Ithuluzi Lokuguqula

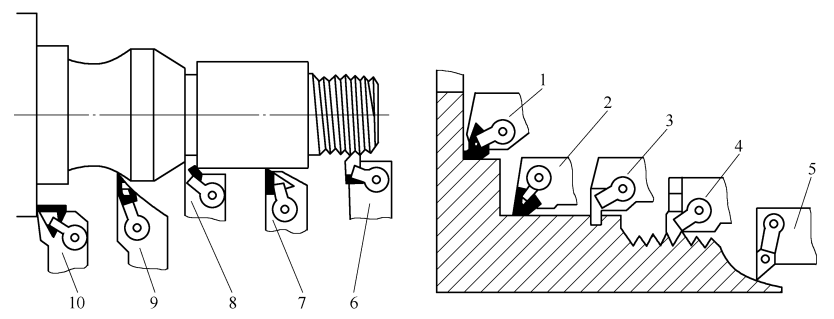

Ithuluzi elivame kakhulu ekusikeni kwensimbi yithuluzi lokuguqula. Amathuluzi okuguqula asetshenziselwa ukusika imibuthano yangaphandle, izimbobo phakathi nendawo, izintambo, ama-grooves, amazinyo, nezinye izimo ezintambo. Izinhlobo zayo eziyinhloko ziboniswa kuMfanekiso 3-18.

Umfanekiso 3-18 Izinhlobo eziyinhloko zamathuluzi okuguqula

1. 10—Ithuluzi lokuphendulela ekugcineni 2. 7—Indilinga yangaphandle (ithuluzi lokuguqula imbobo yangaphakathi) 3. 8—Ithuluzi lokuvula intambo 4. 6—Ithuluzi lokuphendulela uchungechunge 5. 9—Ithuluzi lokuphendula iphrofayela

Amathuluzi okuguqula ahlukaniswa ngokusekelwe esakhiweni sawo ukuze abe ukuphenduka okuqinile, ukuphenduka kwe-welding, ukuphenduka kwe-clamp yomshini, namathuluzi angenakukhomba. Amathuluzi okuguqula anenkomba aya edume kakhulu ngenxa yokwanda kokusetshenziswa kwawo. Lesi sigaba sigxile ekwethuleni izimiso nezindlela zokuklama zamathuluzi okujika anenkomba nokushisela.

1. Ithuluzi lokushisela

Ithuluzi lokuguqula i-welding lenziwe nge-blade yomumo othize kanye nesibambi esixhunywe nge-welding. Ama-blades ngokuvamile enziwa kusuka kumabanga ahlukene we-carbide material. Izinsimbi zamathuluzi ngokuvamile ziyinsimbi engama-45 futhi zilolwe ukuze zivumelane nezidingo ezithile ngesikhathi sokusetshenziswa. Ikhwalithi yamathuluzi okuguqula i-welding kanye nokusetshenziswa kwawo kuncike ebangeni le-blade, imodeli ye-blade, imingcele ye-geometric yethuluzi kanye nokuma nosayizi we-slot. Ikhwalithi yokugaya, njll. Ikhwalithi yokugaya, njll.

(1) Kunezinzuzo kanye nokubi kumathuluzi okujika okushisela

Isetshenziswa kabanzi ngenxa yesakhiwo sayo esilula, esihlangene; ukuqina kwethuluzi eliphezulu; nokumelana nokudlidliza okuhle. Iphinde ibe nokubi okuningi, okuhlanganisa:

(1) Ukusebenza kokusika kwe-blade kubi. Ukusebenza kokusika kwe-blade kuzoncishiswa ngemuva kokuthi kushiselwe ekushiseni okuphezulu. Izinga lokushisa eliphezulu elisetshenziselwa ukushisela nokulola libangela ukuthi i-blade ibe ngaphansi kwengcindezi yangaphakathi. Njengoba i-coefficient enwetshiwe yomugqa we-carbide iyingxenye yengxenye yomzimba wamathuluzi, lokhu kungabangela ukuqhekeka ukuthi kuvele ku-carbide.

(2) Umbambi wethuluzi akaphinde asetshenziswe. Izinto ezingavuthiwe ziyamoshwa ngoba umbambi wamathuluzi akakwazi ukuphinda asetshenziswe.

(3) Isikhathi sokusiza side kakhulu. Ukushintsha ithuluzi nokusetha kuthatha isikhathi esiningi. Lokhu akuhambisani nezimfuno zemishini ye-CNC, amasistimu omshini wokuzenzakalela, noma amathuluzi omshini ozenzakalelayo.

