1. Yiziphi izindlela ezintathu zokubopha ama-workpieces?

Kunezindlela ezintathu zokubopha ama-workpieces afaka:

1) Ukugoqa emgqeni

2) Ukuthola i-clamp efanele ngokuqondile

3) Ukumaka umugqa kanye nokuthola i-clamp efanele.

2. Luhlanganisani uhlelo lokucubungula?

Isistimu yokucubungula ihlanganisa amathuluzi omshini, izinto zokusebenza, izinto ezilungiswayo, namathuluzi.

3. Yiziphi izingxenye zenqubo yokucubungula imishini?

Izingxenye zenqubo yokucubungula imishini zilukhuni, ziqeda kancane, ziqeda, futhi ziqeda kakhulu.

4. Ahlukaniswa kanjani ama-benchmarks?

Amabhentshimakhi ahlukaniswa kanje:

1. Isisekelo sokuklama

2. Isisekelo senqubo: inqubo, ukulinganisa, ukuhlanganisa, ukuma: (okokuqala, okungeziwe): (isisekelo esimahhadla, isisekelo esamukelekayo)

Kuhlanganisani ukunemba kokucubungula?

Ukucubungula ukunemba kuhlanganisa ukunemba kobukhulu, ukunemba komumo, nokunemba kwendawo.

5. Iphutha lokuqala elenzeka ngesikhathi sokucubungula lihlanganisani?

Iphutha lokuqala elenzeka ngesikhathi sokucutshungulwa lihlanganisa iphutha lesimiso, iphutha lokumisa, iphutha lokulungisa, iphutha lethuluzi, iphutha lokulungisa, iphutha lokuzungezisa ithuluzi lomshini, iphutha lesitimela somhlahlandlela wethuluzi lomshini, iphutha lokuhambisa ithuluzi lomshini, ukuguquguquka kokucindezeleka kwesistimu, ukuguquguquka kokushisa kwesistimu, ukuguga kwethuluzi, iphutha lokulinganisa, kanye nephutha le-workpiece residual stress elibangelwa.

6. Ukuqina kwesistimu yenqubo kukuthinta kanjani ukunemba kwemishini, njengokuguquguquka kwethuluzi lomshini kanye nokuguqulwa kwe-workpiece?

Lokhu kungabangela amaphutha omumo we-workpiece ngenxa yezinguquko endaweni yephuzu lesicelo samandla okusika, amaphutha okucubungula abangelwa izinguquko kusayizi wamandla okusika, amaphutha okucubungula abangelwa amandla okubamba kanye namandla adonsela phansi, kanye nomthelela wamandla okudlulisela kanye namandla angasebenzi. ekucubunguleni ukunemba.

7. Yimaphi amaphutha ekuqondisweni kwethuluzi lomshini kanye nokujikeleza kokuphotha?

Umzila wesitimela oqondisayo ungabangela amaphutha okugudluzwa okuhlobene phakathi kwethuluzi nendawo yokusebenza endaweni ezwela iphutha, kuyilapho i-spindle ingaba ne-radial circular runout, i-axial circular runout, kanye nokushwibeka.

8. Iyini inkambiso “yesithombe sephutha,” futhi singayinciphisa kanjani?

Lapho ukuguqulwa kwephutha lesistimu yenqubo kushintsha, iphutha elingenalutho libonakala kancane kucezu lokusebenza. Ukuze sinciphise lo mphumela, singakwazi ukwandisa inani lokudlula kwamathuluzi, sikhulise ukuqina kwesistimu yokucubungula, sinciphise inani lokuphakelayo, futhi sithuthukise ukunemba okungenalutho.

9. Singahlaziya futhi sinciphise kanjani iphutha lokudlulisela leketango lokudlulisela ithuluzi lomshini?

Ukuhlaziywa kwephutha kukalwa ngephutha le-engeli yokuzungezisa Δφ yesici sokugcina sochungechunge lokudlulisela. Ukuze sinciphise amaphutha okudlulisela, singasebenzisa izingxenye ezimbalwa zamaketango okudlulisela, sibe neketango elifushane lokudlulisela, sisebenzise isilinganiso esincane sokudlulisa I (ikakhulukazi emaphethelweni okuqala nesokugcina), senze izingxenye zokugcina zezingxenye zokudlulisela zibe nembe ngangokunokwenzeka, futhi sisebenzise idivayisi yokulungisa.

10. Ahlukaniswa kanjani amaphutha okucubungula? Imaphi amaphutha angamaphutha esistimu anenani eliguquguqukayo, namaphutha angahleliwe?

