Kungani kufanele sikhiphe imikhiqizo egayiwe?

Ukuphepha:

I-Burrs ingase idale imiphetho ebukhali nama-protrusions, okungase kube yingozi kubasebenzi kanye nabasebenzisi bokugcina.

Ikhwalithi:

Ngokususa ama-burrs, ungathuthukisa ikhwalithi nokubukeka komkhiqizo wakho.

Ukusebenza:

I-Burrs ingathinta ukusebenza kwezingxenye kanye nokuxhumana kwazo nezinye izingxenye.

Ukuthobela Umthetho

Izimboni ezithile zinemithetho eqinile mayelana namazinga okubekezelela i-burr ukuze kuqinisekiswe ukusebenza komkhiqizo nokuphepha.

Ukuhlanganisa Nokuphatha

Imikhiqizo eboshiwe yenza kube lula ukuphatha nokuhlanganisa, okunciphisa ingozi yokulimala.

Ama-Burrs avame ukukhiqizwa phakathi nenqubo yokusika insimbi. Ama-Burrs anganciphisa ukunemba kokucubungula kanye nekhwalithi yangaphezulu yesiqeshana sokusebenza. Ziphinde zibe nomthelela ekusebenzeni komkhiqizo futhi, kwezinye izimo, zidale izingozi. I-Deburring ngokuvamile isetshenziselwa ukuxazulula inkinga ye-burr. Ukukhipha imali akuyona inqubo ekhiqizayo. Ukukhipha imali kuyinqubo engakhiqizi. Yandisa izindleko, yandise imijikelezo yokukhiqiza futhi ingaholela ekulahleni wonke umkhiqizo.

Ithimba le-Anebon lihlaziye lachaza izici ezithinta ukwakheka kwama-milling burrs. Baphinde baxoxisana ngezindlela nobuchwepheshe obukhona bokunciphisa ama-milling burrs kanye nokuwalawula, kusukela esigabeni sokuklama kwesakhiwo kuya ohlelweni lokukhiqiza.

1. Qeda ama-burrs okugaya: izinhlobo eziyinhloko

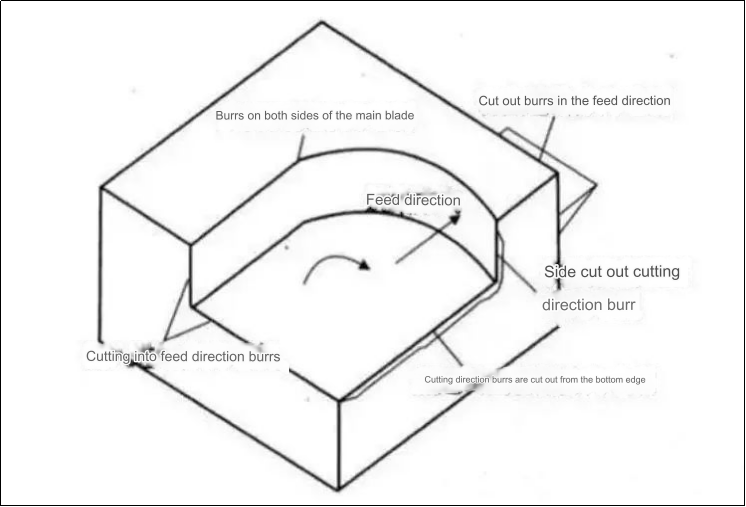

Ngokohlelo lokuhlukaniswa kwama-burrs okusekelwe ekusikeni kokunyakaza kanye nethuluzi lokusika, ama-burrs amakhulu akhiqizwa ngesikhathi sokugaya ahlanganisa ama-burrs womabili ezinhlangothini zendawo eyinhloko, ama-burrs eceleni ohlangothini lokusika, ama-burrs ahambisana ngezansi. ohlangothini lokusika, futhi usike ngaphakathi nangaphandle kokuphakelayo. Kunezinhlobo ezinhlanu zama-burrs aqondisayo.

