Liyini ithuluzi le-CNC?

Inhlanganisela yezinto ezithuthukisiwe zokucubungula kanye namathuluzi wokusika we-CNC aphezulu anganikeza ukudlala okugcwele ekusebenzeni kwayo okufanele futhi azuze izinzuzo ezinhle zezomnotho. Ngokuthuthuka okusheshayo kwezinto zamathuluzi okusika, izinto ezisetshenziswayo ezintsha zokusika ziye zathuthukisa kakhulu izakhiwo zazo ezingokomzimba, zemishini kanye nokusebenza kokusika, futhi uhla lwazo lwesicelo nalo luye lwaqhubeka nokwanda.

Ukwakheka kwesakhiwo samathuluzi e-CNC?

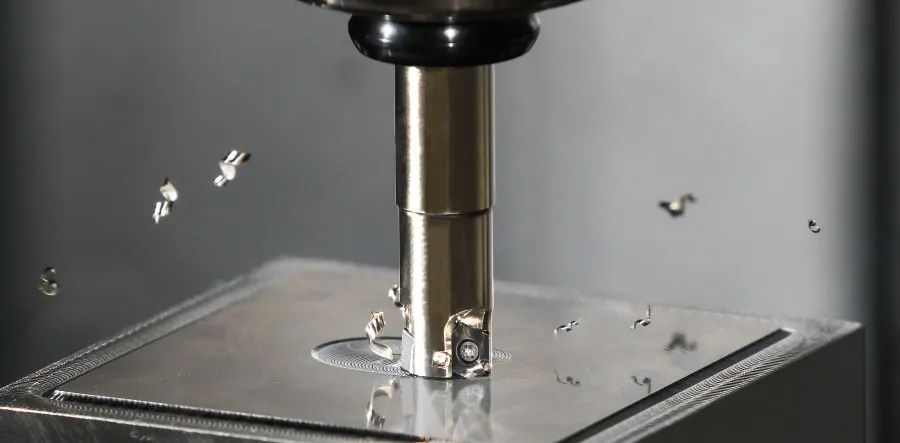

Amathuluzi e-CNC (Computer Numerical Control) angamathuluzi omshini asetshenziswa imiyalo ehleliwe efakwe ikhodi endaweni yokugcina, njengekhompyutha. Lawa mathuluzi asebenzisa isistimu elawulwa ngekhompuyutha ukuze enze imisebenzi yemishini enembayo, njengokusika, ukubhoboza, ukugaya, nokubumba. Amathuluzi asetshenziswa ezinqubweni zokukhiqiza, ikakhulukazi ezimbonini ezifana ne-aerospace, ezezimoto, ezokwelashwa, nezokusebenza kwensimbi.

Amathuluzi e-CNC afaka uhla lwemishini, njengeI-CNC yokugayaimishini, CNCinqubo ye-lathe, CNC routers, CNC plasma cutters, CNC laser cutters. Lawa mathuluzi asebenza ngokuhambisa ithuluzi lokusika noma ucezu lokusebenza ngezimbazo ezintathu noma ngaphezulu kusetshenziswa ukulawula izinombolo zekhompyutha.

Amathuluzi e-CNC aziwa ngokunemba kwawo, ukunemba, nokuphindaphinda, okuwenza alungele ukukhiqiza izingxenye eziyinkimbinkimbi nezingxenye ezibekezelelana ngokuqinile. Bayakwazi futhi ukukhiqiza imikhiqizo yekhwalithi ephezulu ngenani elisheshayo kunemishini yezandla yendabuko, esiza ukwandisa ukukhiqiza nokusebenza kahle ekukhiqizeni.

Yiziphi izinto eziyisisekelo okufanele izinto zamathuluzi e-CNC zibe nazo?

1. Ukuqina: Izinto zamathuluzi e-CNC kufanele zibe nzima ngokwanele ukumelana nokuguga phakathi nenqubo yomshini.

2. Ukuqina: Izinto zamathuluzi e-CNC kufanele zibe nzima ngokwanele ukumelana nomthelela kanye nemithwalo yokushaqeka.

3. Ukumelana nokushisa: Izinto zamathuluzi e-CNC kufanele zikwazi ukumelana namazinga okushisa aphezulu akhiqizwa ngesikhathi senqubo yomshini ngaphandle kokulahlekelwa amandla noma ukuqina.

