Uyabuqonda ubudlelwano phakathi kwama-vernier calipers nama-micrometers kanye nemboni ye-CNC?

Kokubili ama-vernier caliper nama-micrometer angamathuluzi okulinganisa anembayo avame ukusetshenziswa embonini ye-CNC ukuze kukale izilinganiso ezinembile.

Ama-Vernier caliper, aziwa nangokuthi ama-vernier scales noma ama-sliding caliper, amathuluzi okulinganisa aphathwayo asetshenziselwa ukukala ubukhulu bangaphandle (ubude, ububanzi, kanye nogqinsi) bezinto. Aqukethe isikali esiyinhloko kanye nesikali se-vernier esishelelayo, esivumela ukufundwa okunembayo ngale kokuxazululwa kwesikali esikhulu.

Ama-Micrometer, ngakolunye uhlangothi, akhethekile kakhulu futhi ayakwazi ukukala amabanga amancane kakhulu ngokunemba okuphezulu. Asetshenziselwa ukukala ubukhulu obufana nobubanzi, ukujiya, nokujula. Ama-Micrometer ahlinzeka ngezilinganiso ngama-micrometers (µm) noma ingxenye eyinkulungwane yemilimitha.

Embonini ye-CNC, ukunemba kubalulekile ekuqinisekiseni umshini onembile nezinqubo zokukhiqiza. Ama-Vernier caliper nama-micrometer adlala indima ebalulekile ekulawuleni ikhwalithi, ekuhloleni, nasekukaleni okunembayoIzingxenye zomshini ze-CNC. Bavumela opharetha be-CNC nochwepheshe ukuthi baqinisekise ubukhulu, bagcine ukubekezelelana okuqinile, futhi baqinisekise ukusebenza kahle kwemishini ye-CNC.

Inhlanganisela yobuchwepheshe be-CNC namathuluzi okulinganisa anembayo afana nama-vernier caliper nama-micrometer kusiza ukuqondisa izinqubo zokukhiqiza, ukuthuthukisa ukusebenza kahle, nokuletha izingxenye zomshini we-CNC zekhwalithi ephezulu.

Uhlolojikelele lwe-Vernier Calipers

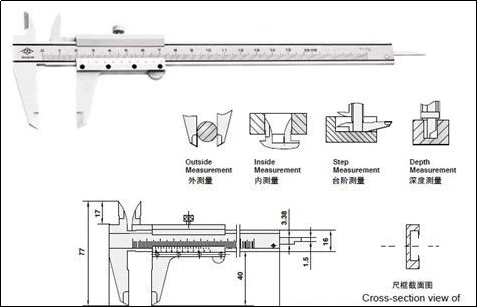

Njengethuluzi elisetshenziswa kabanzi lokulinganisa ukunemba okuphezulu, i-vernier caliper yakhiwe izingxenye ezimbili: isikali esiyinhloko kanye ne-vernier eshelelayo exhunywe esikalini esikhulu. Uma ihlukaniswa ngokwenani lesilinganiso se-vernier, i-vernier caliper ihlukaniswa ngezinhlobo ezintathu: 0.1, 0.05, kanye no-0.02mm.

Ungawafunda kanjani ama-vernier calipers

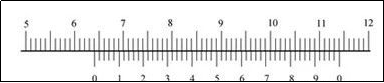

Ukuthatha i-vernier caliper enembayo enenani lesilinganiso esingu-0.02mm njengesibonelo, indlela yokufunda ingahlukaniswa ngezinyathelo ezintathu;

1) Funda yonke imilimitha ngokwesilinganiso esiseduze esikalini esikhulu ukuya kwesokunxele somugqa onguziro wesikalo esisizayo;

2) Phindaphinda ngo-0.02 ukuze ufunde idesimali ngokwenombolo yemigqa eqoshiwe eqondaniswe nesilinganiso esikalini esikhulu kwesokudla somugqa onguziro wesikalo esisizayo;

3) Hlanganisa inombolo ephelele nezingxenye zedesimali ngenhla ukuze uthole usayizi ophelele.

Indlela yokufunda ye-0.02mm vernier caliper

Njengoba kukhonjisiwe emfanekisweni ongenhla, isikali esingaphambili kwesikali esikhulu esibheke umugqa ongu-0 wesikalo esincane singama-64mm, kanti umugqa wesi-9 ngemva komugqa ongu-0 wesikali esingaphansi uqondaniswe nomugqa oqoshiwe wesikali esikhulu.