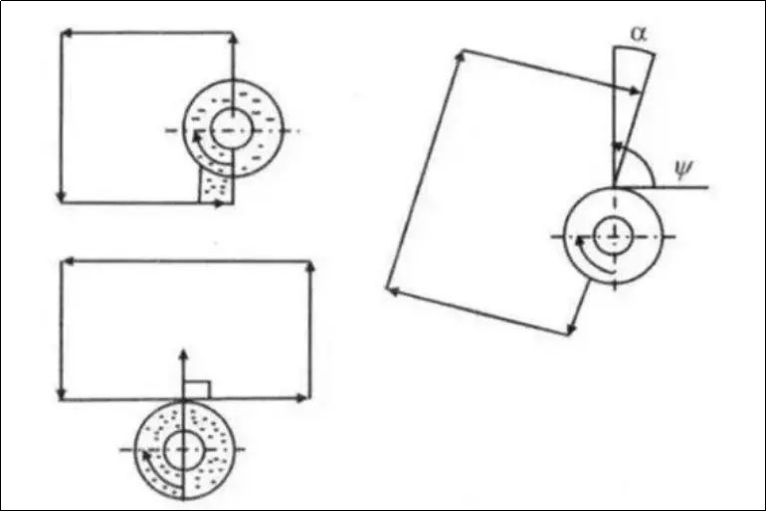

Umfanekiso 1 Ama-Burrs akhiwe ngokugaywa kokuphela

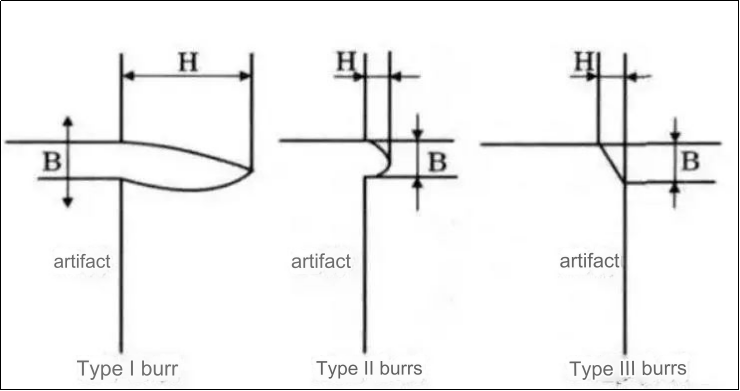

Ngokuvamile, usayizi wama-burrs asendleleni yokusika emaphethelweni aphansi makhulu futhi kunzima kakhulu ukuwasusa. Leli phepha ligxile kuma-burrs onqenqemeni olungezansi asezikhombisi-ndlela zokusika. Usayizi nokuma kungahlukaniswa ngezinhlobo ezintathu ezahlukene zama-burrs atholakala ekugcineni kokuqondisa kokugaya. Amabhula ohlobo lwe-I angaba nzima ukuwasusa futhi abize, ama-Type II burrs angasuswa kalula, futhi ama-Type III burrs angaba negethivu (njengoba kuboniswe kumfanekiso 2).

Umfanekiso 2 Izinhlobo zamaBurrs ngasendleleni yokugaya.

