Izidingo Zobuchwepheshe zemidwebo eyimishini ehlanganiswe ithimba le-Anebon ihlanganisa uhla lwemibhalo lwezimfuneko eziyisisekelo ezilandelayo:

1. Izidingo zobuchwepheshe ezijwayelekile

2. Imfuneko yokwelashwa kokushisa

3. Imfuneko yokubekezelelana

4. I-Engeli Yengxenye

5. Imfuneko yomhlangano

6. Imfuneko yokusakaza

7. Imfuneko yokumboza

8. Izidingo zamapayipi

9. Izidingo zokulungisa i-solder

10. Imfuneko yokuqamba

11. Izidingo zokusika i-workpiece

▌ Izidingo Zobuchwepheshe Ezijwayelekile

1. Izingxenye zisusa isikhumba se-oxide.

2. Ebusweni bokucubungula izingxenye, akufanele kube khona imihuzuko, imihuzuko nezinye iziphambeko ezilimaza ubuso bezingxenye.

3. Susa ama-burrs.

▌ Izidingo Zokwelashwa Kokushisa

1. Ngemuva kokwelashwa kokuthambisa, HRC50 ~ 55.

2. Izingxenye zokucisha imvamisa ephezulu, 350 ~ 370℃ ukushisa, HRC40 ~ 45.

3. Carburizing ukujula 0.3mm.

4. Ukwelashwa kokuguga kokushisa okuphezulu.

▌ Izidingo Zokubekezelelana

1. Ukubekezelelwa komumo okungamakiwe kuzohlangabezana nezidingo ze-GB1184-80.

2. Ukuchezuka okuvunyelwe kosayizi wobude obungabonisiwe kungu-±0.5mm.

3. Indawo yokubekezelela ukusakaza ihambisana nokucushwa kosayizi oyisisekelo wokulingisa okungenalutho.

▌ Amakhona nemiphetho yezingxenye

1. Irediyasi yekhona u-R5 ayicacisiwe.

2. I-chamfer ngaphandle komjovo ingu-2×45°.

3. Amakhona acijile/amakhona acijile/amachopho acijile aba buthuntu.

▌ Izidingo Zomhlangano

1. Ngaphambi komhlangano, uphawu ngalunye kufanele lucwiliswe emafutheni.

2. Ukushisisa uwoyela kuvunyelwe ukushaja okushisayo kwamabheringi aginqikayo ngesikhathi sokuhlanganisa, izinga lokushisa likawoyela lingeqi ku-100℃.

3. Ukulandela ukuhlanganiswa kwegiya, izindawo zokuxhumana kanye nokuhlehla endaweni yezinyo kufanele kuhambisane nezindinganiso ezishiwo ku-GB10095 kanye ne-GB11365.

4. Ekuhlanganisweni kwesistimu ye-hydraulic, ukusetshenziswa kwe-sealing filler noma i-sealant kuvunyelwe, inqobo nje uma kugcinwa ngaphandle kwesistimu.

5. Konkeizingxenye zomshinikanye nezingxenye ezingena kumhlangano (okuhlanganisa nalezo ezithengiwe noma ezikhishwe ngaphandle) kufanele zibe nesitifiketi esivela emnyangweni wokuhlola.

6. Ngaphambi kokuhlanganiswa, izingxenye kufanele zihlanzwe kahle ukuze kuqinisekiswe ukungabikho kwama-burrs, i-flash, i-oxide, ukugqwala, ama-chips, amafutha, ama-coloring agents, nothuli.

7. Ngaphambi kokuhlanganisa, kubalulekile ukuthi kubuyekezwe ubukhulu bokulingana okuyinhloko kwezingxenye nezingxenye, ikakhulukazi ubukhulu besilinganiso sokuphazanyiswa kanye nokunemba okuhlobene.

8. Kuwo wonke umhlangano, izingxenye akumele zingqongqozwe, zithintwe, ziklwejwe, noma zivunyelwe ukuthi zigqwale.

9. Lapho uvikela izikulufu, amabhawodi, namantongomane, kubalulekile ukuthi ungawashayi noma usebenzise izipanela ezingafanele neziklintshi. Izikhala zezikulufu, amantongomane, izikulufu, namakhanda ebhawodi kumele kuhlale kungalimali ngemva kokuqiniswa.