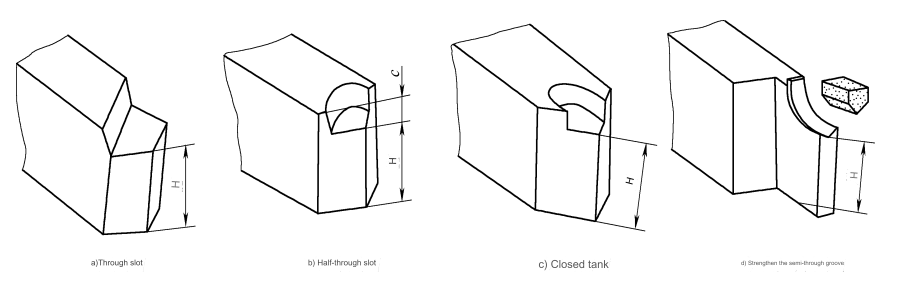

(2) Uhlobo lwesibambi samathuluzi

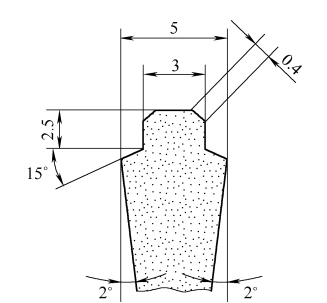

Kumathuluzi okuguqula ashiselwe, ama-shank grooves amathuluzi kufanele enziwe ngokuya ngokuma nosayizi we-blade. I-shank grooves yamathuluzi ihlanganisa ngokusebenzisa imisele, i-semi-through grooves, i-grooves evaliwe, ne-semi-through grooves eqinisiwe. Njengoba kuboniswe kuMfanekiso 3-19.

Umfanekiso 3-19 Ijometri yesibambi samathuluzi

I-groove yesibambi samathuluzi kufanele ihlangabezane nezidingo ezilandelayo ukuze kuqinisekiswe ikhwalithi yokushisela:

(1) Lawula ukujiya. (1) Lawula ukushuba komzimba womsiki.

(2) Lawula igebe phakathi kwe-blade ne-groove yesibambi samathuluzi. Igebe phakathi kwe-blade nesibambi samathuluzi akufanele libe likhulu kakhulu noma libe lincane, ngokuvamile libe ngu-0.050.15mm. Ijoyinti ye-arc kufanele ifane ngangokunokwenzeka futhi igebe elikhulu lendawo akufanele lidlule u-0.3mm. Uma kungenjalo, amandla e-weld azothinteka.

(3) Lawula ivelu yokumahhadla kwendawo yesibambi sethuluzi. Igroove yesibambi samathuluzi inobukhulu obungaphezulu be-Ra=6.3mm. I-blade surface kufanele ibe flat futhi ibushelelezi. Ngaphambi kwe-welding, i-groove yomnikazi wamathuluzi kufanele ihlanzwe uma kukhona amafutha. Ukuze ugcine indawo yokushisela ihlanzekile, ungasebenzisa i-sandblasting noma utshwala noma uphethiloli ukuyixubha.

Lawula ubude be-blade. Ezimweni ezijwayelekile, i-blade ebekwe emgodini wesimeli kufanele iphumele ngaphandle ngo-0.20.3mm ukuvumela ukulola. I-groove yesibambi samathuluzi ingase yenziwe ibe yinde ngo-0.20.3mm kune-blade. Ngemva kokushisela, umzimba wamathuluzi ube usushiselwa. Ukuze ubukeke kahle, susa noma yikuphi okweqile.

(3) Inqubo yokufaka i-blade brazing

I-hard solder isetshenziselwa ukushisela ama-carbide blades (i-hard solder iyimpahla ephikisayo noma yokubhula enezinga lokushisa elincibilikayo elingaphezu kuka-450degC). I-solder ishisiswe ibe yisimo esincibilikisiwe, ngokuvamile esingu-3050degC ngaphezu kwendawo yokuncibilika. I-flux ivikela i-solder ekungeneni nasekusakazeni ebusweni be-izingxenye ezenziwe ngomshini. Ibuye ivumele ukusebenzisana kwe-solder nengxenye ehlanganisiwe. Isenzo sokuncibilika senza i-carbide blade isheleleke ngokuqinile ku-slot.

Amasu amaningi okushisisa ama-brazing ayatholakala, njenge-gas flame welding kanye ne-high frequency welding. I-electric contact welding iyindlela engcono kakhulu yokushisisa. Ukumelana endaweni yokuxhumana phakathi kwebhulokhi yethusi, kanye nekhanda lokusika liphakeme kakhulu, futhi yilapho izinga lokushisa eliphezulu lizokhiqizwa khona. Umzimba wokusika kuqala ubabomvu bese ukushisa kudluliselwa ku-blade. Lokhu kubangela ukuthi i-blade ifudumale kancane futhi ikhuphuke kancane kancane izinga lokushisa. Ukuvimbela imifantu kubalulekile.

