Isingeniso:

Ezihlokweni ezedlule, ithimba lethu le-Anebon labelane nawe ngolwazi oluyisisekelo lokuklama komshini. Namuhla sizophinde sifunde imiqondo eyinselele ekwakhiweni kwemishini.

Yiziphi izithiyo eziyinhloko ezimisweni zokuklama imishini?

Ubunkimbinkimbi bomklamo:

Imiklamo yemishini imvamisa iyinkimbinkimbi, futhi idinga onjiniyela ukuthi bahlanganise amasistimu ahlukahlukene, izakhi nemisebenzi.

Isibonelo, ukuklama i-gearbox edlulisa amandla ngempumelelo ngaphandle kokuphazamisa ezinye izinto ezifana nosayizi nesisindo kanye nomsindo kuyinselele.

Ukukhetha okubalulekile:

Ukukhetha into efanele yokuklama kwakho kubalulekile, njengoba kuthonya izici ezifana nokuqina, amandla, kanye nezindleko.

Isibonelo, ukukhetha into efanelekile yengxenye enengcindezi ephezulu yenjini yendiza akulula ngenxa yesidingo sokwehlisa isisindo kuyilapho ugcina amandla okubekezelela amazinga okushisa aphakeme.

Imikhawulo:

Onjiniyela kufanele basebenze ngaphakathi kwemikhawulo efana nesikhathi, isabelomali kanye nezinsiza ezikhona. Lokhu kunganciphisa imiklamo futhi kudinge ukusetshenziswa kokuhwebelana okuhlakaniphile.

Isibonelo, ukuklama isistimu yokushisisa ephumelelayo ebiza ikhaya futhi esathobelana nezidingo zokonga kwamandla kungase kubangele izinkinga.

Imikhawulo ekukhiqizeni

Abaqambi kufanele bacabangele ukulinganiselwa kwabo ezindleleni namasu okukhiqiza lapho beklama imiklamo eyimishini. Ekulinganiseni inhloso yokuklama namandla emishini nezinqubo kungaba yinkinga.

Isibonelo, ukuklama ingxenye emile eyinkimbinkimbi engakhiqizwa kuphela ngomshini obizayo noma amasu okukhiqiza okungeziwe.

Izidingo zokusebenza:

Ukugcwalisa zonke izidingo zomklamo, okuhlanganisa ukuphepha, ukusebenza, noma ukwethembeka kwedizayini, kungase kube nzima.

Isibonelo, ukuklama isistimu yamabhuleki enikeza amandla aqondile okumisa, kuyilapho nokuqinisekisa ukuphepha kwabasebenzisi kungaba inselele.

Ukuthuthukisa idizayini:

Ukuthola isixazululo esingcono kakhulu sokuklama esilinganisa imigomo eminingi ehlukene, okuhlanganisa isisindo, izindleko, noma ukusebenza kahle, akulula.

Ngokwesibonelo, ukuthuthukisa ukwakheka kwamaphiko endiza ukuze kwehlise ukudonsa nesisindo, ngaphandle kokulimaza ubuqotho besakhiwo, kudinga ukuhlaziya okuyinkimbinkimbi nezindlela zokuklama eziphindaphindiwe.

Ukuhlanganiswa ohlelweni:

Ukufaka izingxenye ezahlukene namasistimu angaphansi edizayini ebumbene kungaba yinkinga enkulu.

Isibonelo, ukuklama uhlelo lokumiswa kwezimoto olulawula ukunyakaza kwezingxenye eziningi, kuyilapho ukukala izici ezifana nokunethezeka, ukuzinza nokubekezela kungase kubangele ubunzima.

I-Design Iteration:

Izinqubo zokuklama ngokuvamile zihlanganisa ukubuyekezwa okuningi nokuphindaphinda ukuze kucwengwe futhi kuthuthukiswe umbono wokuqala. Ukwenza izinguquko zedizayini ngempumelelo nangempumelelo kuyinselelo kokubili ngokwesikhathi esidingekayo kanye nezimali ezitholakalayo.

Isibonelo, ukuthuthukisa idizayini yento yomthengi ngochungechunge lokuphindaphinda okuthuthukisa i-ergonomics yomsebenzisi nobuhle.