10. Izinsimbi ezidinga i-torque ethile yokuqinisa kufanele zivikelwe kusetshenziswa isikrufu setorque futhi ziqiniswe ngokuvumelana netorque eshiwo.

11. Uma uhlanganisa ingxenye efanayo ngezikulufo eziningi (amabholithi), kufanele ziqiniswe ngendlela eyisiphambano, elinganayo, ngesinyathelo ngesinyathelo, nangendlela efanayo.

12. Ukuhlanganiswa kwezikhonkwane zamakhoni kufanele kuhilele ukufaka umbala embobeni, ukuqinisekisa izinga lokuxhumana elingekho ngaphansi kuka-60% wobude obufanayo, obusatshalaliswe ngokulinganayo.

13. Izinhlangothi ezimbili zikakhiye oyisicaba kanye nokhiye ku-shaft kufanele zigcine ukuxhumana okufanayo ngaphandle kwezikhala.

14. Okungenani u-2/3 wezindawo zamazinyo kufanele kuxhunyanwe nazo ngesikhathi sokuhlanganisa i-spline, nezinga lokuthintana elingekho ngaphansi kwama-50% ngobude nobude besiqondiso samazinyo angukhiye.

15. Lapho kuhlanganiswe ukhiye oyisicaba (noma i-spline) womentshisi oshelelayo, izingxenye zesigaba kufanele zihambe ngokukhululeka, kungabi bikho ukucinana okungalingani.

16. I-adhesive eyeqile kufanele isuswe ngemva kokubopha.

17. Imbobo eyisiyingi esiyindilinga yeringi yangaphandle, isihlalo esivulekile sokuthwala, kanye nesembozo sokuthwala akufanele kubhajwe.

18. Iringi yangaphandle ebambayo kufanele igcine ukuxhumana kahle nembobo eyisiyingi eyisiyingi yesihlalo esinobhoko esivulekile kanye nekhava ye-bearing, futhi ibonise ukuthintana okufana nesihlalo esinesihlalo phakathi kwebanga elishiwo ngesikhathi sokuhlolwa kombala.

19. Ngemva kokuhlanganisa, iringi yangaphandle yebheringi kufanele igcine ukuxhumana okufanayo nobuso bokugcina bekhava yokuthwala yesiphetho sokuma.

20. Ngemuva kokufakwa kwama-rolling bearings, ukujikeleza ngesandla kufanele kube nezimo futhi kuzinzile.

21. Ubuso obuhlangene besihlahla esithwalayo esingaphezulu nangaphansi kufanele bunamathele ngokuqinile futhi buhlolwe ngesinzwa esingu-0.05mm.

22. Uma ulungisa igobolondo elithwala ngephini lokumisa, kufanele libhobozwe futhi lisatshalaliswe ukuze kuqinisekiswe ukuhambisana kahle nembobo yokuthwala efanele. Iphinikhodi akufanele ixege ngemva kokufakwa.

23. Umzimba ophethe i-spherical bearing kanye nesihlalo esiphethe kufanele kuthintane okufanayo, ngezinga lokuxhumana elingekho ngaphansi kuka-70% uma lihlolwe ngombala.

24. I-alloy bearing surface akufanele isetshenziswe lapho iphenduka ibe phuzi, futhi i-nucleation phenomenon ayivunyelwe ngaphakathi kwe-engeli yokuxhumana ecacisiwe, indawo ye-nucleation engaphandle kwe-engeli yokuxhumana ilinganiselwe ukuthi ingabi ngaphezu kuka-10% wengqikithi engekho. indawo yokuxhumana.

25. Ubuso bokuphela kwereferensi begiya (igiya lezikelemu) kanye nehlombe le-shaft (noma ubuso bokugcina bomkhono wokumisa) kufanele bulingane ngaphandle kokuvumela into ezwakalayo engu-0.05mm ukuba idlule, iqinisekise ukuhambisana nobuso bokuphela kwereferensi yegiya kanye ne-eksisi.

