Wazini ngenqubo yokwelashwa okungaphezulu kwezinto zokwakha kumishini ye-CNC?

Ngomshini we-CNC, ukwelashwa okungaphezulu kuyinqubo esetshenziselwa ukuthuthukisa ukubukeka kanye nokusebenza nokuhlala isikhathi eside kwezinto ezenziwe ngomshini. Izinqubo ezivame kakhulu ezisetshenziselwa ukwelapha izindawo ezisetshenziswa emishinini ye-CNC zifaka ukuchithwa. Le nqubo ihilela ukususwa kwamachopho acijile, ama-burrs, nanoma iyiphi into eyeqile endaweni emshinini. Ukukhipha imali kuthuthukisa ubuhle nokuphepha komkhiqizo wokugcina.

Ukupholisha:Ukupholisha kungasetshenziselwa ukwenza izinto zibe bushelelezi okuholela ekubukekeni okucwebezelayo nokucwebezelayo. Ithuthukisa ukubukeka kwezingxenye futhi inciphise ukungqubuzana ezingxenyeni.

Ukugaya: Isetshenziselwa ukuqeda ukungapheleli endaweni noma ukuthola ukubekezelelana okunembile. Lokhu kuhilela ukusebenzisa isondo lokugaya ukuze kukhishwe izinto ocezu lomsebenzi.

I-Anodizing:Kuyinqubo ye-electrochemical edala ungqimba oluvikelayo olufana ne-oxide ebusweni bezinto zensimbi njenge-aluminium. Ithuthukisa ukumelana nokugqwala kanye nobuhle, ubulukhuni kanye.

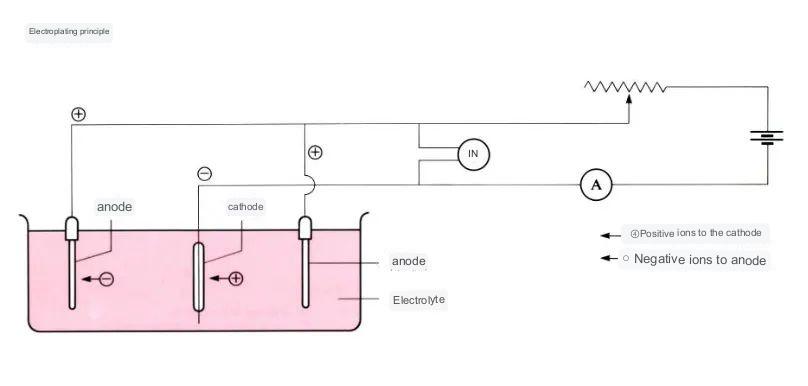

I-Electroplatingkuhilela ukubeka ungqimba oluncane lwensimbi phezu kwento. Ithuthukisa ukumelana nokugqwala kanye ne-conductivity nokubukeka.

Ukugqoka:I-Surface coating inqubo yokufaka isendlalelo esilwa nokugqwala noma upende ngaphezulu kwento. Ingase inikeze ukumelana nokugqwala kanye nokumelana nokugqoka. Ingase futhi ithuthukise ubuhle bobuhle.

Ukwelashwa Kokushisa:Lokhu kuhilela ukuveza izinto ezingeni lokushisa elidlulele kanye nokupholisa okulawulwayo ukuze kulungiswe impahla yazo ewumshini. Le nqubo ithuthukisa ukuqina kwento, ubulukhuni futhi imelana nokuguga nokuguqulwa.

Lokhu kwelashwa kwendawo kungathuthukisa kakhulu ikhwalithi iyonke, ukusebenza nokuphila isikhathi eside kwezingxenye zomshini we-CNC. Uhlobo lokwelapha okhetha ukulusebenzisa luncike kulokho okubalulekile, ukusetshenziswa okuhlosiwe, kanye nemiphumela oyifunayo.

Ukwelashwa kwendawo kuyinqubo yokudala okubalulekile okungaphezulu kwesisekelo esinezici zamakhemikhali, zomzimba, nemishini ezehlukile kulezo zesisekelo.

Inhloso yokwelashwa kwendawo ukwanelisa ukumelana nokuguga, ukugqwala nezinye izidingo ezithengiswayo. Izindlela ezisetshenziswa kakhulu zokwelapha izindawo ezingaphezulu zibandakanya ukugaya ngomshini, ukwelashwa ngamakhemikhali kokushisa okungaphezulu kanye nokufafaza phezulu. Ukwelashwa okungaphezulu kuyinqubo yokuhlanza indawo engaphezulu, ukuyishanela, ukuyisusa nokukhipha amafutha ngaphandle kwesiqephu. Namuhla, sizoxoxa ngenqubo yokwelashwa kwendawo.

Yiziphi izinzuzo ezingalethwa ukwelashwa okungaphezulu ezingxenyeni zomshini?