Iphutha lesistimu:(iphutha lesistimu yenani eliqhubekayo, iphutha lesistimu yenani elihlukile) iphutha elingahleliwe.

Iphutha lesistimu eliqhubekayo:iphutha lesimiso somshini, iphutha lokukhiqiza lamathuluzi omshini, amathuluzi, izinto ezilungiswayo, ukuguqulwa kwengcindezi yohlelo lokucubungula, njll.

Iphutha lesistimu yenani eliguquguqukayo:ukugqokwa kwama-props; Iphutha le-thermal deformation lamathuluzi, ukulungiswa, amathuluzi omshini, njll., ngaphambi kwebhalansi yokushisa.

Amaphutha angahleliwe:ukukopisha amaphutha angenalutho, amaphutha okubeka, amaphutha okuqinisa, amaphutha okulungisa okuningi, amaphutha okuguqulwa okubangelwa ukucindezeleka okusalayo.

11. Yiziphi izindlela zokuqinisekisa nokuthuthukisa ukunemba kokucubungula?

1) Ubuchwepheshe bokuvimbela amaphutha: Ukusetshenziswa okunengqondo kobuchwepheshe obuthuthukisiwe kanye nezinto zokusebenza ukunciphisa ngokuqondile iphutha langempela, ukudlulisa iphutha lokuqala, isilinganiso sephutha langempela, kanye nesilinganiso sephutha langempela.

2) Ubuchwepheshe besinxephezelo sephutha: ukutholwa ku-inthanethi, ukufanisa okuzenzakalelayo nokugaya izingxenye ezilinganayo, nokulawula okusebenzayo kwezinto eziwujuqu zamaphutha.

12. I-geometry yendawo yokucubungula ihlanganisani?

Ubulukhuni beJiyomethri, ukuguquguquka kwendawo, ukuqondiswa kokusanhlamvu, ukonakala kwendawo.

13. Yiziphi izici ezibonakalayo kanye namakhemikhali wezinto zongqimba lwangaphezulu?

1) Umsebenzi obandayo uqina wensimbi yongqimba lwangaphezulu.

2) Isakhiwo se-metallographic deformation yensimbi yongqimba olungaphezulu.

3) Ukucindezeleka okusalayo kwensimbi yongqimba lwangaphezulu.

14. Hlaziya izici ezithinta ubulukhuni obungaphezulu bokucubungula ukusika.

Inani lobunzima linqunywa ukuphakama kwendawo esele yokusika. Izinto eziyinhloko i-arc radius ye-tooltip, i-engeli eyinhloko yokwehla, kanye ne-engeli yesibili yokwehla, inani lokuphakelayo. Izici zesibili ukwanda kwejubane lokusika, ukukhetha okufanele koketshezi lokusika, ukwanda okufanele kwe-rake angle yethuluzi, nokuthuthukiswa konqenqema lwethuluzi, ikhwalithi yokugaya.

15. Izinto Ezithinta Ukuqina Kobuphezulu Ekucubunguleni Ukugaya:

Izici zejiyomethri ezifana nenani lokugaya, usayizi wezinhlayiyana zesondo lokugaya, nokugqoka kwesondo lokugaya kungaba nomthelela ekuqineni kwendawo.Izinto ezibonakalayo, njengokuwohloka kwepulasitiki kwensimbi yongqimba olungaphezulu kanye nokukhethwa kwamasondo okugaya, nakho kungathinta ubuhwaqane obungaphezulu.

16. Izinto Ezithinta Umsebenzi Obandayo Ukuqina Kokusika Indawo:

Inani lokusika, i-geometry yethuluzi, kanye nezakhiwo zezinto ezicutshungulwayo zingathonya ukuqina komsebenzi obandayo wezindawo zokusika.

17. Ukuqonda Ukugaya Ukushisa Ukushiswa, Ukugaya kanye Nokucisha Ukushiswa, kanye Nokugaya I-Annealing Burn:

Ukushisa kwenzeka lapho izinga lokushisa endaweni yokugaya lingadluli izinga lokushisa lokuguqulwa kwesigaba sensimbi ecishiwe kodwa lidlula izinga lokushisa lokuguqulwa kwe-martensite. Lokhu kubangela isakhiwo esiqinile esinobulukhuni obuphansi. Ukucisha kwenzeka lapho izinga lokushisa endaweni yokugaya lidlula izinga lokushisa lokuguqulwa kwesigaba, futhi insimbi engaphezulu inesakhiwo sesibili sokucisha i-martensite ngenxa yokupholisa. Lokhu kunobulukhuni obuphakeme kune-martensite yasekuqaleni kungqimba yayo ephansi kanye nesakhiwo esithambile esinobulukhuni obuphansi kune-martensite yasekuqaleni ene-tendered. Ukufakwa kwe-anneal kwenzeka lapho izinga lokushisa endaweni yokugaya lidlula izinga lokushisa lokushintsha kwesigaba, futhi kungekho nto yokupholisa phakathi nenqubo yokugaya. Lokhu kubangela isakhiwo esine-anealed kanye nokwehla okubukhali kokuqina.