I-blade "ayishiswa kakhulu" ngoba amandla avaliwe ngokushesha nje lapho izinto zincibilika. Ukushisela othintana naye ngogesi kufakazelwe ukuthi kunciphisa ukuqhekeka kwe-blade nokudilizwa. I-Brazing ilula futhi izinzile, enekhwalithi enhle. Inqubo yokubhraza ayisebenzi kahle kunama-weld anemvamisa ephezulu, futhi kunzima ukubhraza amathuluzi anemiphetho eminingi.

Izinga le-brazing lithintwa izici eziningi. I-brazing material, i-flux kanye nendlela yokushisa kufanele ikhethwe ngendlela efanele. Ngethuluzi le-carbide brazing, impahla kumele ibe nendawo yokuncibilika ephakeme kunezinga lokushisa lokusika. Kuyinto enhle yokusika ngoba ingagcina amandla okubopha i-blade ngenkathi igcina i-fluidity yayo, i-wettability kanye ne-thermal conductivity. Izinto zokubhsa ezilandelayo zivame ukusetshenziswa lapho kubhula izindwani zikasimende-carbide:

(1) Izinga lokushisa elincibilikayo lethusi elimsulwa noma ingxubevange yethusi-nickel (i-electrolytic) lilinganiselwa ku-10001200degC. Amazinga okushisa avumelekile okusebenza angu-700900degC. Lokhu kungasetshenziswa ngamathuluzi anomthwalo osindayo wokusebenza.

(2) I-Copper-zinc noma i-105# yensimbi yokugcwalisa enezinga lokushisa elincibilikayo phakathi kuka-900920degC no-500600degC. Ifanele ukusetshenziswa komthwalo omaphakathi.

Iphuzu elincibilikayo le-alloy yesiliva-yethusi yi-670820. Ukushisa kwayo okuphezulu okusebenzayo yi-400 degrees. Kodwa-ke, ilungele ukushisela amathuluzi okuguqula ukunemba nge-cobalt ephansi noma i-titanium carbide ephezulu.

Izinga le-brazing lithinteka kakhulu ekukhethweni nasekusetshenzisweni kwe-flux. I-flux isetshenziselwa ukususa ama-oxide ebusweni bomsebenzi ozokwenziwa nge-brazed, ukwandisa ukumanzi nokuvikela i-weld kusuka ku-oxidation. Ama-fluxes amabili asetshenziselwa ukubopha amathuluzi e-carbide: i-Borax Na2B4O2 ephelelwe amanzi emzimbeni noma i-Borax ephelelwe amanzi engu-25% (i-massfraction) + i-boric Acid 75% (i-massfraction). Amazinga okushisa e-Brazing asukela ku-800 kuya ku-1000degC. I-Borax ingancibilika ngokuncibilikisa i-borax, bese iyichoboza ngemva kokupholisa. Hlunga. Uma ubhula amathuluzi e-YG, i-borax engenamanzi ngokuvamile iba ngcono. Ungakwazi ukuzuza imiphumela egculisayo uma ubhula amathuluzi e-YT usebenzisa ifomula ye-borax ephelelwe amanzi emzimbeni (massfraction) 50% + boric (massfraction) 35% + dehydrated potassium (massfraction) fluoride (15%).

Ukwengezwa kwe-potassium fluoride kuzothuthukisa ukumanzisa kanye nekhono lokuncibilika kwe-titanium carbide. Ukuze kuncishiswe ingcindezi yokushisela lapho ubhusa ama-alloys e-titanium ephezulu (YT30 kanye ne-YN05), izinga lokushisa eliphansi eliphakathi kuka-0.1 no-0.5mm livame ukusetshenziswa. Njenge-gasket yesinxephezelo phakathi kwama-blades nabaphathi bamathuluzi, i-carbon steel noma i-iron-nickel ivame ukusetshenziswa. Ukunciphisa ukucindezeleka okushisayo, i-blade kufanele ifakwe insulated. Ngokuvamile ithuluzi lokuguqula lizofakwa esithandweni esinezinga lokushisa elingu-280 ° C. Faka i-insulate amahora amathathu ku-320degC, bese upholisa kancane kancane esithandweni, noma ku-asbestos noma ku-straw ash powder.

