I-HV, i-HB, ne-HRC zonke izilinganiso zokuqina ezisetshenziswa ekuhlolweni kwezinto. Masizihlukanise:

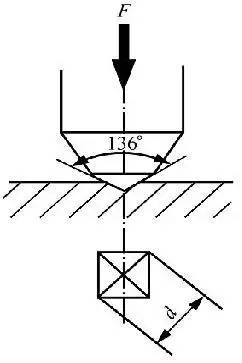

1)HV Ukuqina (Vickers Hardness): Ukuqina kwe-HV isilinganiso sokuphikiswa kokuhlehlisa. Kunqunywa ngokufaka umthwalo owaziwayo ebusweni bento usebenzisa i-indenter yedayimane kanye nokulinganisa usayizi wokuhlehlisa okuwumphumela. Ukuqina kwe-HV kuvezwa ngamayunithi we-Vickers hardness (HV) futhi kuvame ukusetshenziselwa izinto ezisetshenziswayo ezizacile, ama-coatings, nezingxenye ezincane.

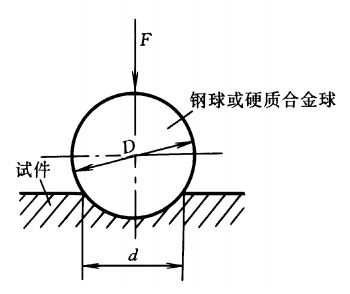

2)HB Ukuqina (Brinell Hardness): Ukuqina kwe-HB kungesinye isilinganiso sokumelana nokuhlehlisa. Kuhilela ukusebenzisa umthwalo owaziwayo ezintweni kusetshenziswa i-indenter yebhola yensimbi eqinile kanye nokulinganisa ububanzi bokuhlehlisa okuwumphumela. Ukuqina kwe-HB kuvezwa ngamayunithi e-Brinell hardness (HB) futhi kuvame ukusetshenziselwa izinto ezinkulu nezinkulu, okuhlanganisa izinsimbi nama-alloys.

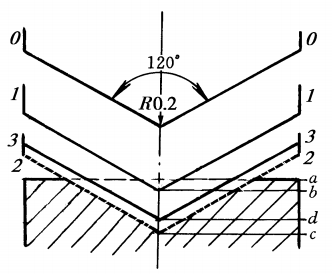

3)HRC Ukuqina (Rockwell Hardness): Ubulukhuni be-HRC isilinganiso sokumelana nokuhlehlisa noma ukungena. Isebenzisa izikali ezihlukene (A, B, C, njll.) ngokusekelwe endleleni yokuhlola ethile kanye nohlobo lwe-indenter esetshenzisiwe (ikhoni yedayimane noma ibhola lensimbi eliqinile). Isikali se-HRC sivame ukusetshenziselwa ukukala ubulukhuni bezinto zensimbi. Inani lokuqina limelelwa njengenombolo esikalini se-HRC, njenge-HRC 50.

Ithebula lokuqhathanisa ubulukhuni be-HV-HB-HRC elisetshenziswa kakhulu:

| Ithebula elivamile lokuqhathanisa ubulukhuni bensimbi eyinsimbi (isilinganiso sokuguqulwa kwamandla) | ||||