Umugqa wesi-9 ngemva komugqa ongu-0 wesikali esingaphansi usho ukuthi: 0.02×9= 0.18mm

Ngakho usayizi we-workpiece elinganisiwe: 64+0.18=64.18mm

Indlela yokusebenzisa i-vernier caliper

Hlanganisa imihlathi ukuze ubone ukuthi i-vernier ihambisana yini ne-zero mark esikalini esikhulu. Uma iqondanisiwe, ingakalwa: uma ingahambisani, iphutha elinguziro kufanele lirekhodwe: umugqa wesikali onguziro we-vernier ubizwa ngephutha elinguziro eliphozithivu kwesokudla somugqa wesikali onguziro emzimbeni werula, futhi Iphutha elinguziro elinegethivu libizwa ngephutha elinguziro elinegethivu ohlangothini lwesobunxele lomugqa wesikali onguziro emzimbeni werula (lokhu Le ndlela yokulawula ihambisana nokulawulwa kwe-eksisi yenombolo, umsuka ulungile lapho imvelaphi ingakwesokudla, futhi inegethivu uma umsuka ungakwesokunxele).

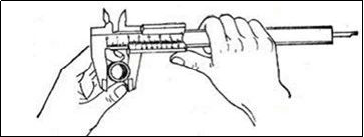

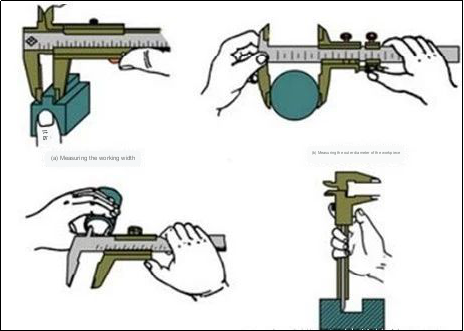

Lapho ukala, bamba umzimba werula ngesandla sakho sokudla, hambisa ikhesa ngesithupha sakho, bese ubambaizingxenye ze-aluminium cncnge-diameter yangaphandle (noma i-diameter engaphakathi) ngesandla sakho sobunxele, ukuze into ezokalwa ibekwe phakathi kwezinzipho zokulinganisa zangaphandle, futhi lapho inamathele ngokuqinile ezinzipho zokulinganisa, ungakwazi Ukufunda, njengoba kuboniswe esithombeni esingezansi. :

Ukusetshenziswa kwe-Vernier Calipers ku-CNC Machining Services

Njengethuluzi lokulinganisa elivamile, i-vernier caliper ingasetshenziswa kulezi zici ezine ezilandelayo:

1) Kala ububanzi bomsebenzi wokusebenza

2) Kala ububanzi obungaphandle bomsebenzi wokusebenza

3) Kala ububanzi bangaphakathi bomsebenzi wokusebenza

4) Linganisa ukujula kwe-workpiece

Izindlela zokulinganisa eziqondile zalezi zici ezine zikhonjiswe emfanekisweni ongezansi:

Ukusetshenziswa kwe-Vernier Calipers kuCNC Machining Services

Njengethuluzi lokulinganisa elivamile, i-vernier caliper ingasetshenziswa kulezi zici ezine ezilandelayo:

1) Kala ububanzi bomsebenzi wokusebenza

2) Kala ububanzi obungaphandle bomsebenzi wokusebenza

3) Kala ububanzi bangaphakathi bomsebenzi wokusebenza

4) Linganisa ukujula kwe-workpiece

Izindlela zokulinganisa eziqondile zalezi zici ezine zikhonjiswe emfanekisweni ongezansi:

Izinyathelo zokuphepha zokusetshenziswa

I-vernier caliper iyithuluzi lokulinganisa elinembe ngokuqhathaniswa, futhi izinto ezilandelayo kufanele zinakwe lapho uyisebenzisa:

1. Ngaphambi kokusebenzisa, hlanza indawo yokulinganisa yezinyawo ezimbili zokunamathisela, vala izinyawo ezimbili zokunamathisela, bese uhlola ukuthi ingabe umugqa ongu-0 werula elisizayo uqondaniswe nomugqa ongu-0 werula eyinhloko. Uma kungenjalo, ukufundwa kokulinganisa kufanele kulungiswe ngokuvumelana nephutha langempela.

