Uyazi ukuthi yiziphi izinkambu ezidinga ukunemba okuphezulu kwezingxenye eziwumshini?

I-Aerospace:

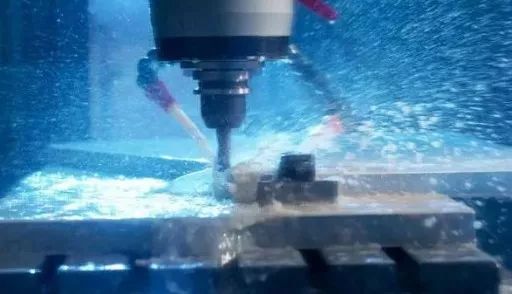

Izingxenye zomkhakha we-Aerospace njengama-turbine blades noma izingxenye zendiza zidinga umshini ngokunemba okuphezulu, futhi ngaphakathi kokubekezelelana okuqinile. Lokhu kwenzelwa ukuqinisekisa ukusebenza nokuphepha. I-jet engine blade, isibonelo, ingadinga ukunemba ngaphakathi kwama-microns ukuze kugcinwe ukusebenza kahle kwamandla nokugeleza komoya.

Imishini yezokwelapha:

Ukuqinisekisa ukuphepha nokuhambisana, zonke izingxenye ezikhishelwa izisetshenziswa zezokwelapha ezifana nezinsimbi zokuhlinza noma izinto ezifakelwayo kufanele zinembile. Ukufakelwa kwamathambo ngokwezifiso, isibonelo, kungase kudinge ubukhulu obunembile kanye nokuqedwa phezulu ukuze kuqinisekiswe ukulingana okufanele nokuhlanganiswa emzimbeni.

Ezezimoto:

Embonini yezimoto, ukunemba kuyadingeka ezingxenyeni ezinjengokudlulisa kanye nezingxenye zenjini. Igiya lokudlulisela elinomshini onembile noma isijojo sikaphethiloli singase sidinge ukubekezelela okuqinile ukuze kuqinisekiswe ukusebenza okufanele nokuqina.

Ezogesi:

Izingxenye ezakhiwe ngomshini embonini yezogesi zidingeka ukuthi zinembe kakhulu ngezidingo ezithile zokuklama. Izindlu ezincane ezisebenza ngomshini onembile zingadinga ukubekezelelana okuqinile ukuze kulungiswe kahle nokusabalalisa ukushisa.

Amandla avuselelekayo:

Ukwandisa ukukhiqizwa kwamandla, kanye nokuqinisekisa ukwethembeka, izingxenye ezinomshini kubuchwepheshe obuvuselelekayo njengezikhwezi zephaneli yelanga noma izingxenye ze-turbine yomoya zidinga ukunemba. Isistimu yegiya ye-turbine yomoya eyenziwe ngokunemba ingase idinge amaphrofayili wamazinyo aqondile nokuqondanisa ukuze kukhuliswe ukusebenza kahle kokuphehla amandla.

Kuthiwani ngezindawo lapho ukunemba kwezingxenye eziwumshini kungadingeki kakhulu?

Ukwakha:

Ezinye izingxenye, njengezixhumi nezakhi zesakhiwo, ezisetshenziswa kumaphrojekthi wokwakha, zingase zingadingi ukunemba okufanayo njengezingxenye zemishini ebalulekile noma izingxenye ze-aerospace. Abakaki bensimbi kumaphrojekthi wokwakha bangase bangadingi ukubekezelelwa okufanayo njengezingxenye ezinemba emishinini enembayo.

Ukukhiqiza Ifenisha:

Ezinye izingxenye zokwenziwa kwefenisha, njenge-trim yokuhlobisa, abakaki noma i-hardware, akudingeki ukuba zibe nezinemba kakhulu. Ezinye izingxenye, njengezingxenye zomshini onembile ezindleleni zefenisha ezilungisekayo ezidinga ukunemba, zinokubekezelela okuxolelayo okwengeziwe.

Izisetshenziswa zokusetshenziswa kwezolimo:

Izingxenye ezithile zemishini yezolimo njengabakaki, izisekelo noma amakhava okuvikela kungase kungadingeki ukuba kubanjwe ngaphansi kokubekezelelana okuqine kakhulu. Ubakaki osetshenziselwa ukukhweza ingxenye yezinto zokusebenza ezinganemba kungenzeka ungadingi ukunemba okufanayo nezingxenye zemishini yezolimo enembayo.