26. Indawo ehlanganisiwe yebhokisi legiya kanye nesembozo kufanele kugcine ukuxhumana okuhle.

27. Ngaphambi kokuhlanganisa, kubalulekile ukuhlola ngokucophelela futhi ususe ama-engeli abukhali, ama-burrs, nezinhlayiya zakwamanye amazwe ezisele ekucutshungulweni kwezingxenye, ukuqinisekisa ukuthi uphawu luhlala lungaklwetshiwe ngesikhathi sokulayisha.

▌ Izidingo zokusakaza

1. Indawo yokulingisa akumele ibonise ukwahlukanisa okuphansi, ukuphuka, ukufinyela, noma ukungapheleli okufana nokungalungile ekubumbeni (isb., ukugcwaliswa okunganele, ukulimala komshini, njll.).

2. Ama-castings kumele ahlanzwe ukuze asuse noma yikuphi ukuvela, imiphetho ebukhali, kanye nezinkomba zezinqubo ezingaqediwe, futhi isango lokuthulula kufanele lihlanzwe izinga nge-casting surface.

3. Indawo okungeyona eyemishini yokulingisa kufanele ibonise ngokucacile uhlobo lokulingisa nokumaka, ihlangabezane nezicaciso zomdwebo ngokwendawo kanye nefonti.

4. Ubunzima bendawo engenziwanga yomshini wokuphonsa, esimweni sokuphonsa isihlabathi R, akufanele kudlule u-50μm.

5. Ukulingwa kufanele kususwe i-sprue, ama-projections, futhi noma iyiphi inhlansi esele endaweni engakhiwe ngomshini kufanele yenziwe ileveli futhi ipholishwe ukuze ihlangabezane nezindinganiso zekhwalithi ephezulu.

6. Ukubunjwa kufanele kungabi nesihlabathi esibumbayo, isihlabathi esiwumgogodla, nezinsalela eziwumgogodla.

7. Izingxenye ezithambekele kanye nendawo yokubekezelela i-dimensional ye-casting kufanele ihlelwe ngokulinganayo eduze kwendiza ethambekele.

8. Noma yisiphi isihlabathi esibumbayo, isihlabathi esiwumgogodla, izinsalela eziwumgogodla, kanye nanoma yisiphi isihlabathi esithambile noma esinamathelayo ekubunjweni, kufanele kwenziwe bushelelezi futhi kuhlanzwe.

9. Uhlobo lokulungile nokungalungile kanye nanoma yikuphi ukuchezuka kokusakazwa kwe-convex kufanele kulungiswe ukuze kuqinisekiswe ukuguquka okushelelayo futhi kuqinisekiswe ikhwalithi yokubukeka.

10. Ama-creases endaweni engenziwanga ngomshini wokulingisa akufanele eqe ukujula kuka-2mm, kube nesikhala esincane esingu-100mm.

11. Indawo okungeyona eyemishini yokulingisa umkhiqizo womshini kufanele idutshulwe ilashwe nge-roller ukuze ihlangabezane nezimfuneko zokuhlanzeka ze-Sa2 1/2.

12. Ukubunjwa kufanele kuqiniswe ngamanzi.

13. I-casting surface kufanele ibe bushelelezi, futhi noma yimaphi amasango, ama-protrusions, isihlabathi sokunamathela, njll, kufanele asuswe.

14. Ama-castings akumele abe nokufaka okuncane, imifantu, i-void, noma amanye amaphutha ekubumbeni angonakalisa ukusetshenziswa.

▌ Izidingo Zokupenda

1. Ngaphambi kokudweba izingxenye zensimbi, kubalulekile ukususa noma yikuphi ukugqwala, i-oxide, inhlabathi, uthuli, inhlabathi, usawoti, nokunye ukungcola.

2. Ukuze ulungise izingxenye zensimbi zokususwa kokugqwala, sebenzisa izinyibilikisi zemvelo, i-caustic soda, ama-emulsifying ejenti, isitimu, noma ezinye izindlela ezifanele zokuqeda amafutha nokungcola okungaphezulu.

3. Ngemva kokuchama kwesibhamu noma ukususwa kokugqwala okwenziwa ngesandla, isikhathi esinqunyiwe phakathi kokulungisa indawo nokufaka i-primer akufanele sidlule amahora angu-6.

