Kungakanani okwaziyo mayelana nendlela yokusika intambo yensimbi?

Ukusika insimbi ukuze kufakwe intambo ngokuvamile kuhilela izinqubo ezifana nokuthepha, ukugaya intambo, kanye nokuhlanganisa iphuzu elilodwa. Lezi zindlela zivame ukusetshenziswa ekukhiqizeni ukudala imicu yangaphakathi noma yangaphandle ezingxenyeni zensimbi.

Ukuthepha kuyinqubo lapho ithuluzi lokuthepha lisetshenziselwa ukusika uchungechunge lube izimbobo ezimbozwe ngaphambilini. Ngokuvamile isetshenziselwa ukudala imicu yangaphakathi. Ukugaya intambo, ngakolunye uhlangothi, kusebenzisa ithuluzi lokusika elizungezayo elinamazinyo amaningi ukusika kancane kancane iphrofayili yentambo. Le ndlela ivame ukusetshenziselwa kokubili imicu yangaphakathi neyangaphandle.

I-single-point threading ihlanganisa ukusebenzisa ithuluzi lokusika elinomphetho owodwa wokusika ukuze usike izintambo ku-workpiece. Le ndlela ivame ukusetshenziswa kuma-lathes noma emishini yokujika ukuze kwakhiwe imicu enembile.

Ukukhethwa kwendlela kuncike ezicini ezifana nohlobo lwento ecushwayo, iphrofayela yochungechunge olufunekayo, ukunemba okudingekayo, kanye nevolumu yokukhiqiza. Amathuluzi ahlukene, imishini, namasu angasetshenziswa ezinhlelweni ezahlukene kanye nezidingo zemboni.

