Insimbi engagqwali iyisinqumo esidumile sokwenza izinsimbi. Ukufunda ngensimbi engagqwali kungasiza abasebenzisi bezinsimbi ukuthi babe nobuchule ekukhetheni nasekusebenziseni izinsimbi ngempumelelo.

Insimbi engagqwali, evame ukufushaniswa ngokuthi i-SS, iyakwazi ukumelana nokuchayeka emoyeni, isitimu, amanzi, nezinye izinto ezibi kakhulu. Ngaleso sikhathi, insimbi ekwaziyo ukumelana nemithelela yokugqwala kwamakhemikhali entweni efana ne-asidi, i-alkali, usawoti, namanye ama-etchants amakhemikhali, yaziwa njengensimbi engamelana ne-asidi.

Insimbi engagqwali, eyaziwa nangokuthi insimbi engagqwali engamelana ne-asidi, ingamelana nomoya, isitimu, amanzi, nezinto ezicekeceke kalula. Nokho, kubalulekile ukuqaphela ukuthi akuzona zonke insimbi engagqwali ukumelana nokugqwala kwamakhemikhali. Ngakolunye uhlangothi, insimbi engazweli i-asidi iklanyelwe ukumelana nemiphumela yemithombo yamakhemikhali efana ne-asidi, i-alkali, nosawoti. Ukumelana nokugqwala kwensimbi engagqwali kunqunywa izakhi ze-alloying ngaphakathi kwensimbi.

Ukuhlukaniswa okuvamile

Ivamise ukuhlukaniswa ngenhlangano ye-metallographic:

Emkhakheni wenhlangano ye-metallographic, insimbi engagqwali evamile ivamise ukuhlukaniswa ngamaqembu amathathu: i-Austenitic stainless steel, i-ferritic stainless steel, ne-martensitic stainless steel. Lawa maqoqo akha isisekelo, futhi ukusuka lapho, insimbi eyi-biphase, insimbi engagqwali eqiniswe kwezulu, kanye nensimbi ephezulu yengxubevange equkethe insimbi engaphansi kuka-50% kuye kwathuthukiswa ukuze kuhlangatshezwane nezidingo ezithile futhi kufezwe izinjongo ezithile.

1, Insimbi Engagqwali Engeyona I-Magnetic

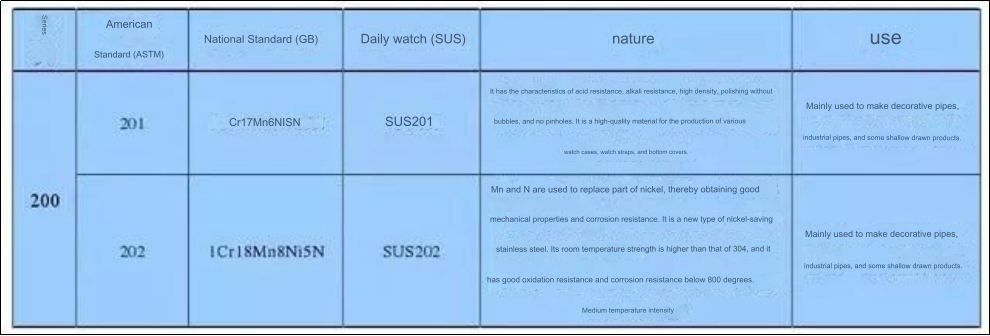

Lolu hlobo lwensimbi engagqwali lunesakhiwo sekristalu esaziwa ngokuthi i-austenitic, esiqiniswa kakhulu ngokusebenza okubandayo. Akuwona uzibuthe, kodwa izinombolo zochungechunge ezingama-200 nezingu-300, njenge-304, zivame ukusetshenziswa yi-American Iron and Steel Institute ukuhlonza le nsimbi.