(4) Ukuxhumana okungaphili

Ukuhlanganiswa kwe-Inorganic kusebenzisa isisombululo se-phosphoric kanye nempushana yethusi ye-inorganic, ehlanganisa amakhemikhali, izinsimbi, kanye ne-physics kuma-bond blades. I-inorganic bonding kulula ukuyisebenzisa kunokubhula futhi akubangeli ukucindezeleka kwangaphakathi noma ukuqhekeka kwe-blade. Le ndlela ilusizo ikakhulukazi ezintweni ze-blade okunzima ukuzishisela, njengezitsha zobumba.

Imisebenzi yesici kanye namacala angokoqobo omshini

4. Ukukhetha i-engeli yokuthambekela konqenqema nokusika kwe-bevel

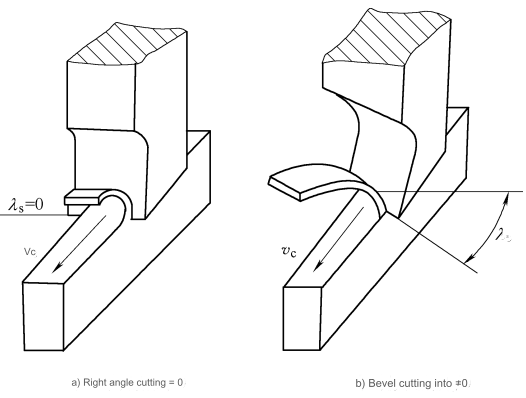

(1) Ukusika kwe-bevel umqondo osunesikhathi eside ukhona.

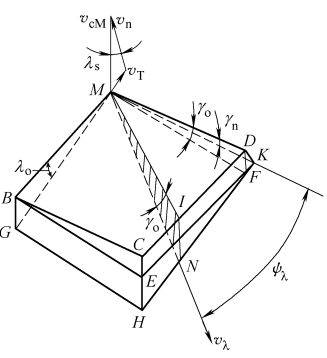

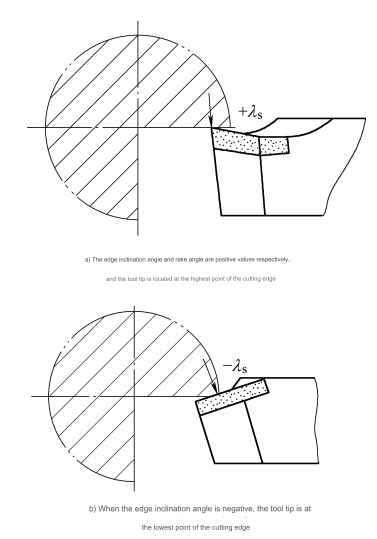

Ukusika i-engeli yesokudla kuwukusika lapho i-blade yokusika yethuluzi ihambisana nendlela ukunyakaza okuzoyithatha. Ukusika kwe-bevel yilapho umkhawulo wokusika wethuluzi ungekho perpendicular nesiqondiso sokunyakaza kokusika. Ukuze kube lula, umphumela wokuphakelayo ungashaywa indiva. Ukusika okuyi-perpendicular ngesivinini esikhulu sokunyakaza noma ama-engeli okuthambekela onqenqemeni lss=0 kuthathwa njengokusika i-engeli engakwesokudla. Lokhu kuboniswe kuMfanekiso 3-9. Ukusika okungahambisani ne-perpendicular ngesivinini esikhulu sokunyakaza noma ama-engeli e-edge inclination lss0, kubizwa ngokuthi i-oblique angle-cutting. Isibonelo, Njengoba kukhonjisiwe kuMfanekiso 3-9.b, uma kunqunywa unqenqema olulodwa kuphela, lokhu kwaziwa njengokusika kwamahhala. Ukusika i-bevel kuvame kakhulu ekusikeni kwensimbi.