Ukunemba kokucubungula yizinga lokuvumelana kosayizi wendawo, umumo kanye nendawo kumapharamitha wejiyomethri acaciswe emdwebeni.

Usayizi ojwayelekile uyipharamitha yejometri efanelekile ngosayizi.

Ijometri engaphezulu iyindilinga, isilinda noma indiza. ;

Kungenzeka ukuthi kube nezindawo ezihambisanayo, i-perpendicular noma i-coaxial. Iphutha lomshini umehluko phakathi kwamapharamitha wejiyomethri wengxenye kanye nemingcele yawo efanelekile yejometri.

1. Isingeniso

Inhloso eyinhloko yokunemba komshini ukukhiqiza imikhiqizo. Kokubili ukunemba komshini namaphutha omshini amagama asetshenziselwa ukuhlola amapharamitha wejiyomethri wendawo esebenza ngomshini. Ibanga lokubekezelela lisetshenziselwa ukukala ukunemba kwemishini. Ukuphakama kokunemba, kubancane ibanga. Iphutha lomshini lingavezwa njengenani lenombolo. Uma inani lenombolo likhulu liba likhulu iphutha. Ngokuphambene, ukunemba okuphezulu kokucubungula kuhlotshaniswa namaphutha amancane okucubungula. Kunamazinga angama-20 okubekezelela, asukela ku-IT01 kuya ku-IT18. I-IT01 izinga lokunemba komshini eliphezulu kakhulu, i-IT18 ephansi kakhulu, futhi i-IT7 ne-IT8 ngokuvamile zingamazinga anokunemba okumaphakathi. izinga.

Akwenzeki ukuthola amapharamitha aqondile ngokusebenzisa noma iyiphi indlela. Uma nje iphutha lokucubungula liwela phakathi kwebanga lokubekezelelana elicaciswe ingxenye yomdwebo futhi lingelikhulu kunomsebenzi wengxenye, ukunemba kokucubungula kungabhekwa njengokuqinisekisiwe.

2. Okuqukethwe Okuhlobene

Ukunemba kobukhulu:

Indawo yokubekezelela indawo lapho ubukhulu bengxenye yangempela kanye nendawo ephakathi nendawo yokubekezelela ilingana.

Ukunemba komumo:

Izinga lapho umumo wejiyomethri wobuso bengxenye emshinini ufana nefomu lejometri elifanele.

Ukunemba kwesikhundla:

Umehluko ekunembeni kwendawo phakathi kwezingxenye ezicutshungulwayo.

Ubudlelwano:

Lapho uklama izingxenye zomshini futhi ucacisa ukunemba kwawo kwemishini, kubalulekile ukulawula iphutha lomumo ngokubekezelela isikhundla. Iphutha lendawo kufanele futhi libe lincane kunokubekezela kobukhulu. Ngezingxenye ezinembayo nezindawo ezibalulekile, izimfuneko zokunemba komumo kufanele zibe phezulu.

3. Indlela Yokulungisa

1. Ukulungiswa kwesistimu yokucubungula

Ukulungiswa kwendlela yokusika isivivinyo: Kala usayizi, lungisa inani lokusika lethuluzi bese usika. Phinda uze ufinyelele usayizi oyifunayo. Le ndlela isetshenziswa ikakhulukazi ekukhiqizeni inqwaba encane kanye nesiqephu esisodwa.

Indlela yokulungisa: Ukuze uthole usayizi owufunayo, lungisa izindawo ezihambisanayo zethuluzi lomshini, isihluthulelo kanye nesiqeshana sokusebenza. Le ndlela ikhiqiza kakhulu futhi isetshenziswa kakhulu ekukhiqizeni ngobuningi.

2. Yehlisa amaphutha ethuluzi lomshini

1) Thuthukisa ukunemba kokukhiqizwa kwengxenye ye-spindle

Ukunemba kokujikeleza kwe-bearing kufanele kuthuthukiswe.

1 Khetha ama-bearings anembe kakhulu;

2 Sebenzisa ama-dynamic bearings anezingqimba ezinamafutha amaningi anembayo.

3 Ukusebenzisa ukunemba okuphezulu kwe-hydrostatic bearings

Kubalulekile ukuthuthukisa ukunemba kwezesekeli zokuzala.