2, Insimbi Engagqwali Yenziwe Kakhulu Ngensimbi

Lolu hlobo lwensimbi engagqwali ngokuyinhloko luqukethe isakhiwo sekristalu esibuswa i-ferrite (isigaba A), esiwuzibuthe. Ngokuvamile ayikwazi ukuqina ngokushisisa, kodwa ukusebenza okubandayo kungaholela ekwenyukeni okuncane kwamandla. I-American Iron and Steel Institute icacisa u-430 no-446 njengezibonelo.

3, Insimbi Engagqwali Eqinile

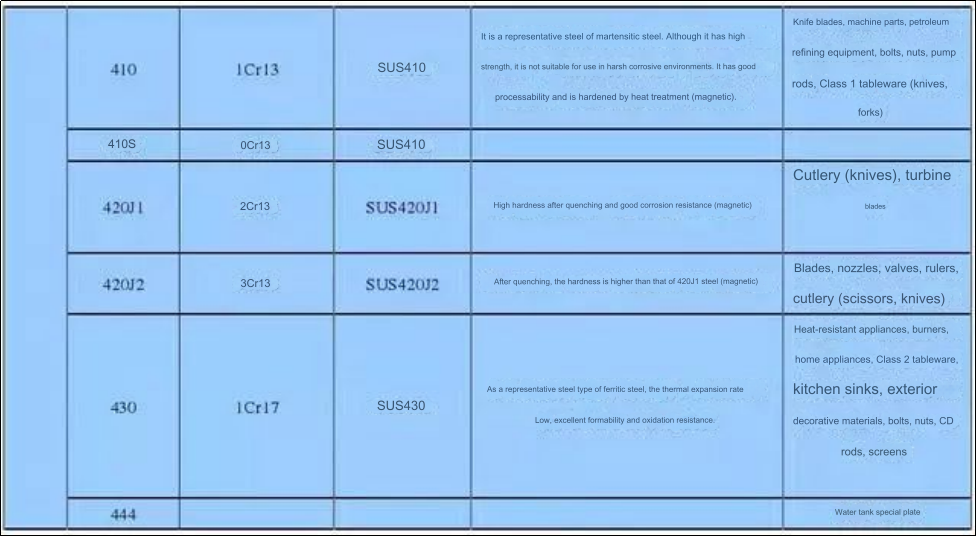

Lolu hlobo lwensimbi engagqwali lunokwakheka kwekristalu okubizwa ngokuthi i-martensitic enozibuthe. Izakhiwo zayo zemishini zingashintshwa ngokwelashwa kokushisa. I-American Iron and Steel Institute ibhekisela kuyo ngokuthi 410, 420, kanye no-440. I-Martensite iqala ngesakhiwo se-austenitic emazingeni okushisa aphezulu futhi ingashintsha ibe yi-martensite (okungukuthi, iba lukhuni) uma ipholisa ngesivinini esilungile kuya ekamelweni lokushisa.

4, Duplex Stainless Steel

Lolu hlobo lwensimbi engagqwali lunengxube yezakhiwo ze-austenitic kanye ne-ferritic. Ingxenye yesigaba esincane esakhiweni ivamise ukuba ngaphezu kuka-15%, okuyenza ibe kazibuthe futhi ikwazi ukuqiniswa ngokusebenza okubandayo. I-329 iyisibonelo esaziwayo salolu hlobo lwensimbi engagqwali. Uma iqhathaniswa ne-austenitic stainless steel, i-duplex steel ibonisa amandla amakhulu kanye nokwenyuka okuphawulekayo kokumelana nokugqwala kwe-intergranular, ukugqwala kwengcindezi ye-chloride, nokugqwala kwephoyinti.

5, Insimbi Engagqwali Enamandla Okwenza Ukuqina Kwemvula

Lolu hlobo lwensimbi engagqwali lune-matrix okungenzeka ukuthi i-austenitic noma i-martensitic futhi ingaqiniswa ngokuqiniswa kwemvula. I-American Iron

futhiI-Steel Institute yabela izinombolo zochungechunge ezingama-600 kulezi zinsimbi, njenge-630, eyaziwa nangokuthi i-17-4PH.