Izinqubo zokwelapha endaweni engaphezulu zingaletha izinzuzo eziningiizingxenye ezenziwe ngomshini, okuhlanganisa: Ubuhle obuthuthukisiwe: Ukwelashwa kwendawo okungaphezulu njengokuqhakaza, ukugcotshwa kwe-anodizing, ukucwenga kanye nokuqeda kungathuthukisa ukukhanga okubonakalayo kwezingxenye eziwumshini. Inganikeza isiphetho esibushelelezi, esicwebezelayo noma esenziwe ngokwezifiso, sithuthukise ukubukeka okuphelele kwento.

Ukumelana nokugqwala okuthuthukisiwe: Izindlela zokwelapha eziningi zendawo, ezifana ne-anodizing, plating, kanye nokuqeda, zakha ungqimba oluvikelayo ebusweni bento. Lesi singqimba sisebenza njengesithiyo, sivikela ingxenye ukuthi ingahlangani nendawo ebolayo, ngakho-ke ithuthukisa ukumelana kwayo nokugqwala.

Ukumelana nokugqokwa okuthuthukisiwe: Imithi yokwelapha engaphezulu njengokwelashwa kwemfudumalo noma ukuqedwa kungakhuphula ngokuphawulekayo ukumelana nokugqokwa kwezingxenye eziwumshini. Lezi zinqubo zingathuthukisa ukuqina, ukuqina kanye nokuqina kwezinto, kuzenze zingavikeleki kakhulu ekukhuhleni, ukuhuzuka kanye nokuguga. Khulisa ukuthambisa futhi wehlise ukuhlikihla: Okunye ukwelashwa kwendawo, njengokupholisha noma ungqimba olunezinto ezishayisanayo kancane, kunganciphisa ukungqubuzana phakathi kwezingxenye ezihambayo. Lokhu kubangela inqubo ebushelelezi, kwehlisa ukuguga, futhi kuphinde kuthuthukise ukusebenza okuphelele kwezingxenye zomshini.

Ukumelana namakhemikhali okungcono kakhulu: Ngokwelashwa okungaphezulu, ukumelana kwamakhemikhali ezingxenyeni zomshini kungathuthukiswa. Lokhu kunenzuzo ikakhulukazi lapho izingxenye zihlangana namakhemikhali anobutha noma izinhlanganisela ezingaphula umkhiqizo. Ukubekezelela Okuqinile Kanye Nokunemba Okuphakeme: Ukwelapha okungaphezulu okufana nokugaya noma ukupholishwa kuthola ukumelana nobukhulu obuqinile futhi kuqinisekisa ukunemba okukhulu ezingxenyeni zomshini. Lokhu kubalulekile ezinhlelweni ezidinga ukunemba okuphezulu kanye nokubekezelelana okuqinile.

Ukunamathela Okuthuthukisiwe kanye Nokubopha: Ukulungiswa kwendawo kungakha indawo efanelekile yezinto zokunamathisela, opende noma ezinye izindlela zokubopha. Lokhu kuvumela isibopho esinamandla futhi esihlonipheka kakhulu phakathi kwezakhi ezahlukahlukene, ukuthuthukisa ubuqotho bomkhiqizo. Sekukonke, izinqubo zokwelashwa kwangaphandle zidlala indima ebalulekile ekwandiseni isici, ukuphila isikhathi eside kanye nokubukeka kwasoizingxenye ezenziwe ngomshini, okubenza bafaneleke kakhulu isicelo sabo abasifunayo futhi bathuthukise ikhwalithi yabo ephezulu.

Izinqubo ezisetshenziswa kakhulu zokwelashwa kwendawo yilezi:

I-Vacuum electroplating, inqubo ye-electroplating, i-anodizing, i-electrolytic polishing, inqubo yokuphrinta iphedi, inqubo yokufaka i-galvanizing, i-powder coating, ukuphrinta kokudlulisa amanzi, ukuphrinta kwesikrini, i-electrophoresis, njll.