| Ukuhlukaniswa kokuqina | Amandla aqinile N/mm2 | |||

| Rockwell | Vickers | Brinell | ||

| HRC | HRA | HV | HB | |

| 17 | - | 211 | 211 | 710 |

| 17.5 | - | 214 | 214 | 715 |

| 18 | - | 216 | 216 | 725 |

| 18.5 | - | 218 | 218 | 730 |

| 19 | - | 221 | 220 | 735 |

| 19.5 | - | 223 | 222 | 745 |

| 20 | - | 226 | 225 | 750 |

| 20.5 | - | 229 | 227 | 760 |

| 21 | - | 231 | 229 | 765 |

| 21.5 | - | 234 | 232 | 775 |

| 22 | - | 237 | 234 | 785 |

| 22.5 | - | 240 | 237 | 790 |

| 23 | - | 243 | 240 | 800 |

| 23.5 | - | 246 | 242 | 810 |

| 24 | - | 249 | 245 | 820 |

| 24.5 | - | 252 | 248 | 830 |

| 25 | - | 255 | 251 | 835 |

| 25.5 | - | 258 | 254 | 850 |

| 26 | - | 261 | 257 | 860 |

| 26.5 | - | 264 | 260 | 870 |

| 27 | - | 268 | 263 | 880 |

| 27.5 | - | 271 | 266 | 890 |

| 28 | - | 274 | 269 | 900 |

| 28.5 | - | 278 | 273 | 910 |

| 29 | - | 281 | 276 | 920 |

| 29.5 | - | 285 | 280 | 935 |

| 30 | - | 289 | 283 | 950 |

| 30.5 | - | 292 | 287 | 960 |

| 31 | - | 296 | 291 | 970 |

| 31.5 | - | 300 | 294 | 980 |

| 32 | - | 304 | 298 | 995 |

| 32.5 | - | 308 | 302 | 1010 |

| 33 | - | 312 | 306 | 1020 |

| 33.5 | - | 316 | 310 | 1035 |

| 34 | - | 320 | 314 | 1050 |

| 34.5 | - | 324 | 318 | 1065 |

| 35 | - | 329 | 323 | 1080 |

| 35.5 | - | 333 | 327 | 1095 |

| 36 | - | 338 | 332 | 1110 |

| 36.5 | - | 342 | 336 | 1125 |

| 37 | - | 347 | 341 | 1140 |

| 37.5 | - | 352 | 345 | 1160 |

| 38 | - | 357 | 350 | 1175 |

| 38.5 | - | 362 | 355 | 1190 |

| 39 | 70 | 367 | 360 | 1210 |

| 39.5 | 70.3 | 372 | 365 | 1225 |

| 40 | 70.8 | 382 | 375 | 1260 |

| 40.5 | 70.5 | 377 | 370 | 1245 |

| 41 | 71.1 | 388 | 380 | 1280 |

| 41.5 | 71.3 | 393 | 385 | 1300 |

| 42 | 71.6 | 399 | 391 | 1320 |

| 42.5 | 71.8 | 405 | 396 | 1340 |

| 43 | 72.1 | 411 | 401 | 1360 |

| 43.5 | 72.4 | 417 | 407 | 1385 |

| 44 | 72.6 | 423 | 413 | 1405 |

| 44.5 | 72.9 | 429 | 418 | 1430 |

| 45 | 73.2 | 436 | 424 | 1450 |

| 45.5 | 73.4 | 443 | 430 | 1475 |

| 46 | 73.7 | 449 | 436 | 1500 |

| 46.5 | 73.9 | 456 | 442 | 1525 |

| 47 | 74.2 | 463 | 449 | 1550 |

| 47.5 | 74.5 | 470 | 455 | 1575 |

| 48 | 74.7 | 478 | 461 | 1605 |

| 48.5 | 75 | 485 | 468 | 1630 |

| 49 | 75.3 | 493 | 474 | 1660 |

| 49.5 | 75.5 | 501 | 481 | 1690 |

| 50 | 75.8 | 509 | 488 | 1720 |

| 50.5 | 76.1 | 517 | 494 | 1750 |

| 51 | 76.3 | 525 | 501 | 1780 |

| 51.5 | 76.6 | 534 | - | 1815 |

| 52 | 76.9 | 543 | - | 1850 |

| 52.5 | 77.1 | 551 | - | 1885 |

| 53 | 77.4 | 561 | - | 1920 |

| 53.5 | 77.7 | 570 | - | 1955 |

| 54 | 77.9 | 579 | - | 1995 |

| 54.5 | 78.2 | 589 | - | 2035 |

| 55 | 78.5 | 599 | - | 2075 |

| 55.5 | 78.7 | 609 | - | 2115 |

| 56 | 79 | 620 | - | 2160 |

| 56.5 | 79.3 | 631 | - | 2205 |

| 57 | 79.5 | 642 | - | 2250 |

| 57.5 | 79.8 | 653 | - | 2295 |

| 58 | 80.1 | 664 | - | 2345 |

| 58.5 | 80.3 | 676 | - | 2395 |

| 59 | 80.6 | 688 | - | 2450 |

| 59.5 | 80.9 | 700 | - | 2500 |

| 60 | 81.2 | 713 | - | 2555 |

| 60.5 | 81.4 | 726 | - | - |

| 61 | 81.7 | 739 | - | - |

| 61.5 | 82 | 752 | - | - |

| 62 | 82.2 | 766 | - | - |

| 62.5 | 82.5 | 780 | - | - |

| 63 | 82.8 | 795 | - | - |

| 63.5 | 83.1 | 810 | - | - |

| 64 | 83.3 | 825 | - | - |

| 64.5 | 83.6 | 840 | - | - |

| 65 | 83.9 | 856 | - | - |

| 65.5 | 84.1 | 872 | - | - |

| 66 | 84.4 | 889 | - | - |

| 66.5 | 84.7 | 906 | - | - |

| 67 | 85 | 923 | - | - |

| 67.5 | 85.2 | 941 | - | - |

| 68 | 85.5 | 959 | - | - |

| 68.5 | 85.8 | 978 | - | - |

| 69 | 86.1 | 997 | - | - |

| 69.5 | 86.3 | 1017 | - | - |

| 70 | 86.6 | 1037 | - | - |

I-HRC/HB Amathiphu Okuguqulwa Alinganiselwe

Ukuqina kuphakeme kune-20HRC, 1HRC≈10HB,

Ukuqina kungaphansi kuka-20HRC, 1HRC≈11.5HB.