Ngokuvamile, ngaphandle kwama-alloys, insimbi engagqwali ye-austenitic inikeza ukumelana nokugqwala okukhethekile. Ezindaweni ezingagqwali kancane, insimbi engagqwali ye-ferritic ingasetshenziswa, kuyilapho endaweni egqwala kancane lapho kudingeka khona amandla aphezulu noma ubulukhuni, insimbi engagqwali ye-martensitic kanye nemvula eqinile eqinile insimbi engagqwali izinketho ezifanele.

Izici nezindawo zohlelo lokusebenza

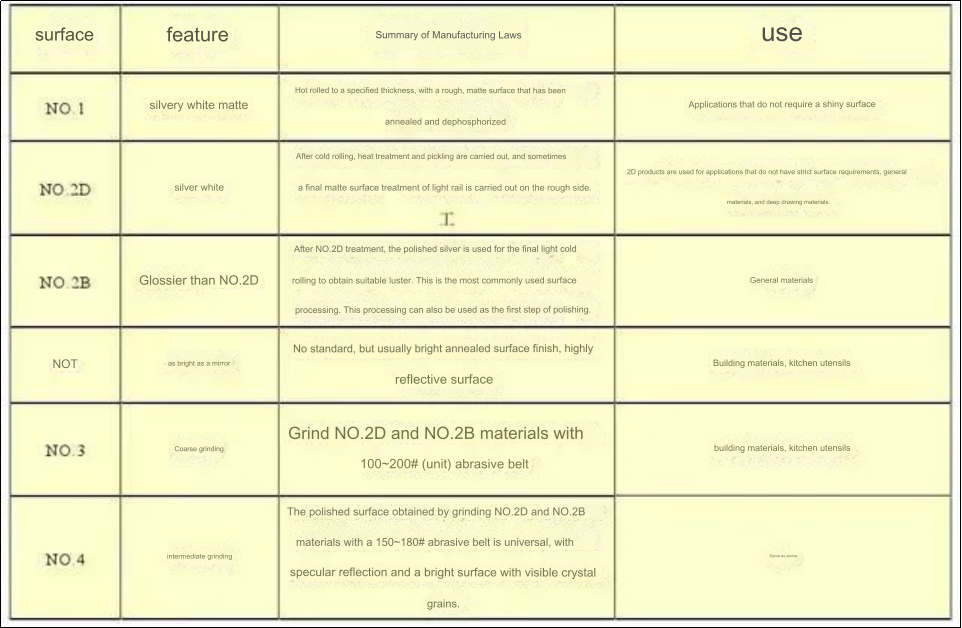

Ubuchwepheshe bomphezulu

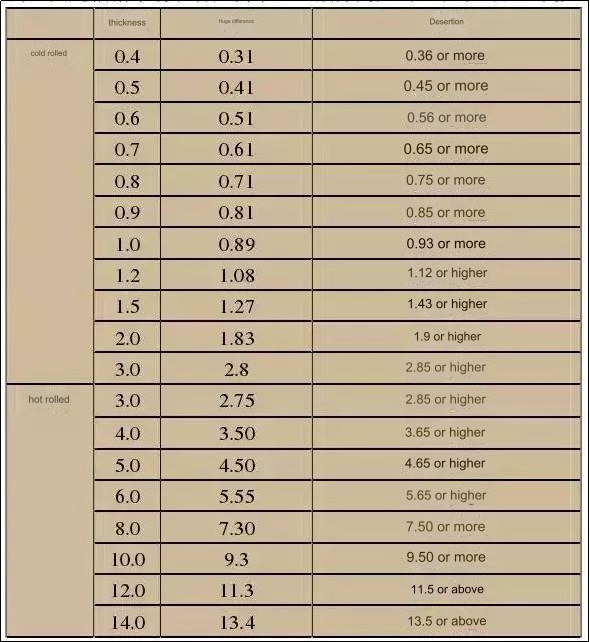

Ukuhlukaniswa kokuqina

1, ngenxa yokuthi umshini wokugaya insimbi lapho uginqika, ukushisa kweroll kubonakala kuguquguquka kancane, okuholela ekuchezukeni kokuchezuka kwebhodi eligoqiwe, ngokuvamile eliwugqinsi ezinhlangothini zombili zomncane. Lapho ukala ubukhulu bebhodi, umbuso ubeka ukuthi ingxenye ephakathi yekhanda lebhodi kufanele ilinganiswe.