1. Ulwazi olubalulekile oluyisisekelo lokucubungula intambo

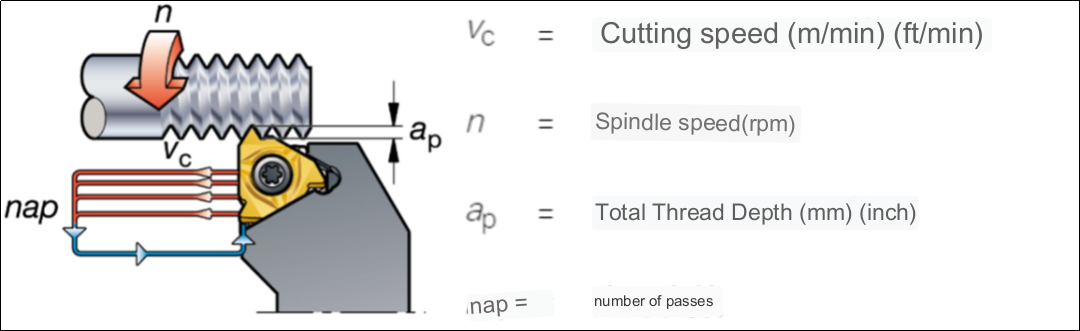

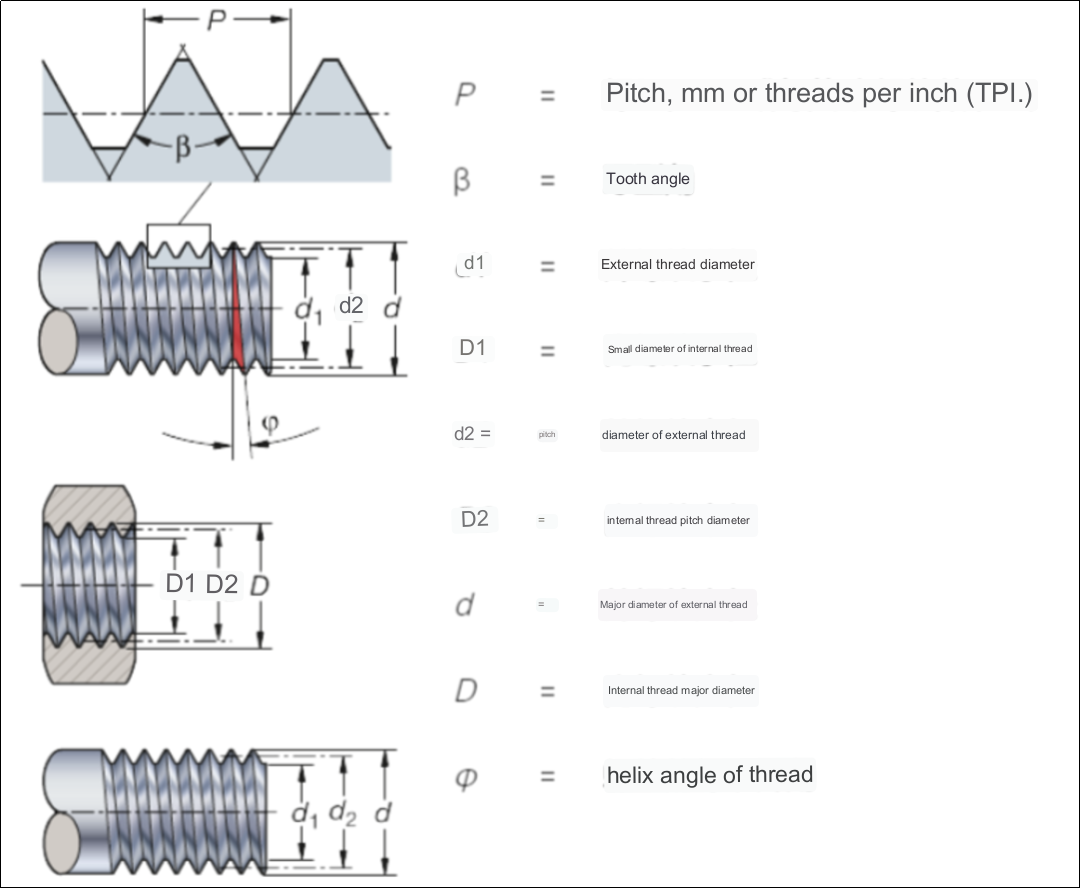

1. Incazelo yamagama

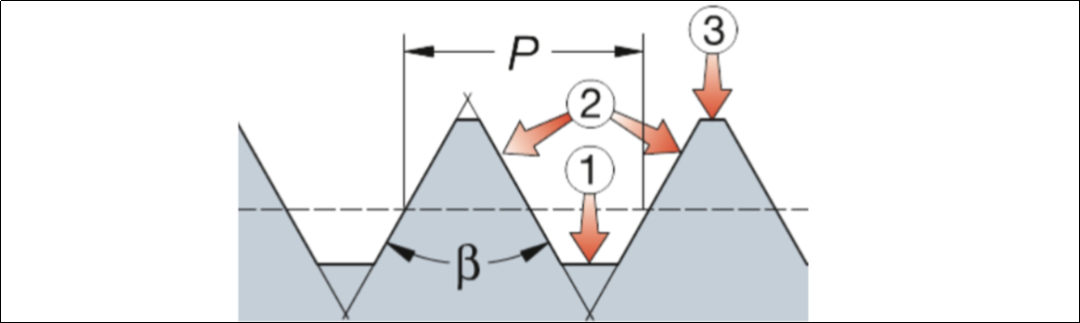

①Iphansi lezinyo ②Uhlangothi lwezinyo ③Phezulu kwezinyo

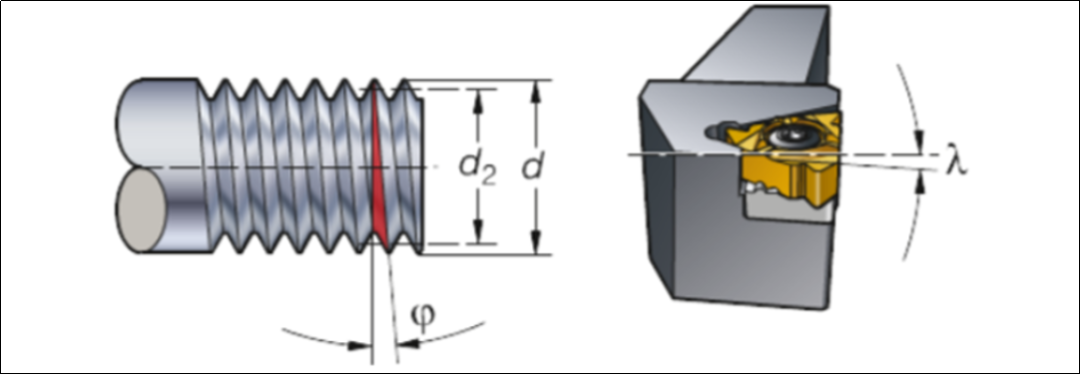

I-Helix angle:

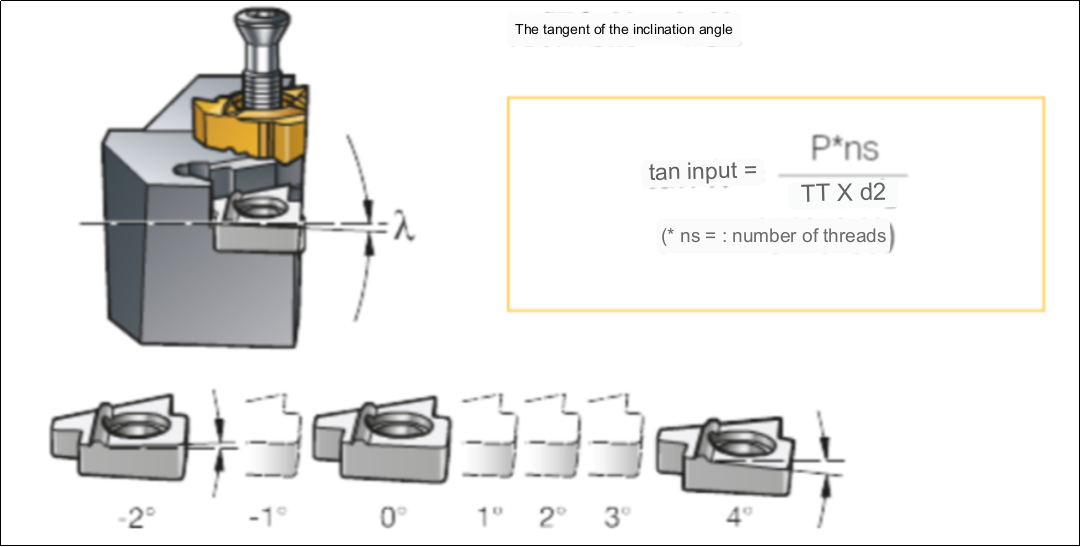

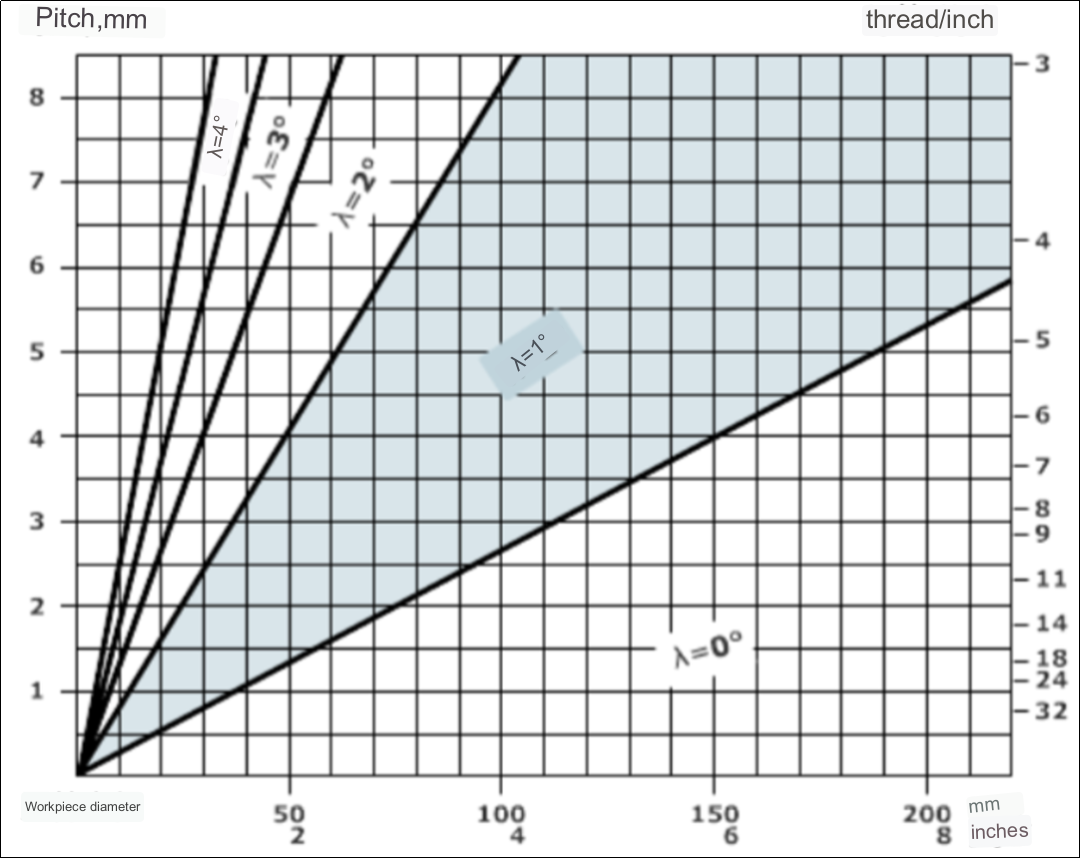

I-engeli ye-helix incike kububanzi ne-pitch yentambo.

Lungisa ukukhululeka kwe-flank ye-blade ngokushintsha i-shim.

I-engeli ye-blade inclination ngu-γ. I-engeli ye-bevel evame kakhulu ngu-1°, ehambisana neshimu elijwayelekile kusibambi.

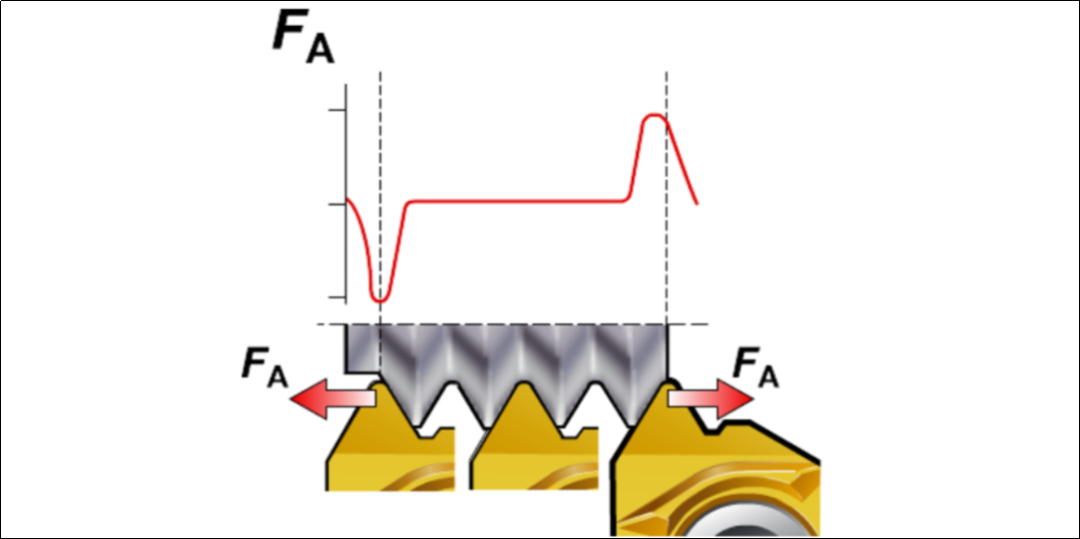

Ukusika amandla lapho ungena futhi uphuma kuchungechunge:

Amandla aphakeme kakhulu okusika i-axial emisebenzini yokuthunga ayenzeka ngesikhathi sokungena nokuphuma kwethuluzi lokusika endaweni yokusebenza.

Ukusika idatha ephakeme kakhulu kungabangela ukunyakaza kokufaka okuboshwe ngokungathembeki.

Tshekisa i-blade ukuze uvule:

I-engeli ye-bevel ingasethwa ngeshimu ngaphansi kwe-blade esibambeni. Bheka ishadi kukhathalogi yamathuluzi ukuze ukhethe ukuthi iyiphi i-shim ongayisebenzisa. Zonke izibambi ziza namashimu ajwayelekile asethwe ku-1° i-rake angle.

Khetha i-shim ngokuya nge-engeli ye-bevel. Idayamitha yesiqeshana sokusebenza kanye nokuphakama kwentambo kuthinta i-engeli ye-rake. Njengoba kungabonakala esithombeni esingezansi, ububanzi be-izingxenye ze-cnc lathezingu-40mm kanti iphimbo lingu-6mm, ushimu odingekayo kufanele ube ne-engeli ye-bevel engu-3° (amashimu ajwayelekile angeke asetshenziswe).

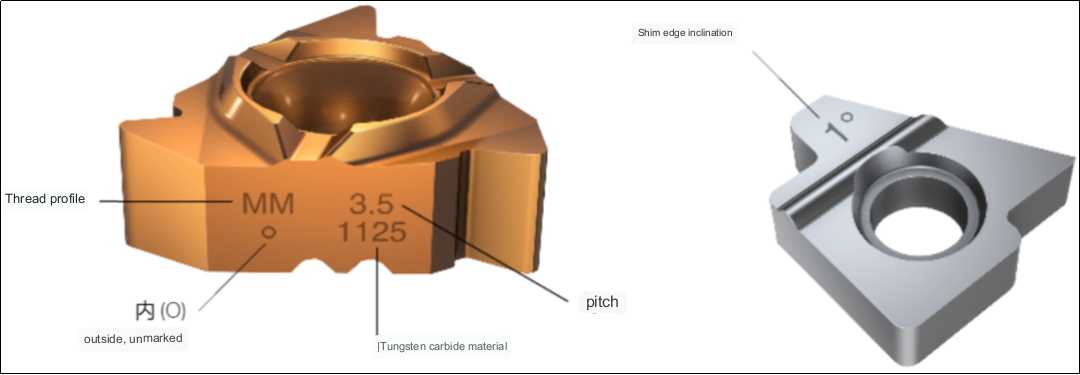

Izimpawu zokufaka uchungechunge namashimu:

Umumo womucu kanye nokusebenza kwawo:

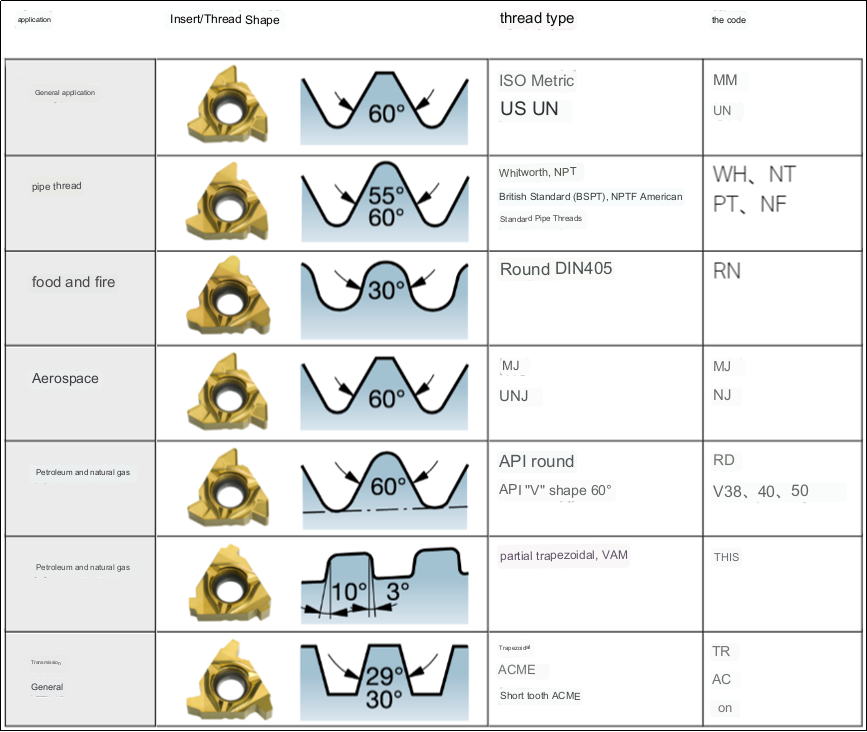

2. Uhlobo lokufaka intambo nesikimu sokubopha

1. Multi tooth blade

Inzuzo:

Yehlisa inani lokuphakelayo

Ukukhiqiza okuphezulu kakhulu

Okushodayo:

Kudingeka i-clamping eqinile

Kudingeka isikhala esanele sokuhoxisa ngemva kokulutha

2. I-blade yephrofayili egcwele

Inzuzo:

Ukulawula okukhulu phezu komumo wochungechunge

amaphutha amancane

Okushodayo:

I-blade eyodwa ingasika iphimbo elilodwa kuphela

3. I-V-profile blade

Inzuzo:

Ukuvumelana nezimo, ukufaka okufanayo kungasetshenziswa kuma-pitches amaningana.

Okushodayo:

Izodala ukuthi ama-burrs akhe futhi adinga ukuhoxiswa.

Isixazululo se-clamping i-LOCK:

Intambo eqinile kakhulu enokufakwa okungaguquki

Iqondiswa umzila wesitimela, i-blade ibekwe endaweni efanele

Isikulufu sicindezela into efakwayo kumzila wegayidi ibuyele esitobhini se-radial ebusweni obunye bokuxhumana (ubuso obuthintana naye obomvu) esihlalweni sokufaka.

Isixhumi esibonakalayo esinokwethenjelwa siqinisekisa impilo yamathuluzi ende kanye nekhwalithi ephezulu yochungechunge

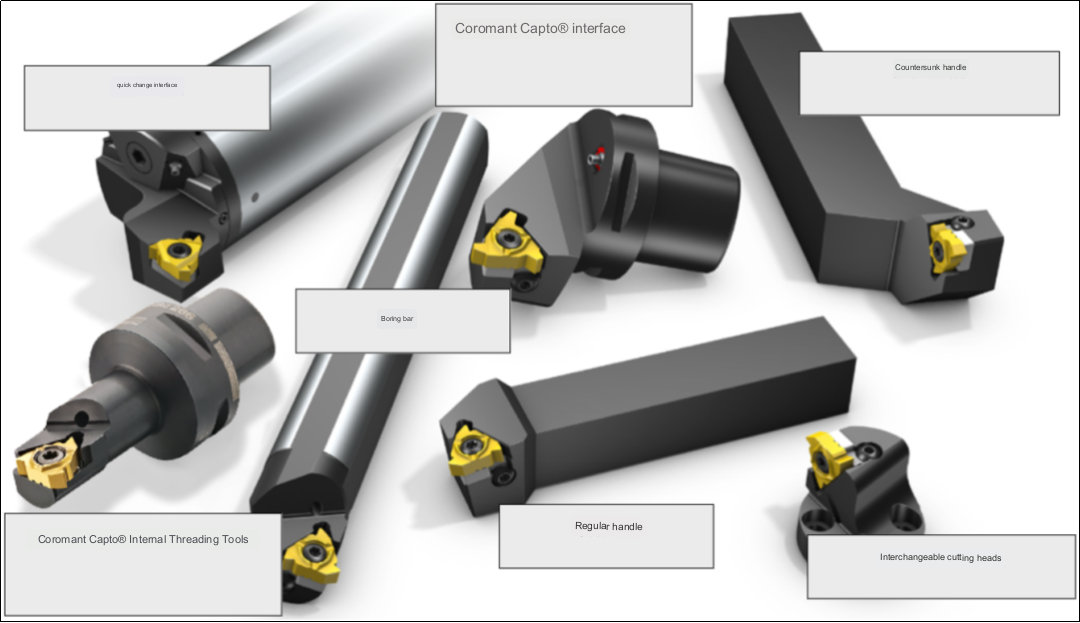

Izibambo ezahlukahlukene:

3. Izinhlobo ezintathu ezahlukene zezindlela zokudla

Indlela yokuphakelayo ingaba nomthelela omkhulu ku-threading process. Kuyathinta: Ukulawula ukusika, ukufaka ukuguga, ikhwalithi yentambo, impilo yamathuluzi.