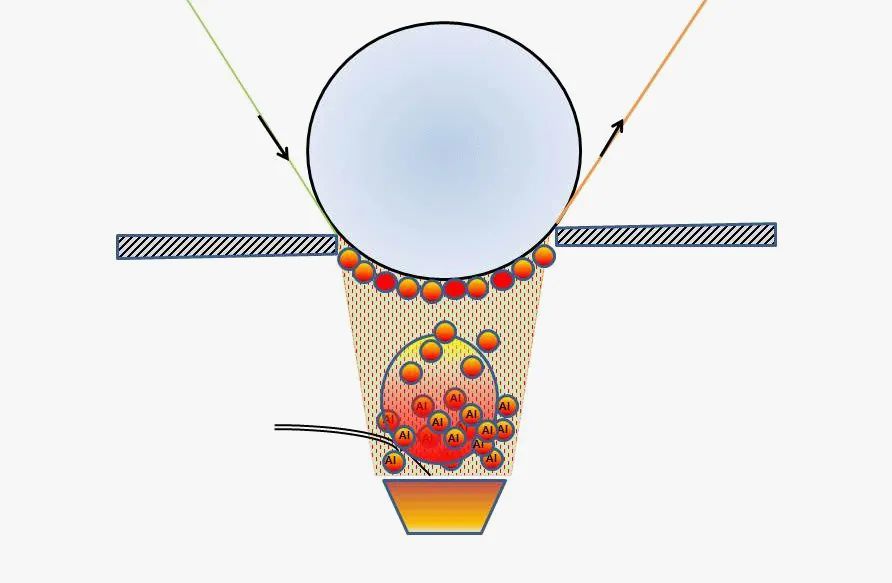

01. Vacuum plating

—— Vacuum Metalizing ——

I-vacuum plating ingachazwa njengenqubo yokufaka ngokomzimba. Empeleni, igesi ye-argon ijovwa esimweni se-vacuum, ama-athomu egesi ashaya into ekhethiwe, futhi impahla eqondiswe kuyo ihlukaniswa ibe ama-molecule, abese amuncwa izinto eziqhutshwayo ukuze enze ungqimba lwensimbi olufana nolubushelelezi. .

Izinto ezisetshenziswayo:

1. Izinhlobonhlobo zezinto zingagcotshwa, okuhlanganisa izinsimbi eziqinile nezithambile zepulasitiki, izitsha zobumba, izinto eziyinhlanganisela nezingilazi. Indlela evame ukusetshenziswa kakhulu ye-electroplating i-aluminium, elandelwa ithusi nesiliva.

2. Izinto ezisetshenziswayo zemvelo azifanelekile ku-vapor plating ngenxa yokuthi umswakama wezinto zemvelo ungashintsha indawo yevacuum.

Izindleko zale nqubo izindleko zokufaka umhwamuko into okufanele ifuthwe ingalayishwa, ilayishwe bese ibuyiselwa ukuze ifuthwe, okusho ukuthi izindleko zabasebenzi ziyabiza, nokho kuncike kusayizi nobunkimbinkimbi besiqephu sokusebenza.

Umthelela wendawo: I-vacuum electroplating idala imithelela encane yemvelo, efana nomthelela wenqubo endaweni ezungezile.

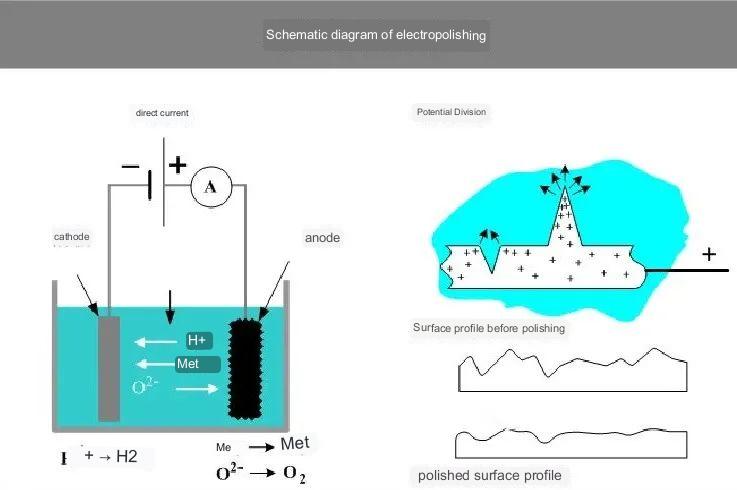

02. Electropolishing

—— Electropolishing ——

I-Electropolishing isho inqubo ye-electrochemical lapho ama-athomu aku-izingxenye eziphendukayo ze-cncezicwiliswa ku-electrolyte ziguqulwa zibe ama-ion bese zikhishwa phezulu ngokugeleza kweshaje kagesi, okuholela ekukhipheni ama-burrs amahle futhi kuthuthukise ukugqama kwendawo.

Izinto ezisetshenziswayo:

1. Iningi lezinsimbi zipholishwa ngogesi okuhlanganisa nokupholishwa kwendawo okudlula kuyo insimbi engagqwali iyona esetshenziswa kakhulu (ikakhulukazi nge-austenitic stainless grade).

2. Izinto ezihlukene azikwazi ukufakwa nge-electropolished ngesikhathi esisodwa noma ngisho nangaphakathi kwe-solvent efanayo ye-electrolysis.

Izindleko zenqubo: Yonke inqubo yokupholisha i-electrolytic icishe izenzekele ngokuphelele, okusho ukuthi izindleko zabasebenzi ziphansi kakhulu. Umthelela emvelweni: Ukupholisha nge-Electrolytic kusebenzisa amakhemikhali angenawo umthelela ophansi. Yonke le nqubo idinga amanzi amancane kuphela, futhi kulula kakhulu ukuyisebenzisa. Ngaphezu kwalokho, ingase ithuthukise izakhiwo zensimbi engagqwali futhi ibambezele ukugqwala kwensimbi engagqwali.