1 Thuthukisa ukunemba kwejenali yokuphotha kanye nezimbobo zokusekela amabhokisi;

2 Thuthukisa ukunemba kokumataniswa kobuso ne-bearing.

3 Linganisa futhi ulungise ububanzi be-radial bezingxenye ukuze unciphise noma unxephezele amaphutha.

2) Layisha kuqala ama-bearings ngendlela efanele

1 Ingakwazi ukuqeda izikhala;

2 Khulisa ukuthwala ukuqina

3 Iphutha lesici sokugoqa esilinganayo.

3) Gwema ukubonakaliswa kokunemba kwe-spindle ku-workpiece.

3. Amaphutha ochungechunge lokudlulisela: Anciphise

1) Ukunemba kokudlulisela kanye nenani lezingxenye ziphezulu.

2) Isilinganiso sokudlulisela sincane uma ipheya yokudlulisela isiseduze nokuphela.

3) Ukunemba kocezu lokugcina kufanele kube kukhulu kunezinye izingxenye zokudlulisela.

4. Yehlisa Ukugqoka Kwamathuluzi

Amathuluzi okulola kabusha ayadingeka ngaphambi kokuba afinyelele esigabeni sokuguga okunzima.

5. Yehlisa ukuguqulwa kokucindezeleka ohlelweni lwenqubo

Ikakhulukazi evela ku:

1) Khulisa ukuqina namandla ohlelo. Lokhu kufaka phakathi izixhumanisi ezibuthakathaka zesistimu yenqubo.

2) Yehlisa umthwalo kanye nokuhluka kwawo

Khulisa ukuqina kwesistimu

1 Idizayini yesakhiwo enengqondo

1) Ngangokunokwenzeka, nciphisa inani lezindawo ezixhumekayo.

2) Vimbela izixhumanisi zendawo zokuqina okuphansi;

I-3) Izingxenye eziyisisekelo nezinto ezisekelayo kufanele zibe nesakhiwo esinengqondo kanye nesigaba esiphambene.

2 Thuthukisa ukuqina kokuxhumana endaweni yokuxhumana

1) Thuthukisa ikhwalithi nokuvumelana kwezindawo ezihlanganisa izingxenye ndawonye ezingxenyeni zamathuluzi omshini.

2) Ukulayisha kuqala izingxenye zethuluzi lomshini

3) Khulisa ukunemba kokuma kwe-workpiece futhi unciphise ama-roughness ebusweni.

3 Ukwamukela izindlela zokuphoqa ezinengqondo kanye nezindlela zokuma

Yehlisa umthwalo nemiphumela yawo

1 Khetha ipharamitha yejiyomethri yethuluzi kanye nenani lokusika ukuze unciphise amandla okusika.

2 Izikhala ezingenalutho kufanele zihlanganiswe ndawonye futhi imvume yokuyicubungula kufanele ifane nokulungiswa.

6. Ukuguqulwa okushisayo kwesistimu yenqubo kungancishiswa

1 Hlukanisa imithombo yokushisa futhi unciphise ukukhiqizwa kokushisa

1) Sebenzisa inani elincane lokusika;

2) Hlukanisa ama-roughing kanye nokuqeda niniizingxenye zokugayazidinga ukunemba okuphezulu.

3) Ngokusemandleni akho, hlukanisa umthombo wokushisa kanye nomshini ukuze unciphise ukuwohloka kokushisa.

4) Uma imithombo yokushisa ingenakuhlukaniswa (njengama-spindle bearings noma ama-screw nut pairs), thuthukisa izakhiwo zokungqubuzana kusuka kusakhiwo, okokugcoba nezinye izici, ukunciphisa ukukhiqizwa kokushisa, noma sebenzisa izinto ezibamba ukushisa.

5) Sebenzisa ukupholisa umoya ngempoqo noma ukupholisa amanzi kanye nezinye izindlela zokuqeda ukushisa.

2 Inkambu yokushisa yokulinganisa

3 Yamukela izindinganiso ezifanele zokuhlanganisa nesakhiwo sengxenye yethuluzi lomshini

I-1) Ukwamukela ukwakheka kwe-thermal-symmetrical ku-gearbox - ama-shaft ahlela ngokulinganayo, ama-bearings kanye namagiya okudlulisela kunganciphisa ukukhubazeka kwebhokisi ngokuqinisekisa ukuthi izinga lokushisa lodonga lwebhokisi lifana.