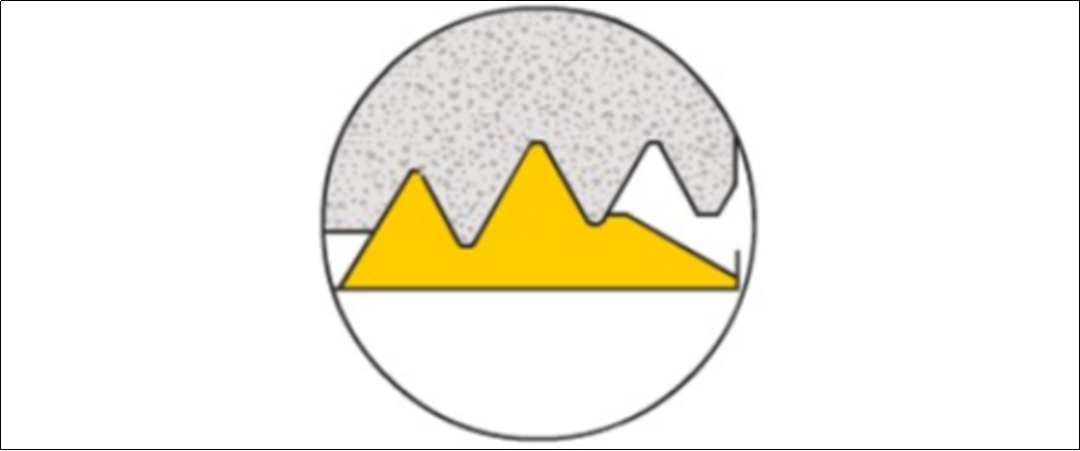

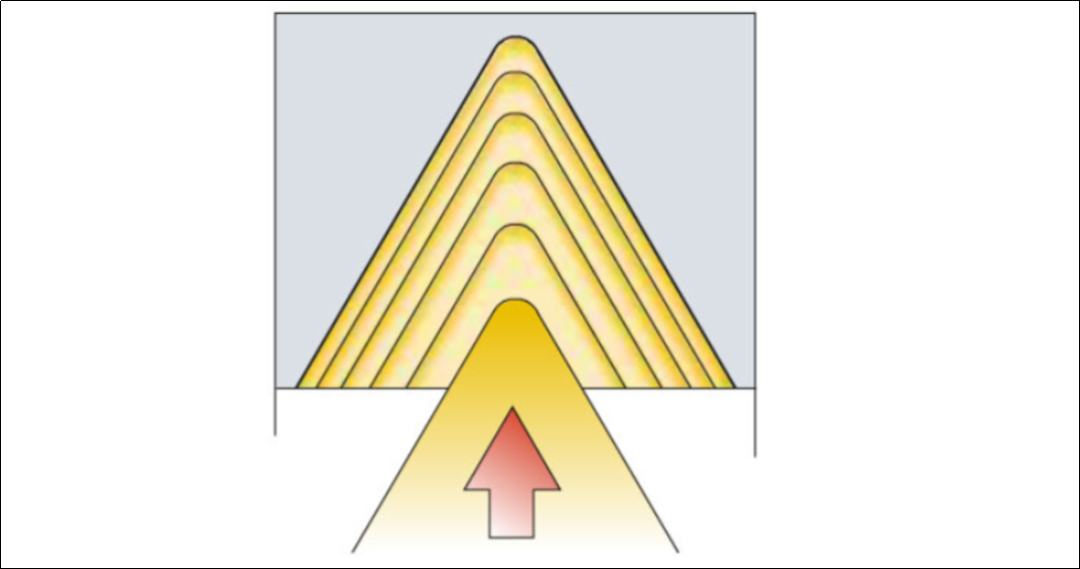

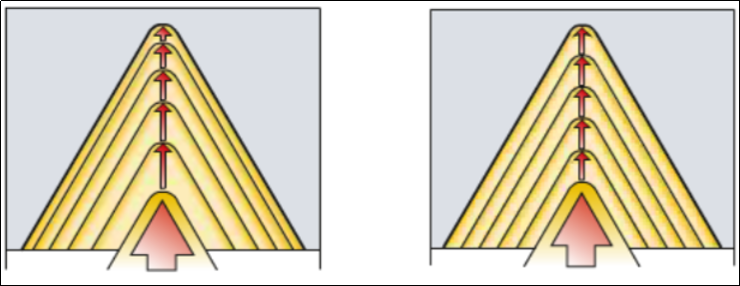

1. Okuphakelayo okuseceleni okuthuthukisiwe

Amathuluzi amaningi omshini we-CNC angasebenzisa le ndlela yokondla ngezinhlelo zomjikelezo:

Ama-chips ngokumelene nezinhlobo ezijwayelekile zokuphenduka - kulula ukwakha nokuqondisa