Umfanekiso 3-9 Ukusika i-engeli yesokudla nokusika i-bevel

(2) Ithonya lokusika kwe-bevel kwinqubo yokusika

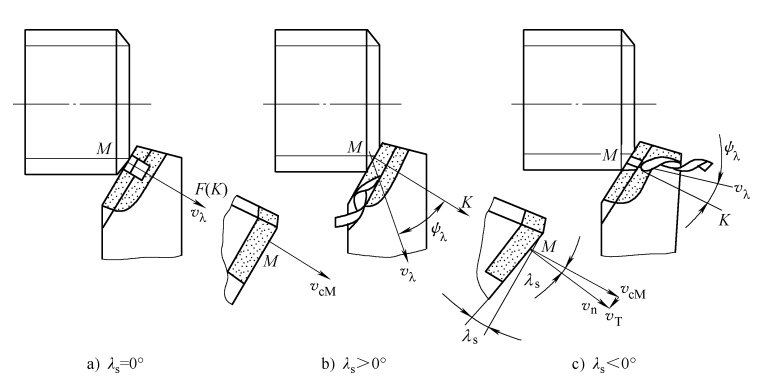

1. Ithonya isiqondiso sokuphuma kwe-chip

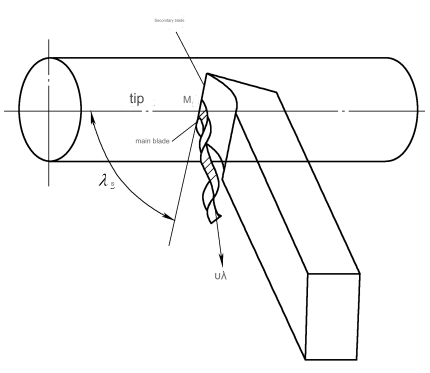

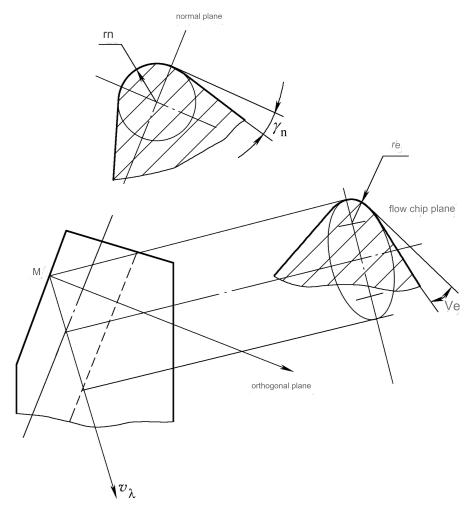

Umfanekiso 3-10 ubonisa ukuthi ithuluzi lokujika langaphandle lisetshenziselwa ukuvula ukufaka ipayipi. Lapho kuphela umkhawulo oyinhloko wokusika ubamba iqhaza ekusikeni, inhlayiya engu-M engqimbeni yokusika (kucatshangwa ukuthi ilingana nobude obuphakathi nendawo) iba yi-chip ngaphansi kwe-extrusion phambi kwethuluzi futhi igeleza iphumele ngaphambili. Ubudlelwano phakathi kwesiqondiso sokugeleza kwe-chip kanye ne-engeli yokuthambekela konqenqema ukunqamula umzimba weyunithi we-MBCDFHGM ngendiza ye-orthogonal kanye nendiza yokusika kanye nezindiza ezimbili ezihambisana nazo ngephuzu elingu-M.

Umfanekiso 3-10 Umthelela we-λs ekuqondeni kwe-chip chip

I-MBCD iyindiza eyisisekelo kuMfanekiso 3-11. Lapho ls=0, i-MBEF ingaphambili kuMfanekiso 3-11, futhi indiza ye-MDF iyindiza ye-orthogonal nevamile. Iphoyinti M manje seliyi-perpendicular onqenqemeni lokusika. Lapho ama-chips ekhishwa, i-M iyingxenye yesivinini eduze konqenqema lokusika. I-MF ihambisana ne-perpendicularly ne-cutting edge. Njengoba kuboniswe kuMfanekiso 3-10a, kuleli qophelo, ama-Chips agobile abe yisimo esifana nentwasahlobo noma ageleza ngomugqa oqondile. Uma i-ls inenani elihle khona-ke indiza ye-MGEF ingaphambili futhi ukunyakaza okuyinhloko kokusika isivinini i-vcM ayihambisani ne-MG enqenqemeni. I-particle M velocityizingxenye zokuguqula i-cncI-vT ehlobene nethuluzi elibheke ezindaweni zokusika ezibheke ku-MG. Uma iphoyinti M liguqulwa libe yi-chip egeleza ngaphambili futhi ithintwa i-vT isivinini se-chip sizochezuka endizeni evamile i-MDK nge-chip angle ye-psl. Uma i-ls inenani elikhulu, ama-chips azogeleza aye lapho kucutshungulwa khona indawo.