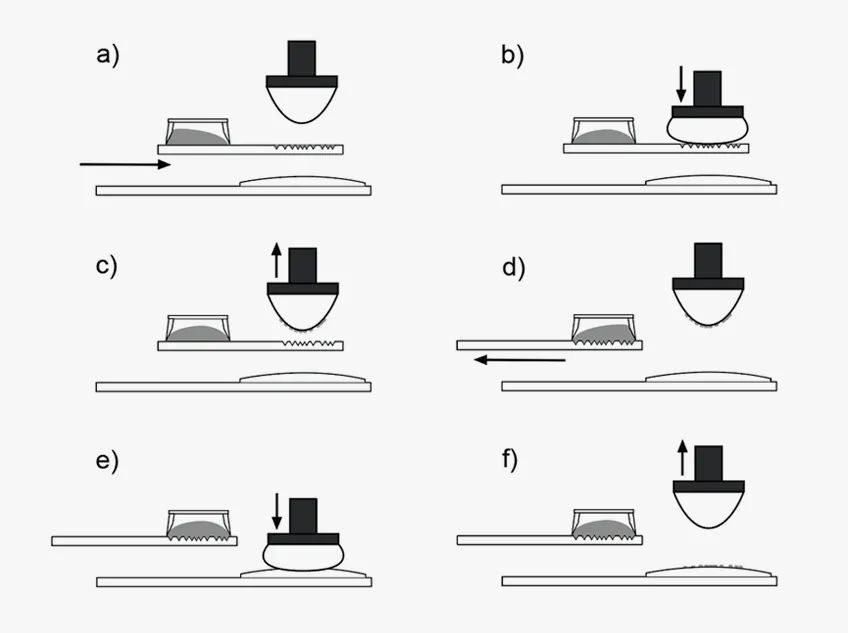

03. Inqubo yokuphrinta yephedi

——Ukuphrinta Kwephedi——

Ikhono lokuphrinta izithombe, umbhalo kanye nezithombe endaweni engaphezulu yezinto ezinokwakheka okungavamile liba isici esibalulekile sokuphrinta okukhethekile.

Izinto ezisetshenziswayo:

Ukuphrinta kwephedi kuyindlela esebenzayo cishe kunoma iyiphi into, ngaphandle kwezinto eziqinile njengamaphedi abicah njenge-PTFE.

Izindleko zenqubo Izindleko eziphansi zokukhunta kanye nezindleko eziphansi zabasebenzi.

Umthelela wendawo: Njengoba le nqubo ivinjelwe koyinki abancibilikayo (abangcoliswe amakhemikhali ayingozi) futhi aba nomthelela omkhulu kwezemvelo.

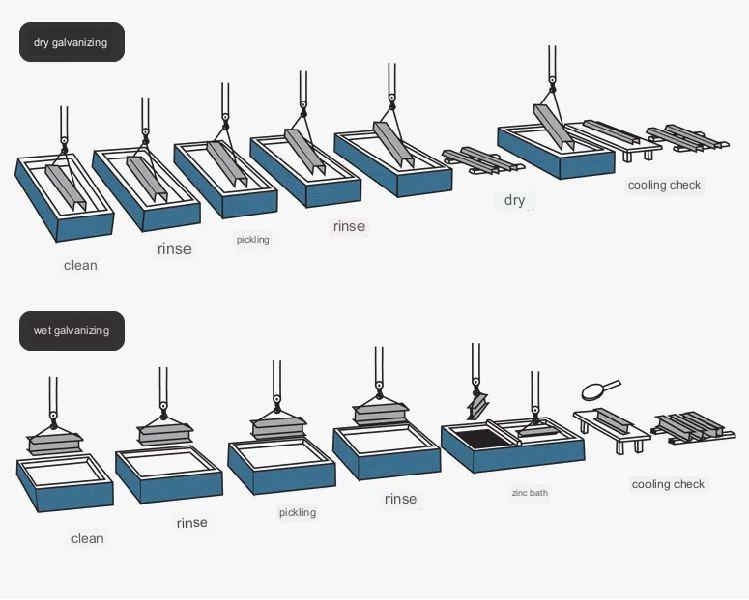

04. Inqubo yokugaya

—— Galvanizing ——

Ubuchwepheshe bokwelapha izindawo ezimboza ungqimba lwezinki ngaphezulu kwama-alloys enziwe ngensimbi ngobuhle nezinzuzo zokulwa nokugqwala. I-zinc enamathelayo engaphezulu isebenza njengesendlalelo sokuvikela i-electrochemical esivimbela ukugqwala kwensimbi. Izindlela ezimbili ezisetshenziswa kakhulu i-hot-dip galvanizing kanye neGalvanized.

Izinto ezisetshenziswayo:

Ngenxa yokuthi i-galvanizing incike ekuhlanganisweni kwe-metallurgical le nqubo ifanele ukwelashwa kwezindawo zensimbi nensimbi.

Izindleko zenqubo: Azikho izindleko zesikhunta, umjikelezo omfushane noma izindleko zokusebenza ezimaphakathi, njengoba ikhwalithi yendawo yokusebenza inqunywa kakhulu ukwelashwa okungaphezulu okwenziwa ngesandla ngaphambi kokufaka uthayela.