4. Ngaphambi kokuxhuma, sebenzisa ijazi eliwugqinsi elingama-30 kuya ku-40μm lepende eliphikisana nokugqwala ezindaweni zezingxenye ezigoqiwe ezithintana. Vala unqenqema lwesihlanganisi sethango ngopende, isigcwalisi, noma okunamathelayo. Uma i-primer ilimele ngesikhathi somshini noma i-welding, phinda usebenzise ijazi elisha.

▌ Izidingo zamapayipi

1. Khipha noma yikuphi ukukhanya, ama-burrs, noma ama-bevels emaphethelweni epayipi ngaphambi kokuhlanganisa. Sebenzisa umoya ocindezelweyo noma indlela efanelekile yokususa ukungcola nokugqwala okusele odongeni lwangaphakathi lwamapayipi.

2. Ngaphambi kokuhlanganisa, qinisekisa ukuthi wonke amapayipi ensimbi, okuhlanganisa nalawo asenziwe ngaphambilini, aphathwa ngokususa amafutha, ukucosha, ukungathathi hlangothi, ukuwashwa nokuvikela ukugqwala.

3. Ngesikhathi sokuhlanganisa, qinisa ngokuvikelekile uxhumo oluluchungechunge olufana nezinsimbi zamapayipi, izisekelo, ama-flange, namajoyinti ukuze uvimbele ukuxega.

4. Yenza ukuhlolwa kwengcindezi ezingxenyeni ezishiselwe zamapayipi akhiwe ngaphambili.

5. Lapho uhambisa noma udlulisela amapayipi, vala indawo yokuhlukanisa ipayipi nge-adhesive tape noma i-cap yepulasitiki ukuze uvimbele udoti ukuthi ungangeni, futhi uqinisekise ukuthi ibhalwe ngokufanele.

▌ Izidingo zokulungisa izingxenye ze-welding

1. Ngaphambi kokushisela, kubalulekile ukuqeda noma yikuphi ukungapheleli futhi uqinisekise ukuthi indawo ye-groove ilingana futhi ayinamaphethelo abukhali.

2. Ngokuya ngokungaphelele okutholakala ensimbi ekhonjiwe, indawo yokushisela ingalungiswa ngokusebenzisa ukumba, ukuhuzuka, i-carbon arc gouging, ukusika igesi, noma izinqubo zemishini.

3. Hlanza zonke izindawo ezizungezile ngaphakathi kwe-radius engu-20mm yemisele yokushisela, uqinisekise ukususwa kwesihlabathi, uwoyela, amanzi, ukugqwala, nokunye ukungcola.

4. Kuyo yonke inqubo yokushisela, indawo yokushisa yangaphambili ye-casting yensimbi kufanele igcine izinga lokushisa elingekho ngaphansi kuka-350 ° C.

5. Uma izimo zivuma, zama ukwenza i-welding endaweni evundlile kakhulu.

6. Uma ulungisa ukulungiswa kwe-welding, nciphisa ukunyakaza kwe-lateral okweqile kwe-electrode.

7. Qondanisa kahle iphasi ngalinye le-welding, uqinisekise ukuthi ukunqwabelana okungenani ku-1/3 yobubanzi bokudlula. I-weld kufanele iqine, ingabi nokusha, imifantu, kanye nokungahambi kahle okubonakalayo. Ukubonakala kwe-weld kufanele kujabulise, ngaphandle kokunciphisa, i-slag ngokweqile, i-porosity, imifantu, i-spatter, noma amanye amaphutha. Ubuhlalu be-welding kufanele buhambisane.

▌ Izidingo Zokwenza

1. Umlomo wamanzi nesikhuphukeli se-ingot kufanele kusikwe ngokwanele ukuze kuvinjelwe ukuncipha nokuchezuka okukhulu ngesikhathi sokufoja.

2. Ama-forging kufanele alotshwe emshinini wokunyathelisa onamandla owanele ukuze kuqinisekiswe ukuhlanganiswa okuphelele kwangaphakathi.

3. Ukuba khona kokuqhekeka okubonakalayo, ama-creases, noma okunye ukungapheleli okubonakalayo okuphazamisa ukusebenza akuvumelekile ekufosheni. Amaphutha endawo angase alungiswe, kodwa ukujula kokulungiswa akufanele kudlule u-75% wesibonelelo somshini. Amaphutha endaweni engasetshenziswanga kufanele asuswe futhi aguqulwe kalula.