4. Ukumelana nokugqoka: Izinto zamathuluzi e-CNC kufanele zimelane nokuguga okuhugayo okubangelwa ukuthintana ne-workpiece.

5. Ukuzinza kwamakhemikhali: Izinto zamathuluzi e-CNC kufanele zizinze ngokwamakhemikhali ukuze zigweme ukugqwala nezinye izinhlobo zokulimala kwamakhemikhali.

6. Ukusebenziseka kalula: Izinto zamathuluzi e-CNC kufanele zibe lula ukuzisebenzisa futhi zilolonge zibe yifomu elifunayo.

7. Ukusebenza kahle kwezindleko: Izinto zamathuluzi e-CNC kufanele zithengeke futhi zingabizi kakhulu, kucatshangelwa ukusebenza kwazo nokuphila isikhathi eside.

Izinhlobo, izakhiwo, izici kanye nokusetshenziswa kwezinto ezisetshenziswayo zokusika

Uhlobo ngalunye lwempahla lunezici zalo ezihlukile, izici, kanye nokusetshenziswa kwalo. Nazi ezinye izinto ezijwayelekile zamathuluzi okusika, kanye nezakhiwo nezindlela ezisetshenziswayo:

1. High-Speed Steel (HSS):

I-HSS ithuluzi lokusika elivame ukusetshenziswa, elenziwe ngenhlanganisela yensimbi, i-tungsten, i-molybdenum, nezinye izakhi. Yaziwa ngobulukhuni bayo obuphakeme, ukumelana nokugqokwa, kanye nokuqina, okuyenza ifaneleke ukwenza izinto eziningi ezihlukahlukene, okuhlanganisa izinsimbi, ama-alloys e-aluminium, namapulasitiki.

2. I-Carbide:

I-Carbide iyinhlanganisela yezinto ezenziwe ngengxube yezinhlayiya ze-tungsten carbide kanye ne-metallic binder, njenge-cobalt. Yaziwa ngobulukhuni bayo obukhethekile, ukumelana nokugqokwa, kanye nokumelana nokushisa, okuyenza ilungele ukwenza izinto eziqinile, njengensimbi engagqwali, insimbi ewugqinsi, nama-alloys asezingeni eliphezulu.

3. I-Ceramic:

Amathuluzi okusika i-Ceramic enziwe ngezinto ezihlukahlukene ze-ceramic, njenge-aluminium oxide, i-silicon nitride, ne-zirconia. Zaziwa ngobulukhuni bazo obuphakeme, ukumelana nokugqoka, nokuzinza kwamakhemikhali, okuzenza zifaneleke ukwenza izinto eziqinile neziqhumayo, njengezitsha zobumba, izinhlanganisela, nama-superalloys.

4. I-Cubic Boron Nitride (CBN):

I-CBN yinto yokwenziwa eyenziwe ngamakristalu ayi-cubic boron nitride. Iyaziwa ngobulukhuni bayo obungavamile, ukumelana nokugqoka, nokumelana nokushisa, okwenza ifaneleke ukukhanda izinsimbi eziqinile nezinye izinto okunzima ukuzisebenzisa ngokusebenzisa ezinye izinto zokusika.

5. Idayimane:

Amathuluzi okusika idayimane enziwe ngamadayimane emvelo noma okwenziwa. Zaziwa ngobulukhuni bazo obukhethekile, ukumelana nokugqokwa, nokumelana nokushisa, okuzenza zifaneleke ukwenza izinsimbi ezingenayo ayoni, izinhlanganisela, nezinye izinto eziqinile neziqhumayo.

Kukhona futhi uhlobo lwethuluzi olukhethekile olubizwa ngokuthi ithuluzi elihlanganisiwe.

Ngokuvamile, izinto ezingenhla zisetshenziswa njengezingubo zokugqoka, futhi zisetshenziswa kakhulu kumathuluzi omshini we-CNC.