I-2, isizathu sokubekezelelana sihambisana nemakethe kanye nesidingo samakhasimende, ngokuvamile sihlukaniswe ukubekezelelana okukhulu nokubekezelelana okuncane: isibonelo,

Hlobo luni lwensimbi engagqwali okungelula ukugqwala?

Kunezici ezintathu eziyinhloko ezithinta ukugqwala kwensimbi engagqwali:

1, okuqukethwe izakhi ingxubevange.

Umthelela Wezinto Ezihlanganisiwe Ngokuvamile, insimbi equkethe okungenani i-chromium engu-10.5% ibonisa ukumelana nokugqwala. Ngaphezu kwalokho, insimbi engagqwali enamazinga aphezulu e-chromium ne-nickel, njengoba itholakala kunsimbi engu-304 eno-8-10% nickel kanye no-18-20% we-chromium, ibonisa ukumelana nokugqwala okuthuthukisiwe futhi ngokuvamile imelana nokugqwala ezimeni ezijwayelekile.

2. Umthelela Wenqubo Yokuncibilikisa Ekumelaneni Nokugqwala

Ukumelana nokugqwala kwensimbi engagqwali nakho kungathinteka inqubo yokuncibilikisa ezindaweni zokukhiqiza. Izitshalo ezinkulu zensimbi engagqwali ezifakwe ubuchwepheshe obuphambili kanye nemishini yesimanje ingaqinisekisa ikhwalithi yomkhiqizo ozinzile futhi onokwethenjelwa ngokulawula okunembile kwezakhi ze-alloying, ukukhishwa okusebenzayo kokungcola, nokuphathwa okunembile kwamazinga okushisa okupholisa ama-billet. Lokhu kubangela izinga eliphezulu langaphakathi kanye nokunciphisa amathuba okuba nokugqwala. Ngokuphambene, izigayo zensimbi ezincane ezinemishini nobuchwepheshe obuphelelwe yisikhathi zingase zibe nzima ukususa ukungcola ngesikhathi sokuncibilikiswa, okuholela ekugqwaleni okungenakugwenywa kwemikhiqizo yazo.

3. imvelo yangaphandle, isimo sezulu esomile futhi imvelo umoya akulula ukugqwala.

Isimo sendawo yangaphandle, ikakhulukazi isimo sezulu esomile nesingena umoya, asikhuthazi ukwakheka kokugqwala. Ngakolunye uhlangothi, amazinga aphezulu omswakama womoya, isimo sezulu esinemvula isikhathi eside, noma izindawo ezine-pH ephakeme zingaholela ekwakhekeni kokugqwala. Ngisho nensimbi engagqwali engu-304 izogqwala uma ingaphansi kwezimo ezingezinhle zemvelo.

Insimbi engagqwali ibonakala ukugqwala indawo kanjani ukubhekana?

1. Izindlela zamakhemikhali

Sebenzisa izindlela zamakhemikhali ezifana ne-picling paste noma isifutho ukuze usize ukudlula kabusha kwezindawo ezigqwalile, wenze ifilimu ye-chromium oxide ebuyisela ukumelana nokugqwala. Ukulandela ukukha, ukugeza kahle ngamanzi kubalulekile ukuze kukhishwe konke ukungcola nezinsalela ze-asidi. Qedela inqubo yokwelapha ngokuphinda upholishwe ngezinto ezifanele futhi uvale nge-wax. Ezindaweni zokugqwala ezincane zasendaweni, ingxube kaphethiloli namafutha engu-1:1 ingasetshenziswa ngendwangu ehlanzekile ukuze kukhishwe ukugqwala.

