Ziningi izinto ezinomthelela ekuhlanekeni kwezingxenye ze-aluminium ngesikhathi sokukhiqiza, okuhlanganisa izakhiwo zezinto ezibonakalayo, ingxenye yejometri, nemingcele yokukhiqiza.

Izinto eziyinhloko zihlanganisa ingcindezi yangaphakathi ngaphakathi kwempahla eluhlaza, ukuhlanekezela okubangelwa amandla omshini nokushisa, kanye nokuguqulwa okubangelwa ukucindezela kokubopha.

1. Izinyathelo zenqubo zokunciphisa ukuwohloka kokucubungula

1. Yehlisa ukucindezeleka kwangaphakathi kokungenalutho

Ukushuba kwangaphakathi kwempahla eluhlaza kungadanjiswa ngokuguga okungokwemvelo noma okwenziwayo kanye nezinqubo zokudlidliza. Ukucubungula kokuqala nakho kuyindlela esebenzayo. Endabeni yezinto zokusetshenziswa ezinama-overhangs amaningi kanye ne-protrusions enkulu, ukuhlanekezela ukucubungula kwangemuva nakho kubalulekile.

Ukucubungula ingxenye eyinsalela yezinto ezingavuthiwe ngaphambili nokunciphisa ukunqwabelana kwesigaba ngasinye ngeke nje kunciphise ukuhlanekezelwa kokucubungula ezinqubweni ezilandelayo, kodwa futhi kuvumele ukuthi kubekelwe eceleni isikhathi sangemva kokucutshungulwa kokuqala, okungase kunciphise okunye ukungezwani kwangaphakathi.

2. Thuthukisa ikhono lokusika lethuluzi

Amandla okusika kanye nokushisa okusika ngesikhathi somshini kuthonywa kakhulu ukwakheka kwezinto kanye nokuma okuqondile kwethuluzi. Ukukhetha ithuluzi elifanele kubalulekile ukuze unciphise ukuhlanekezela ngesikhathi sokucubungula ingxenye.

1) Khetha ngokunengqondo ithuluzi lamapharamitha wejometri.

①I-engeli ye-Rake idlala indima ebalulekile ekusikeni imisebenzi. Kubalulekile ukukhetha ngokucophelela i-engeli enkulu ye-rake ngenkathi uqinisekisa ukuthi amandla e-blade agcinwe. I-engeli enkulu ye-rake ayisizi nje kuphela ukufeza umkhawulo wokusika obukhali kodwa futhi inciphisa ukuhlanekezela okusikiwe futhi yenza kube lula ukukhishwa kwe-chip, okuholela ekunciphiseni kwamandla nezinga lokushisa. Amathuluzi anama-rake engeli angalungile kufanele agwenywe ngazo zonke izindleko.

②I-engeli yokukhulula: Ubukhulu be-engeli yokukhululeka buthinta kakhulu ukuguga okusehlangothini kanye nekhwalithi yendawo esebenza ngomshini. Ukukhethwa kwe-engeli yokusiza kuncike ebukhulu bokusikwa. Ekugayweni okungalungile, lapho kunezinga eliphezulu lokudla, umthwalo osindayo wokusika, kanye nokukhiqizwa kokushisa okuphezulu, kubalulekile ukuqinisekisa ukunqanyulwa kokushisa okuphelele ethuluzini. Ngakho-ke, kufanele kukhethwe i-angle encane yokusiza. Ngakolunye uhlangothi, ukuze kugaywe kahle, kudingeka unqenqema olucijile ukuze kuncishiswe ukungqubuzana phakathi kwe-flank nendawo esebenza ngomshini kanye nokunciphisa ukuwohloka okunwebekayo. Ngakho-ke, kunconywa i-angle yokususa enkulu.

③I-engeli ye-Helix: Ukuze wenze ukugaya kushelele futhi kuncishiswe amandla okugaya, i-engeli ye-helix kufanele ibe nkulu ngangokunokwenzeka.

