Ukwakhiwa kwezinto zamathuluzi kuyinqubo ehambisana nezidingo ezithile zenqubo ethile yokukhiqiza. Lokhu kwenziwa ngemva kokuphothulwa kwenqubo yomshini wezingxenye. Lapho uthuthukisa inqubo yokukhiqiza, kubalulekile ukucabangela ukuthi kungenzeka yini ukusebenzisa izinto ezilungiswayo. Ukwengeza, ukuguqulwa kwenqubo kungahlongozwa ngesikhathi sokuklanywa kwesakhiwo uma kubonakala kudingekile. Ikhwalithi yomklamo wesakhiwo sikalwa ngekhono layo lokuqinisekisa izinga lokucubungula elizinzile le-workpiece, ukusebenza kahle kokukhiqiza okuphezulu, izindleko eziphansi, ukususwa kwe-chip okulula, ukusebenza okuphephile, ukonga abasebenzi, kanye nokukhiqiza nokugcinwa okulula.

1. Izimiso eziyisisekelo zokuklama impahla yamathuluzi imi kanje:

1. Isakhiwo kufanele siqinisekise ukuzinza nokuthembeka kokuma kwendawo yokusebenza ngesikhathi sokusetshenziswa.

2. Isakhiwo kufanele sibe namandla anele okuthwala noma okubamba ukuze kuqinisekiswe ukucutshungulwa kwendawo yokusebenza.

3. Inqubo yokubopha kufanele ibe lula futhi isheshe ukusebenza.

4. Izingxenye ezigqokwayo kufanele zishintsheke ngokushesha, futhi kungcono ukungasebenzisi amanye amathuluzi uma izimo zivuma.

5. Isakhiwo kufanele sihlangabezane nokuthembeka kokuma okuphindaphindiwe ngesikhathi sokulungiswa noma ukushintshwa.

6. Gwema ukusebenzisa izakhiwo eziyinkimbinkimbi kanye nezindleko ezibiza kakhulu ngangokunokwenzeka.

7. Sebenzisa izingxenye ezijwayelekile njengezingxenye noma nini lapho kunokwenzeka.

8. Yakha i-systematization kanye nokumiswa kwemikhiqizo yangaphakathi yenkampani.

2. Ulwazi oluyisisekelo lwe-tooling kanye ne-fixture design

Ithuluzi lomshini elihle kakhulu kufanele lihlangabezane nezidingo eziyisisekelo ezilandelayo:

1. Ukhiye wokuqinisekisa ukunemba komshini usekukhetheni ireferensi yokuma, indlela, nezingxenye ngendlela efanele. Kubalulekile futhi ukuhlaziya amaphutha okubeka futhi ucabangele umthelela wesakhiwo sendawo ekunembeni komshini. Lokhu kuzoqinisekisa ukuthi i-fixture ihlangabezana nezidingo zokunemba ze-workpiece.

2. Ukuthuthukisa ukusebenza kahle kokukhiqiza, sebenzisa izindlela zokubopha ezisheshayo nezisebenzayo ukuze unciphise isikhathi esiyisizayo futhi uthuthukise ukukhiqiza. Ubunkimbinkimbi bezinto ezifakiwe kufanele buvumelane namandla okukhiqiza.

3. Izakhiwo ezikhethekile ezinohlelo oluhle lokusebenza kufanele zibe nesakhiwo esilula nesinengqondo esenza kube lula ukukhiqiza, ukuhlanganisa, ukulungisa, nokuhlola.

4. Izakhiwo zokusebenza ezisebenza kahle kufanele zibe lula, zonge abasebenzi, ziphephe, futhi zithembeke ukuze zisebenze. Uma kungenzeka, sebenzisa i-pneumatic, hydraulic, nezinye izinsimbi zokubopha ezenziwe ngomshini ukuze unciphise umfutho wokusebenza komsebenzisi. I-fixture kufanele futhi yenze kube lula ukukhishwa kwe-chip. Isakhiwo sokususwa kwe-chip singavimbela ama-chips ukuthi alimaze ukuma kwengcezu yokusebenza kanye nethuluzi futhi kuvimbele ukunqwabelana kokushisa kusuka konakalise isistimu yenqubo.