2. Indlela yemishini

Ukusetshenziswa kokuqhuma kwesihlabathi, ingilazi noma ukudubula kwezinhlayiyana ze-ceramic, ukuhuzuka, ukuxubha, nokupholishwa kuhlanganisa izindlela ezibonakalayo zokususa ukungcola okushiywe ukupholishwa noma ukuhuzuka kwangaphambi kwemisebenzi. Noma yiluphi uhlobo lokungcoliswa, ikakhulukazi izinhlayiya zensimbi zangaphandle, lungaholela ekugqwaleni, ikakhulukazi ezindaweni eziswakeme. Ngakho-ke, kuhle ukwenza ukuhlanzwa ngokomzimba kwezindawo ngaphansi kwezimo ezomile. Kubalulekile ukuqaphela ukuthi ukusetshenziswa kwezindlela zomzimba kungasusa kuphela ukungcola okungaphezulu futhi akuguquli ukumelana nokugqwala okungokwemvelo kwezinto. Ngakho-ke, kuyatuseka ukuthi uqedele inqubo ngokupholisha kabusha ngemishini efanele futhi uvalwe nge-wax yokupholisha.

Insimbi evame ukusetshenziswa engagqwali grade kanye nokusebenza

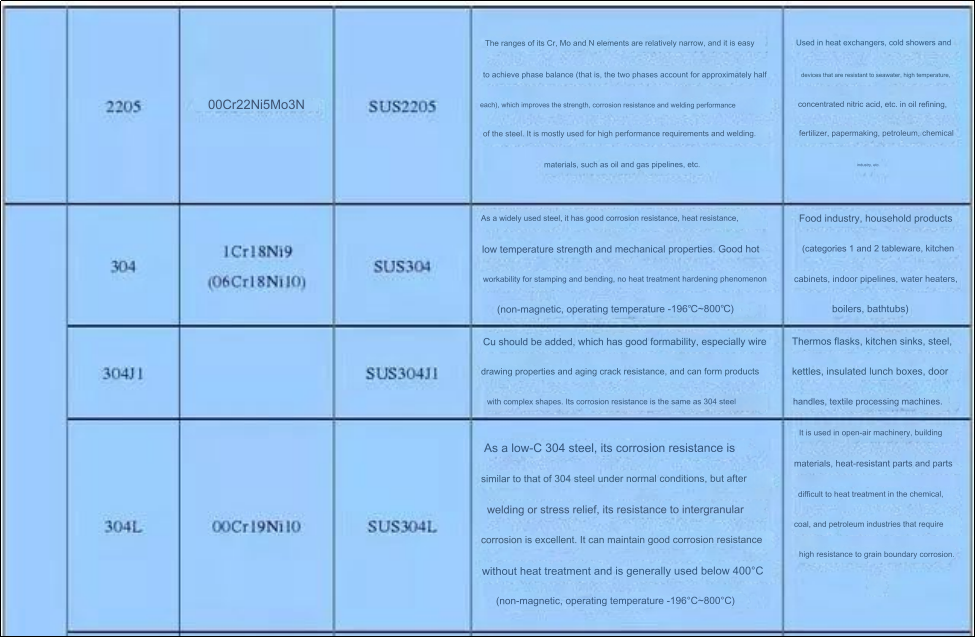

I-1, 304 insimbi engagqwali isetshenziswa kakhulu i-austenitic stainless steel, ilungele ukukhiqiza ukudonsa okujulile.cnc izingxenye zomshini, amapayipi ane-asidi, iziqukathi, izingxenye zesakhiwo, nezinhlaka zezinsimbi ezihlukahlukene. Ukwengeza, iyakwazi ukukhiqiza imishini nezinto ezingezona uzibuthe nezisezingeni eliphansi lokushisa.