2) Khetha izinga lokuhlanganisa lamathuluzi omshini ngokucophelela.

4 Sheshisa ibhalansi yokudlulisa ukushisa

5 Lawula izinga lokushisa le-ambient

7. Yehlisa ukucindezeleka okusalayo

1. Engeza inqubo yokushisa ukuze uqede ukucindezeleka ngaphakathi komzimba;

2. Hlela inqubo yakho ngendlela efanele.

4. Izizathu zethonya

1 Iphutha lomgomo womshini

Igama elithi "iphutha lesimiso somshini" libhekisela ephutheni elenzeka lapho ukwenziwa kwemishini kwenziwa kusetshenziswa iphrofayili eseduze yonqenqema, noma ubudlelwano bokudlulisa. Ukwenziwa kwezindawo eziyinkimbinkimbi, izintambo kanye namagiya kungabangela iphutha lomshini.

Ukuze kube lula ukuyisebenzisa, esikhundleni sokusebenzisa isibungu esiyisisekelo se-involute, isibungu esiyisisekelo se-Archimedean noma iphrofayili evamile eyisisekelo isetshenziswa. Lokhu kubangela amaphutha ekumeni kwezinyo.

Lapho ukhetha igiya, inani lika-p lingalinganiselwa kuphela (p = 3.1415) ngenxa yokuthi kunenani elilinganiselwe kuphela lamazinyo ku-lathe. Ithuluzi elisetshenziselwe ukwenza i-workpiece (ukunyakaza kwe-spiral), ngeke libe nembayo. Lokhu kuholela ephutheni lephimbo.

Ukucubungula kuvame ukwenziwa ngokucutshungulwa okulinganiselwe ngaphansi kokucatshangwa ukuthi amaphutha etiyetha angancishiswa ukuze kuhlangatshezwane nezidingo zokunemba kokucubungula (ukubekezelela ngo-10% -15% kubukhulu) ukuze kwandiswe ukukhiqiza nokunciphisa izindleko.

2 iphutha lokulungisa

Uma sithi ithuluzi lomshini linokulungiswa okungalungile, sisho iphutha.

3 Iphutha lomshini

Igama elithi iphutha lethuluzi lomshini lisetshenziselwa ukuchaza iphutha lokukhiqiza, iphutha lokufaka, nokuguga kwethuluzi. Lokhu kubandakanya ikakhulukazi amaphutha omhlahlandlela kanye nokuzungezisa wesitimela esiqondisa ithuluzi lomshini kanye nephutha lokudlulisa ochungechungeni lokuhambisa ithuluzi lomshini.

Iphutha lomhlahlandlela womshini

1. Ukunemba kwesiqondiso sesitimela esiqondisayo - umehluko phakathi kokunyakaza kwezingxenye ezihambayo kanye nesiqondiso esifanele. Kuhlanganisa:

Umhlahlandlela ulinganiswa ngobuqotho be-Dy (indiza evundlile) kanye ne-Dz (indiza eqondile).

2 Ukufana kwamareyili angaphambili nangemuva (ukuhlanekezela);

(3) Amaphutha okuphakama noma okuhambisana phakathi kokuphenduka okuphothayo kanye nomzila wesitimela kuzo zombili izindiza ezivundlile nezime mpo.

2. Ukunemba komhlahlandlela wesitimela kunomthelela omkhulu ekusikeni imishini.

Lokhu kungenxa yokuthi kucabangela ukugudluzwa okuhlobene phakathi kwethuluzi nesiqeshana somsebenzi okubangelwa iphutha lesitimela somhlahlandlela. Ukuphenduka kuwumsebenzi wokujika lapho isiqondiso esivundlile sizwela iphutha. Amaphutha ezikhombisi-ndlela eziqondile angazitshwa. Isiqondiso sokuzungezisa sishintsha isiqondiso lapho ithuluzi lizwela khona iphutha. Isiqondiso esime mpo isiqondiso esizwela kakhulu amaphutha lapho uhlela. Ukuqonda kwemihlahlandlela yokulala endizeni eqondile inquma ukunemba kokucaba kanye nokuqondile kwezindawo ezisebenza ngomshini.

Iphutha lokuzungezisa ithuluzi lomshini

Iphutha lokuzungezisa i-spindle liwumehluko phakathi kwe-eksisi yangempela nelungile yokuzungezisa. Lokhu kufaka i-spindle face circular, spindle circular radial kanye ne-spindle angle tilt.