④ I-engeli enkulu yokuchezuka: Ukunciphisa kahle i-engeli eyinhloko yokuchezuka kungathuthukisa izimo zokulahla ukushisa futhi kunciphise izinga lokushisa elimaphakathi lendawo yokucubungula.

2) Thuthukisa isakhiwo samathuluzi.

①Ukuthuthukisa ukuphuma kwe-chip, kubalulekile ukwehlisa inani lamazinyo kusisiki sokugaya futhi wandise isikhala se-chip. Ngenxa yepulasitiki enkulu yezingxenye ze-aluminium, kukhona ukuwohloka kokusika okukhulayo ngesikhathi sokucubungula, okudinga isikhala esikhulu se-chip. Ngenxa yalokho, kunconywa irediyasi enkulu engezansi ye-chip groove kanye nokuncipha kwenani lamazinyo okusika agayo.

②Yenza ukugaya okunembile kwamazinyo e-blade, uqinisekise ukuthi inani lokuma elibukhali lingaphansi kuka-Ra=0.4um. Uma usebenzisa ummese omusha, kutuswa ukuba ugaye kancane amazinyo angaphambili nangemuva usebenzisa itshe likawoyela elicolisekile ukuze kukhishwe noma yiziphi izigaxa nokungahambi kahle okungase kube umphumela wokulola. Le nqubo ayigcini nje ukunciphisa ukushisa okusika kodwa futhi inciphisa ukubola kokusika.

③Kubalulekile ukuqapha ngokucophelela izindinganiso zokugqoka zamathuluzi okusika. Njengoba ithuluzi liwohloka, inani lokushosha phansi kwendawo yokusebenza liyakhuphuka, izinga lokushisa lokusika liyenyuka, futhi ukuwohloka kocezu lokusebenza kuba sobala kakhulu. Ngaphezu kokukhetha izinto ezisetshenziswayo zokusika ezinokumelana okuhle nokugqokwa, kubalulekile ukunamathela kumkhawulo wokugqoka wamathuluzi omkhulu ongu-0.2mm ukuze uvimbele ukwenzeka konqenqema olwakhiwe. Ngesikhathi sokusika, kunconywa ukugcina izinga lokushisa elingaphansi kuka-100 ° C ukuvimbela ukubola.

3. Thuthukisa indlela yokuqinisa ama-workpieces

Ezindaweni zokusebenza ze-aluminium ezinezindonga ezincane ezinokuqina okubi, izindlela zokubopha ezilandelayo zingasetshenziswa ukunciphisa ukuwohloka:

①Uma usebenza ngezingxenye zehlathi ezinezindonga ezincanyana, ukusebenzisa i-chuck enemihlathi emithathu egxile ngaphakathi noma i-spring chuck ukuze ubambe izingxenye ezinkulu kungaholela ekuwohlokeni kocezu lomsebenzi lapho luxegiswa ngemva kokucubungula. Ezimweni ezinjalo, kuhle ukusebenzisa indlela eqinile yokucindezela ubuso be-axial ekupheleni. Qala ngokuthola imbobo engaphakathi yengxenye, udale i-mandrel enentambo yangokwezifiso, bese uyifaka emgodini ongaphakathi. Sebenzisa ipuleti lekhava ukuze ufake ingcindezi ebusweni bokugcina, bese ubuvikela endaweni nge nut. Ngokusebenzisa le ndlela, ungavimbela ukuwohloka kwe-clamping ngesikhathi sokucubungula umbuthano wangaphandle, okuholela ekuthuthukisweni kokunemba kokucubungula.

②Uma usebenza ngezingxenye zeshidi elinezindonga ezincane ezinodonga oluncane, kuyancomeka ukuthi kusetshenziswe ubuchwepheshe bokuzibamba ukuze kuzuzwe amandla okubamba afanayo, ahlanganiswe nemingcele yokusika kahle. Le ndlela inciphisa ngempumelelo ingozi yokuguqulwa kwe-workpiece ngesikhathi sokucubungula.Okunye, ukusekelwa kwangaphakathi kungenziwa ukuze kuthuthukiswe ukuzinza kwezingxenye ezinezindonga ezincane.