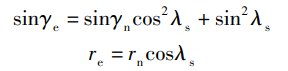

Indiza MIN, njengoba kukhonjisiwe ku-Figure 3-10b kanye no-3-11, yaziwa njengokugeleza kwe-chip. Uma i-ls inevelu elinegethivu ingxenye yesivinini i-vT ekuqondeni konqenqema iyahlehliswa, ikhomba ku-GM. Lokhu kubangela ukuthi ama-chips ahluke endizeni evamile. Ukugeleza kubheke kolunye uhlangothi olubheke ebusweni bomshini. Njengoba kukhonjisiwe kuMfanekiso 3-10.c. Le ngxoxo imayelana nomthelela we-ls ngesikhathi sokusika mahhala. Ukugeleza kwepulasitiki kwensimbi ethiphu yethuluzi, unqenqema oluncane lokusika, kanye ne-chip groove konke kuzoba nomthelela ekuqondeni kokuphuma kwama-chips phakathi nenqubo yomshini wangempela yokuphendula imibuthano yangaphandle. Umfanekiso 3-12 ubonisa ukuthintwa kwezimbobo nezimbobo ezivaliwe. Umthelela wokuthambekela konqenqema ekugelezeni kwe-chip. Uma uthepha uchungechunge olungenambobo, inani elithi ls liphozithivu, kodwa uma uthepha eyodwa ngembobo, inani elingaphansi.

Umfanekiso 3-11 I-Oblique cutting chip flow direction

2. Ireki yangempela kanye ne-obtuse radii kuyathinteka

Uma ls = 0, ekusikeni kwamahhala, ama-engeli e-rake endizeni ye-orthogonal kanye nendiza yokugeleza kwe-chip acishe alingane. Uma i-ls ingeyena uziro, ingathinta ngempela ukucija konqenqema nokumelana nokungqubuzana lapho ama-chips ephushelwa ngaphandle. Endizeni yokugeleza kwe-chip, ama-engeli e-rake asebenzayo kanye ne-cutting edge obtuse radii re kufanele kukalwe. Umfanekiso 3-13 uqhathanisa ijiyomethri yendiza evamile edlula endaweni engu-M yonqenqema oluyinhloko ne-obtuse radii re yendiza yokugeleza kwe-chip. Endabeni yomkhawulo obukhali, indiza evamile ibonisa i-arc eyakhiwe yi-obtuse radius rn. Kodwa-ke, kuphrofayili yokugeleza kwe-chip, ukusika kuyingxenye ye-ellipse. Irediyasi yokugoba eduze kwe-eksisi ende iyindawo yangempela yokusika i-obtuse radius re. Ifomula elandelayo elinganiselwe ingabalwa kusukela kuzibalo zobudlelwane bejiyomethri kuFigure 3-11 kanye no-3-13.

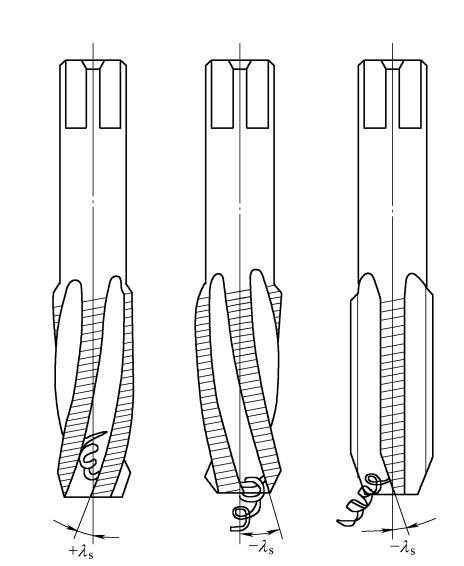

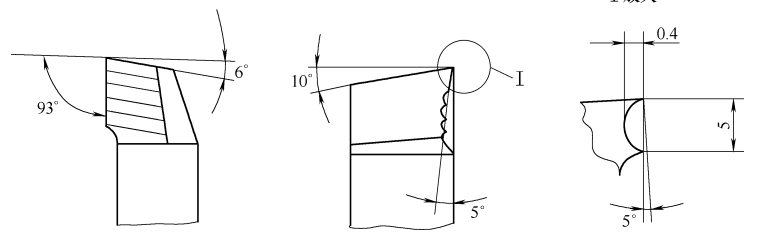

Ifomula engenhla ibonisa ukuthi kabusha liyakhuphuka njengoba inani eliphelele ls likhuphuka, kuyilapho u-ge encipha. Uma ls=75deg, kanye ne-gn=10deg eno-rn=0.020.15mm khona-ke i-ge ingaba mkhulu njengo-70deg. futhi kungaba kuncane njengo-0.0039mm. Lokhu kwenza unqenqema lokusika lubukhali kakhulu, futhi lungafinyelela ukusika okuncane (ap0.01mm) ngokusebenzisa inani elincane lokusika emuva. Umfanekiso 3-14 ubonisa indawo yokusika yethuluzi langaphandle lapho i-ls isethwe ku-75deg. Imiphetho eyinhloko neyesibili yethuluzi iqondiswe ngendlela eqondile. Umphetho wethuluzi ubukhali ngokwedlulele. Unqenqema lokusika alulungisiwe ngesikhathi sokusika. Iphinde ibe yi-tangent ne-outer cylindrical surface. Ukufaka nokulungisa kulula. Ithuluzi lisetshenziswe ngempumelelo ekuqedeni ukujika kwe-carbon steel ngesivinini esikhulu. Ingase futhi isetshenziselwe ukuqedela ukucubungula izinto ezisebenza kanzima emshinini njengensimbi enamandla amakhulu.