2. Lapho ukala ucezu lokusebenza, indawo yokulinganisa yonyawo lokubopha kufanele ihambisane noma i-perpendicular ebusweni bomsebenzi wokusebenza, futhi akufanele isonteke. Futhi amandla akufanele abe makhulu kakhulu, ukuze angawohloki noma agqoke izinyawo zokunamathisela, okuzothinta ukunemba kokulinganisa. 3. Uma ufunda, umugqa wokubona kufanele ube yi-perpendicular surface yesikali, ngaphandle kwalokho inani elilinganisiwe lizobe lingalungile.

4. Uma ukala ububanzi bangaphakathi, yinyakazise kancane ukuze uthole inani eliphezulu.

5. Ngemva kokuba i-vernier caliper isetshenzisiwe, yisule ngokucophelela, sebenzisa amafutha okuvikela, futhi uyibeke phansi ekhavani. uma igqwala noma igobile.

I-spiral micrometer, ebizwa nangokuthi i-micrometer, iyithuluzi lokulinganisa elinembile. Umgomo, ukwakheka kanye nokusetshenziswa kwe-spiral micrometer kuzochazwa ngezansi.

Iyini i-Spiral Micrometer?

I-Spiral micrometer, eyaziwa nangokuthi i-micrometer, i-spiral micrometer, ikhadi lesentimitha, iyithuluzi elinembe kakhulu lokulinganisa ubude kune-vernier caliper. Ingakwazi ukukala ubude ngokunembile ku-0.01mm, futhi ububanzi bokulinganisa bungamasentimitha ambalwa.

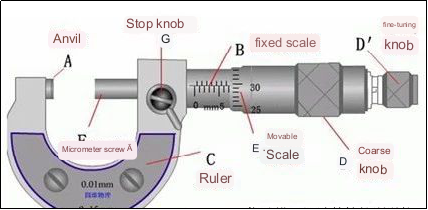

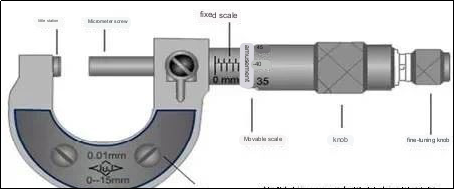

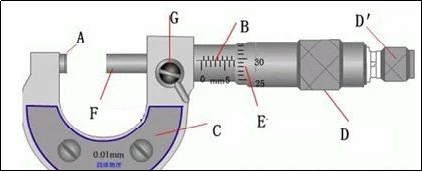

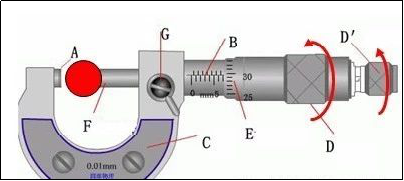

Isakhiwo se-spiral micrometer

Okulandelayo umdwebo wohlelo lwesakhiwo se-spiral micrometer:

Umgomo wokusebenza we-screw micrometer

I-micrometer yesikulufu senziwa ngokomgomo wokukhulisa isikulufu, okungukuthi, isikulufu sizungeza kanye kunothi, futhi isikulufu siyaqhubekela phambili noma sihlehle ngasendleleni ye-eksisi yokuzungezisa ngebanga le-pitch eyodwa. Ngakho-ke, ibanga elincane elinyakaziswayo ku-eksisi lingavezwa ngokufundwa komjikelezo.

Ukuphakama kwentambo enembayo ye-screw micrometer ngu-0.5mm, futhi isikali esisusekayo sinezikali ezihlukaniswe ngokulinganayo ezingu-50. Uma isikali esisusekayo sizungeza kanye, isikulufu se-micrometer singaqhubekela phambili noma sihlehle ngo-0.5mm, ngakho ukuzungezisa ingxenye encane ngayinye kulingana nokulinganisa I-micro screw iya phambili noma ihlehla 0.5/50=0.01mm. Kungabonakala ukuthi ukuhlukaniswa okuncane ngakunye kwesikali esisusekayo simele u-0.01mm, ngakho-ke i-micrometer yesikulufu ingaba nenembile ibe ngu-0.01mm. Ngenxa yokuthi ingalinganiselwa ukuthi ifundeka enye, ingafundwa ifinyelele engxenyeni eyinkulungwane yamamilimitha, ngakho ibizwa nangokuthi i-micrometer.