18. Ukuvimbela Nokulawula Ukudlidliza Kokucubungula Kwemishini:

Ukuze uvimbele futhi ulawule ukudlidliza kokucubungula komshini, kufanele ukhiphe noma wenze buthaka izimo ezikukhiqizayo. Ungaphinda uthuthukise izici eziguqukayo zesistimu yokucubungula, uthuthukise ukuzinza, futhi usebenzise amadivayisi ahlukahlukene okunciphisa ukudlidliza.

19. Chaza kafushane umehluko omkhulu kanye nezikhathi zokusetshenziswa kwamakhadi enqubo yokwenza imishini, amakhadi okucubungula, namakhadi okucubungula.

Ikhadi lokucubungula:Isiqephu esisodwa kanye nokukhiqizwa kwe-batch encane kwenziwa kusetshenziswa izindlela ezijwayelekile zokucubungula.

Ikhadi lobuchwepheshe bokucubungula imishini:“Ukukhiqizwa kweqoqwana elimaphakathi” kusho inqubo yokukhiqiza lapho kukhiqizwa inani elilinganiselwe lemikhiqizo ngesikhathi. Ngakolunye uhlangothi, "ukukhiqizwa kwevolumu enkulu" kudinga umsebenzi ocophelelayo nohlelekile ukuze kuqinisekiswe ukuthi inqubo yokukhiqiza isebenza kahle nangempumelelo. Kubalulekile ukugcina izinyathelo eziqinile zokulawula izinga ezimweni ezinjalo.

*20. Yiziphi izimiso zokukhetha amabhentshimakhi angalungile? Izimiso zokukhetha ibhentshimakhi enhle?

Idatha engalungile:1. Umgomo wokuqinisekisa izidingo zesikhundla esifanayo; 2. Umgomo wokuqinisekisa ukusatshalaliswa okufanele kwemvume yomshini endaweni ewumshini; 3. Umgomo wokusiza ukubopha i-workpiece; 4. Isimiso sokuthi idatha engalungile ngokuvamile ayinakuphinda isetshenziswe

Idatha yokunemba:1. Umgomo we-datum coincidence; 2. Umgomo wedatha ehlanganisiwe; 3. Isimiso se-mutual datum; 4. Umgomo wokuzibheka; 5. Isimiso sokubopha okulula

21. Yiziphi izimiso zokuhlela ukulandelana kwenqubo?

1) Cacisa indawo engaphezulu yedatha kuqala bese ucubungula ezinye izindawo;

2) Engxenyeni yezimo, sebenza indawo engaphezulu kuqala bese ucubungula izimbobo;

3) Cacisa indawo engaphezulu kuqala, bese ucubungula indawo yesibili;

4) Hlela inqubo yokwenza imishini enzima kuqala, bese uhlela inqubo yokwenza imishini emihle. Icubungula izinyathelo

22. Sizihlukanisa kanjani izigaba zokucubungula? Yiziphi izinzuzo zokuhlukanisa izigaba zokucubungula?

Ukwahlukaniswa kwezigaba zokucubungula: 1. Isiteji somshini onzima - isigaba sokuqeda - isigaba sokuqeda - isigaba sokuqeda ngokunemba

Ukuhlukanisa izigaba zokucubungula kungasiza ekuqinisekiseni isikhathi esanele sokuqeda ukuwohloka kokushisa nokucindezeleka okusalayo okubangelwa umshini onzima, okuholela ekuthuthukisweni kokunemba kokucubungula okulandelayo. Ukwengeza, uma ukukhubazeka kutholakala endaweni engenalutho phakathi nesigaba somshini onzima, ukuqhubekela esigabeni esilandelayo sokucutshungulwa kungagwenywa ukuze kuvinjelwe imfucuza.