Umthelela wendawo: Njengoba inqubo yokufaka uthayela ingakhuphula isikhathi sokuphila sezingxenye zensimbi phakathi kweminyaka engu-40 ne-100 futhi iphinde ivimbele ukugqwala nokugqwala okungenzeka kuyo, inqubo ingaba nomthelela ekuvikelweni kwendawo ezungezile. Ngaphezu kwalokho ucezu lokusebenza olufakwe uthayela lungabuyiselwa ethangini le-zinc uma isikhathi salo sokusebenzisa sesiphelile futhi ukusetshenziswa okuqhubekayo kwe-zinc ewuketshezi akubangeli udoti obonakalayo noma wamakhemikhali.

05. Inqubo ye-Electroplating

—— Electroplating ——

Inqubo yokunamathisela ungqimba oluncane lwefilimu yensimbi ebusweni bezingxenye ngokusebenzisa i-electrolysis, ukuze kumiswe i-oxidation yensimbi, kuthuthukise ukumelana nokuguga ukuguquguquka kokumelana nokugqwala kokukhanya, kanye nokuthuthukisa ukubukeka. Ungqimba lwangaphandle lwezinhlamvu zemali eziningi lungabuye lube yi-electroplated. .

Izinto ezisetshenziswayo:

1. Izinsimbi eziningi zi-electroplated. Kodwa-ke, izinsimbi ezihlukahlukene ziza namazinga ahlukene okuhlanzeka nokusebenza kahle kwe-plating. Okudume kakhulu kulokhu okulandelayo: ithini ne-chromium, isiliva, i-nickel, ne-rhodium.

2. Izinto ezidume kakhulu zokuqhuba i-electroplating yi-ABS. I-ABS.

3. Insimbi ye-nickel akufanele isetshenziselwe imikhiqizo ye-electroplate ethinta isikhumba ngoba iyacika futhi iyingozi esikhumbeni.

Izindleko zenqubo: Azikho izindleko zesikhunta, nokho ukulungiswa kuyadingeka ukuze kuvikelwe izindleko zesikhathi sezingxenye zisuselwa kuzinga lokushisa kanye nohlobo lwezindleko zensimbi noma zomsebenzi (ukuphakama okumaphakathi) kuncike ohlotsheni oluthile lwezingxenye zokucwenga, njengobucwebe nobucwebe. i-silverware, edinga izinga eliphezulu lobuchwepheshe. Iphethwe abasebenzi abanamakhono aphezulu ngenxa yezidingo eziphezulu mayelana nokubukeka nokuphila isikhathi eside.

Umthelela wemvelo we-electroplating: Kusetshenziswa inani elikhulu lamakhemikhali anobuthi enqubweni ye-electroplating yingakho ukuphambukisa okuwuchwepheshe kanye nokukhipha kubalulekile ukuze kuncishiswe umthelela wendawo.

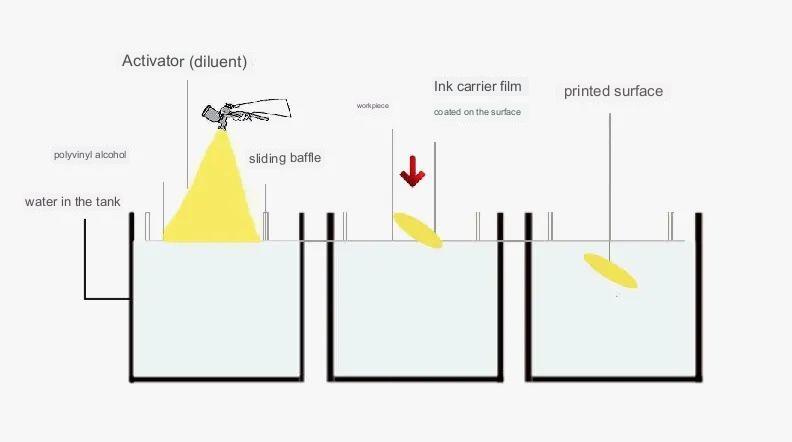

06. Ukuphrinta kokudlulisa amanzi

—— I-Hydro Transfer Printing ——

Kuyisu lokuphrinta iphethini yombala ephepheni lokudlulisa ubuso bomkhiqizo wezinhlangothi ezintathu usebenzisa amanzi okucindezela. Njengoba izimfuno zabantu zokupakishwa kwemikhiqizo kanye nokuhlobisa izindawo ezingaphezulu ukusetshenziswa kokuphrinta-lapho kudingeka khona kuya ngokuya kusabalala.

Izinto ezisetshenziswayo:

Zonke izinhlobo zezinto eziqinile zifanele ukuphrinta ukudluliswa kwamanzi futhi izinto ezifanele ukufafaza kufanele zifanele ukuphrinta ngamanzi. Okudume kakhulu izingxenye ezibunjwe ngomjovo kanye nezingxenye zensimbi.

Izindleko zenqubo: Azikho izindleko ezihlobene nesikhunta, nokho imikhiqizo eminingi kufanele idluliselwe emanzini ngesikhathi esifanayo kusetshenziswa izinto ezilungiswayo. izindleko eziphelele azikho ngaphezu kwenani lesikhathi ngomjikelezo ngamunye.