5. Izakhiwo ezikhethekile ezinomnotho omuhle kufanele zisebenzise izingxenye ezijwayelekile kanye nezakhiwo ukuze kuncishiswe izindleko zokukhiqiza zale nto. Ukuhlaziywa okudingekayo kwezobuchwepheshe nezomnotho kwesisombululo sendawo kufanele kwenziwe ukuze kuthuthukiswe izinzuzo zaso zezomnotho ekukhiqizeni, ngokusekelwe ku-oda namandla okukhiqiza ngesikhathi sokuklama.

3. Uhlolojikelele lokumiswa kwamathuluzi nokuklanywa kwesakhiwo

1. Izindlela eziyisisekelo kanye nezinyathelo zokusebenzisa amathuluzi nokuklama kwesakhiwo

Ukulungiselela ngaphambi kokuklama Idatha yasekuqaleni yamathuluzi nesakhiwo sesakhiwo ihlanganisa lokhu okulandelayo:

a) Sicela ubuyekeze imininingwane yobuchwepheshe elandelayo: isaziso sokuklama, ingxenye yemidwebo eqediwe, imizila yenqubo yemidwebo engalungile, neminye imininingwane ehlobene. Kubalulekile ukuqonda izidingo zobuchwepheshe zenqubo ngayinye, okuhlanganisa uhlelo lokumisa nokubopha, ukucubungula okuqukethwe kwenqubo yangaphambilini, isimo esinzima, amathuluzi omshini namathuluzi asetshenziswa ekucubunguleni, amathuluzi okulinganisa okuhlola, izibonelelo zomshini, kanye nokusika inani.Isaziso sokuklama , imidwebo yengxenye eqediwe, imizila yenqubo yemidwebo engalungile, nolunye ulwazi lobuchwepheshe, ukuqonda izidingo zobuchwepheshe zokucubungula zenqubo ngayinye, uhlelo lokumisa nokuhlanganisa, ukucubungula okuqukethwe kwenqubo yangaphambilini, isimo esibi, amathuluzi omshini kanye amathuluzi asetshenziswa ekucubunguleni, amathuluzi okulinganisa okuhlola, izibonelelo zomshini kanye nenani lokusika, njll.;

b) Ukuqonda usayizi weqoqo lokukhiqiza kanye nesidingo sezinto ezilungiswayo;

c) Qonda amapharamitha wobuchwepheshe ayinhloko, ukusebenza, ukucaciswa, ukunemba, nobukhulu obuhlobene nesakhiwo sengxenye yokuxhuma kwento yethuluzi lomshini elisetshenzisiwe;

d)Uhlu lwempahla ejwayelekile yezakhiwo.

2. Izinkinga okufanele zicatshangelwe ekwakhiweni kwezinto zamathuluzi

Ukuklanywa kwe-clamp kubonakala kulula, kodwa kungabangela izinkinga ezingadingekile uma kungacatshangelwa ngokucophelela phakathi nenqubo yokuklama. Ukuthandwa okwandayo kwama-hydraulic clamps kwenze kwaba lula ukwakheka komshini wokuqala. Nokho, ukucatshangelwa okuthile kufanele kucatshangelwe ukuze kugwenywe izinkinga esikhathini esizayo.

Okokuqala, i-margin engenalutho ye-workpiece ezocutshungulwa kufanele inakwe. Uma usayizi wokungenalutho mkhulu kakhulu, ukuphazamiseka kwenzeka. Ngakho-ke, imidwebo enzima kufanele ilungiswe ngaphambi kokuklama, ishiye isikhala esiningi.

Okwesibili, ukususwa kwe-chip ebushelelezi kubalulekile. I-fixture ivame ukuklanywa endaweni ehlangene, engaholela ekuqoqweni kwezinhlamvu zensimbi emakhoneni afile omshini, nokuphuma kahle koketshezi lokusika, okubangela izinkinga esikhathini esizayo. Ngakho-ke, izinkinga ezivela ngesikhathi sokucubungula kufanele zicatshangelwe ekuqaleni kokusebenza.