Okucatshangwayo mayelana nemvelo:

Ukuhlanganisa ukusimama ekwakhiweni kanye nokunciphisa umthelela wemvelo wesakhiwo kubaluleka kakhulu. Ibhalansi phakathi kwezici zokusebenza nezinto ezifana nekhono lokuphinda isetshenziswe, ukonga amandla kanye nokukhishwa kwesisi kungaba nzima. Isibonelo, ukuklama injini ephumelelayo enciphisa ukukhishwa kwegesi ebamba ukushisa, kodwa ingafaki ukusebenza kahle.

Idizayini yokukhiqiza nokuhlanganisa

Ikhono lokuqinisekisa ukuthi idizayini izokhiqizwa futhi ihlanganiswe phakathi nesikhathi nezinkinga zezindleko kungaba yinkinga.

Isibonelo, ukwenza kube lula ukuhlanganiswa komkhiqizo oyinkimbinkimbi kuzokwehlisa izindleko zabasebenzi nezokukhiqiza, kuyilapho kuqinisekisa amazinga ekhwalithi.

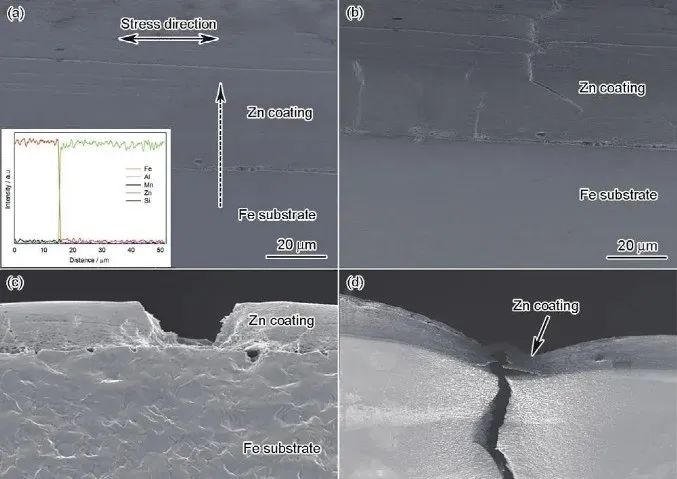

1. Ukwehluleka kuwumphumela wezingxenye zemishini ngokuvamile eziphukayo, ukuwohloka kwensalela kanzima, ukulimala kwezingxenye ezingaphezulu (ukugqwala, ukukhathala okuthintana nokuguga) Ukwehluleka ngenxa yokuguga nokuwohloka kwendawo yokusebenza evamile.

2. Izingxenye zedizayini kufanele zihlangabezane nezimfuneko zokuqinisekisa ukuthi azihluleki phakathi nesikhathi sempilo yazo enqunywe kusengaphambili (amandla noma ukuqina, ubude bokuphila) kanye nezimfuneko zenqubo yesakhiwo izidingo zezomnotho, izidingo zesisindo esiphansi, nezimfuneko zokwethenjelwa.

3. Inqubo yokudizayina yezingxenye ezifaka imibandela yamandla nokuqina, izimfuneko zempilo kanye nemibandela yokuzinza kokudlidliza kanye nemibandela yokwethembeka.

4. Izindlela zokuklama izingxenye: idizayini yethiyori, idizayini ye-empirical kanye nomklamo wokuhlola oyimodeli.

5. Okuvame ukusetshenziswa ezingxenyeni eziwumshini izinto zensimbi, izinto zobumba, izinto ze-polymer kanye nezinto eziyinhlanganisela.

6. Amandla ezingxenye angahlukaniswa abe amandla okucindezeleka okuqinile kanye namandla okucindezeleka okuguquguqukayo.

7. Isilinganiso sokucindezeleka: = -1 ukucindezeleka okulinganayo kwifomu le-cyclic; inani elithi r = 0 ingcindezi ye-cyclic eshayayo.

8. Kukholakala ukuthi isigaba se-BC sibizwa ngokuthi yi-strain fatigue (low cycle fatigue) I-CD ibhekisela esigabeni sokukhathala okungapheli. Ingxenye yomugqa elandela iphoyinti D iyileveli engapheli yokwehluleka kwempilo yesifanekiso. Iphoyinti D umkhawulo wokukhathala unomphela.