Umthelela wendawo: Uma kuqhathaniswa nokufafaza emikhiqizweni ukuphrinta kokudluliswa kwamanzi kusebenza ngokuphelele kupende wokuphrinta okunciphisa ithuba lokuvuza nokumosha.

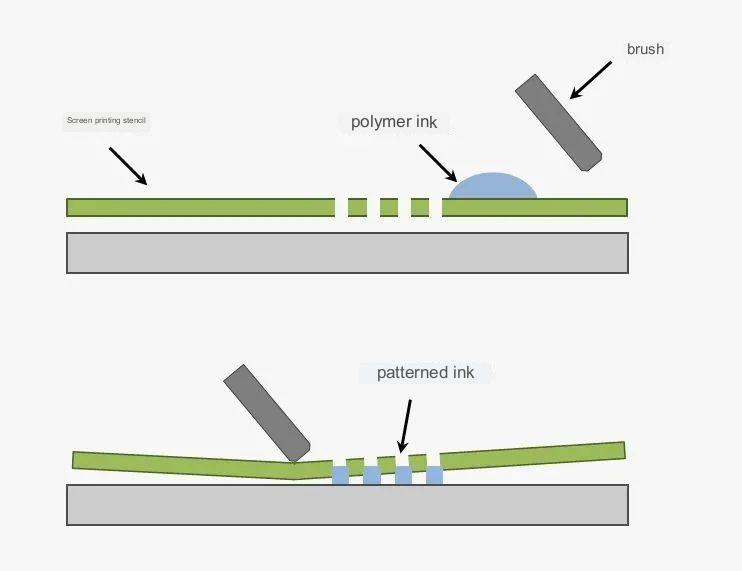

07. Ukuphrinta isikrini

—— Ukuphrinta Isikrini ——

Ngokukhipha i-scraper, uyinki udluliselwa phezulu nge-mesh yayo futhi yakhe isithombe esifanayo ncamashi esaphrintwa ekuqaleni. Amaphrinta esikrini asebenziseka kalula, futhi kulula ukuwaphrinta nokwenza amapuleti, anenani eliphansi kanye nokuguquguquka okuhle kakhulu.

Izinto zokuphrinta ezivame ukusetshenziswa zifaka amaphosta emidwebo kawoyela enemibala, amakhadi ebhizinisi, izembozo eziboshwe ngamaphosta, izimpawu zempahla, kanye nezindwangu ezidayiwe neziphrintiwe.

Izinto ezisetshenziswayo:

Cishe noma iyiphi into ingaphrintwa isikrini, okuhlanganisa insimbi, ipulasitiki, izitsha zobumba zephepha, ingilazi nokunye.

Izindleko zenqubo Izindleko zesikhunta zincane, kodwa zisancike enanini lemibala esetshenzisiwe, njengoba umbala ngamunye kufanele uzenzele wona. Izindleko zomsebenzi ziphezulu kakhulu, ikakhulukazi endabeni yokuphrinta ngemibala eminingi.

Umthelela wendawo: Ukuphrinta isikrini ngoyinki okhanyayo akunawo umthelela omubi endaweni ezungezile, nokho oyinki abenziwe nge-PVC ne-formaldehyde bayinhlanganisela yamakhemikhali anobuthi, futhi badinga ukugaywa kabusha bese balahlwa ngesikhathi esifanele ukumisa ukungcoliswa kwamanzi. .