Ngaphezu kwalokho, okokusebenza kungasetshenziswa ngokunengqondo ngokusebenzisa amathuluzi omshini anembe kancane ukwenza imishini enzima nokugcina amathuluzi omshini onembile ukuze aqedelwe ukuze kugcinwe izinga lawo lokunemba. Izinsiza zabantu nazo zingahlelwa kahle, nabasebenzi bobuchwepheshe obuphezulu abasebenza ngokunemba nokucoleka kwemishini ukuze kuqinisekiswe kokubili.izingxenye zensimbiikhwalithi kanye nokuthuthukiswa kwezinga lenqubo, okuyizici ezibalulekile.

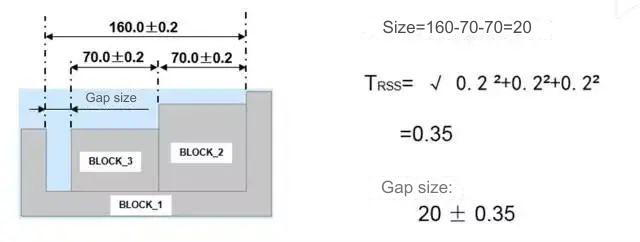

23. Yiziphi izici ezithinta umkhawulo wenqubo?

1) Ukubekezelelana kwe-Dimensional Ta kwenqubo yangaphambilini;

2) Ubuhwaba obungaphezulu obu-Ry kanye nokushona kobuso obujulile bukhiqizwe inqubo yangaphambilini;

3) Iphutha lendawo elishiywe inqubo yangaphambilini

24. Ingakanani isilinganiso sehora lokusebenza?

T quota = T isikhathi socezu olulodwa + t enemba isikhathi sokugcina/n inombolo yezingcezu

25. Yiziphi izindlela zobuchwepheshe zokuthuthukisa umkhiqizo?

1) Fushanisa isikhathi esiyisisekelo;

2) Yehlisa ukugqagqana phakathi kwesikhathi esiyisizayo nesikhathi esiyisisekelo;

3) Yehlisa isikhathi sokuhlela umsebenzi;

4) Yehlisa ukulungiselela nesikhathi sokuqeda.

26. Yikuphi okuqukethwe okuyinhloko kwemithethonqubo yenqubo yomhlangano?

1) Hlaziya imidwebo yomkhiqizo, uhlukanise amayunithi omhlangano, futhi unqume izindlela zokuhlanganisa;

2) Yakha ukulandelana komhlangano futhi uhlukanise izinqubo zomhlangano;

3) Bala isilinganiso sesikhathi somhlangano;

4) Thola izidingo zobuchwepheshe bomhlangano, izindlela zokuhlola ikhwalithi, namathuluzi okuhlola enqubo ngayinye;

5) Thola indlela yokuthutha yezingxenye zomhlangano kanye nemishini edingekayo namathuluzi;

6) Khetha futhi uklame amathuluzi, izinto ezilungiswayo, nezinto zokusebenza ezikhethekile ezidingekayo ngesikhathi sokuhlanganisa

27. Yini okufanele icatshangelwe ekuhlanganiseni kwesakhiwo somshini?

1) Isakhiwo somshini kufanele sikwazi ukuhlukaniswa ngamayunithi omhlangano azimele;

2) Yehlisa ukulungiswa kanye nomshini ngesikhathi somhlangano;

3) Isakhiwo somshini kufanele kube lula ukuhlanganisa nokuhlakazwa.

28. Ukunemba komhlangano ngokuvamile kuhlanganisani?

1. Ukunemba kwesikhundla; 2. Ukunemba kokunyakaza okuhlangene; 3. Ukunemba ngokubambisana ngokubambisana

29. Yiziphi izindaba okufanele zinakwe lapho kuseshwa amaketango okulinganisa?

1. Yenza lula uchungechunge lobukhulu bomhlangano njengoba kudingeka.

2. Iketango lobukhulu bomhlangano kufanele libe nesiqephu esisodwa nesixhumanisi esisodwa.

3. Iketango lobukhulu bomhlangano linokuqondisa, okusho ukuthi esakhiweni esifanayo somhlangano, kungase kube khona umehluko wokunemba komhlangano ezindaweni nezikhombisi-ndlela ezahlukene. Uma kudingeka, uchungechunge lobukhulu bomhlangano kufanele lugadwe ngezindlela ezihlukene.