Ithuluzi elimboziwe ithuluzi elinongqimba oluncane lwento esetshenziswa endaweni yalo ukuze lithuthukise ukusebenza kwalo nokwelula ukuphila kwalo. Izinto zokumboza zikhethwa ngokusekelwe ekusetshenzisweni okuhlosiwe kwethuluzi, futhi izinto ezivamile zokuhlanganisa zihlanganisa i-titanium nitride (TiN), i-titanium carboni (TiCN), kanye nekhabhoni efana nedayimane (DLC).

Ama-coatings angathuthukisa ukusebenza kwethuluzi ngezindlela ezihlukahlukene, njengokunciphisa ukungqubuzana nokuguga, ukwandisa ubulukhuni nokuqina, nokuthuthukisa ukumelana nokugqwala nokulimala kwamakhemikhali. Isibonelo, i-TiN-coated drill bit ingahlala isikhathi eside ngokuphindwe kathathu kune-One engagcotshiwe, futhi umshini wokugaya ohlanganiswe ne-TiCN ungasika izinto eziqinile ngokuguga okuncane.

Amathuluzi amboziwe avame ukusetshenziswa ezimbonini ezifana nezokukhiqiza, i-aerospace, ezezimoto, kanye nokukhiqizwa kwemishini yezokwelapha. Angasetshenziselwa ukusika, ukubhola, ukugaya, ukugaya, neminye imisebenzi yomshini.

Izimiso zokukhetha zezinto zamathuluzi e-CNC

Ukukhethwa kwezinto zamathuluzi e-CNC kuwukucatshangelwa okubalulekile lapho uklama futhi ukhiqiza ukunembaizingxenye eziphendukayo. Ukukhethwa kwento yethuluzi kusekelwe ezintweni eziningi, okuhlanganisa uhlobo lwento eyenziwa ngomshini, ukusebenza komshini, nesiphetho esifiswayo.

Nazi ezinye zezimiso zokukhetha zezinto zamathuluzi e-CNC:

1. Ukuqina:Izinto zamathuluzi kufanele zibe nzima ngokwanele ukumelana namandla namazinga okushisa akhiqizwa ngesikhathi somshini. Ukuqina ngokuvamile kukalwa esikalini se-Rockwell C noma esikalini se-Vickers.

2. Ukuqina:Impahla yethuluzi kumele futhi iqine ngokwanele ukumelana nokuphuka nokuqhekeka. Ukuqina ngokuvamile kukalwa ngamandla okushayisana noma ukuqina kokuphuka.

3. Ukumelana nokugqoka:Izinto zamathuluzi kufanele zibe nokumelana nokugqokwa okuhle ukuze zigcine unqenqema lwazo futhi zigweme ukwehluleka kwamathuluzi. Ukumelana nokugqokwa kwento esetshenziswayo kuvame ukukalwa ngevolumu yezinto ezikhishwa ethuluzini phakathi nenani elithile lomshini.

4. I-thermal conductivity: Izinto zamathuluzi kufanele zibe ne-conductivity enhle yokushisa ukuze kukhishwe ukushisa okukhiqizwa ngesikhathi somshini. Lokhu kusiza ukugwema ukwehluleka kwamathuluzi nokugcina ukunemba kobukhulu.

5. Ukuzinza kwamakhemikhali:Ithuluzi kufanele lizinze ngokwekhemikhali ukuze kugwenywe ukusabela kwamakhemikhali ngezinto zokusebenza.

6. Izindleko:Izindleko zezinto zamathuluzi nazo ziwukucatshangelwa okubalulekile, ikakhulukazi ekugijimeni kokukhiqizwa kwevolumu ephezulu.

Izinto ezijwayelekile ezisetshenziselwa amathuluzi e-CNC zifaka i-carbide, insimbi enesivinini esikhulu, i-ceramic, nedayimane. Ukukhethwa kwempahla yethuluzi kuncike ekusebenzeni kwemishini ethile kanye nesiphetho esifiswayo, kanye nezinto ezenziwa ngomshini kanye nemishini etholakalayo.

1) Ithuluzi lokusika lifana nezakhiwo zemishini zento eyenziwe ngomshini

Ukufanisa impahla yethuluzi lokusika nezakhiwo zemishini yento eyenziwe ngomshini kuwukucatshangelwa okubalulekile kumishini ye-CNC. Izakhiwo zemishini yento eyenziwe ngomshini zihlanganisa ubulukhuni bayo, ukuqina, kanye ne-ductility, phakathi kokunye. Ukukhetha ithuluzi lokusika elifana noma elihambisana nezakhiwo zemishini zento eyenziwe ngomshini kungathuthukisa ukusebenza komshini nokusebenza kahle, kunciphise ukuguga kwamathuluzi, futhi kuthuthukise ikhwalithi yengxenye eqediwe.