1, Umthelela we-spindle runout circular ekucubunguleni ukunemba.

① Awukho umthelela wokwelashwa kwendawo eyicylindrical

② Izodala iphutha le-perpendicularity noma flatness phakathi kwe-cylindrical axis kanye ne-endface lapho uyijika futhi uyibhora.

③ Iphutha lomjikelezo we-pitch likhiqizwa lapho imicu yenziwa ngomshini.

2. Umthelela we-spindle radial usebenza ngokunemba:

① Iphutha eliyindingilizi lendingilizi ye-radial likalwa nge-runout amplitude yembobo.

② Irediyasi yesiyingi ingabalwa kusukela ekugcineni kwethuluzi kuya kushafti evamile, kungakhathaliseki ukuthi i-shaft iyaphendulwa noma ibhorekile.

3. Umthelela we-engeli yokutsheka ye-eksisi ye-shaft yejiyomethri eyinhloko ekunembeni komshini

① I-eksisi yejiyomethri ihlelwa ngendlela eyikhonikhi ene-engeli yekhoni, ehambisana nokunyakaza kwe-eccentric eduze kwe-axis ye-axis yejometri uma ibukwa esigabeni ngasinye. Leli nani le-eccentric liyahluka kulelo lombono we-axial.

② I-eksisi iyijiyomethri eshwibeka endizeni. Lokhu kuyafana ne-eksisi yangempela, kodwa ihamba endizeni ngomugqa oqondile we-harmonic.

③ Eqinisweni, i-engeli ye-eksisi yejiyomethri yeshaft eyinhloko imelela inhlanganisela yalezi zinhlobo ezimbili zokushwiba.

Iphutha lokudlulisa lochungechunge lokudlulisa amathuluzi omshini

Iphutha lokudlulisela umehluko phakathi kokunyakaza okuhlobene phakathi kwento yokuqala yokudlulisela kanye nengxenye yokugcina yochungechunge lokudlulisela.

④ Iphutha lokukhiqiza nokuguga endaweni

Iphutha elikhulu ku-fixture yileli: 1) iphutha lokukhiqiza lesici sokuma nezinto eziqondisayo zethuluzi, kanye nendlela yokukhomba nokhonkolo wokugoqa. 2) Ngemva kokuhlanganiswa kwesakhiwo, iphutha losayizi abahlobene phakathi kwalezi zingxenye ezihlukahlukene. 3) Gqoka ebusweni bomsebenzi obangelwa ukulungiswa. Okuqukethwe kwe-Metal Processing Wechat kuhle kakhulu, futhi kufanele ukunake.

⑤ amaphutha okukhiqiza nokuguga kwamathuluzi

Izinhlobo ezahlukene zamathuluzi zinethonya elihlukile ekunembeni komshini.

1) Ukunemba kwamathuluzi anobukhulu obunqunyiwe (njengama-drill, ama-reamers, ukusikeka kokhiye wokugaya, ama-broache ayindilinga, njll.). Ukunemba kwe-dimensional kuthintwa ngokuqondile i-workpiece.

2) Ukunemba kwethuluzi lokwakha (njengamathuluzi okuguqula, amathuluzi okugaya, amasondo okugaya, njll.), kuzothinta ngokuqondile ukunemba komumo. Ukunemba komumo we-workpiece kuthinteka ngokuqondile ngokunemba komumo.

3) Iphutha lomumo ku-blade yesisiki elithuthukisiwe (njengama-giya hob, ama-spline hobo, ama-gear shaper cutters, njll.). Ukunemba komumo ongaphezulu kuzothintwa iphutha le-blade.

4) Ukunemba kokukhiqiza kwethuluzi akuthinti ngokuqondile ukunemba kokucubungula kwalo. Nokho, kulula ukuyisebenzisa.

⑥ Inqubo yokuguqulwa kwengcindezi yesistimu

Ngaphansi kwethonya le-clamping force namandla adonsela phansi, isistimu izokhubazeka. Lokhu kuzoholela emaphutheni okucubungula futhi kuzothinta ukuzinza. Okucatshangelwayo okuyinhloko ukuwohloka kwamathuluzi omshini, ukuwohloka kwezingcezu zokusebenza kanye nengqikithi yokuwohloka kwesistimu yokucubungula.