Okwesithathu, ukuvuleka okuphelele kwe-fixture kufanele kubhekwe. Ukuziba ukuvuleka kwenza kube nzima ku-opharetha ukufaka ikhadi, okudla isikhathi futhi okudinga abasebenzi abaningi, futhi kuyihlazo ekwakhiweni.

Okwesine, izimiso zetiyori eziyisisekelo zomklamo wesakhiwo kufanele zilandelwe. Isakhiwo kufanele sigcine ukunemba kwayo, ngakho-ke akukho lutho okufanele luklanywe olungqubuzana nomgomo. Idizayini enhle kufanele ihambisane nesikhathi.

Okokugcina, ukushintshwa kwezingxenye zokubeka kufanele kucatshangelwe. Izingxenye zokumisa zigugile kakhulu, ngakho-ke ukushintshwa okusheshayo nokulula kufanele kwenzeke. Kungcono ukungaklami izingxenye ezinkulu.

Ukuqoqwa kokuhlangenwe nakho komklamo wesakhiwo kubalulekile. Idizayini enhle iyinqubo yokuqongelela okuqhubekayo nokufingqa. Kwesinye isikhathi ukuklama kuyinto eyodwa futhi ukusetshenziswa okusebenzayo kungenye. Ngakho-ke, kubalulekile ukucabangela izinkinga ezingase ziphakame ngesikhathi sokucubungula nokuklama ngendlela efanele. Inhloso yezakhiwo ukuthuthukisa ukusebenza kahle nokwenza lula ukusebenza.

Izinto ezisetshenziswayo ezisetshenziswa kakhulu zihlukaniswe ikakhulukazi izigaba ezilandelayo ngokuya ngokusebenza kwazo:

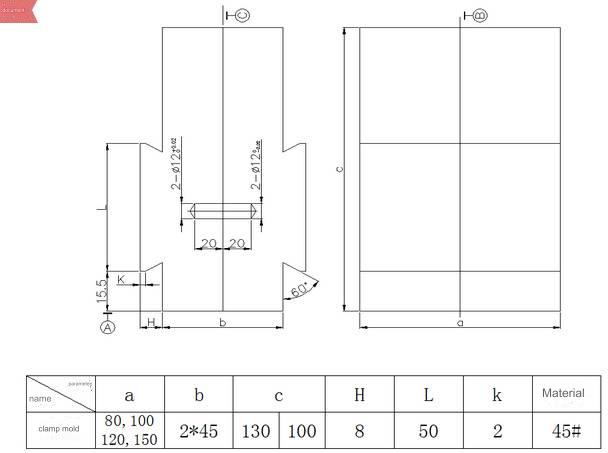

01 isikhunta se-clamp

02 Ukubhoboza nokugaya amathuluzi

03 CNC, insimbi chuck

04 Amathuluzi okuhlola igesi namanzi

05 Ukunquma nokushaya amathuluzi

06 Ukushisela amathuluzi

07 Ukupholisha i-jig

08 Amathuluzi womhlangano

09 Ukuphrinta kwephedi, ithuluzi lokuqopha nge-laser

01 isikhunta se-clamp

Incazelo:Ithuluzi lokubeka kanye nokuhlanganisa ngokusekelwe kumumo womkhiqizo

Amaphuzu Wokuklama:

1. Lolu hlobo lwe-clamp lusetshenziswa kakhulu kuma-vises, futhi ubude balo bungasikwa njengoba kudingeka;

2. Amanye amadivaysi okumisa asizayo angaklanywa kusikhunta sokubopha, futhi isikhunta sokubopha ngokuvamile sixhunywa ngokushisela;