9. Amasu okuthuthukisa amandla ezingxenye ezikhathele anciphisa umphumela wokucindezeleka ezintweni (ama-grooves okusiza umthwalo ovulekile amasongo) Khetha izinto ezinamandla amakhulu okukhathala bese ucacisa izindlela zokwelapha ukushisa kanye namasu okuqinisa okwandisa amandla zakhathala izinto zokwakha.

10. Ukungqubuzana kwamaslayidi: Ukungqubuzana kwemingcele yokungqubuzana okomile, ukungqubuzana koketshezi, nokungqubuzana okuxubile.

11. Inqubo yokuguga yezingxenye ihlanganisa ukugijima esiteji, isiteji sokuguga esizinzile kanye nesiteji sokuguga okukhulu Kufanele sizame ukunciphisa isikhathi sokugijima kanye nokwelula isikhathi sokuguga okuzinzile futhi simise ukubukeka kokuguga. lokho kunzima.

12. Isigaba sokugqokwa wukugqoka Okunamathelayo, ukuguguleka nokugqwala kokukhathala, ukuguguleka kokuguguleka, nokugqokwa okukhathazayo.

13. Izinto zokugcoba zingahlukaniswa zibe izigaba ezine okuwuketshezi, i-gas semi-solid, solid and liquid greases ahlukaniswa abe amagrisi asuselwa kuCalcium, amafutha asuselwa ku-Nano-based Grease aluminium-based, kanye ne-lithium-based grease.

14. Imicu yokuxhuma evamile ifaka ifomu likanxantathu elilinganayo kanye nezakhiwo ezinhle kakhulu zokuzikhiya. imicu yokudlulisa engunxande inikeza ukusebenza okuphezulu ekudluliseni kuneminye imicu. Izintambo zokudlulisa i-trapezoidal ziphakathi kwemicu yokudlulisa ethandwa kakhulu.

15. Izintambo zokuxhuma ezivame ukusetshenziswa zidinga ukuzikhiya, ngakho-ke intambo eyodwa ivame ukusetshenziswa. Imicu yokudlulisela idinga ukusebenza kahle okuphezulu kokudlulisa ngakho-ke imicu enemicu emithathu noma enemicu ekabili isetshenziswa njalo.

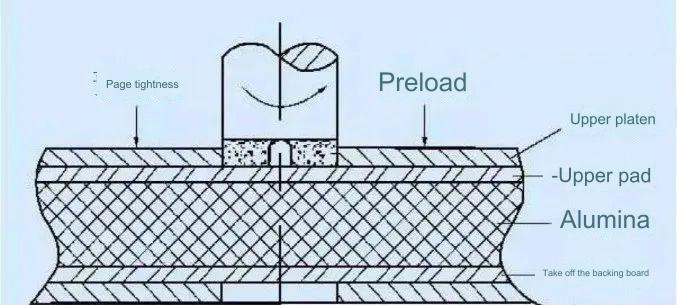

16. Ukuxhumana okujwayelekile kwebhawodi (izingxenye ezixhumene zifaka izimbobo eziphumayo noma ziphinde zenziwe kabusha) Izikulufu zokuxhuma izinsimbi ezinamakhanda amabili, ukuxhuma ngezikulufu, kanye nezikulufu ezinesethi yokuxhumana.

17. Umgomo wokuxhuma okunentambo ukuqinisa ngaphambilini ukuthuthukisa ukuqina namandla okuxhumana, nokumisa izikhala noma ukushelela phakathi kwezingxenye ezimbili uma kulayishiwe. Inkinga eyinhloko ngoxhumo oluqinisayo oluxegayo ukumisa ipheya evunguzayo ekuphendukeni ngokuhloniphana ngenkathi ilayishiwe. (I-Frictional anti-loosening kanye nemishini yokumisa ukuxega, isusa isixhumanisi phakathi kokunyakaza nokunyakaza kombhangqwana ozungezayo)

18. Thuthukisa ukuqina koxhumano olunentambo kunciphisa ukuphakama kokucindezeleka okuthonya amandla amabhawodi wokukhathala (ukunciphisa ukuqina kwebhawodi, noma ukwandise ukuqina kokuxhuma.izingxenye ze-cnc zangokwezifiso) futhi uthuthukise ukusatshalaliswa okungalingani komthwalo phezu kwemicu. nciphisa umphumela wokunqwabelana kwengcindezi, futhi usebenzise inqubo yokukhiqiza ephumelela kakhulu.