2, 304L insimbi engagqwali isetshenziselwa ukubhekana nokuthinteka kokugqwala kwe-intergranular kwensimbi engagqwali engu-304 ngenxa yemvula engu-Cr23C6 ngaphansi kwezimo ezithile. Isimo esizwelayo sale nsimbi engagqwali ye-ultra-low carbon austenitic sinikeza ukumelana nokugqwala okuthuthuke ngokuphawulekayo uma kuqhathaniswa nensimbi engagqwali engu-304. Ukwengeza, ngenkathi ikhombisa amandla aphansi kancane, yabelana ngezakhiwo ezifanayo nensimbi engagqwali engu-321 futhi isetshenziselwa kakhulu ukushisela. Ifaneleka kahle ukukhiqizwa kwezindikimba zamathuluzi ahlukahlukene kanye nezinto ezimelana nokugqwala kanye nezingxenye ezingakwazi ukwelashelwa isixazululo esiqinile.

3, 304H insimbi engagqwali. Igatsha langaphakathi le-304 insimbi engagqwali, ingxenye ye-carbon mass engu-0.04% -0.10%, ukusebenza kwezinga lokushisa eliphezulu kungcono kune-304 yensimbi engagqwali.

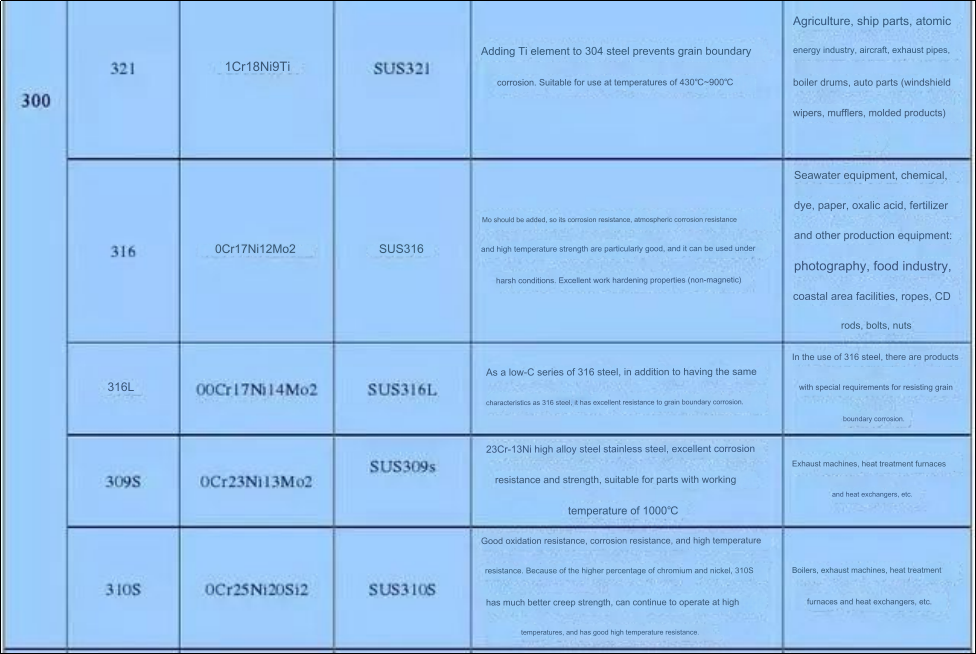

4, 316 insimbi engagqwali. Ukwengezwa kwe-molybdenum ngesisekelo sensimbi engu-10Cr18Ni12 kwenza insimbi ibe nokumelana okuhle nokunciphisa imidiya kanye nokugqwala kwamaphuzu. Emanzini olwandle nakweminye imidiya, ukumelana nokugqwala kungcono kunensimbi engagqwali engama-304, esetshenziselwa ikakhulukazi izinto zokumelana nokugoba.

5, 316L insimbi engagqwali. I-Ultra-low carbon steel, ekwazi ukumelana nokugqwala kwe-intergranular ezwelayo, ifaneleka ukwakhiwa kwezingxenye ezishiselwe kanye nemishini enosayizi abaminyene besigaba esiphambanayo, njengezinto ezimelana nokugqwala emishinini ye-petrochemical.