Ukusika amandla nokunemba komshini

Iphutha le-cylindricity lidaleka lapho ingxenye yomshini iwugqinsi phakathi nendawo futhi izacile ekugcineni, ngokusekelwe ekushintshashintsheni okubangelwa umshini. Ukuze kucutshungulwe izingxenye ze-shaft, kucatshangelwa ukuguqulwa nokucindezeleka kwe-workpiece kuphela. I-workpiece ibonakala iminyene phakathi nendawo futhi izacile ekugcineni. Uma ukuguqulwa kuphela okucatshangelwa ukucutshungulwa kwecnc shaft machining izingxenyei-deformation noma ithuluzi lomshini, khona-ke ukuma kwe-workpiece ngemva kokucubungula kuyoba okuphambene nezingxenye ze-shaft ezicutshunguliwe.

Umthelela we-clamping force ekunembeni komshini

I-workpiece izokhubazeka lapho iboshiwe ngenxa yokuqina kwayo okuphansi noma amandla okugoqa angafanele. Lokhu kubangela iphutha lokucubungula.

⑦ Ukuguqulwa kwe-thermal ezinhlelweni zenqubo

Isistimu yenqubo iyashisisa futhi ikhubazekile phakathi nokucubungula ngenxa yokushisa okukhiqizwa umthombo wokushisa wangaphandle noma umthombo wokushisa wangaphakathi. Ukuwohloka kwe-thermal kunesibopho samaphutha angama-40-70% omshini kucezu lokusebenza olukhulu kanye nomshini wokunemba.

Kunezinhlobo ezimbili ze-thermal deformation ye-workpiece engathinta ukucubungula igolide: ukushisa okufanayo nokushisa okungalingani.

⑧ Ukucindezelwa Okusele ngaphakathi kwe-Workpiece

Ukukhiqiza ingcindezi esimweni sensalela:

1) Ingcindezi eyinsalela ekhiqizwa ngesikhathi sokwelashwa kokushisa kanye nenqubo yokukhiqiza umbungu;

I-2) Ukuqondisa okubandayo kwezinwele kungabangela ukucindezeleka okusele.

I-3) Ukusika kungabangela ukucindezeleka okusele.

⑨ Ukucubungula umthelela wendawo endaweni

Ngokuvamile kunezinhlayiya eziningi zensimbi ezincane endaweni yokucubungula. Lawa ma-chips ensimbi azoba nomthelela ekunembeni komshini wengxenye uma etholakala eduze nendawo yembobo noma ngaphezuluizingxenye eziphendukayo. Ama-metal chips amancane kakhulu ukuthi angabonwa azoba nomthelela ekunembeni ekucubunguleni okunembayo okuphezulu. Kuyaziwa ukuthi lesi sici sethonya singaba yinkinga, kodwa kunzima ukuyiqeda. Isu lomqhubi nalo liyisici esikhulu.

Inhloso eyinhloko ye-Anebon kuzoba ukukunikeza abathengi bethu ubudlelwano bebhizinisi obungathi sína nobunomthwalo wemfanelo, ukunikeza ukunakwa komuntu siqu kubo bonke nge-New Fashion Design ye-OEM Shenzhen Precision Hardware Factory Custom Fabrication CNC inqubo yokugaya, ukusakaza ngokunemba, isevisi ye-prototyping. Ungathola inani eliphansi kakhulu lapha. Futhi uzothola imikhiqizo yekhwalithi enhle nezixazululo kanye nenkonzo enhle lapha! Akufanele ube manqikanqika ukubamba i-Anebon!

Idizayini Entsha Yemfashini Yesevisi Yemishini Ye-CNC Ye-China NokwezifisoIsevisi yemishini ye-CNC, I-Anebon inezinombolo zezinkundla zokuhweba zangaphandle, okuyi-Alibaba,Globalsources,Global Market,Made-in-china. Imikhiqizo nezixazululo ze-"XinGuangYang" ze-HID zithengiswa kahle kakhulu eYurophu, eMelika, eMpumalanga Ephakathi nakwezinye izifunda emazweni angaphezu kuka-30.

Uma ufuna ukucaphuna izingxenye ezenziwe ngomshini, sicela ukhululeke ukuthumela imidwebo ku-imeyili esemthethweni yase-Anebon: info@anebon.com

Isikhathi sokuthumela: Dec-20-2023