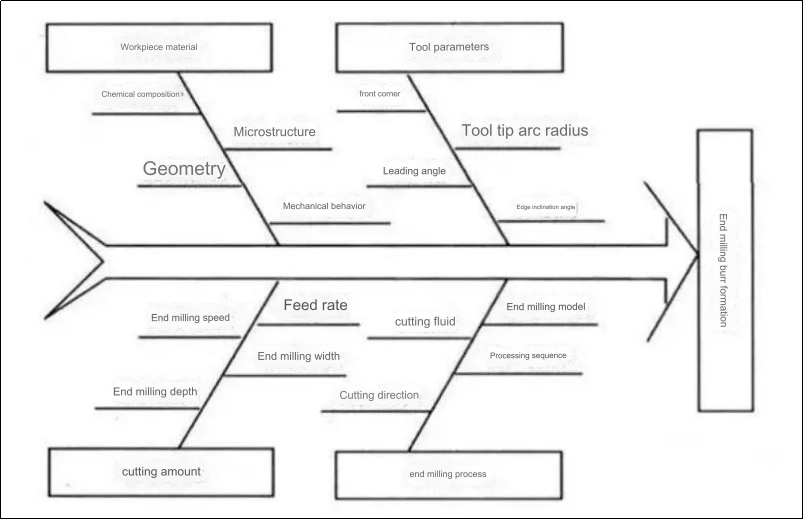

2. Izici eziyinhloko ezithinta ukwakheka kwama-burrs emishinini yokugaya ekugcineni

Ukwakheka kwe-Burr kuyinqubo eyinkimbinkimbi yokuguqulwa kwezinto. Ukwakheka kwama-burrs kuthintwa izinto eziningi, okuhlanganisa izici ezibonakalayo ze-workpiece, ijometri yayo, ukwelashwa kwendawo, i-geometry yamathuluzi nendlela yokusika, ukugqokwa kwamathuluzi, imingcele yokusika, ukusetshenziswa kokupholisa, njll. Umdwebo webhulokhi kuMfanekiso 3 ibonisa izici ezithinta ukuphela kokugaya. Umumo nosayizi wokuphela kwe-millings burrs kuncike emthelela wokuqongelela wezinto ezithonya ezahlukahlukene ngaphansi kwezimo ezithile zokugaya. Kodwa-ke, izici ezihlukene zinomthelela ohlukile ekwakhekeni kwama-burr.

Umfanekiso 3: Ishadi Lembangela Nomphumela Wokwakhiwa Kwe-Milling Burr

1. Ukungena/ukuphuma kwethuluzi

Ama-burrs akhiqizwa lapho ithuluzi lizungeza lisuka kucezu lokusebenza livame ukuba likhulu kunalawo akhiqizwayo uma lizungeza ngaphakathi.

2. Susa i-engeli endizeni

Ama-engeli anqunyiwe endiza anethonya elikhulu kuma-burrs okwakheka eduze konqenqema olungezansi. Lapho unqenqema lokusika luzungeza lusuka endaweni yetheminali yesiqeshana sokusebenza endizeni, sidlula endaweni ethile e-eksisi yomsiki wokugaya ngaleso sikhathi, inhlanganisela ye-vector yejubane lamathuluzi nesivinini sokuphakelayo ilingana ne-engeli ephakathi kokuqondisa kobuso bokuphela kwe-hekta. umsebenzi. Ubuso bokugcina bomsebenzi wokusebenza busuka kusikulufa samathuluzi buqonde endaweni yokuphuma yamathuluzi. Emfanekisweni 5, ububanzi be-Ps, i-engeli enqunywe endizeni ngu-0degPs=180deg.