Amandla okusika i-axial anciphisa ubungozi bokudlidliza

Ama-chips aminyene kodwa thinta kuphela uhlangothi olulodwa lokufaka

Ukudlulisa ukushisa okuncishisiwe ku-blade

Inketho yokuqala yemisebenzi eminingi yokulutha

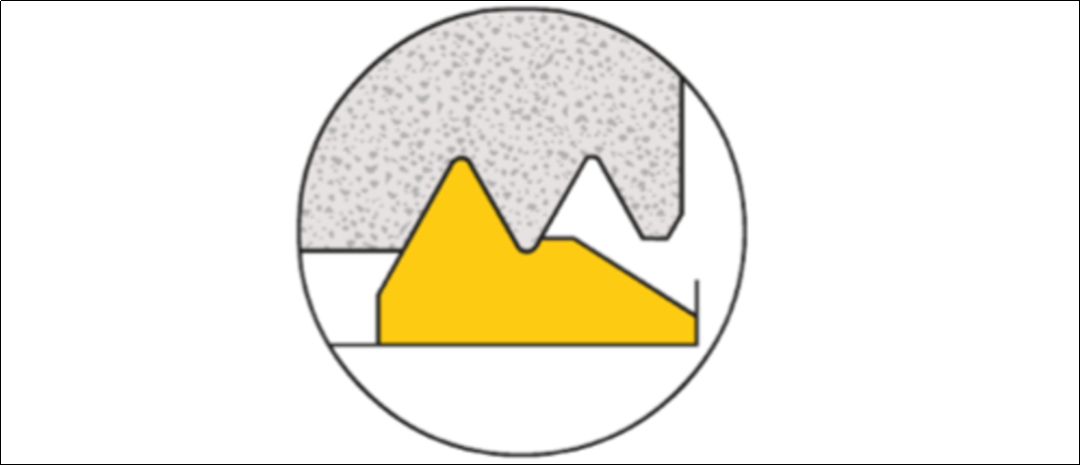

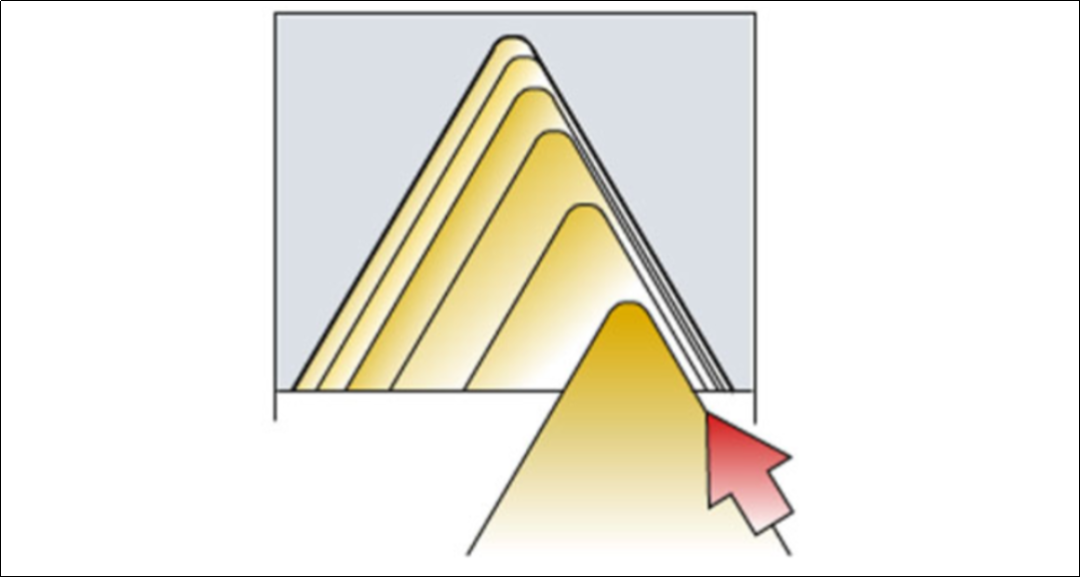

2. I-radial infeed

Indlela ejwayeleke kakhulu - okuwukuphela kwendlela amalathesi amadala angewona awe-CNC akwazi ukuwasebenzisa:

Ikhiqiza ama-chips aqinile anomumo othi “V”

I-Uniform Blade Wear

Amaphakethe okufaka avezwa emazingeni okushisa aphezulu, akhawulela ukujula kokuphakelayo

Ifanele ukucubungula uchungechunge oluhle

Ukudlidliza okungaba khona kanye nokulawulwa kwe-chip okungalungile lapho kwenziwa uchungechunge lwamaholo

Inketho yokuqala yezinto zokwakha eziqinile

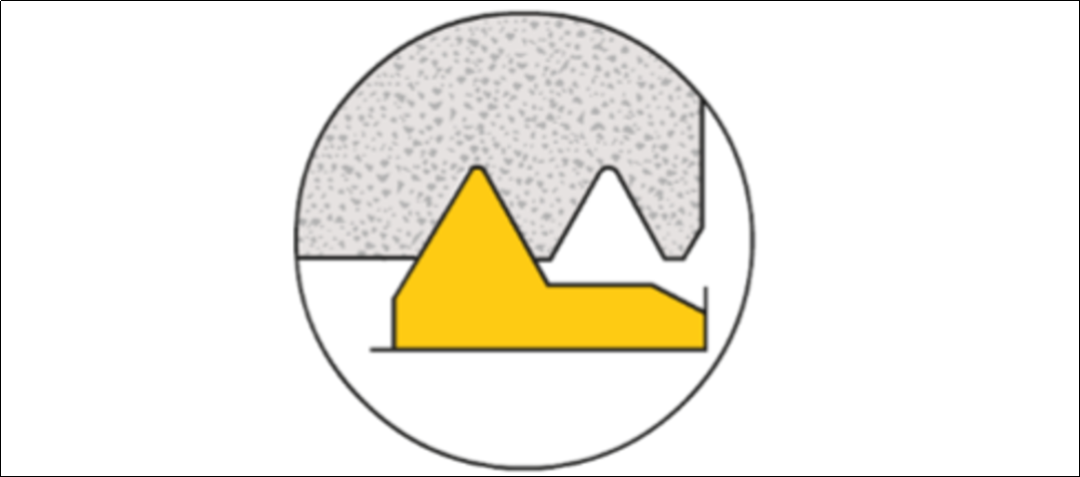

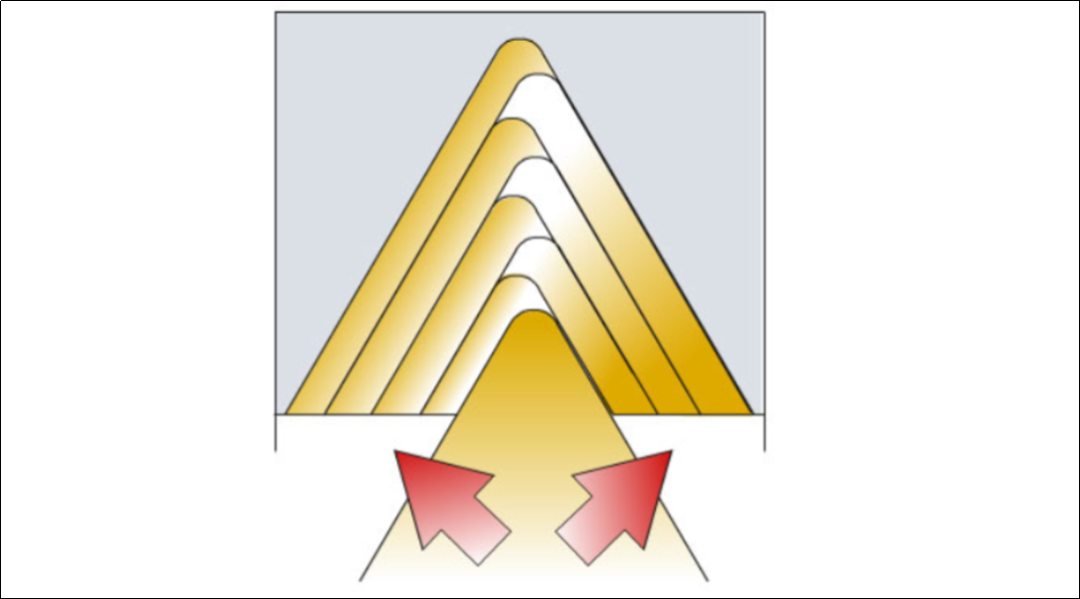

3. Okunye ukudla

Kunconywa amazinyo amakhulu

Ukugqokwa kokufakwa okufanayo kanye nempilo ephezulu yamathuluzi lapho kwenziwa imicu yephimbo emikhulu kakhulu