Umfanekiso 3-12 Umthelela we-engeli yokuthambekela konqenqemeni ekuqondeni kokugeleza kwe-chip ngesikhathi sokuthinta intambo

Umfanekiso 3-13 Ukuqhathaniswa kwamajometri we-rn kanye ne-re

3. Ukuphikiswa komthelela namandla wethiphu yethuluzi kuyathinteka

Uma i-ls inegethivu, njengoba kukhonjisiwe kuMfanekiso 3-15b, ithiphu lethuluzi lizoba yiphuzu eliphansi kunawo wonke onqenqemeni lokusika. Lapho imiphetho ukusika singeneizingxenye ze-prototypeiphuzu lokuqala lomthelela nge-workpiece yi-tooltip (uma ukuhamba kunenani elihle) noma ngaphambili (uma kunegeji) Lokhu akuvikeli kuphela futhi kuqinise ithiphu, kodwa futhi kusiza ukunciphisa ingozi yokulimala. Amathuluzi amaningi ane-rake angle enkulu asebenzisa ukuthambekela konqenqema olunegethivu. Zombili zingathuthukisa amandla futhi zinciphise umthelela ethiphu yethuluzi. I-back force Fp iyanda kuleli phuzu.

Umfanekiso 3-14 Ithuluzi elikhulu lokujika i-engeli ye-blade ngaphandle kwethiphu engashintshi

4. Kuthinta ukuzinza kokusika ngaphakathi nangaphandle.

Uma i-ls = 0, umkhawulo wokusika unqamula ngaphakathi nangaphandle kwendawo yokusebenza cishe ngesikhathi esisodwa, amandla okusika ashintsha ngokuzumayo, futhi umthelela mkhulu; lapho i-ls ingeyona i-zero, umkhawulo wokusika usika kancane kancane ungene futhi uphume ku-workpiece, umthelela mncane, futhi ukusika kuyashelela. Isibonelo, izisiki ezinkulu ze-helix angle cylindrical milling kanye nezigayo zokuphela zinemiphetho yokusika ebukhali kanye nokusika okushelelayo kunezisiki ezindala zokugaya ezijwayelekile. Ukusebenza kahle kokukhiqiza kukhuphuka izikhathi ezi-2 kuye kweziyi-4, futhi inani lobunzima obungaphezulu kuka-Ra lingafinyelela ngaphansi kuka-3.2 mm.

5. Ukusika ukuma onqenqemeni

Ukuma konqenqema lwethuluzi kungenye yezinto eziyisisekelo zemingcele yejometri enengqondo yethuluzi. Izinguquko ekubunjweni kwe-blade yethuluzi zishintsha iphethini yokusika. Okubizwa ngokuthi iphethini yokusika ibhekisela ekuhleleni nasekubunjweni lapho ungqimba lwensimbi oluzocutshungulwa lususwa khona ngokusika. Kuthinta usayizi womthwalo osemaphethelweni, izimo zokucindezelwa, impilo yamathuluzi kanye nekhwalithi yendawo esebenza ngomshini. linda. Amathuluzi amaningi athuthukile ahlobene eduze nokukhethwa okunengqondo komumo we-blade. Phakathi kwamathuluzi asebenzayo athuthukile, izimo ze-blade zingafingqwa zibe izinhlobo ezilandelayo:

(1) Thuthukisa ukuma kwe-blade onqenqemeni lokusika. Lesi simo se-blade ngokuyinhloko ukuqinisa amandla onqenqemeni lokusika, ukwandisa i-angle enqenqemeni yokusika, ukunciphisa umthwalo kubude beyunithi yomkhawulo wokusika, nokuthuthukisa izimo zokushisa ukushisa. Ngaphezu komumo wethiphu wamathuluzi amaningana aboniswe kuMfanekiso 3-8, kukhona futhi umumo we-arc onqenqemeni (amathuluzi okuguqula unqenqema lwe-arc, ama-arc edge hobbing face milling cutters, ama-arc edge drill bits, njll.), ama-engeli amaningi abukhali ama-edge (izingcezu zokubhoboza , njll.) )linda;