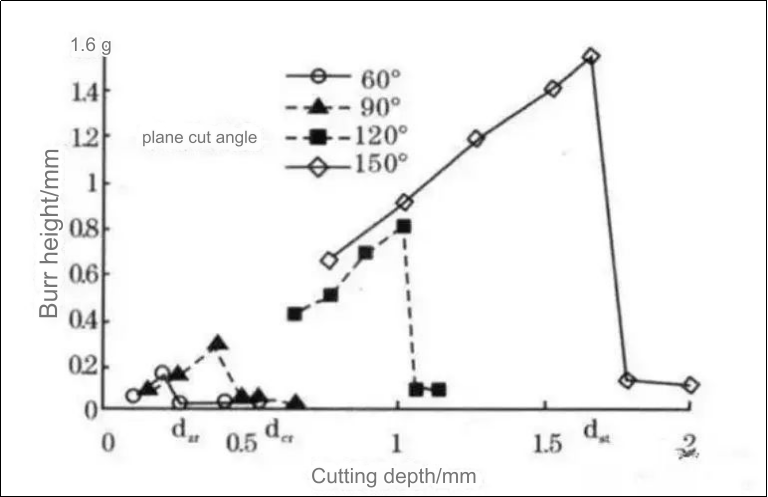

Imiphumela yokuhlolwa ikhombisa ukuthi njengoba ukujula kokusika kukhuphuka ama-burrs ashintsha ukusuka ohlotsheni I kuya ohlotsheni II. Ngokuvamile, ubuncane bokujula kokugaya okudingekayo ukukhiqiza uhlobo lwe-II burrs (okwaziwa nangokuthi ukujula kokusika komkhawulo noma i-dcr) kubizwa ngokuthi ukujula kokugaya okuncane. Umfanekiso wesi-6 ukhombisa umthelela wama-engeli okusika indiza kanye nokusika ukujula ekuphakameni kwe-burr ngesikhathi somshini we-aluminium alloy.

Umfanekiso 6 I-engeli yokusika indiza, ifomu le-burr kanye nokujula kokusika

Umfanekiso wesi-6 ubonisa ukuthi, lapho i-engeli yokusika indiza inkulu ukuthi i-120deg uhlobo I-burrs inkulu futhi ukujula lapho ishintsha khona ku-type II burrs kuyanda. I-engeli encane yokusika indiza izokhuthaza ukwakheka kohlobo lwe-II burrs. Isizathu siwukuthi inani eliphansi le-Ps, kukhulu ukuqina kobuso endaweni yokugcina. Lokhu kwenza kube mancane amathuba okuba ama-burrs.

Isivinini sokuphakelayo kanye nokuqondisa kwayo kuzothonya isivinini kanye ne-engeli yokusikwa kwendiza kanye nokwakheka kwama-burrs. Uma kukhulu izinga lokuphakelayo kanye nokususwa konqenqema ekuphumeni, a, kanye ne-P encane, kuphumelela kakhulu ukucindezela ukwakheka kwama-burrs amakhulu.

Umfanekiso 7 Imiphumela yendlela yokuphakelayo ekukhiqizweni kwe-burr

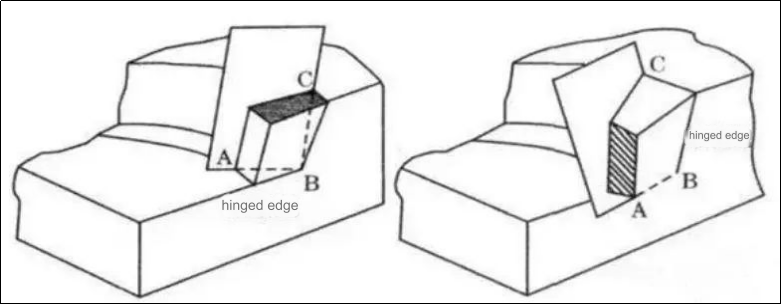

3. Ithiphu yethuluzi ukulandelana kokuphuma kwe-EOS

Usayizi we-burr unqunywa kakhulu indlela ithiphu lethuluzi eliphuma ngayo esigayweni sokugcina. Emfanekisweni wesi-8, iphuzu A limelela unqenqema oluncane lokusika. Iphuzu C limelela amaphethelo amakhulu okusika. Futhi iphoyinti B limelela i-tip apex. Irediyasi yethiphu yethuluzi ayinakwa ngoba kucatshangwa ukuthi ibukhali. Ama-chips azoxhonywa ngaphezulu kwendawo yokusebenza ewumshini uma unqenqema u-AB lushiya ucezu lokusebenza ngaphambi konqenqema luka-BC. Njengoba inqubo yokugaya iqhubeka, ama-chips aphushwa kusuka kucezu lokusebenza enze i-burr enkulu yokusika enqenqemeni. Uma unqenqema AB lushiya ucezu lokusebenza ngaphambi konqenqema BC, ama-chips azoncika endaweni yoshintsho. Bese bayasikwa ku-workpiece bebheke ekusikeni.

Ukuhlolwa kubonisa:

①Ithuluzi lokuphuma ngokulandelana kwethiphu ye-ABC/BAC/ACB/BCA/CAB/CBA ekhulisa usayizi we-burr ngokulandelana.