Amazwana: Ukuze kucutshungulwe, kungaguqulwa ngokulinganayo 1HRC≈10HB (ubulukhuni bempahla yokusebenza bunobubanzi obuguquguqukayo)

Ukuqina kwensimbi

Ukuqina kusho ikhono lempahla ukumelana nokuguquguquka kwendawo, ikakhulukazi ukuwohloka kwepulasitiki, ukuhlehlisa noma ukunwaya. Kuyinkomba yokukala ukuthamba nobulukhuni bempahla.

Ngokwezindlela ezihlukene zokuhlola, ubulukhuni buhlukaniswe ngezinhlobo ezintathu.

①Ukuqina kokuqina. Ngokuyinhloko isetshenziselwa ukuqhathanisa ukuthamba nobulukhuni bamaminerali ahlukene. Indlela yokukhetha induku enomkhawulo owodwa oqinile kanti enye ithambile, udlulise izinto okufanele zihlolwe eduze kwenduku, futhi unqume ubulukhuni bento okufanele ihlolwe ngokuya ngokuma kokuklwebheka. Uma sikhuluma ngokufaneleka, izinto eziqinile zenza imihuzuko emide kanti izinto ezithambile zenza imihuzuko emifushane.

②Ukuqina kokuhlehlisa. Ikakhulukazi esetshenziselwa izinto zensimbi, indlela iwukusebenzisa umthwalo othile ukuze ucindezele i-indenter eshiwo entweni ezohlolwa, futhi uqhathanise ukuthamba nobulukhuni bezinto okufanele zihlolwe ngosayizi we-deformation yepulasitiki yendawo ebusweni bendawo. impahla. Ngenxa yomehluko we-indenter, ubude bomthwalo nomthwalo, kunezinhlobo eziningi zokuqina kokuhlehlisa, ikakhulukazi okuhlanganisa ukuqina kwe-Brinell, ukuqina kwe-Rockwell, ubulukhuni be-Vickers kanye nokuqina okuncane.

③Bopha kabusha ubulukhuni. Ikakhulukazi esetshenziselwa izinto zensimbi, indlela yokwenza isando esincane esikhethekile siwe ngokukhululekile ukusuka ekuphakameni okuthile ukuze sibe nomthelela kusampula yezinto ezizohlolwa, futhi sisebenzise inani lamandla obunzima agcinwe (bese ekhululwa) kusampula ngesikhathi sokuhlolwa. umthelela (ngokubuya kwesando esincane) isilinganiso sobude bokweqa) ukuze kunqunywe ubulukhuni bento.

Ubulukhuni be-Brinell obuvame kakhulu, ubulukhuni be-Rockwell kanye nobulukhuni be-Vickers bezinto zensimbi kungobokuqina kokuhlehlisa. Inani lobulukhuni libonisa ikhono lendawo yezinto ezibonakalayo ukumelana nokuguqulwa kwepulasitiki okubangelwa enye into ecindezelwa phakathi; C) ukukala ubulukhuni, futhi inani lobulukhuni limelela ubukhulu bomsebenzi wokuguquguquka okunwebeka wensimbi.

Ukuqina kweBrinell

Sebenzisa ibhola lensimbi elicishiwe noma ibhola le-alloy eliqinile elinobubanzi buka-D njenge-indenter, licindezele ebusweni besiqephu sokuhlola ngamandla okuhlola ahambisanayo F, futhi ngemva kwesikhathi esibekiwe sokubamba, susa amandla okuhlola ukuze uthole indentation nge. ububanzi be-d. Hlukanisa amandla okuhlola ngendawo engaphezulu yokuhlehlisa, futhi inani eliwumphumela liyivelu yobulukhuni be-Brinell, futhi uphawu lumelwe yi-HBS noma i-HBW.