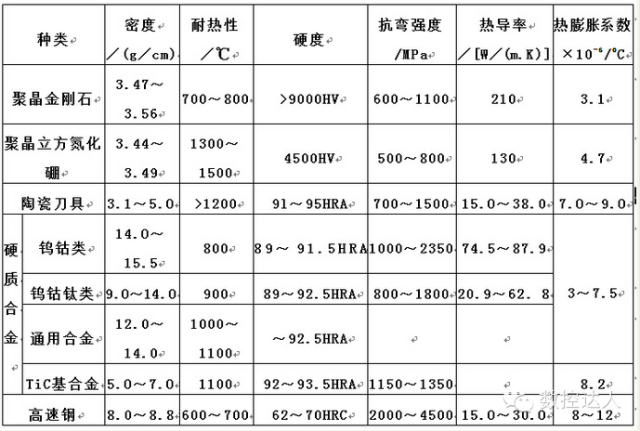

① Ukuhleleka kokuqina kwento yamathuluzi yilokhu: ithuluzi ledayimane>ithuluzi le-cubic boron nitride>ithuluzi le-ceramic>tungsten carbide>insimbi enesivinini esikhulu.

② Ukuhleleka kwamandla okugoba kwezinto zamathuluzi yilokhu: insimbi enesivinini esikhulu > i-carbide enosimende > amathuluzi e-ceramic > idayimane ne-cubic boron nitride amathuluzi.

③ Ukuhleleka kokuqina kwezinto zamathuluzi yilokhu: insimbi enesivinini esikhulu > i-carbide enosimende > i-cubic boron nitride, amathuluzi edayimane nawe-ceramic.

Isibonelo, uma into emshinini yenziwe ngezinto eziqinile neziphukayo njengensimbi eqinile noma insimbi ecijile, ithuluzi lokusika elenziwe ngento eqinile futhi engagugi njenge-carbide noma i-ceramic ingaba inketho engcono kakhulu. Lezi zinto zingakwazi ukumelana namandla amakhulu okusika kanye namazinga okushisa akhiqizwa ngesikhathi somshini futhi zigcine imiphetho yazo ebukhali yokusika isikhathi eside.

Ngakolunye uhlangothi, uma into eyenziwe ngomshini yenziwe ngezinto ezithambile futhi ezidonsa kakhudlwana njenge-aluminium noma ithusi, ithuluzi lokusika elenziwe ngezinto eziqinile njengensimbi enesivinini esikhulu lingase lifaneleke kakhulu. Insimbi enesivinini esiphezulu ingakwazi ukumunca kangcono ukushaqeka nokudlidliza ngesikhathi somshini, inciphise ubungozi bokuphuka kwamathuluzi futhi ithuthukise impilo yamathuluzi.

2) Ukumatanisa ithuluzi lokusika nezinto ezibonakalayo zento eyenziwe ngomshini

Ukufanisa ithuluzi lokusika lezinto ezibonakalayo zento eyenziwe ngomshini nakho kubalulekile ekusetshenzisweni kwemishini ye-CNC. Izici ezibonakalayo zento emshinini zifaka phakathi ukushintshwa kwayo okushisayo, i-coefficient yokunwetshwa kwe-thermal, nezidingo zokuqedwa kwendawo, phakathi kokunye. Ukukhetha ithuluzi lokusika elifana noma elihambisana nezinto ezibonakalayo zento eyenziwe ngomshini kungathuthukisa ukusebenza komshini, kunciphise ukuguga kwamathuluzi, futhi kuthuthukise ikhwalithi yengxenye eqediwe.

① Izinga lokushisa elikwazi ukumelana nokushisa lamathuluzi ahlukahlukene: 700-8000C wamathuluzi edayimane, 13000-15000C wamathuluzi e-PCBN, 1100-12000C wamathuluzi e-ceramic, 900-11000C we-TiC(N)-based cemented carbide ye-11000C-WC1000C - okusekelwe okusanhlamvu kwe-ultrafine I-carbide enosimende ingu-800~9000C, i-HSS ingu-600~7000C.