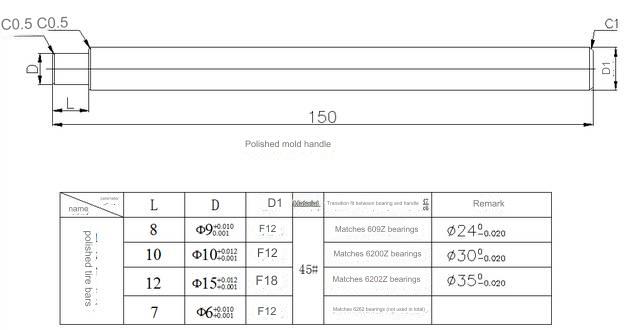

3. Isithombe esingenhla siwumdwebo owenziwe lula, futhi ubukhulu besakhiwo somgodi wokubunjwa bunqunywa isimo esithile;

4. Faka iphinikhodi yendawo enobubanzi obungu-12 endaweni efanele ekubunjweni okugudlukayo, kanye nembobo yokubeka endaweni ehambisanayo yamaslayidi esikhunta esingaguquki ukuze ilingane iphinikhodi;

5. Umgodi wokuhlanganisa udinga ukusulwa futhi ukhuliswe ngo-0.1mm ngokusekelwe endaweni ewuhlaka yomdwebo ongenalutho ongashwabeki lapho uklanywa.

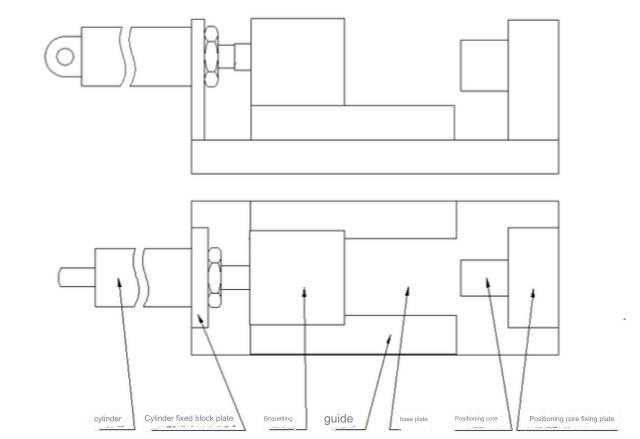

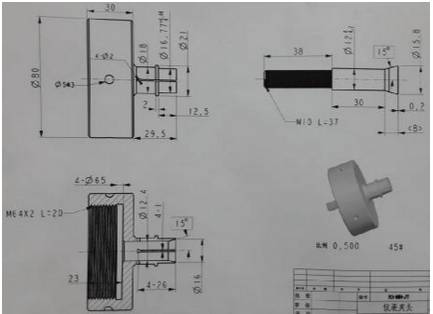

02 Ukubhoboza nokugaya amathuluzi

Amaphuzu Wokuklama:

1. Uma kunesidingo, ezinye izinto ezisizayo zokubeka zingaklanywa kumongo ongashintshi kanye nepuleti lawo elingashintshi;

2. Isithombe esingenhla siwumdwebo owenziwe lula. Isimo sangempela sidinga ukuklama okuhambisanayo ngokusho kweizingxenye ze-cncisakhiwo;

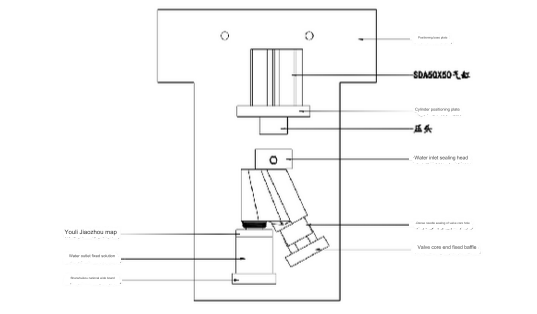

3. Isilinda sincike ngobukhulu bomkhiqizo kanye nokucindezeleka ngesikhathi sokucubungula. I-SDA50X50 isetshenziswa kakhulu;