30. Yiziphi izindlela zokuqinisekisa ukunemba komhlangano? Zisetshenziswa kanjani izindlela ezahlukahlukene?

1. Indlela yomehlukanondlela; 2. Indlela yokukhetha; 3. Indlela yokuguqula; 4. Indlela yokulungisa

31. Yiziphi izingxenye nemisebenzi yamathuluzi omshini?

Ithuluzi lomshini idivayisi esetshenziselwa ukubopha ucezu lokusebenza ethuluzini lomshini. I-fixture inezingxenye ezimbalwa, okuhlanganisa izinto zokubeka, izisetshenziswa eziqondisa amathuluzi, izinsimbi zokubopha, izingxenye zokuxhuma, umzimba we-clamp, namanye amathuluzi. Umsebenzi walezi zingxenye ukugcina i-workpiece isesimweni esifanele mayelana nethuluzi lomshini kanye nethuluzi lokusika futhi ugcine lesi sikhundla ngesikhathi senqubo yomshini.

Imisebenzi esemqoka yalolu hlelo ihlanganisa ukuqinisekisa ikhwalithi yokucubungula, ukuthuthukisa ukusebenza kahle kokukhiqiza, ukwandisa ububanzi bobuchwepheshe bamathuluzi omshini, ukunciphisa amandla okusebenza kwabasebenzi, kanye nokuqinisekisa ukuphepha kokukhiqiza. Lokhu kuyenza ithuluzi elibalulekile kunoma iyiphi inqubo yokwenza imishini.

32. Izinto ezilungiswayo zemishini zihlukaniswa kanjani ngokwebanga lokusebenzisa kwazo?

1. Indawo yonke 2. Isakhiwo esikhethekile 3. Isakhiwo esilungisekayo neqembu 4. Isakhiwo esihlanganisiwe nokungahleliwe

33. I-workpiece ibekwe endizeni. Yiziphi izingxenye zokumisa ezivame ukusetshenziswa?

Futhi hlaziya isimo sokuqeda amazinga enkululeko.

I-workpiece ibekwe endizeni. Izingxenye zokumisa ezisetshenziswa ngokuvamile zifaka ukwesekwa okungaguquki, usekelo olulungisekayo, usekelo lokuzimisa, kanye nosekelo oluyisizayo.

34. I-workpiece ibekwe ngembobo ye-cylindrical. Yiziphi izingxenye zokumisa ezivame ukusetshenziswa?

I-workpiece ibekwe ngembobo ye-cylindrical. Yiziphi Izingxenye zokumisa Ezisetshenziswa Ezivamise ukusetshenziselwa umsebenzi onembobo eyicylindrical ezihlanganisa iphini lokuphotha nokubeka indawo. Isimo sokuqeda amazinga enkululeko singahlaziywa.

35. Uma ubeka ucezu lomsebenzi endaweni eyindilinga yangaphandle, yiziphi izingxenye zokumisa ezivame ukusetshenziswa? Futhi hlaziya isimo sokuqeda amazinga enkululeko.

I-workpiece ibekwe endaweni eyindilinga yangaphandle. Ukuma okuvame ukusetshenziswacnc waphenduka izingxenyezihlanganisa amabhlogo amise okwe-V.

I-Anebon izibophezele ekuzuzeni impumelelo kanye nokwenza ngcono izinyathelo zayo ukuze ibe yibhizinisi lezinga eliphezulu nelobuchwepheshe obuphezulu ezingeni lamazwe ngamazwe. Njengomphakeli wegolide waseChina, sisebenza ngokukhethekile ekuhlinzekeni ngezinsizakalo ze-OEM,ngokwezifiso CNC machining, izinsiza zokwenziwa kwensimbi, kanye nezinsiza zokugaya. Siyaziqhenya ngokunakekela izidingo eziqondile zamakhasimende ethu futhi silwela ukufeza lokho akulindele. Ibhizinisi lethu lihlanganisa iminyango eminingana, okuhlanganisa ukukhiqiza, ukuthengisa, ukulawulwa kwekhwalithi, kanye nesikhungo sesevisi.

Sinikeza ngokunemba izingxenye kanyeizingxenye ze-aluminiumezihlukile futhi eziklanyelwe ukuhlangabezana nezidingo zakho. Ithimba lethu lizosebenzisana nawe ukuze lidale imodeli yomuntu siqu ehlukile kwezinye izingxenye ezitholakala emakethe. Sizinikezele ekukunikezeni isevisi engcono kakhulu ukuze uhlangabezane nazo zonke izidingo zakho. Ungangabazi ukusithinta e-Anebon futhi usazise ukuthi singakusiza kanjani.

Isikhathi sokuthumela: Apr-01-2024