②Ukuhleleka kokusebenza okushisayo kwezinto zamathuluzi ahlukahlukene: PCD>PCBN>WC-based cemented carbide>TiC(N)-based carbide enosimende>HSS>Si3N4-based ceramics>A1203-based ceramics.

③ Ukuhleleka kwe-thermal expansion coefficient yezinto ezisetshenziswayo zamathuluzi yilokhu: HSS>WC-based cemented carbide>TiC(N)>A1203-based ceramics>PCBN>Si3N4-based ceramics>PCD.

④Ukuhleleka kokumelana nokushaqeka okushisayo kwezinto ezisetshenziswayo zamathuluzi yilokhu: HSS>WC-based cemented carbide>Si3N4-based ceramics>PCBN>PCD>TiC(N)-based cemented carbide>A1203-based ceramics.

Isibonelo, uma into emshinini inomshini wokushisa ophezulu, njengethusi noma i-aluminium, ithuluzi lokusika eline-conductivity ephezulu ye-thermal kanye ne-coefficient ephansi yokwandisa okushisayo kungase kube ukukhetha okungcono kakhulu. Lokhu kuvumela ithuluzi ukuthi likhiphe ukushisa kahle ngesikhathi somshini futhi kunciphisa ingcuphe yokulimala kokushisa kukho kokubili ithuluzi nento emshinini.

Ngokufanayo, uma into emshinini inezidingo eziqinile zokuqeda indawo, ithuluzi lokusika elinokumelana nokugqokwa okuphezulu kanye ne-coefficient ephansi yokungqubuzana kungase kube ukukhetha okungcono kakhulu. Lokhu kungasiza ukufeza isiphetho esifiselekayo ngaphandle kokugqoka kwamathuluzi okweqile noma ukulimala kwento eyenziwe ngomshini.

3) Ukuqhathanisa ithuluzi lokusika nezakhiwo zamakhemikhali zento eyenziwe ngomshini

Ukufanisa impahla yethuluzi lokusika nezakhi zamakhemikhali zento eyenziwe ngomshini nakho kubalulekile ekusetshenzisweni kwemishini ye-CNC. Izakhiwo zamakhemikhali zento eyenziwe ngomshini zihlanganisa ukuphinda isebenze, ukumelana nokugqwala, nokwakheka kwamakhemikhali, phakathi kokunye. Ukukhetha ithuluzi lokusika elifana noma eligcwalisa izici zamakhemikhali zento eyenziwe ngomshini kungathuthukisa ukusebenza komshini, kunciphise ukuguga kwamathuluzi, futhi kuthuthukise ikhwalithi yengxenye eqediwe.

Isibonelo, uma into emshinini yenziwe ngezinto ezisebenzayo noma ezibolayo njenge-titanium noma insimbi engagqwali, ithuluzi lokusika elenziwe ngezinto ezimelana nokugqwala njengedayimane noma i-PCD (i-polycrystalline diamond) kungaba ukukhetha okungcono kakhulu. Lezi zinto zingakwazi ukumelana nemvelo ebolayo noma esebenzayo futhi zigcine imiphetho yazo ebukhali isikhathi eside.

Ngokufanayo, uma into emshinini inokwakheka kwamakhemikhali okuyinkimbinkimbi, ithuluzi lokusika elenziwe ngezinto ezizinzile kumakhemikhali futhi ezingenasici, njengedayimane noma i-cubic boron nitride (CBN), kungaba ukukhetha okungcono kakhulu. Lezi zinto zingagwema ukusabela kwamakhemikhali ngezinto zokusebenza futhi zigcine ukusebenza kwazo kokusika ngokuhamba kwesikhathi.

① Izinga lokushisa elivimbela ukubopha lezinto zamathuluzi ahlukahlukene (ngensimbi) lithi: PCBN>ceramic>hard alloy>HSS.

② Izinga lokushisa lokumelana ne-oxidation lamathuluzi ahlukahlukene limi kanje: ceramic>PCBN>tungsten carbide>diamond>HSS.