19. Izinhlobo zokuxhuma eziyisihluthulelo: uxhumano oluyisicaba (zombili izinhlangothi zisebenza njengendawo engaphezulu) uxhumano lwe-semicircular key connection wedge key connection key connection with tangential angle.

20. I-belt drive ingahlukaniswa ngezinhlobo ezimbili: uhlobo lwe-meshing kanye nohlobo lwe-friction.

21. Isikhathi sokucindezeleka okukhulu kwebhande yilapho ingxenye encane yalo iqala ku-pulley. Ukushuba kushintsha izikhathi ezine phakathi nenguquko eyodwa ebhandeni.

22. Ukuqina kwedrayivu yebhande le-V: Indlela yokucindezela evamile, idivayisi yokucindezela okuzenzakalelayo, kanye nedivayisi yokucindezela esebenzisa isondo elicindezelayo.

23. Izixhumanisi kuchungechunge lwerola ngokuvamile ziyinombolo eyinqaba (inani lezinyo ku-sprocket ngeke libe inombolo evamile). Uma i-roller chain inezinombolo ezingezona ezemvelo, izixhumanisi ezeqile ziyasetshenziswa.

24. Umgomo wokuqinisa i-chain drive ukuvimbela izinkinga ze-meshing kanye nokudlidliza kweketango lapho imiphetho exegayo yeketango iba miningi, kanye nokuthuthukisa i-engeli ye-meshing phakathi kwe-sprocket neketango.

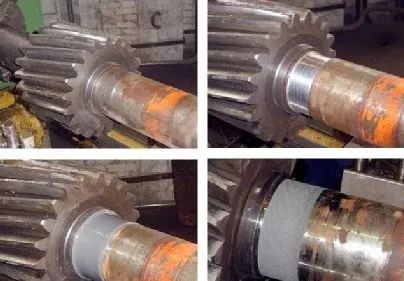

25. Izindlela zokwehluleka kwamagiya zihlanganisa: ukuphuka kwamazinyo kumagiya nokuguga endaweni yezinyo (amagiya avuliwe) ukubhoboza indawo yezinyo (amagiya avaliwe) ingcina yeglue yezinyo kanye nokonakala kwepulasitiki (ama-ridges on the wheel driven grooves on the drive wheel). ).

26. Amagiya anobuso obuqinile obungaphezu kuka-350HBS, noma 38HRS aziwa ngokuthi anobuso obunzima noma anobuso obunzima noma, uma engewona, anobuso obuthambile.

27. Ukuthuthukisa ukunemba kokukhiqiza, ukwehlisa ububanzi begiya ukuze kwehliswe isivinini sokuzungezisa, kunganciphisa umthwalo oguqukayo. Ukuze kwehliswe umthwalo oguquguqukayo, igiya lingase lisikwe. Inhloso yokuguqula amazinyo egiya abe isigubhu ukukhulisa amandla okuma kwephuzu lezinyo. ukusatshalaliswa komthwalo oqondile.

28. Uma inkulu i-engeli eholayo ye-diameter coefficient iba nkulu ukusebenza kahle, kanye nekhono lokuzikhiya liyancipha.

29. Igiya lezikelemu kufanele lisuswe. Ngemva kokugudluzwa indilinga yenkomba kanjalo nokufanisa isiyingi seworm nokho kuyacaca ukuthi umugqa phakathi kwezibungu ezimbili ushintshile, futhi awuhambisani nendingilizi yenkomba yegiya lezikelemu.

30. Izindlela zokuhluleka ukudluliswa kwezikelemu njengokugqwala kwempande yezinyo ebhodweni igqekeza indawo engaphezulu yezinyo kanye nokuguga okukhulu; lokhu kuvame ukuba njalo kumagiya wezikelemu.

31. Ukuphelelwa amandla okuvela ekugugekeni kwe-meshing worm drive nokuguga kuma-bearings kanye nokulahlekelwa ama-splash kawoyela njengecnc izingxenye zokugayaezifakwa echibini lamafutha zivuse amafutha.

