Umqondo oyisisekelo wokumba

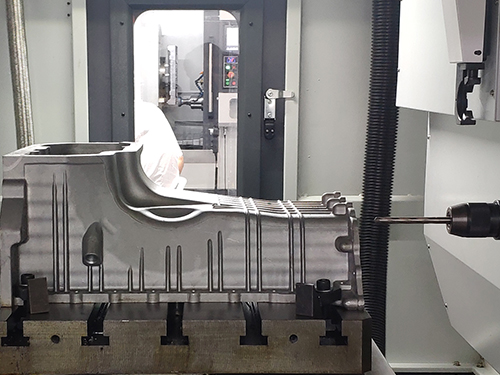

Ngaphansi kwezimo ezijwayelekile, ukubhola kusho indlela yokucubungula lapho i-drill yenza izimbobo ekuboniseni umkhiqizo. Ngokuvamile, lapho ubhoboza umkhiqizo emshinini wokubhoboza, i-drill bit kufanele iqedele ukunyakaza okubili ngasikhathi sinye:Ingxenye yemishini ye-CNC

① Ukunyakaza okuyinhloko, okungukuthi, ukunyakaza kokujikeleza kwebhithi yokubhoboza eduze kwe-eksisi (ukusika ukunyakaza);

②Ukunyakaza kwesibili, okungukuthi, ukunyakaza okuqondile kokubhoboza kuya endaweni yokusebenza eduze kwe-eksisi (ukunyakaza kokuphakelayo).

Lapho ubhoboza, ngenxa yamaphutha esakhiweni se-drill bit, kuzoshiya iminonjana ezingxenyeni ezicutshunguliwe zomkhiqizo futhi kuthinte ikhwalithi yokucubungula ye-workpiece. Ukunemba kokucubungula kuvame ukuba ngaphansi kwe-IT10, futhi ubulukhuni obungaphezulu bucishe bube ngu-Ra12.5μm, okuyingxenye yesigaba sokucubungula.

Inqubo yokusebenza yokumba

Dwebela

Ngaphambi kokumba, qala uqonde izidingo zomdwebo. Ngokwezidingo eziyisisekelo zokubhoboza, sebenzisa amathuluzi ukudweba umugqa ophakathi nendawo yembobo. Umugqa omaphakathi kufanele ucace futhi unembile, futhi omncane ube ngcono. Ngemuva kokuthi umugqa udwetshiwe, sebenzisa i-vernier caliper noma irula yensimbi. Thatha izilinganiso.ingxenye eyenziwe ngomshini

Hlola isikwele noma hlola indilinga

Ngemuva kokuthi umugqa udwetshiwe futhi udlule ukuhlolwa, igridi yokuhlola noma indilinga yokuhlola enomugqa omaphakathi wembobo njengesikhungo se-symmetry kufanele sidwetshwe njengomugqa wokuhlola wokubhoboza ukuhlolwa, ukuze isiqondiso sokumba sihlolwe futhi silungiswe. ngesikhathi sokumba.

Ukuqinisekisa

Ngemva kokumaka isikwele sesheke esihambisanayo noma hlola indilinga, kufanele ufakazele ngokucophelela iso. Yenza indawo encane kuqala, futhi ulinganise izikhathi eziningi ngezindlela ezihlukene zomugqa omaphakathi wesiphambano ukuze ubone ukuthi i-punch ishaya ngempela yini ukuphambana komugqa omaphakathi wesiphambano, bese ushaya isibhakela kwesokudla, nxazonke, futhi enkulu ukuze iqonde. Ummese ugxile.

I-clamping

Sebenzisa i-rag ukuhlanza ithebula lomshini, indawo yokulungisa, nendawo eyireferensi yendawo yokusebenza, bese ucindezela ucezu lokusebenza. I-clamping iphansi futhi ithembekile njengoba kudingeka, futhi kulula ukubuza nokukala nganoma yisiphi isikhathi. Kudingekile ukuthi unake indlela yokubopha ye-workpiece ukuvimbela ucezu lokusebenzela ukuthi lungaguquki ngenxa ye-clamping.

Isivivinyo sokuprakthiza

Ukuhlola ukubhoboza kuyadingeka ngaphambi kokumba okusemthethweni: i-drill bit iqondaniswe nenkaba yembobo ukuze kubhojwe umgodi ongashoni, bese ubheka ngokubukeka ukuthi umgodi ongashoni usendaweni efanele yini, futhi ukulungiswa okuqhubekayo kuyadingeka ukwenza umgodi ongashoni u-coaxial. nombuthano wokuhlola. Uma ukwephulwa kuncane, ungaphoqa i-workpiece ukuthi ihambe iye kolunye uhlangothi lokwephulwa kohambo ukuze ufinyelele ukuhlolwa kancane kancane.

Ukubhoboza

Ukumba okufakwa ngomshini ngokuvamile kusekelwe ekusebenzeni kokuphakelayo mathupha. Lapho ukunemba kwe-azimuth kokumba ukuhlolwa kuyadingeka, ukubhoboza kungenziwa. Ngesikhathi sokuphakela okwenziwa ngesandla, amandla okuphakelayo akufanele abangele ukuthi i-drill igobe futhi igweme i-axis yembobo ekutshekeni.cnc turning ingxenye

Indlela enembe kakhudlwana yokumba

Ukulola i-drill bit kuyisiqalo sayo yonke into

Ngaphambi kokumba, khetha i-drill bit ehambisanayo ukuze ucije. Ibhithi yokubhola ecijile igcina i-apex angle enembile, i-engeli yokukhulula kanye ne-chisel edge edge bevel angle, ubude bamaphethelo amabili ayinhloko ayisicaba futhi alinganayo emugqeni omaphakathi webhithi yokubhoboza, futhi izindawo ezimbili eziyinhloko zeflank zibushelelezi, ukuze lula ukugxila futhi unciphise ukugoqa kodonga lwembobo , Unqenqema lweshizolo kanye nonqenqema lokusika kufanele lugaywe kahle (kungcono kakhulu umhlabathi omahhadla ku-grinder kuqala, bese ugaya etsheni lamafutha).