4. Izimbobo azivunyelwe ukuba zibonise amabala amhlophe, imifantu yangaphakathi, nama-shrinkage voids asele.

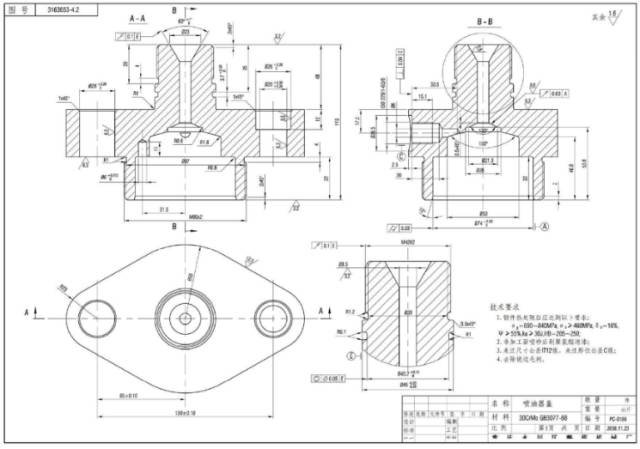

▌ Izimfuneko zokusika i-workpiece

1. Izingxenye eziphendulwe ngokunembakufanele icutshungulwe futhi ivunywe ngokuhambisana nezinqubo zokukhiqiza, kuqinisekiswe ukuqhubekela phambili esigabeni esilandelayo kuphela ngemva kokuqinisekiswa kokuhlolwa kwangaphambilini.

2. Izingxenye eziqediwe akumele zibonise noma yikuphi ukungahambi kahle ngendlela yokwakheka.

3. Izingcezu eziqediwe akufanele zibekwe ngqo phansi, futhi izinyathelo ezidingekayo zokusekela nokuvikela kufanele zisetshenziswe. Ukuqinisekisa ukungabikho kokugqwala, ukugqwala, nanoma imuphi umthelela olimazayo ekusebenzeni, ukuphila isikhathi eside, noma ukubukeka, okuhlanganisa nokucwila, ukuklwebheka, noma amanye amaphutha, kubalulekile endaweni eqediwe.

4. Ingaphezulu elilandela inqubo yokuqeda ukuginqika akufanele libonise noma yiziphi izenzakalo zokuxebuka ngemva kokugingqika.

5. Izingxenye ezilandela ukwelashwa kokushisa kokugcina akufanele zibonise noma iyiphi i-oxidation yendawo. Ukwengeza, izindawo zokukhwelana nezinyo ngemva kokuqedwa kufanele zihlale zingenakho ukuhushulwa.

6. Ingaphezulu lentambo ecutshunguliwe akufanele ibonise noma yikuphi ukungapheleli njengamachashaza amnyama, ama-protrusions, amaqhuqhuva angavamile, noma ama-protrusions.

Ukudala inzuzo eyengeziwe kubathengi ifilosofi yebhizinisi le-Anebon; ukukhula kwe-shopper kungamandla okusebenza e-Anebon. Ngemikhiqizo Emisha Eshisayo I-aluminium ehlala isikhathi esideizingxenye zemishini ye-cncfuthiizingxenye zokugaya zethusikanye nezingxenye zokugxiviza ngokwezifiso, ingabe usawufuna umkhiqizo wekhwalithi enhle ohambisana nesithombe sakho esihle kakhulu sokuhleleka ngenkathi unweba uhla lwemakethe yempahla yakho? Cabangela okuthengiswayo kwekhwalithi enhle kwe-Anebon. Ukukhetha kwakho kuzobonakala kuhlakaniphile!

Imikhiqizo Emisha Emisha I-China Glass ne-Acrylic Glass, i-Anebon ithembele ezintweni zekhwalithi ephezulu, idizayini ephelele, isevisi yamakhasimende enhle kakhulu kanye nenani lokuncintisana ukuze lizuze ukwethenjwa kwamakhasimende amaningi ekhaya naphesheya. Imikhiqizo engama-95% ithunyelwa ezimakethe zaphesheya.

Uma ufuna ukwazi okwengeziwe noma udinga ukubuza, sicela uxhumaneinfo@anebon.com.

Isikhathi sokuthumela: Jan-30-2024