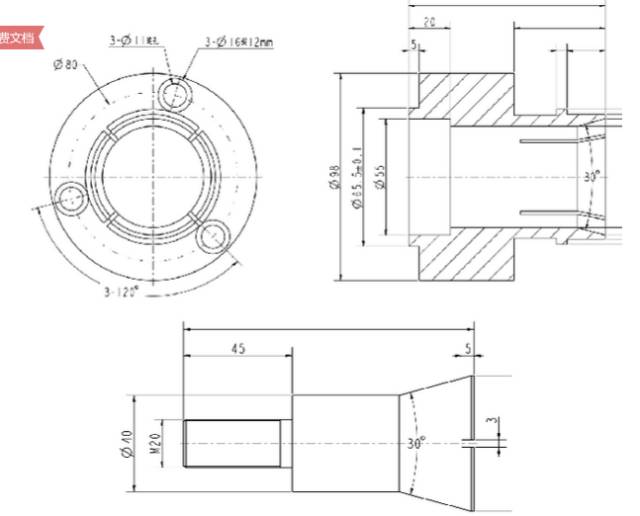

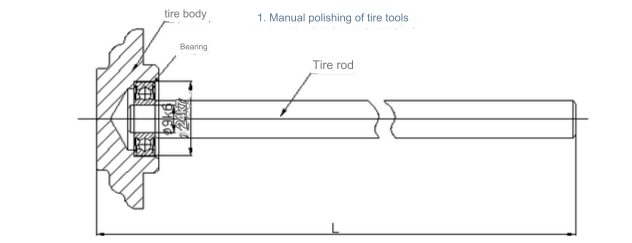

03 CNC, insimbi chuck

Inani eliphakeme kakhulu lama-CNC

I-toe-in chuck

Amaphuzu Wokuklama:

Sicela uthole ngezansi umbhalo obuyekeziwe walungiswa:

1. Ubukhulu obungalebulanga esithombeni esingenhla busekelwe kusayizi wembobo engaphakathi yomkhiqizo wangempela.

2. Ngesikhathi senqubo yokukhiqiza, indilinga yangaphandle esendaweni ethintana nembobo yangaphakathi yomkhiqizo kufanele ishiye umkhawulo ongu-0.5mm ohlangothini olulodwa. Okokugcina, kufanele ifakwe ethuluzini lomshini we-CNC futhi iguqulwe kahle ibe usayizi, ukuvimbela noma yikuphi ukuguquguquka kanye ne-eccentricity ebangelwa inqubo yokucisha.

3. Kunconywa ukusebenzisa insimbi yasentwasahlobo njengengxenye yengxenye yomhlangano kanye ne-45 # yengxenye ye-tie rod.

4. Intambo ye-M20 engxenyeni yenduku yokubopha iyintambo evame ukusetshenziswa, engalungiswa ngokuvumelana nesimo sangempela.

Amaphuzu Wokuklama:

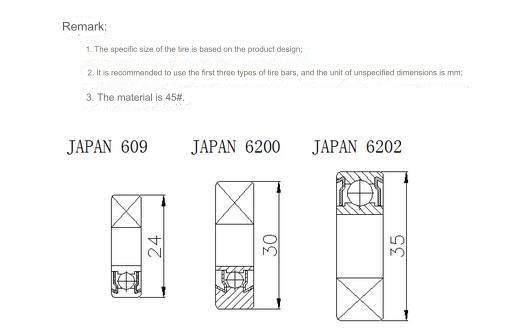

1. Isithombe esingenhla siwumdwebo wereferensi, futhi ubukhulu bomhlangano nesakhiwo kusekelwe kubukhulu nokwakheka komkhiqizo wangempela;

2. Impahla ingu-45# futhi yacinywa.

Insimbi yangaphandle yokuqinisa

Amaphuzu Wokuklama:

1. Isithombe esingenhla siwumdwebo wereferensi, futhi usayizi wangempela uncike esakhiweni sosayizi wembobo yangaphakathi yomkhiqizo;

2. Indilinga yangaphandle esendaweni ethintana nembobo engaphakathi yomkhiqizo idinga ukushiya imajini engu-0.5mm ohlangothini olulodwa ngesikhathi sokukhiqiza, futhi ekugcineni ifakwe ku-lathe yensimbi bese iphendulwa kahle ibe usayizi ukuze kuvinjelwe ukuwohloka kanye nokugqama okubangelwa. ngenqubo yokucima;