③Amandla okusabalalisa wezinto zamathuluzi (ensimbi) yilawa: idayimane>Izitsha zobumba ezisekelwe ku-Si3N4>PCBN>A1203-based ceramics. Amandla okusabalalisa (kwe-titanium) yilokhu: i-Ceramics esekwe ku-A1203>PCBN>SiC>Si3N4>idayimane.

4) Ukukhetha okunengqondo kwezinto zamathuluzi okusika i-CNC

Ukukhethwa kwezinto zamathuluzi okusika e-CNC kuncike ezintweni ezahlukahlukene ezifana nempahla yokusebenza, ukusebenza komshini, kanye nejiyomethri yamathuluzi. Kodwa-ke, eminye imihlahlandlela ejwayelekile yokukhetha amathuluzi wokusika wemishini ye-CNC ifaka:

1. Izakhiwo ze-Material ye-workpiece: Cabangela izici zemishini, zomzimba, kanye namakhemikhali we-workpiece material uma ukhetha ithuluzi lokusika. Qondanisa ithuluzi lokusika nezinto zokusebenza ukuze uzuze umshini osebenza kahle futhi ophezulu.

2. Ukusebenza komshini: Cabangela uhlobo lomsebenzi womshini owenziwayo, njengokujika, ukugaya, ukubhola, noma ukugaya. Imisebenzi yemishini ehlukene idinga amajiyometri amathuluzi okusika ahlukene nezinto zokwakha.

3. I-geometry yethuluzi: Cabangela i-geometry yethuluzi lokusika lapho ukhetha impahla yethuluzi. Khetha into engagcina unqenqema olubukhali futhi imelane namandla okusika akhiqizwa ngesikhathi sokusebenza kwemishini.

4. Ukuguga kwamathuluzi: Cabangela izinga lokuguga kwamathuluzi lapho ukhetha into yethuluzi lokusika. Khetha into engakwazi ukumelana namandla okusika futhi igcine umkhawulo wayo obukhali wokusika isikhathi eside ngangokunokwenzeka ukuze unciphise izinguquko zamathuluzi futhi uthuthukise ukusebenza kahle kwemishini.

5. Izindleko: Cabangela izindleko zethuluzi lokusika lapho ukhetha ithuluzi. Khetha impahla enikeza ibhalansi engcono kakhulu yokusika ukusebenza nezindleko.

Ezinye izinto ezijwayelekile zokusika ezisetshenziswa kuCNC imishinizihlanganisa insimbi enesivinini esikhulu, i-carbide, i-ceramic, idayimane, ne-CBN. Impahla ngayinye inezinzuzo zayo kanye nokubi, futhi ukukhethwa kwezinto zamathuluzi kufanele kusekelwe ekuqondeni okuphelele kokusebenza komshini kanye nezinto zokusebenza.

Okuphishekela ingunaphakade kwe-Anebon yisimo sengqondo “sokubheka imakethe, bheka inkambiso, bheka isayensi” kanye nethiyori “yekhwalithi eyisisekelo, themba owokuqala nokuphatha okuthuthukile” kwe-Hot sale Factory OEM Service High Precision CNC Machining izingxenye zokuzenzakalela. yezimboni, i-Anebon quote yombuzo wakho. Ukuze uthole ulwazi olwengeziwe, sicela uxhumane nathi, i-Anebon izokuphendula ASAP!

I-Hot sale Factory China 5 axis cnc machining parts, i-CNC yaphenduka izingxenye kanye nengxenye yethusi yokugaya. Siyakwamukela ukuvakashela inkampani yethu, ifektri kanye negumbi lethu lokubonisa lapho libonisa khona ukuthengiswa kwezinwele okuhlukahlukene okuzohlangabezana nokulindela kwakho. Okwamanje, kulula ukuvakashela iwebhusayithi ye-Anebon, futhi abasebenzi bezokuthengisa be-Anebon bazozama konke okusemandleni abo ukukuletha isevisi engcono kakhulu. Sicela uxhumane ne-Anebon uma kufanele ube nolwazi oluthe xaxa. Inhloso ye-Anebon ukusiza amakhasimende abone izinhloso zawo. I-Anebon ibilokhu yenza imizamo emikhulu yokufeza lesi simo sokunqoba.

Isikhathi sokuthumela: Mar-08-2023