abathengi abavela ekhaya lakho naphesheya kwezilwandle ukuze basebenzisane nathi ukuze bathole imiphumela evamile.

Abathengisi Abahle I-Wholesale yase-China yakha insimbi engagqwali, ingxenye ye-axis machining enembile engu-5 kanye nezinsiza zokugaya ze-cnc. Izinjongo eziyinhloko ze-Anebon ukuhlinzeka amakhasimende ethu emhlabeni wonke ngekhwalithi enhle, amanani ancintisanayo, ukulethwa okwanelisayo kanye nezinsizakalo ezinhle kakhulu. Ukwaneliseka kwekhasimende kuwumgomo wethu oyinhloko. Siyakwamukela ukuthi uvakashele i-showroom yethu kanye nehhovisi. I-Anebon ibheke ngabomvu ukusungula ubudlelwano bebhizinisi nawe.

Isikhathi sokuthumela: May-22-2023