Ngokufaka i-workpiece nge-medium esekelayo, njengesixazululo se-urea esiqukethe u-3% kuya ku-6% we-potassium nitrate, amathuba okuguquka ngesikhathi sokubopha nokusika angancishiswa. Lesi sigcwalisi singancibilika futhi sisuswe ngokucwilisa ucezu lokusebenza emanzini noma ekucutshungulweni kotshwala.

4. Hlela inqubo ngendlela efanele

Ngesikhathi sokusika ngesivinini esikhulu, inqubo yokugaya ijwayele ukudlidliza ngenxa yemvume yomshini omkhulu kanye nokusika ngezikhathi ezithile, okuholela emthelela omubi ekunembeni komshini kanye nokubangwa kwengaphezulu. Ngakho-ke, inqubo ye-CNC yokusika isivinini esikhulu ngokuvamile ihlanganisa izigaba ezihlukahlukene, okuyimishini enzima, ukuqeda kancane, ukuhlanzwa kwamakhona, nokuqeda, phakathi kokunye.

Ezimweni lapho izingxenye zidinga ukunemba okuphezulu, kungase kudingeke ukuba kwenziwe ukuqeda okuyingxenye yesibili okulandelwa ukuqeda. Ngemuva komshini onzima, kuyazuzisa ukuvumela izingxenye ukuthi ziphole ngokwemvelo ukuze unciphise ukucindezelwa kwangaphakathi okubangelwa ukumshini okungekuhle futhi kuncishiswe ukuwohloka. Imajini esele ngemva komshini onzima kufanele idlule izinga lokuguquguquka, ngokuvamile elisukela ku-1 kuya ku-2 mm.

Ngaphezu kwalokho, lapho uqedela ukuqedela, kubalulekile ukugcina imvume yomshini engaguquki endaweni eqediwe yengxenye, ngokuvamile esukela ku-0.2 kuya ku-0.5mm. Lo mkhuba uqinisekisa ukuthi ithuluzi lihlala lisesimweni esizinzile ngesikhathi sokucubungula, ngaleyo ndlela linciphise ngokuphawulekayo ukuwohloka kokusika, ukufeza ikhwalithi ephakeme yokucubungula indawo, kanye nokusekela ukunemba komkhiqizo.