32. Idrayivu yezikelemu kufanele yenze izibalo zebhalansi ye-thermal ngokusekelwe ekucabangeni kokuthi amandla akhiqizwa ngeyunithi ngayinye yesikhathi ayafana nokukhishwa kokushisa ngesikhathi esifanayo. Izinyathelo okufanele uzithathe: Faka osinki bokushisa, futhi wandise indawo yokuqeda ukushisa futhi ufake amafeni emaphethelweni eshafti ukuze kwandiswe ukuhamba komoya, futhi ekugcineni, ufake amapayipi okupholisa ajikelezayo ngaphakathi kwebhokisi.

33. Izimo ezivumela ukuthuthukiswa kokugcotshwa kwe-hydrodynamic: izindawo ezimbili ezishelelayo zakha igebe elimise okwe-wedge eliguquguqukayo futhi izindawo ezimbili ezihlukaniswa ifilimu kawoyela kufanele zibe nezinga lokushelela elanele futhi ukunyakaza kwazo kufanele kuvumele uwoyela wokugcoba ukuze ugeleze ngembobo enkulu ungene kwencane futhi ukugcoba kufanele kube kwe-viscosity ethile, futhi inani lamafutha atholakalayo kufanele lanele.

34. Idizayini eyisisekelo yamabheringi agingqayo: iringi yangaphandle, izindandatho zangaphakathi, umzimba we-hydraulic kanye nekheji.

35. Ama-roller bears ama-3 ajikijela ama-thrust ama-bearing ayisithupha amabhola ayisikhombisa angama-angular athintanayo angama-N cylindrical roller bearings 01, 02 kanye no-03 ngokulandelanayo. D=10mm, 12mm 15mm, 17,mm ibhekisela ku-20mm ithi d=20mm, 12 ibhekisela ku-60mm.

36. Isilinganiso sempilo esiyisisekelo inani lamahora okusebenza lapho u-10% wamabheringi angaphakathi kwesethi yamabheringi ethintwa ukugqwala kwe-pitting, kodwa amaphesenti angu-90 awo awahlushwa ukulimala kokugqwala kwemigodi kuthathwa njengokuphila isikhathi eside kwaleyo ngxenye. ukuzala.

37. Isilinganiso esiyisisekelo esiguquguqukayo somthwalo: inani elithwalayo elikwazi ukulithwala esimweni lapho impilo eyisisekelo yeyunithi ingama-revolution angu-106 ngokunembile.

38. Indlela yokuthwala ukumisa: I-fulcrum ngayinye emibili imiswe ohlangothini olulodwa. kunephuzu eligxilile kuzo zombili izinkomba, kuyilapho enye isiphetho se-fulcrum ayinyakazi. Zombili izinhlangothi zisizwa ukunyakaza kwamahhala.

39. Ama-bearings ahlukaniswe ngokuhambisana nomthwalo osetshenziswa ku-shaft ejikelezayo (isikhathi sokugoba kanye ne-torque) kanye ne-spindle (isikhathi sokugoba) kanye ne-transmission shaft (torque).

I-Anebon inamathela esimisweni esiyisisekelo sokuthi "Ikhwalithi iyimpilo yebhizinisi nakanjani, futhi isimo singase sibe umphefumulo walo" ukuze uthole isaphulelo esikhulu sokunemba ngokwezifiso 5 Axis CNC LatheCNC Machined Ingxenye, I-Anebon inethemba lokuthi singahlinzeka ngemikhiqizo yekhwalithi ephezulu nezisombululo ngamathegi entengo aphusile, ukwesekwa okuphezulu kwangemuva kokuthengisa kubathengi. Futhi i-Anebon izokwakha isikhathi eside esinempilo.

Uchwepheshe waseShayinaIngxenye ye-China CNCkanye ne-Metal Machining Parts, i-Anebon ithembele ezintweni ezisezingeni eliphezulu, idizayini ephelele, isevisi yamakhasimende enhle kakhulu kanye nentengo yokuncintisana ukuze izuze ukwethenjwa kwamakhasimende amaningi ekhaya naphesheya. Imikhiqizo efika kuma-95% ithunyelwa ezimakethe zaphesheya.

Uma ungathanda ukwazi okwengeziwe noma ukubuza mayelana namanani, sicela uxhumaneinfo@anebon.com

Isikhathi sokuthumela: Nov-24-2023