Umehluko phakathi kwe-HBS ne-HBW umehluko ku-indenter. I-HBS isho ukuthi i-indenter iyibhola lensimbi eliqinile, elisetshenziselwa ukukala izinto ezinenani lokuqina le-Brinell elingaphansi kuka-450, njengensimbi emnene, insimbi empunga nezinsimbi ezingenayo insimbi. I-HBW isho ukuthi i-indenter iyi-carbide enosimende, esetshenziselwa ukukala izinto ngenani lokuqina le-Brinell elingaphansi kuka-650.

Kubhulokhi yokuhlola efanayo, lapho ezinye izimo zokuhlola zifana ncamashi, imiphumela yokuhlola okubili ihlukile, futhi inani le-HBW livamise ukuba likhulu kunevelu ye-HBS, futhi awukho umthetho womthamo ongalandelwa.

Ngemuva kuka-2003, izwe lami selithathe ngokulinganayo izindinganiso zamazwe ngamazwe, izikhombe zensimbi ezikhanseliwe, nawo wonke amakhanda ebhola e-carbide asetshenzisiwe. Ngakho-ke, i-HBS iyekwa, futhi i-HBW isetshenziselwa ukumela uphawu lokuqina lwe-Brinell. Ezimweni eziningi, ubulukhuni be-Brinell buvezwa kuphela nge-HB, kubhekiselwa ku-HBW. Nokho, i-HBS isabonakala ngezikhathi ezithile emaphepheni ezincwadi.

Indlela yokulinganisa ubulukhuni be-Brinell ifanele insimbi ekhonjiwe, ama-alloys angeyona i-ferrous, izinsimbi ezihlukahlukene ezicishiwe nezicishiwe nezipholile, futhi ayifanele ukuhlola amasampula nomaizingxenye eziphendukayo ze-cnceziqinile kakhulu, ezincane kakhulu, ezizacile kakhulu, noma ezingakuvumeli ukuhlehla okukhulu phezulu.

Ukuqina kwe-Rockwell

Sebenzisa ikhoni yedayimane ene-engeli yekhoni engu-120° noma engu-Ø1.588mm kanye ne-Ø3.176mm amabhola ensimbi acinywe njenge-indenter nomthwalo ukuze usebenzisane nayo. Umthwalo wokuqala ungu-10kgf kanti isamba somthwalo singama-60, 100 noma 150kgf (okungukuthi, umthwalo wokuqala kanye nomthwalo omkhulu). Ukuqina kuboniswa umehluko phakathi kokujula kokuhlehlisa lapho kususwa umthwalo omkhulu kanye nokujula kokuhlehlisa lapho kugcinwa umthwalo omkhulu kanye nokujula kokuhlehlisa ngaphansi komthwalo wokuqala ngemva kokusetshenziswa komthwalo ophelele.

Ukuhlolwa kokuqina kwe-Rockwell kusebenzisa amandla amathathu okuhlola nama-identers amathathu. Kunezinhlanganisela eziyisi-9 zazo, ezihambisana nezikali eziyi-9 zobulukhuni be-Rockwell. Ukusetshenziswa kwalaba babusi abangu-9 kuhlanganisa cishe zonke izinto zensimbi ezivame ukusetshenziswa. Kunama-HRA amathathu asetshenziswa kakhulu, i-HRB kanye ne-HRC, phakathi kwawo i-HRC esetshenziswa kakhulu.

Ithebula elijwayelekile lokuhlola ubulukhuni be-Rockwell:

| Ukuqina | | | Ukuqina | |

| | | | | I-Carbide, i-carbide, |

| | | | | I-annealed, insimbi evamile, i-aluminium alloy |

| | | | | insimbi eqinile, insimbi ecishiwe futhi eqinile, ejulile |

Ububanzi bokusetshenziswa kwesikali se-HRC ngu-20~70HRC. Uma ubulukhuni bungaphansi kuka-20HRC, ngoba i-conicalaluminium cnc machining ingxenyeye-indenter icindezelwe kakhulu, ukuzwela kuyehla, futhi isikali se-HRB kufanele sisetshenziswe esikhundleni salokho; lapho ubulukhuni besampula bungaphezu kuka-67HRC, ukucindezela esihlokweni se-indenter kukhulu kakhulu, futhi idayimane lonakala kalula. Impilo ye-indenter izofushaniswa kakhulu, ngakho-ke isikali se-HRA kufanele sivame ukusetshenziswa esikhundleni salokho.