6, 316H insimbi engagqwali. Igatsha langaphakathi lensimbi engu-316, ingxenye ye-carbon mass engu-0.04% -0.10%, ukusebenza kwezinga lokushisa eliphezulu kungcono kune-316 insimbi engagqwali.

7, 317 insimbi engagqwali. Ukumelana ne-pitting kanye nokukhasa kungcono kune-316L yensimbi engagqwali, esetshenziswa ekwenzeni i-petrochemical kanye ne-organic acid ukumelana nokugqwala.

8, 321 insimbi engagqwali iyinsimbi engagqwali ye-austenitic ene-titanium stabilization. Ukwengezwa kwe-titanium kuhloswe ngayo ukuthuthukisa ukumelana nokugqwala kwe-intergranular, futhi kukhombisa izakhiwo ezinhle zemishini emazingeni okushisa aphezulu. Ngaphansi kwezimo eziningi, ayiphakanyiselwa ukusetshenziswa, ngaphandle kwezimo ezithile ezifana nokuhlangabezana nezinga lokushisa eliphezulu noma ukugqwala okubangelwa i-hydrogen.

9, 347 insimbi engagqwali iyingxube yensimbi engagqwali ye-austenitic eqiniswa nge-niobium. Ukwengezwa kwe-niobium kusiza ukuthuthukisa ukumelana kwayo nokugqwala kwe-intergranular kanye nekhono layo lokumelana nokugqwala endaweni ene-asidi, i-alkaline, enosawoti kanye nezinye izindawo zamakhemikhali ezinokhahlo. Iphinde ibonise izici ezinhle kakhulu zokushisela, okuyenza ifanelekele ukusetshenziswa njengezinto ezimelana nokugqwala nanjengensimbi engashisi. Le ngxubevange yensimbi isetshenziswa kakhulu ezimbonini zamandla ashisayo nasezimbonini ze-petrochemical ezisetshenziswa ezahlukahlukene ezifana neziqukathi zokukhiqiza, amapayipi, izishintshisi zokushisa, ama-shafts, namashubhu omlilo ezithandweni zezimboni, kanye nama-thermometers eshubhu lomlilo.

I-10, 904L insimbi engagqwali iyinsimbi engagqwali ethuthuke kakhulu ye-austenitic eyakhiwe yi-OUTOKUMPU (Finland) enokuqukethwe kwe-nickel kusuka ku-24% kuya ku-26% kanye nekhabhoni engaphansi kuka-0.02%. Inomelana nokugqwala okukhethekile futhi isebenza kahle kuma-asidi anga-oxidizing njenge-sulfuric acid, i-acetic acid, i-formic acid, ne-phosphoric acid. Ukwengeza, ikhombisa ukumelana okuqinile nokugqwala kwe-crevice kanye nokugqwala kwengcindezi. Ilungele ukusetshenziswa ne-sulfuric acid ezindaweni ezihlukahlukene ezingaphansi kuka-70 ℃ futhi inikeza ukumelana nokugqwala okuphakeme ku-acetic acid nama-acids axubile e-formic acid ne-acetic acid kunoma yikuphi ukugxila kanye nezinga lokushisa ngaphansi kwengcindezi evamile. Ekuqaleni ihlukaniswe njengengxube ye-nickel-based alloy ngaphansi kwezinga le-ASMESB-625, manje isiphinde yahlelwa njengensimbi engagqwali. Ngenkathi insimbi yaseChina i-015Cr19Ni26Mo5Cu2 yabelana ngokufana ne-904L, abakhiqizi bezinsimbi abambalwa base-Europe basebenzisa insimbi engagqwali engu-904L njengento eyinhloko yabo.izingxenye ze-cnc, njengeshubhu yokulinganisa imitha yokugeleza kwe-E+ H kanye nekesi lewashi le-Rolex.