②Imiphumela ye-EOS iyafana, ngaphandle kweqiniso lokuthi usayizi we-burr okhiqizwa ngezinto zepulasitiki ngaphansi kokulandelana okufanayo kokuphuma mkhulu kunalowo okhiqizwa ngezinto eziphukayo. Ukulandelana kokuphuma kwethiphu yethuluzi akuhlobene nje kuphela nejiyomethri yamathuluzi kodwa futhi nezici ezifana nenani lokuphakelayo, ukujula kokugaya, i-workpiece geometry, nezimo zokusika. Ama-Burrs akhiwa yinhlanganisela yezinto eziningi.

Umfanekiso 8 Ukwakhiwa kwethiphu yethuluzi kanye nokulandelana kokuphuma

4. Ithonya Lezinye Izinto

① Amapharamitha wokugaya (izinga lokushisa, indawo yokusika, njll.). Ukwakheka kwama-burrs nakho kuzothintwa yizici ezithile. Umthelela wezici ezinkulu ezifana nesivinini sokuphakelayo, ibanga lokugaya, njll. I-engeli yokusika indiza kanye nokulandelana kwethiphu yethiphu yamathiyori e-EOS kubonakala kumbono wokusika ama-engeli endiza. Ngeke ngingene emininingwaneni lapha;

② Ipulasitiki eyengeziwe impahlaizingxenye eziphendukayo ze-cnc, kuzoba lula ukwenza ukuthi ngibhale ama-burrs. Uma uqeda umshini wokugaya, amanani amakhulu okuphakelayo noma ama-engeli amakhulu okusika indiza kungaholela ekushiyekeni kohlobo lwe-III.

③ Ukuqina okukhuphukile kwendawo kungacindezela ukwakheka kwama-burrs lapho i-engeli phakathi kwendawo yokugcina kanye nendiza eyenziwe ngomshini idlula i-engeli engakwesokudla.

④ Ukusetshenziswa koketshezi lokugaya kunenzuzo ekwandiseni impilo yamathuluzi, ukunciphisa ukuguga, ukugcoba inqubo yokugaya kanye nokunciphisa amasayizi we-burr;

⑤ Ukuguga kwethuluzi kunomthelela omkhulu ekwakhekeni kwe-burr. I-arc yethiphu iyanda lapho ithuluzi ligqokwe ngezinga elithile. Usayizi we-burr uyakhuphuka lapho uphuma khona insimbi, nasendleleni yokusika. Ucwaningo olwengeziwe luyadingeka ukuze uqonde indlela. Gubha ujule.

⑥ Ezinye izici, ezifana nethuluzi, zingaba nomthelela ekwakhekeni kwe-burr. Amathuluzi edayimane acindezela ama-burrs kangcono kunamanye amathuluzi ngaphansi kwezimo ezifanayo.

3. Ukulawula ukwakheka kwama-milling burrs kulula.

Izinto eziningi zinomthelela ekwakhekeni kwama-end-milling burrs. Inqubo yokugaya iyisici esisodwa kuphela esithinta ukwakheka kwama-end milling burrs. Ezinye izici zihlanganisa i-geometry yethuluzi, isakhiwo kanye nosayizi we-workpiece, njll. Ukuze unciphise inani lama-burrs okuphela akhiqizwayo, kuyadingeka ukulawula nokunciphisa ukukhiqizwa kwe-burr kusuka kuma-engeli amaningi.

1. Idizayini yesakhiwo enengqondo

Isakhiwo se-workpiece siyisici esibalulekile ekwakhekeni kwama-burrs. Umumo nosayizi ngemva kokucutshungulwa kwama-burrs emaphethelweni nakho kuzohluka kuye ngesakhiwo se-workpiece. Lapho impahla kanye nokwelashwa surface of theizingxenye ze-cncziyaziwa, i-geometry nemiphetho idlala indima enkulu ekwakhekeni kwama-burrs.