Ukuhlolwa kokuqina kwe-Rockwell kulula, kuyashesha, futhi kuncane ukuhlehlisa, futhi kungavivinya ingaphezulu lemikhiqizo eqediwe kanye nezinto zokusebenza eziqinile nezincane. Ngenxa yokuhlehlisa okuncane, ezintweni ezinokwakheka okungalingani nobulukhuni, inani lokuqina liyashintshashintsha kakhulu, futhi ukunemba akuphakeme njengobulukhuni beBrinell. Ukuqina kwe-Rockwell kusetshenziselwa ukunquma ubulukhuni bensimbi, izinsimbi ezingenayo insimbi, ama-alloys aqinile, njll.

Vickers Ubulukhuni Vickers Ubulukhuni

Isimiso sokulinganisa ubulukhuni be-Vickers siyefana nesobulukhuni bukaBrinell. Sebenzisa i-indenter yesikwele sephiramidi yedayimane ene-engeli efakiwe engu-136° ukuze ucindezele ebusweni bento ethile ngamandla okuhlola ashiwo F, futhi ususe amandla okuhlola ngemva kokugcina isikhathi esishiwo. Ubulukhuni buboniswa ingcindezi emaphakathi endaweni yeyunithi yokuhlehlisa isikwele sephiramidi. Inani, uphawu lophawu yi-HV.

Ibanga lokulinganisa ubulukhuni be-Vickers likhulu, futhi lingakala izinto ezinobunzima obusuka ku-10 kuye ku-1000HV. I-indent incane, futhi ijwayele ukusetshenziselwa ukukala izinto ezizacile kanye nezendlalelo eziqinile ezifana ne-carburizing ne-nitriding.

U-Leeb Ukuqina U-Leeb Ukuqina

Sebenzisa umzimba onomthelela onesisindo esithile sekhanda lebhola le-tungsten carbide ukuze uthinte ingaphezulu lesiqephu sokuhlola ngaphansi kwesenzo samandla athile, bese ubophe kabusha. Ngenxa yobulukhuni obuhlukene bezinto, isivinini sokubuyela emuva ngemva komthelela sihlukile. Kufakwe uzibuthe ongunaphakade kudivayisi yomthelela. Lapho umzimba womthelela wehla wenyuka, ikhoyili yawo ezungezile izokwenza isignali kazibuthe kagesi ilingane nesivinini, bese iyiguqula ibe ivelu yokuqina kwe-Leeb ngesekhethi ye-elekthronikhi. Uphawu luphawulwe ngokuthi HL.

I-Leeb hardness tester ayidingi i-worktable, futhi inzwa yayo yokuqina incane njengepeni, engasebenza ngokuqondile ngesandla, futhi ingabonakala kalula ukuthi i-workpiece enkulu, esindayo noma i-workpiece enezilinganiso eziyinkimbinkimbi zejometri.

Enye inzuzo yobulukhuni be-Leeb ukuthi inomonakalo omncane kakhulu ebusweni bomkhiqizo, futhi ngezinye izikhathi ingasetshenziswa njengokuhlola okungabhubhisi; ihlukile ekuhlolweni kokuqina kuzo zonke izinkomba, izindawo eziwumngcingo nezikhethekileizingxenye ze-aluminium.

I-Anebon ibambelela esimisweni esithi “Ithembekile, ikhuthele, iyathakazelisa, inobuhlakani obusha” ukuze ithole izixazululo ezintsha ngokuqhubekayo. I-Anebon ibheka amathemba, impumelelo njengempumelelo yayo yomuntu siqu. Vumela i-Anebon yakhe ikusasa eliphumelelayo ngesandla sezingxenye zomshini wethusi kanye nezingxenye ze-Complex titanium cnc / izinsimbi zokugxiviza. I-Anebon manje inokunikezwa kwezimpahla okuphelele kanye nentengo yokuthengisa kuyinzuzo yethu. Siyakwamukela ukubuza mayelana nemikhiqizo ye-Anebon.

Imikhiqizo Ethrendayo Yase-China CNC Machinging Ingxenye kanye Nengxenye Yokunemba, ngempela uma noma iyiphi yalezi zinto ingaba nesithakazelo kuwe, sicela usazise. I-Anebon izokujabulela ukukunikeza ikhotheshini lapho yathola imininingwane yomuntu. I-Anebon inonjiniyela bethu bomuntu siqu be-R&D ukuze bahlangabezane nanoma yiziphi izimfuneko. I-Anebon ibheke ngabomvu ukuthola imibuzo yakho maduze futhi inethemba lokuba nethuba lokusebenza nawe esikhathini esizayo. Siyakwamukela ukuze ubheke inhlangano ye-Anebon.

Isikhathi sokuthumela: May-18-2023