2. Amakhono okusebenza ukunciphisa ukuguqulwa kokucubungula

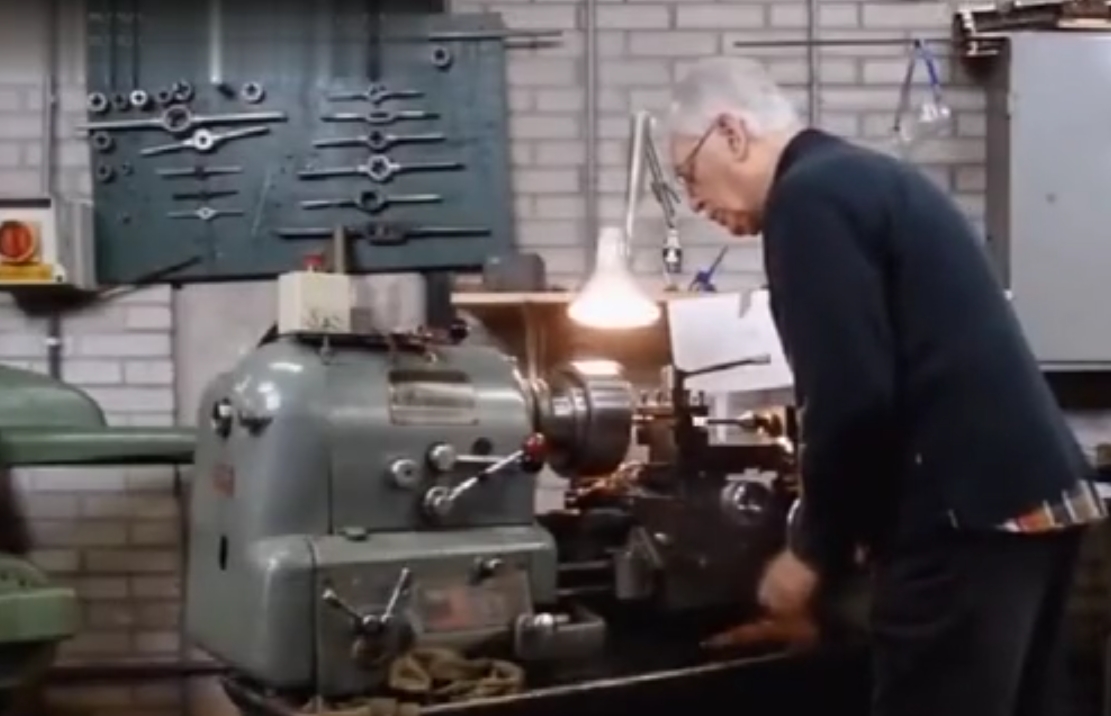

Izingxenye ezenziweizingxenye ze-aluminium ezenziwe ngomshini we-cnczikhubazekile ngesikhathi zicutshungulwa. Ngaphezu kwezizathu ezingenhla, indlela yokusebenza nayo ibaluleke kakhulu ekusebenzeni kwangempela.

1. Ezingxenyeni ezinemvume yomshini omkhulu, kubalulekile ukusebenzisa amasu okucubungula alinganayo ukuze kuthuthukiswe ukunqanyulwa kokushisa ngesikhathi somshini nokuvimbela ukugxila kokushisa. Njengomfanekiso, lapho unciphisa ishidi eliwugqinsi elingu-90mm libe ngu-60mm, ukugaya uhlangothi olulodwa bese ugaya ngokushesha olunye, okulandelwa inqubo eyodwa yokugcina yokulinganisa kuphumela ekubeni isicaba okungu-5mm. Ngokuphambene, ukusebenzisa ukucutshungulwa kwe-symmetrical okuphindaphindiwe, uhlangothi ngalunye olugaywe ngezigaba ezimbili, kuqinisekisa usayizi wokugcina onesicaba esingu-0.3mm.

2. Uma kukhona ama-indentation amaningana engxenyeni yepuleti, akunconywa ukusebenzisa indlela yokucubungula isinyathelo ngesinyathelo sokuhlehlisa ngakunye. Lokhu kungase kuholele ekusabalaliseni ukucindezeleka okungajwayelekile kanye nokuguqulwa okulandelayo kwengxenye. Kunalokho, cabanga ukusebenzisa ukucubungula okunengqimba ukuze umshini wonke ama-indent ngesikhathi esisodwa kusendlalelo ngasinye, ngaphambi kokudlulela kusendlalelo esilandelayo. Lokhu kuzosiza ekuqinisekiseni ukusatshalaliswa kokucindezeleka futhi kunciphise ukuguga.

3. Ukunciphisa amandla okusika nokushisa, inani lokusika lingashintshwa. Phakathi kwezinto ezintathu zokusika inani, inani lokusika emuva lithinta kakhulu amandla okunciphisa. Imvume yemishini eyeqile namandla okusika ingaholela ekulimaleni kwengxenye, kubeke engcupheni ukuqina kokuphotha kwethuluzi lomshini, futhi kunciphise ukuqina kwamathuluzi. Ukuncipha kwenani lokusika emuva kunganciphisa kakhulu ukusebenza kahle kokukhiqiza. Noma kunjalo, ukugaya ngesivinini esikhulu kumashini we-CNC kungabhekana nalolu daba. Ngokunciphisa ngesikhathi esifanayo inani lokusika emuva nokwandisa isivinini sokuphakelayo nethuluzi lomshini, amandla okusika angancipha ngenkathi kugcinwa ukusebenza kahle kokucubungula.