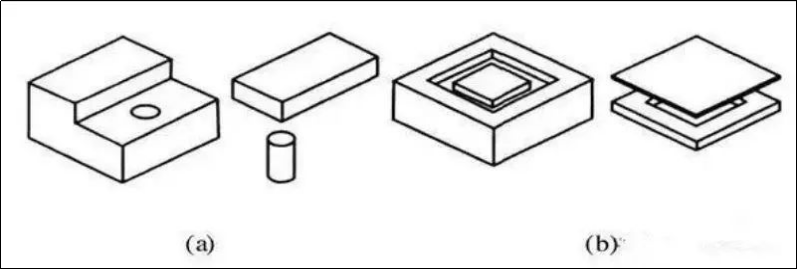

2. Ukulandelana kokucubungula

Uhlelo olwenziwa ngalo ukucubungula lungaphinda lube nomthelela kusayizi we-burr nomumo. Ukukhipha imali kuthinteka ngokuma nosayizi, kanye nomthwalo wokukhipha imali kanye nezindleko. Izindleko zokukhokha zingancishiswa ngokukhetha ukulandelana kokucubungula okufanele.

Umfanekiso 9 Ukukhetha indlela yokulawula ukulandelana kokucubungula

Uma indiza ekuMdwebo 10a ibhojwa kuqala bese igaywa, khona-ke kuzoba nama-milling burrs amakhulu azungeze umgodi. Kodwa-ke, uma kuqala ukugaywa bese kubhojwa, khona-ke ama-burrs amancane kuphela abonakalayo. Emfanekisweni we-10b, i-burr encane iyakhiwa lapho indawo ye-concave iqala ukugaywa, kulandelwa ukugaya kwendawo engaphezulu.

3. Gwema Ukuphuma Kwethuluzi

Kubalulekile ukugwema ukuhoxiswa kwamathuluzi, njengoba lokhu kuyimbangela eyinhloko yama-burrs akha endaweni yokusika. Ama-burrs akhiqizwa lapho ithuluzi lokugaya lizungeziswa lisuka kucezu lokusebenza livame ukuba likhulu kunalawo akhiqizwayo uma lifakwe ngesikulufi. Isisiki sokugaya kufanele sigwenywe ngesikhathi sokucubungula kakhulu ngangokunokwenzeka. Umfanekiso wesi-4 ubonisa ukuthi i-burr edalwe kusetshenziswa uMfanekiso 4b yayincane kunaleyo ekhiqizwe uMdwebo 4.

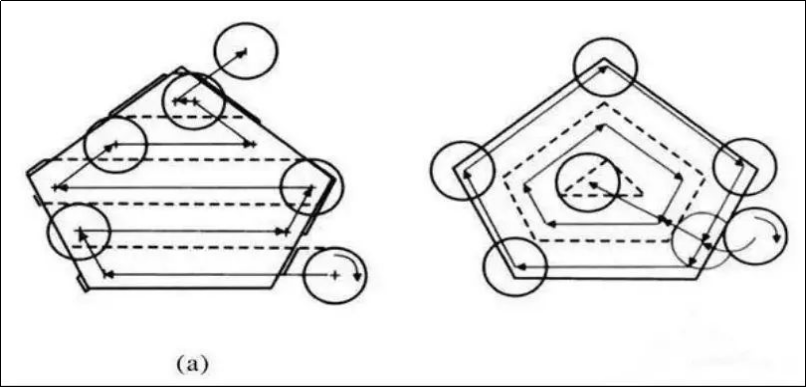

4. Khetha indlela yokusika efanele

Ukuhlaziywa kwangaphambilini kubonisa ukuthi usayizi we-burr mncane lapho i-engeli yokusika indiza ingaphansi kwenombolo ethile. Izinguquko kububanzi bokugaya, isivinini sokuzungezisa kanye nesivinini sokuphakela kungashintsha i-engeli yokusika indiza. Ngokukhetha indlela yamathuluzi efanelekile, kungenzeka ukugwema ukudala ama-burrs ohlobo lwe-I (bheka uMdwebo 11).