(2) Isimo sonqenqema esinciphisa indawo esele. Lesi simo sonqenqema sisetshenziselwa ikakhulukazi amathuluzi okuqedela, njengamathuluzi amakhulu okuphendukisa okuphakelayo kanye nezisiki zokugaya ubuso ezinama-wiper, amathuluzi antantayo ayisicefe namathuluzi ajwayelekile ayisicefe anama-wiper angamacylindrical. Ama-Reamers, njll.;

Umfanekiso 3-15 Umthelela we-engeli yokuthambekela konqenqemeni endaweni yomthelela lapho ithuluzi lokusika

(3) Isimo se-blade esabalalisa ngokunengqondo imajini yesendlalelo esisikiwe futhi sikhiphe ama-chips ngokushelela. Isici salolu hlobo lwe-blade shape ukuthi luhlukanisa ungqimba olubanzi noluncane lokusika lube ngama-chips ambalwa amancane, angavumeli nje kuphela ukuthi ama-chips akhululwe kahle, kodwa futhi akhulise izinga lokuhamba phambili. Nikeza inani futhi unciphise amandla okusika iyunithi. Isibonelo, uma kuqhathaniswa nemimese yokusika enqenqemeni evamile, imimese yokusika enezinyathelo ezimbili ihlukanisa unqenqema oluyinhloko lube izingxenye ezintathu, njengoba kuboniswe kuMfanekiso 3-16. Ama-chips nawo ahlukaniswe abe yimichilo emithathu ngokufanele. Ukungqubuzana phakathi kwama-chips nezindonga ezimbili kuyancishiswa, okuvimbela ama-chips ukuthi angavinjelwa futhi kunciphisa kakhulu amandla okusika. Njengoba ukujula kokusika kukhuphuka, izinga lokuncipha liyakhula, futhi umphumela uba ngcono. Ngesikhathi esifanayo, izinga lokushisa lokusika liyancishiswa futhi impilo yamathuluzi iyathuthukiswa. Kunamathuluzi amaningi alolu hlobo lomumo we-blade, njengabasiki bezinyathelo zokugaya, abasiki begayo abahlelekile, ama-saha onqenqema anyakazayo, izingcezu ze-chip drill, izinqamuleli zokugaya ummbila wezinyo, nezigayo zokuphela kwegagasi. Futhi ama-broaches anqunywe ngamasondo, njll.;

Umfanekiso 3-16 Ummese wokusika onyathelwe kabili onqenqemeni

(4) Ezinye izimo ezikhethekile. Izimo ezikhethekile ze-blade ziyizimo ze-blade eziklanyelwe ukuhlangabezana nezimo zokucubungula zengxenye kanye nezici zayo zokusika. Umfanekiso 3-17 ukhombisa umumo webhodi lokuwasha langaphambili elisetshenziselwa ukucubungula ithusi lomthofu. Ingxenye eyinhloko yokusika yale blade yakheke ngamakhothamo angama-three-dimensional amaningi. Iphuzu ngalinye onqenqemeni lokusika line-engeli yokuthambekela ekhuphuka isuka ku-negative, iye ku-zero bese iye kuphozithivu. Lokhu kudala ukuthi imfucumfucu ikhishwe ibe ngama-chips amise okweribhoni.

I-Anebon alyways isekela ifilosofi ethi "Yiba nguNo.1 kukhwalithi ephezulu, isekelwe ekweletini nokwethembeka ekukhuleni". I-Anebon izoqhubeka nokunikeza amathuba angaphambilini namasha asekhaya naphesheya kwezilwandle ngokushisa okugcwele kwe-Ordinary Discount 5 Axis Precision Custom Rapid Prototype5 i-axis cnc millingI-Turning Machining, E-Anebon enekhwalithi ephezulu ukuqala ngayo njengesiqubulo sethu, sikhiqiza imikhiqizo eyenziwe ngokuphelele e-Japan, kusukela ekuthengeni izinto kuya ekucutshungulweni. Lokhu kuvumela amakhasimende avela ezweni lonke ukuthi asetshenziswe ngokuthula kwengqondo.

Izinqubo zokwenziwa zaseShayina, izinsizakalo zokugaya insimbi kanye nesevisi ye-prototyping esheshayo. I-Anebon ibheka “amanani aphansi, isikhathi sokukhiqiza esisebenzayo kanye nesevisi enhle yangemva kokuthengisa” njengemfundiso yethu. I-Anebon inethemba lokubambisana namakhasimende amaningi ukuze kuthuthukiswe nokuzuza. Siyabamukela abangaba abathengi ukuthi baxhumane nathi.

Isikhathi sokuthumela: Dec-14-2023