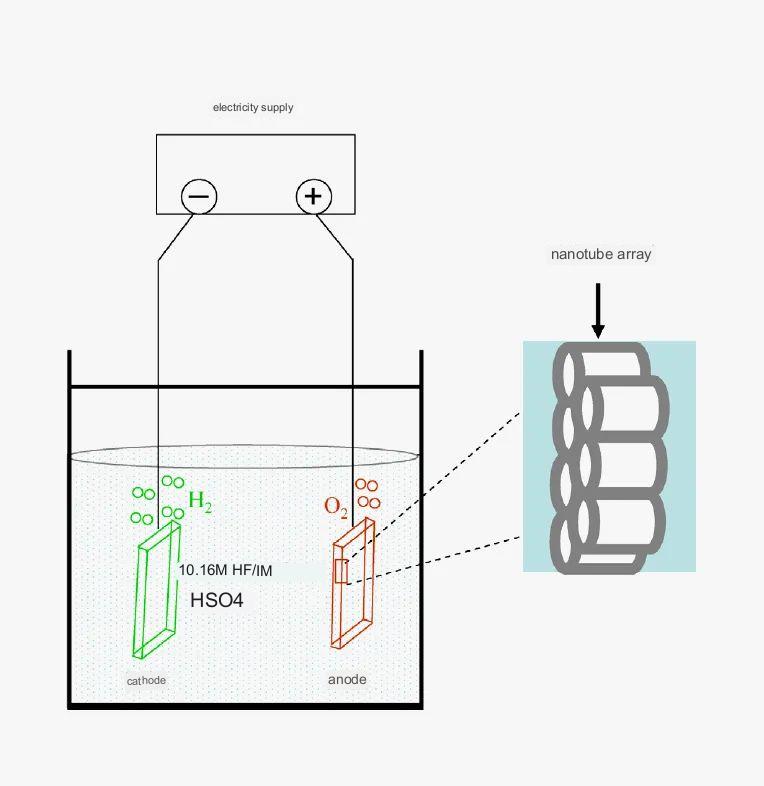

08. Anodizing

I-Anodic Oxidation ——

Inqubo ye-anodic oxidation ye-aluminium ngokuyinhloko isekelwe kumqondo we-electrochemical ukuze kwakheke ungqimba oluncane olungaphansi oluhlanganiswe nefilimu ye-Al2O3 (i-aluminium oxide) ku-aluminium kanye ne-aluminium alloy. I-oxide inezici ezihlukile njengokuvikela ekugqwaleni, ekuhlobiseni, ekushiseni nasekuqineni ukugqokwa.

Izinto ezisetshenziswayo:

I-Aluminium, i-aluminium alloy, neminye imikhiqizo ye-aluminium

Izindleko zenqubo: Enqubweni yokukhiqiza ukusetshenziswa kukagesi namanzi kukhulu, ikakhulukazi ngesikhathi senqubo ye-oxidation. Ukusetshenziswa kwamandla ngomshini ngokwawo kudinga ukupholiswa ngokuqhubekayo ngamanzi agelezayo. Amandla asetshenziswa ngethani ngalinye ngokuvamile cishe amadigri ayi-1000.

Imithelela yezemvelo: I-anodizing ayihlukile ngokonga amandla. Nokho, ohlelweni lokukhiqiza i-electrolysis ye-aluminium ukusabela kwe-anode kukhiqiza amagesi anemiphumela emibi eyingozi kungqimba lwe-Ozone emkhathini.

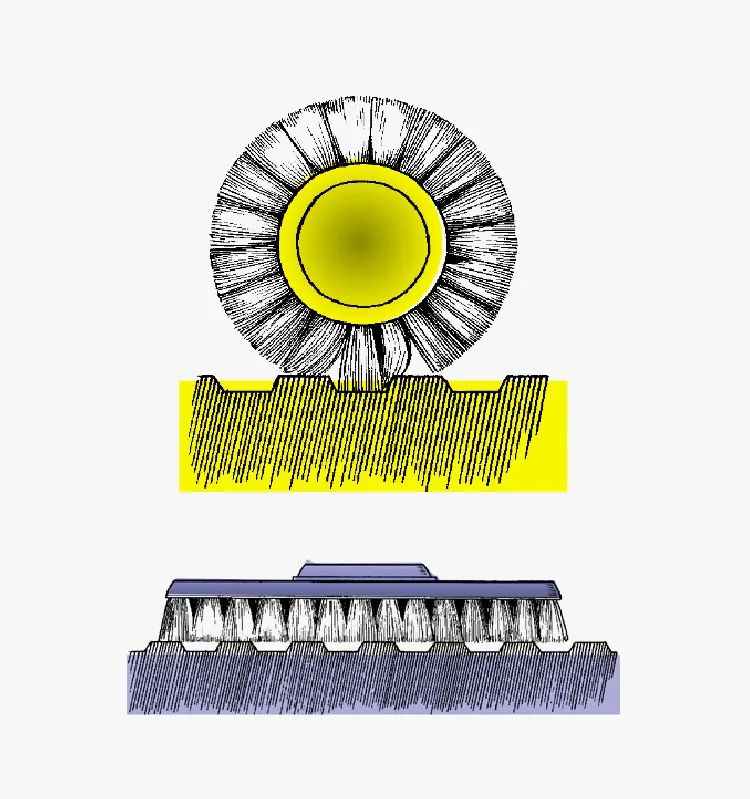

09. Umdwebo wocingo lwensimbi

—— Intambo Yensimbi ——

Kuyindlela yokwelapha engaphezulu eyenza imigqa endaweni yokusebenza ngokugaya into ukuze kutholwe umthelela okhangayo. Ngokwezakhiwo ezihlukahlukene ngemva komfanekiso wekhebula, ingahlukaniswa ibe: umdwebo wekhebula eliqondile, umdwebo wekhebula ongahlelekile, uthayela, kanye nokushwibeka.

Izinto ezifanele: Cishe zonke izinto zensimbi zingasebenzisa inqubo yokudweba intambo yensimbi.

Izindleko zenqubo: Indlela yenqubo ilula, izisetshenziswa ziqondile, ukusetshenziswa kwezinto ezibonakalayo kuncane kakhulu, izindleko zehliswa ngendlela efanele, futhi inzuzo yezezimali iphezulu.

Umthelela wendawo: imikhiqizo yensimbi emsulwa, akukho pende noma yiluphi uhlobo lwezinto zamakhemikhali ezingaphezulu, izinga lokushisa eliphakeme elingu-600 degrees alincibiliki, alikhiqizi amagesi anobuthi, lihlangabezana nokuphepha komlilo kanye nezidingo zokuvikela imvelo.