Umfanekiso 10: Indlela yethuluzi lokulawula

Umfanekiso 10a ukhombisa indlela yamathuluzi endabuko. Indawo enomthunzi wesibalo ibonisa indawo engenzeka lapho ama-burrs angenzeka endaweni yokusika. Umfanekiso 10b ubonisa indlela yamathuluzi ethuthukisiwe enganciphisa ukwakheka kwama-burrs.

Indlela yamathuluzi eboniswe kuMfanekiso 11b ingase ibe yinde kancane futhi ithathe ukugaywa okwengeziwe, kodwa ayidingi ukukhokhelwa okwengeziwe. Umdwebo 10a, ngakolunye uhlangothi, udinga ukuchithwa okuningi (nakuba engekho ama-burrs amaningi kule ndawo, empeleni, kufanele ususe wonke ama-burrs emaphethelweni). Kafushane, indlela yamathuluzi yomfanekiso 10b iphumelela kakhulu ekulawuleni ama-burrs kune-Figure 10a's.

5. Khetha amapharamitha okugaya afanelekile

Amapharamitha wokugaya ekugcineni (okufana nokuphakelayo ngezinyo ngalinye, ubude bokugaya, ukujula, kanye ne-engeli yejometri) angaba nomthelela omkhulu ekwakhekeni kwama-burrs. Ama-Burrs athintwa amapharamitha athile.

Ziningi izici ezinomthelela ekwakhekeni kwamaswarfs okuphela kokugaya. Izici eziyinhloko zifaka: ukungena/ukuphuma kwamathuluzi, ama-engeli okusika indiza, ukulandelana kwethiphu yamathuluzi, imingcele yokugaya njll. Ukuma nosayizi we-end milling burr kuwumphumela wezinto eziningi.

I-athikili iqala ngokuklama kwesakhiwo se-workpiece, inqubo yomshini, inani lokugaya kanye nethuluzi elikhethiwe. Ibese ihlaziya futhi idingide izici ezithonya ama-milling burrs futhi inikeze izindlela zokulawula izindlela zokusika izigayo, ikhethe ukulandelana kokucubungula okufanele kanye nokuthuthukisa ukwakheka kwesakhiwo. Ubuchwepheshe, izindlela, kanye nezinqubo ezisetshenziselwa ukucindezela noma ukunciphisa ama-milling burrs kunikeza izixazululo zobuchwepheshe ezinokwenzeka ezingasetshenziswa ekugayweni kokulawula okusebenzayo kosayizi we-burr nekhwalithi, ukunciphisa izindleko, kanye nemijikelezo yokukhiqiza emifushane.

Cabanga “ngesiqalo seKhasimende, Ikhwalithi ephezulu kuqala” engqondweni, i-Anebon isebenza eduze namakhasimende ethu futhi iwanikeze izinsiza ezisebenza kahle nezichwepheshile zeFactory For.CNC ukugaya izingxenye ezincane, cncizingxenye ze-aluminium ezenziwe ngomshinikanye nezingxenye zokuphonsa ze-Die. Ngoba i-Anebon ihlala njalo nalo mugqa ngaphezu kweminyaka eyi-12. I-Anebon ithole ukwesekwa kwabahlinzeki abaphumelela kakhulu ngokuhle kakhulu nangezindleko. Futhi i-Anebon yayinabahlinzeki bokhula abanekhwalithi ephansi ephansi. Manje izimboni ezimbalwa ze-OEM zibambisane nathi futhi.

I-Factory For China Aluminium Section and Aluminium, i-Anebon ingahlangabezana nezidingo ezihlukahlukene zamakhasimende ekhaya naphesheya. Samukela amakhasimende amasha namadala ukuthi eze azobonisana futhi axoxisane nathi. Ukwaneliseka kwakho kuyisisusa sethu! Vumela i-Anebon isebenzisane ukuze ibhale isahluko esisha esihle!

Uma ungathanda ukwazi okwengeziwe noma ukuthola ikhotheshini, sicela uxhumaneinfo@anebon.com

Isikhathi sokuthumela: Dec-06-2023