3. Impahla ingu-45# futhi yacinywa.

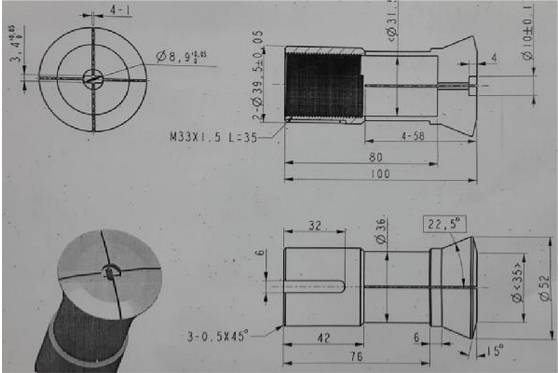

04 Amathuluzi okuhlola igesi

Amaphuzu Wokuklama:

1. Isithombe esingenhla siyireferensi yesithombe samathuluzi okuhlola igesi. Isakhiwo esithile sidinga ukuklanywa ngokuya ngesakhiwo sangempela somkhiqizo. Inhloso ukuvala umkhiqizo ngendlela elula ngangokunokwenzeka, ukuze ingxenye ezohlolwa futhi ivalwe igcwaliswe ngegesi ukuze kuqinisekiswe ukuqina kwayo.

2. Ubukhulu besilinda bungalungiswa njengosayizi wangempela womkhiqizo. Kuyadingeka futhi ukubheka ukuthi ngabe ukushaywa kwesilinda kungaba lula ukucosha nokubeka umkhiqizo.

3. Indawo evalayo exhumene nomkhiqizo ngokuvamile isebenzisa izinto ezikwazi ukuminyanisa kahle njenge-Uni glue nezindandatho zerabha ze-NBR. Ukwengeza, sicela uqaphele ukuthi uma kukhona amabhlogo wokumisa athintana nokubukeka komkhiqizo, zama ukusebenzisa amabhulokhi epulasitiki amhlophe futhi ngesikhathi sokusebenzisa, vala ikhava ephakathi ngendwangu kakotini ukuvimbela ukulimala ekubukeni komkhiqizo.

4. Isiqondiso sokuma komkhiqizo kufanele sinakwe ngesikhathi sokuklanywa ukuze kuvinjwe ukuvuza kwegesi ekuvalelekeni ngaphakathi kwendawo yomkhiqizo futhi kubangele ukutholwa okungamanga.

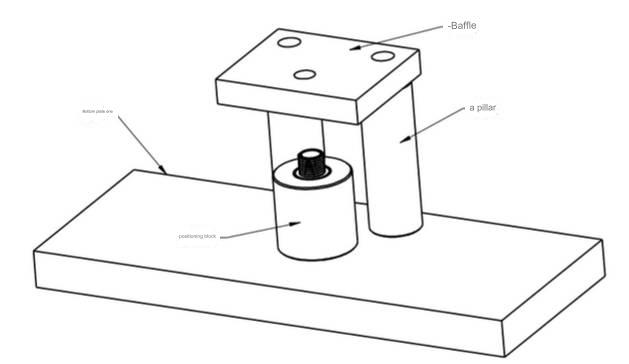

05 Ukubhoboza amathuluzi

Amaphuzu okuklama:Isithombe esingenhla sibonisa ukwakheka okujwayelekile kwethuluzi lokubhoboza. Ipuleti elingezansi lisetshenziselwa ukunamathisela ibhentshi lomsebenzi womshini wokubhoboza kalula, kuyilapho ibhulokhi yokumisa isetshenziselwa ukuvikela umkhiqizo. Isakhiwo se-tooling siklanywe ngokwezifiso isimo sangempela somkhiqizo. Iphoyinti elimaphakathi lizungezwe indawo emaphakathi ukuze kuqinisekiswe ukucoshwa nokubekwa komkhiqizo okuphephile nokufanelekile. I-baffle isetshenziselwa ukuhlukanisa kalula umkhiqizo nombese wokubhoboza, kuyilapho izinsika zisetshenziswa njengama-baffles angashintshi. Izikhundla zomhlangano nobukhulu balezi zingxenye zingenziwa ngezifiso ngokusekelwe ezimweni zangempela zomkhiqizo.