4. Kufanele futhi kuqashelwe ukulandelana kokusika. Emashini amabi, kugxilwa ekuthuthukiseni ukusebenza kahle kokucubungula kanye nokulwela ukukhishwa okuphezulu kweyunithi ngayinye yesikhathi. Ngokuvamile, ukugaya phezulu kuyakhethwa. Lokhu kusho ukuthi impahla enqwabelene engaphezulu kwendawo yokusebenza isuswa ngesivinini esiphezulu futhi ngesikhathi esifushane ngangokunokwenzeka ukuze kusungulwe uhlaka lwejometri oludingekayo ukuze kuqedwe. Ngakolunye uhlangothi, inqubo yokuqedela ibeka phambili ukunemba okuphezulu kanye nekhwalithi ephezulu, yingakho ukugaya phansi kuyanconywa. Njengoba ubukhulu bokusika bethuluzi buncipha kancane kancane ukusuka kokuphezulu kuye kuqanda ngesikhathi sokugaya phansi, kunciphisa kakhulu ukuqina komsebenzi futhi kunciphisa ukuwohloka kwengxenye.

5. Ukuguqulwa kweziqephu zokusebenzela ezinezindonga ezincane ezibangelwa ukugoqa ngesikhathi sokucutshungulwa kuyindaba engenakugwenywa, ngisho nangemva kokuba seziqediwe. Ukuze unciphise ukuguqulwa kwe-workpiece, kunconywa ukukhulula ingcindezi ngaphambi kokuqeda ukufeza izilinganiso zokugcina. Lokhu kuvumela i-workpiece ukuthi ibuyele ngokwemvelo esimweni sayo sangempela. Ngokulandelayo, ingcindezi ingaqiniswa ngokucophelela kuze kube yilapho ucezu lokusebenza luboshiwe ngokugcwele, kuzuzwe umphumela wokucubungula oyifunayo. Ngokufanelekile, amandla okubamba kufanele asetshenziswe endaweni esekelayo, iqondaniswe nokuqina kwendawo yokusebenza. Ngenkathi uqinisekisa ukuthi i-workpiece ihlala ivikelekile, kungcono ukusebenzisa amandla amancane okubamba.

6. Uma kwenziwa izingxenye ezinendawo engenalutho, kuhle ukugwema isigayo sokugaya singene ngqo engxenyeni efana ne-drill phakathi nenqubo. Lokhu kungaholela esikhaleni esilinganiselwe se-chip yesisiki sokugaya, ukuphuma kwe-chip okukhinyabezekile, kanye nomphumela wokushisa ngokweqile, ukwanda, kanye nokuwohloka kwezingxenye. Izehlakalo ezingathandeki ezifana nokuhlanekezela nokuphuka kwamathuluzi kungase kuvele. Kuyatuswa ukuthi ekuqaleni usebenzise i-drill bit enobukhulu obulinganayo noma obukhudlwana kunesisiki sokugaya ukuze ubhoboze imbobo bese uqasha umsiki wokugaya ukuze umshini. Kungenjalo, uhlelo lokusika oluvunguzayo lungakhiqizwa kusetshenziswa isoftware ye-CAM.