11, 440C insimbi engagqwali. Insimbi engagqwali ye-Martensitic, ubulukhuni obuphakeme kakhulu ensimbi engagqwali eqinile, insimbi engagqwali, ubulukhuni yi-HRC57. Ikakhulukazi esetshenziselwa ukwenza imibhobho, ama-bearings, i-valve spool, isihlalo, umkhono, isiqu nokunye.

12, 17-4PH insimbi engagqwali ihlukaniswa njengensimbi engagqwali eqinile ye-martensitic precipitation enobulukhuni be-Rockwell obungu-44. Inikeza amandla akhethekile, ubulukhuni, nokumelana nokugqwala, nakuba ingafaneleki ukusetshenziswa emazingeni okushisa angaphezu kuka-300°C. Le nsimbi ibonisa ukumelana kahle nezimo zomoya, kanye nama-acids ahlanjululwe noma usawoti. Ukumelana nokugqwala kwayo kuqhathaniswa nalokho kwensimbi engagqwali engama-304 kanye nensimbi engagqwali engama-430. Izicelo zale nsimbi zihlanganisa ukusetshenziswa kwayo ekukhiqizeni amapulatifomu angasogwini, ama-turbine blades, ama-valve spools, izihlalo, imikhono, iziqu zamavalvu, nokunye.

Emkhakheni wezinsimbi zobungcweti, ukukhethwa kwensimbi engagqwali ye-austenitic evamile kunqunywa izici ezifana nokuguquguquka kanye nezindleko. Ukulandelana okuvame ukunconywa kokukhetha insimbi engagqwali yi-304-304L-316-316L-317-321-347-904L. Ngokuphawulekayo, i-317 ayisetshenziswa kakhulu, i-321 ayithandwa, i-347 ikhethwa ngenxa yokumelana nokugqwala okuphezulu kwezinga lokushisa, kanti i-904L iyinto ezenzakalelayo yezingxenye ezithile ezikhiqizwa izinkampani ezithile. Insimbi engagqwali engu-904L ngokuvamile ayiyona into evamile ekusetshenzisweni kokuklama.

Ekwakheni nasekukhethweni kwensimbi, kuvame ukuhlangana nezinhlelo ezahlukahlukene ezahlukahlukene, uchungechunge, amamaki ensimbi engagqwali, ukukhethwa kufanele kusekelwe kumidiya ethile yenqubo, izinga lokushisa, ingcindezi, izingxenye zokucindezeleka, ukugqwala, izindleko nezinye izici zokucatshangelwa.

Ukuphishekela i-Anebon kanye nenhloso yebhizinisi ukuthi “Njalo ukwanelisa izidingo zamakhasimende ethu”. I-Anebon iyaqhubeka nokusungula kanye nesitayela nokuklama izimpahla ezisezingeni eliphezulu zamathemba ethu aphelelwe yisikhathi namasha futhi ithole ithemba lokuwina kumakhasimende ethu njengoba nje senza ngendlela oyifisayo amaphrofayili e-extrusion anembe kakhulu,izingxenye ze-aluminium eziphendukayo ze-cncfuthiizingxenye zokugaya i-aluminiumkumakhasimende. I-Anebon enezandla ezivulekile, imeme bonke abathengi abanentshisekelo ukuthi bavakashele iwebhusayithi yethu noma baxhumane nathi ngqo ukuze uthole imininingwane eyengeziwe.

Ifekthri Yenziwe Ngokwezifiso I-China CNC Machine kanye ne-CNC Engraving Machine, umkhiqizo we-Anebon waziwa kabanzi futhi wethenjwa ngabasebenzisi futhi ungahlangabezana ngokuqhubekayo nezidingo zomnotho nezenhlalo. I-Anebon yamukela amakhasimende amasha namadala avela kuyo yonke imikhakha yempilo ukuze asithinte ukuze athole ubudlelwano bebhizinisi besikhathi esizayo futhi azuze impumelelo efanayo!

Isikhathi sokuthumela: Jan-23-2024