06 Ukushisela amathuluzi

Inhloso ye-welding tooling ukulungisa isikhundla sengxenye ngayinye emhlanganweni we-welding futhi ulawule ubukhulu obuhlobene bengxenye ngayinye. Lokhu kufezwa ngokusebenzisa ibhulokhi yokumisa eyakhelwe ngokusho kwesakhiwo sangempela somkhiqizo. Kubalulekile ukuqaphela ukuthi lapho ubeka umkhiqizo ku-tooling ye-welding, indawo evaliwe akufanele idalwe phakathi kwe-tooling. Lokhu kwenzelwa ukuvimbela ukucindezelwa ngokweqile ekwakheni endaweni evaliwe, okungase kuthinte ubukhulu bezingxenye ngemva kokushisela ngesikhathi sokushisa.

07 Uhlelo lokupholisha

08 Amathuluzi womhlangano

Amathuluzi okuhlanganisa kuyithuluzi elisiza ekubekeni izingxenye ngesikhathi senqubo yokuhlanganisa. Umqondo ongemuva komklamo ukuvumela ukulandwa kalula nokubekwa komkhiqizo ngokusekelwe esakhiweni somhlangano wezingxenye. Kubalulekile ukuthi ukubukeka kwengokwezifiso izingxenye ze-aluminium ze-cncazilinyazwa ngesikhathi somhlangano. Ukuze uvikele umkhiqizo ngesikhathi sokusetshenziswa, ungambozwa ngendwangu kakotini. Lapho ukhetha izinto zokwakha, kunconywa ukusebenzisa izinto ezingezona ezensimbi njengeglue elimhlophe.

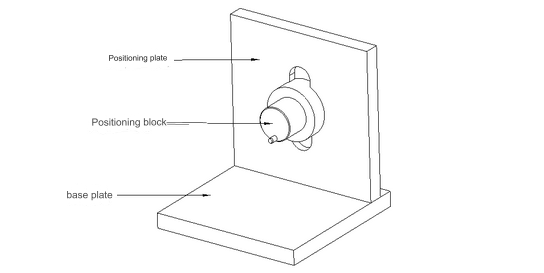

09 Ukuphrinta kwephedi, ithuluzi lokuqopha nge-laser

Amaphuzu Wokuklama:

Dizayina isakhiwo sokuma samathuluzi ngokuya ngezidingo zokuqoshwa komkhiqizo wangempela. Naka ukuba lula kokukha nokubeka umkhiqizo, kanye nokuvikelwa kokubukeka komkhiqizo. Ibhulokhi yokumisa kanye nensiza yokubeka idivayisi ethintana nomkhiqizo kufanele yenziwe ngeglue emhlophe nezinye izinto ezingezona ezensimbi ngangokunokwenzeka.

I-Anebon inikezelwe ekudaleni izixazululo zekhwalithi ephezulu kanye nokwakha ubudlelwano nabantu abavela kuwo wonke umhlaba. Banothando olukhulu futhi bathembekile ekuletheni izinsizakalo ezingcono kakhulu kumakhasimende abo. Basebenza ngokukhethekile eChina imikhiqizo yokukhipha i-aluminium,amapuleti e-aluminium okugaya, ngokwezifisoaluminium izingxenye ezincane CNC, kanye ne-Original Factory China Extrusion Aluminium kanye ne-Aluminium Yephrofayili.

I-Anebon ihlose ukunamathela kufilosofi yebhizinisi ethi "Ikhwalithi yokuqala, ukuphelela kuze kube phakade, okuqondiswe kubantu, ukusungulwa kobuchwepheshe". Basebenza kanzima ukwenza inqubekelaphambili futhi basungule embonini ukuze babe yibhizinisi elisezingeni lokuqala. Balandela imodeli yokuphatha yesayensi futhi balwela ukufunda ulwazi lobungcweti, bathuthukise imishini yokukhiqiza ethuthukisiwe nezinqubo, futhi bakhe imikhiqizo yekhwalithi yokuqala. I-Anebon inikeza amanani aphusile, amasevisi ekhwalithi ephezulu, nokulethwa okusheshayo, ngenhloso yokudala inani elisha lamakhasimende abo.

Isikhathi sokuthumela: Mar-25-2024