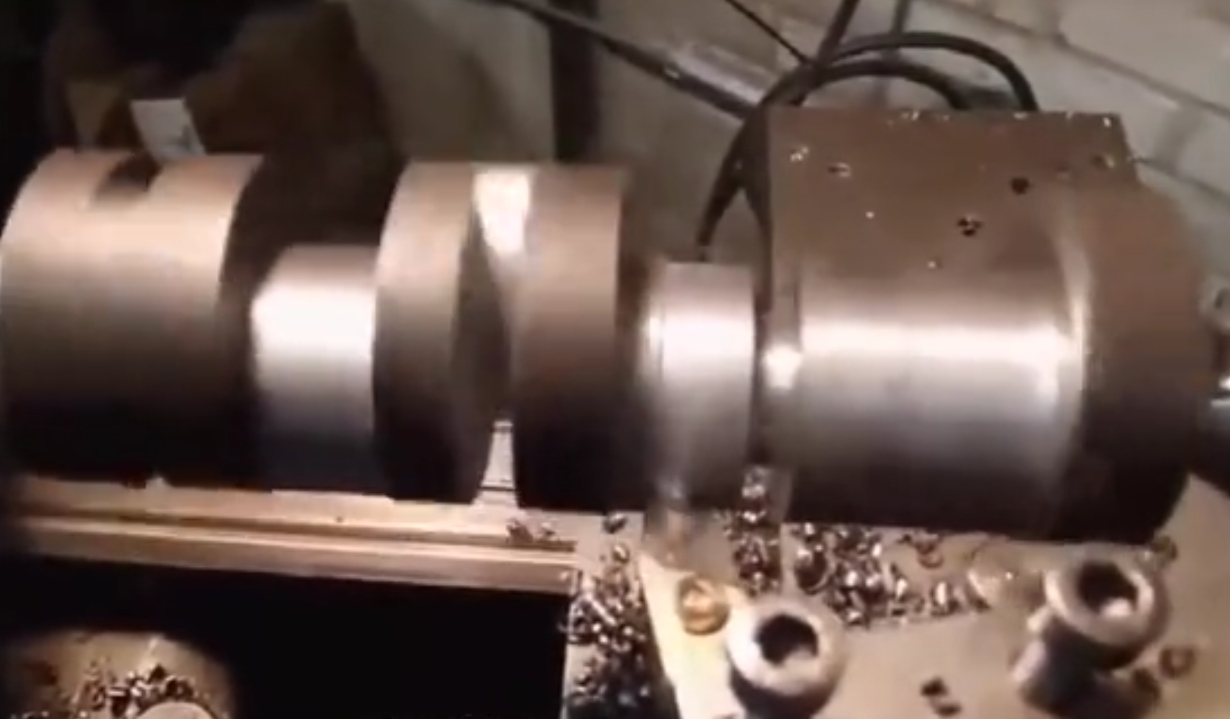

Inselele eyinhloko ethonya ukunemba kokwenziwa kwengxenye ye-aluminium kanye nekhwalithi yokuqedwa kwayo okungaphezulu ukuthambekela kwalezi zingxenye ukuthi zihlanekezelwe ngesikhathi sokucubungula. Lokhu kudinga ukuthi umqhubi abe nezinga elithile lobuchwepheshe bokusebenza kanye nekhono.

I-Anebon incike emandleni obuchwepheshe aqinile futhi iqhubeka idala ubuchwepheshe obuyindida ukuze ihlangabezane nesidingo somshini wensimbi we-cnc,5 i-axis cnc millingkanye nemoto yokushayela. Yonke imibono neziphakamiso zizokwaziswa kakhulu! Ukubambisana okuhle kungasithuthukisa sobabili sibe yintuthuko engcono!

ODM Manufacturer ChinaIzingxenye ze-CNC ezenziwe ngezifisokanye nokwenza izingxenye zemishini, Okwamanje, izinto ze-Anebon zithunyelwe emazweni angaphezu kwamashumi ayisithupha nasezifundeni ezahlukene, njengaseNingizimu-mpumalanga ye-Asia, eMelika, e-Afrika, eMpumalanga Yurophu, eRussia, eCanada njll. I-Anebon inethemba lobuqotho lokusungula ukuxhumana okubanzi nawo wonke amakhasimende angaba khona kokubili eChina nasemhlabeni wonke.

Uma ufuna ukwazi okwengeziwe ngathi noma ufuna ukubuza, sicela uthumele i-imeyili kuinfo@anebon.com

Isikhathi sokuthumela: Feb-02-2024