Ukumaka okunembile kuyisisekelo

Uma usebenzisa irula lokuphakama ukuze udwebe ngokunembile umugqa, into yokuqala okufanele uyenze ukuqinisekisa ukunemba kwezinga. Uma ubhala, yenza i-angle yenaliti yokubhala kanye nendiza yokubhala ye-workpiece yakha i-engeli yama-degrees angu-40 kuya kwangu-60 (ngokuhambisana nesiqondiso sokubhala), ukuze imigqa edwetshiwe icace futhi ilingane.

Naka ukukhethwa kwendiza yedatha yokumaka, indiza ye-datum kufanele icutshungulwe ngokunembile, futhi ukuqina kwayo ngokwayo kanye ne-perpendicularity endaweni eseduze kufanele kuqinisekiswe. Ngemuva kokuthi umugqa wesiphambano wesikhundla somgodi udwetshiwe, ukuze uqinisekise ukuqondanisa kalula lapho ubhoboza, sebenzisa i-punch ephakathi ukuze ukhiphe iphuzu eliphakathi emgqeni wesiphambano (idinga iphuzu le-punch libe lincane futhi isiqondiso sibe nenembile).

Ukubopha okulungile kuyisihluthulelo

Ngokuvamile, ezimbobeni ezinobubanzi obungaphansi kuka-6mm, uma ukunemba kungenalo phezulu, sebenzisa izimpintsha zesandla ukuze ubambe ucezu lomsebenzi wokubhola; emigodini ye-6 kuya ku-10mm, uma i-workpiece ivamile futhi injalo, i-flat-nose pliers ingasetshenziswa ukubamba i-workpiece, kodwa i-workpiece kufanele iboshwe I-surface i-perpendicular ku-spindle yomshini wokubhoboza. Uma ubhoboza imbobo enobubanzi obukhulu, i-flat-nose pliers kufanele ilungiswe ngepuleti yokucindezela i-bolt; kuma-workpieces amakhulu anobubanzi bembobo obuyi-10mm noma ngaphezulu, indlela yokucindezela ipuleti isetshenziselwa ukubhoboza imbobo.

Ukusesha okunembile kuyisihluthulelo

Ngemuva kokuthi i-workpiece iboshwe, ungajahi ukulahla i-drill, futhi okokuqala wenze ukuqondanisa.

Ukuqondanisa kunokuqondanisa okumile nokuqondanisa okuguquguqukayo. Okubizwa ngokuthi ukulungiswa kwe-static kubhekisela ekuqondaneni ngaphambi kokuba umshini wokubhoboza uqaliswe, ukuze umugqa ophakathi we-spindle yomshini wokubhoboza kanye nomugqa wesiphambano we-workpiece uqondaniswe. Le ndlela iphephile futhi ilungele abaqalayo futhi kulula ukuyiqonda, kodwa ngenxa yokuthi ukujikijela kwe-spindle yomshini wokumba akucatshangelwa, isibonelo Kanye nezinye izici ezingaqinisekile, ukunemba kokumba kuphansi. Ukusesha okunamandla kwenziwa ngemva kokwethulwa komshini wokumba. Ngesikhathi sokulungiswa, kucatshangelwa izici ezithile ezingaqinisekile, futhi ukunemba kuphakeme kakhulu.

Ukuhlola ngokucophelela kubalulekile

Ukutholwa kungathola ngokunembile nangesikhathi ukunemba kwembobo ukuze kuthathwe izinyathelo ezidingekayo ukuze kunxeshezelwe.

Emigodini enembayo ephezulu enembayo, ngokuvamile sisebenzisa izindlela zokumba, ukulungisa kabusha, nezindlela zokucubungula kabusha. Ngemva kokubhoboza imbobo encane esinyathelweni sokuqala, sebenzisa i-caliper ukuthola iphutha ukusuka maphakathi nembobo engezansi kuya endizeni eyireferensi, futhi ubale indawo yembobo engezansi kanye nesikhungo esikahle ngemva kokulinganisa kwangempela. Uma iphutha lingelikhulu kuno-0.10mm, lingashintshwa kabusha Yandisa kahle i-engeli ephezulu ye-drill bit, yenza buthaka umphumela wokumisa othomathikhi, usunduze kahle ucezu lokusebenzela ohlangothini oluhle, futhi kancane kancane wandise ububanzi bethiphu yokubhoboza ukuze unxephezele. . Uma inani lephutha likhulu kuno-0.10mm, ungasebenzisa amafayela ayindilinga ahlukahlukene ukuze usike izindonga ezisemaceleni ezimbili zembobo engezansi, futhi ingxenye yokunquma kufanele ixhunywe nokushintshwa okubushelelezi kwembobo engezansi.

We are a reliable supplier and professional in CNC Machining service. If you need our assistance please contact me at info@anebon.com.

I-Anebon Metal Products Limited inganikeza i-CNC Machining, i-Die Casting, isevisi yokwenziwa kwe-Sheet Metal, sicela ukhululeke ukuxhumana nathi.

Tel: +86-769-89802722 E-mail: info@anebon.com URL: www.anebon.com

Isikhathi sokuthumela: Mar-02-2021