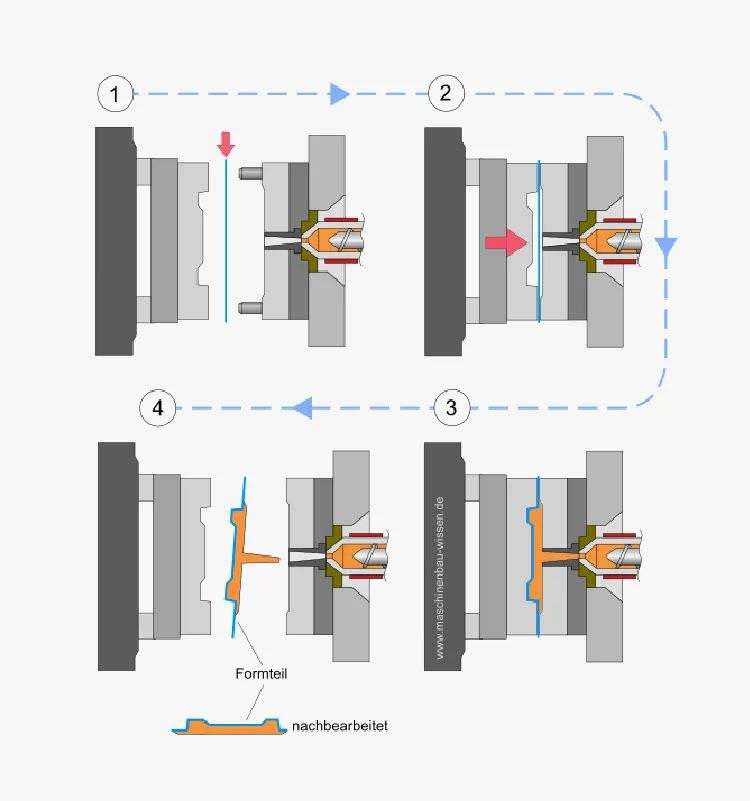

10. Umhlobiso ongaphakathi kwesikhunta

—— In-Mold Decoration-IMD ——

Kuyindlela yokubumba ebeka i-diaphragm ephrintiwe iphethini khona kanye esibunjeni sensimbi kanye nesikhutha, ifake inhlaka ukuze ibunjwe khona kanye esibunjeni sensimbi kanye nesikhutha futhi ihlanganise i-diaphragm, futhi yenze i-diaphragm ephrintiwe iphethini kanye i-resin ihlanganiswe futhi yaqina ibe umkhiqizo oqediwe.

Umkhiqizo ofanelekile: indawo yepulasitiki

Izindleko zokucwenga: vele uvule iqoqo lesikhunta nesikhutha, elinganciphisa izindleko kanye namahora omuntu, ukukhiqizwa okuzenzakalelayo okuphezulu, inqubo yokukhiqiza eyenziwe lula, indlela yokubumba umjovo wesikhathi esisodwa, kanye nokuthola ukubumba nokuhlobisa endaweni. Ngisikhathi esifanayo.

Umthelela wendawo: Lobu buchwepheshe besimanje buhambisana nemvelo kanye nemvelo, bunqanda ukungcoliswa okubangelwa ukudweba okuvamile kanye nokufakwa kwe-electroplating.

Izinzuzo ze-Anebon izindleko ezincishisiwe, ithimba lemali engenayo eliguqukayo, i-QC ekhethekile, amafekthri aqinile, izinsizakalo zekhwalithi ye-premium ye-cnc machining aluminium yokwenza izingxenye kanye nesevisi yokwenza izingxenye ze-cnc machining. I-Anebon izibekele umgomo wokuqamba kabusha uhlelo oluqhubekayo, ukusungula izinto ezintsha zokuphatha, ukusungula izinto ezintsha kanye nokuqanjwa kabusha komkhakha, inikeze ukudlala okuphelele ukuze uthole izinzuzo zizonke, futhi ihlale yenza intuthuko ukuze isekele kahle kakhulu.

I-Anebon New Product China Lock-Hole Processing Machine kanye ne-Aluminium Window Lock Hole Processing Machine, i-Anebon inolayini wokukhiqiza ophelele, umugqa wokuhlanganisa, uhlelo lokulawula ikhwalithi, futhi okubaluleke kakhulu, manje i-Anebon inobuchwepheshe obuningi bamalungelo obunikazi kanye nethimba elinolwazi lobuchwepheshe nokukhiqiza, isevisi yokuthengisa enolwazi. iqembu. Ngazo zonke izinzuzo zabantu, besilokhu sidala “umkhiqizo ohlonishwayo wamazwe ngamazwe we-nylon monofilaments”, futhi sisabalalisa okuthengiswayo kwethu kuwo wonke amagumbi omhlaba. Besilokhu sihamba futhi sizama konke okusemandleni ethu ukusiza amakhasimende ase-Anebon.

Isikhathi sokuthumela: Jul-29-2023