Ama-chips aqondiswa ngezindlela ezimbili, okwenza kube nzima ukuwalawula

4. Izindlela zokuthuthukisa imiphumela yokucubungula

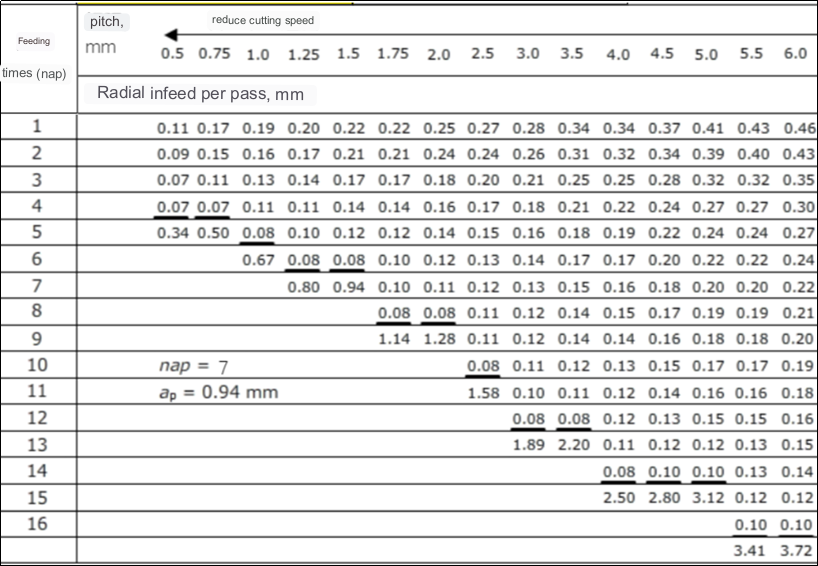

Ukunciphisa ukujula kokusika (kwesokunxele), ukujula okungaguquki kokusika (kwesokudla)

1. Ukujula kokusikwa kunciphisa isendlalelo ngongqimba (indawo ye-chip ihlala ingashintshiwe)

Ikwazi ukufeza indawo ye-chip engashintshi, okuyindlela esetshenziswa kakhulu ezinhlelweni ze-NC.

Iphasi lokuqala elijule kakhulu

Landela izincomo kuthebula lokuphakelayo kukhathalogi

Indawo ye-chip "elinganiselayo" eyengeziwe

Ukudlula kokugcina empeleni cishe ku-0.07mm

2. Ukujula njalo kokusika

Iphasi ngalinye linokujula okufanayo kungakhathaliseki inani lamaphasi.

Kunezidingo eziphakeme ku-blade

Qinisekisa ukulawulwa kwe-chip okulungile

Akufanele isetshenziswe lapho iphimbo lilikhulu kune-TP1.5mm noma 16TP

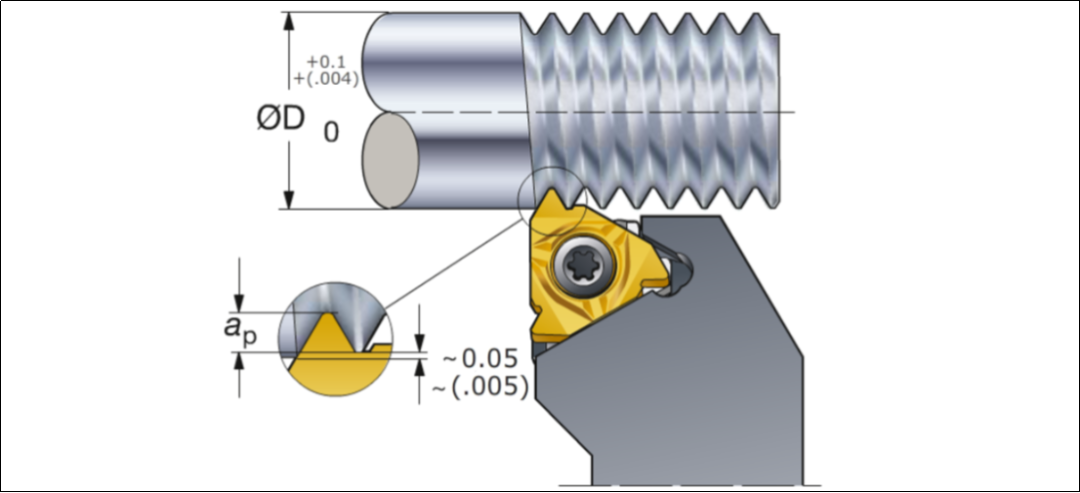

Qedela ama-thread crests ngesitoko esengeziwe:

Asikho isidingo sokuguqulela isitoko sibe ububanzi obunembile ngaphambi kokulutha, sebenzisa isitoko/impahla eyengeziwe ukuze uqedele ama-crest ochungechunge. Ukuze uqedele ukufakwa kwe-crest, inqubo yangaphambilini yokujika kufanele ishiye u-0.03-0.07mm wento ukuze kuvunyelwe i-crest ukuthi yakheke kahle.

Inani lokuphakelayo kochungechunge lwangaphandle elinconyiwe (uhlelo lwemethrikhi ye-ISO):

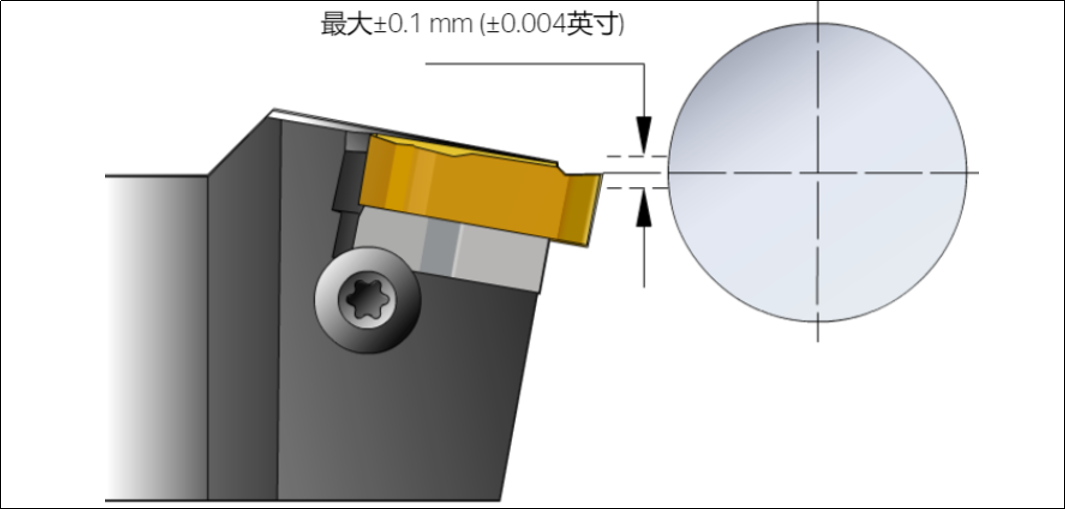

Ukuqinisekisa ukuhambisana kwe-workpiece kanye nethuluzi:

Sebenzisa ukuchezuka komugqa omaphakathi okuphezulu okungu-±0.1mm. Iphakeme kakhulu indawo yokusika futhi i-engeli yokusiza izokwehla futhi umkhawulo wokusika uzoklwejwa (uqhekeke); indawo ephansi kakhulu yonqenqema futhi iphrofayili yochungechunge kungenzeka ingalungile.

5.intambo turning amakhono isicelo impumelelo

1) Ngaphambi kokuphenduka kwentambo, hlola ukuthi ngabe i-izingxenye ze-aluminium machiningububanzi bunemvume yomshini efanele, bese wengeza u-0.14mm njengesabelo somqhele.

2) Ukuma okunembile kwethuluzi ethuluzini lomshini.

3) Hlola ukulungiselelwa konqenqema lokusika oluhlobene nobubanzi be-pitch.

4) Qiniseka ukuthi usebenzisa i-geometry elungile yokufaka (A, F noma C).

5) Qinisekisa ukuvunyelwa okukhulu ngokwanele nokufana (ishimu elitshekile nge-blade) ngokukhetha ushimu ofanele ukuze uthole imvume efanele yeflank.

6) Uma intambo ingafaneleki, hlola konke ukusetha kufaka phakathi ithuluzi lomshini.

7) Bheka izinhlelo ze-NC ezitholakalayo zokujika intambo.

8) Lungiselela indlela yokudla, inani lamaphasi nosayizi.

9) Qinisekisa isivinini esilungile sokusika ukuze uhlangabezane nezidingo zohlelo lokusebenza.

10) Uma iphimbo lentambo ye-workpiece lingalungile, hlola ukuthi iphimbo lethuluzi lomshini lilungile.

11) Ngaphambi kokusika ku-workpiece, kunconywa ukuthi ithuluzi kufanele liqale ngebanga elincane lezikhathi ezi-3 iphimbo.

12) Isipholile esinembe kakhulu singanweba impilo yamathuluzi futhi sithuthukise ukulawulwa kwe-chip.

13) Uhlelo lokushintsha okusheshayo luqinisekisa ukugoqa okulula nokusheshayo.

Lapho ukhetha amathuluzi okusebenza kokuguqula intambo, cabanga:

Hlola ama-overhangs nanoma yikuphi ukucaciswa okudingekayo (isb. ihlombe, i-sub-spindle, njll.)

Nciphisa i-overhang yamathuluzi ukuze umise ngokushesha

Ukuze uthole ukusetha okungaqinile kancane, khetha okufakwayo okunamandla okusika aphansi

Ukujika kwe-cnc okunembe kakhului-coolant inweba impilo yamathuluzi futhi ithuthukise ukulawula ukusika

Ukufinyelela okulula kokupholisa nge-adaptha ye-plug-and-play epholile

Ukuze kuqinisekiswe ukukhiqiza nempilo yamathuluzi, ukufakwa kwamaphrofayela amaningi kuyakhethwa, ukufakwa kwephrofayela egcwele konqenqema olulodwa kuyinketho yesibili, futhi ukufakwa kwephrofayela ye-V kuwukukhiqiza okuphansi kanye nezinketho ezimfishane zokuphila zamathuluzi.

Faka impilo nempilo yamathuluzi:

Indlela yokuphakelayo, thuthukisa indlela yokuphakelayo, inani lokudlula nokujula

Ukuthambekela kwe-blade ukuze kuqinisekiswe ukuvunyelwa okukhulu ngokwanele nokufana (ishimu elitsheke nge-blade)

Faka ijometri, qiniseka ukuthi usebenzisa ijometri elungile (A, F noma C geometry)

I-Blade material, khetha i-material efanele ngokwezinto ezibonakalayo kanye nezidingo zokuqina

Ukusika imingcele, uma kunesidingo, shintsha isivinini sokusika kanye nenani lokudlula ohlelweniizingxenye zokugaya ze-cnc.

I-Anebon enamathela enkolelweni yakho “Yokudala izixazululo zekhwalithi ephezulu nokukhiqiza abangani nabantu abavela emhlabeni wonke”, i-Anebon ihlale ibeka umdlandla wamakhasimende kuMkhiqizi waseChina womkhiqizo wokuphonsa we-aluminium waseChina, ipuleti le-aluminium lokugaya, i-aluminium eyenziwe ngokwezifiso incane. izingxenye ze-cnc, ngothando olumangalisayo nokwethembeka, zizimisele ukukunikeza ngamasevisi angcono kakhulu futhi ziqhubekele phambili nawe ukuze wenze ikusasa eliqhakazile elibonakalayo.

I-Original Factory China Extrusion Aluminium kanye ne-Aluminiyamu Yephrofayili, i-Anebon izonamathela "Kukhwalithi kuqala, , ukuphelela kuze kube phakade, okugxile kubantu, ukusungulwa kobuchwepheshe"ifilosofi yebhizinisi. Ukusebenza kanzima ukuze uqhubeke nokwenza inqubekelaphambili, ukuqamba okusha embonini, yenza yonke imizamo ebhizinisini elisezingeni lokuqala. Sizama konke okusemandleni ethu ukwakha imodeli yokuphatha yesayensi, ukufunda ulwazi oluningi lochwepheshe, ukuthuthukisa imishini yokukhiqiza ethuthukisiwe nenqubo yokukhiqiza, ukwakha imikhiqizo yekhwalithi yokuqala, intengo enengqondo, ikhwalithi ephezulu yesevisi, ukulethwa okusheshayo, ukukunikeza ukudala. inani elisha .

Isikhathi sokuthumela: Jun-14-2023