Ungayisebenzisa kanjani i-spiral micrometer

Lapho ngokuvamile sisiza amakhasimende ukuxhuma ithuluzi lethu lokutholwa kwedatha nge-spiral micrometer ukuze kukale ukusebenza kahle kakhulu, sivamise ukuqondisa amakhasimende ukuthi enze okulandelayo lapho enza i-spiral micrometer:

1. Hlola iphoyinti elinguziro ngaphambi kokulisebenzisa: vula kancane ifindo lokuhlela kahle elithi D′ ukuze wenze intonga yokulinganisa (F) ixhumane ne-anvil yokulinganisa (A) kuze kube yilapho i-ratchet yenza umsindo. Ngalesi sikhathi, iphoyinti elinguziro eruleni eligudlukayo (umkhono onyakazayo) Umugqa oqoshiwe kufanele uqondaniswe nomugqa wereferensi (umugqa omude ovundlile) kumkhono ongashintshi, ngaphandle kwalokho kuzoba nephutha elinguziro.

2. Bamba ifremu yerula (C) esandleni sobunxele, vula ifindo lokulungisa elimahhadla D ngesandla sokudla ukuze wenze ibanga phakathi kwentonga yokulinganisa F kanye ne-anvil A libe likhudlwana kunento elinganisiwe, faka into elinganisiwe, vula ifindo lokuvikela D' ukuze ubambe into elinganisiwe kuze kube i-ratchet yenza umsindo, vula ifindo eligxilile G ukuze ulungise induku yokulinganisa futhi ufunde.

Indlela yokufunda ye-screw micrometer

1. Funda isikali esimisiwe kuqala

2. Funda isikali esinguhhafu futhi, uma umugqa wesikali uhhafu uvezwa, urekhode njengo-0.5mm; uma umugqa wesikali uhhafu ungadalulwanga, urekhode njengo-0.0mm;

3. Funda isikali esinyakazayo futhi (naka isilinganiso), bese usibhala ngokuthi n×0.01mm;

4. Umphumela wokugcina wokufunda uyisikali esimisiwe + isikali esiyingxenye + isikali esinyakazayo

Ngenxa yokuthi umphumela wokufundwa kwe-spiral micrometer unembile kuze kube yinkulungwane nge-mm, i-spiral micrometer ibizwa nangokuthi i-micrometer.

Izinyathelo zokuphepha ze-spiral micrometer

1. Lapho ukala, qaphela ukuyeka ukusebenzisa ifindo lapho isikulufu se-micrometer sisondela entweni ezolinganiswa, futhi usebenzise ifindo lokushuna kahle esikhundleni salokho ukuze ugweme ukucindezela okukhulu, okungeke kwenze umphumela wokulinganisa unembile, kodwa futhi uvikele. i-screw micrometer.

2. Lapho ufunda, qaphela ukuthi umugqa oqoshiwe obonisa uhhafu wemilimitha esikalini esingashintshi udaluliwe yini.

3. Lapho kufundwa, kunenani elilinganiselwe endaweni yenkulungwane, elingenakulahlwa nje ngokunganaki. Ngisho noma iphoyinti elinguziro lesikali esilungisiwe livele liqondaniswe nomugqa wesikali othize wesilinganiso esisusekayo, indawo yenkulungwane kufanele ifundwe njengokuthi “0”.

4. Uma i-anvil encane kanye nesikulufu se-micrometer kusondelene, iphuzu elinguziro lesikali esinyakazayo alihambisani nephoyinti elinguziro lesikali esinqunyiwe, futhi kuzoba nephutha elinguziro, okufanele lilungiswe, okungukuthi, inani lephutha elinguziro kufanele lisuswe ekufundweni kokulinganisa kobude bokugcina.

Ukusetshenziswa Okufanelekile Nokugcinwa Kwe-Spiral Micrometer

• Hlola ukuthi ulayini uziro unembile yini;

• Uma ukala, indawo elinganiselwe ye-workpiece kufanele isulwe ihlanzeke;

• Uma i-workpiece inkulu, kufanele ikalwe ngensimbi emise okwe-V noma ipuleti eliyisicaba;

• Sula induku yokulinganisa kanye nedlozi ngaphambi kokulinganisa;

• Kudingeka idivayisi ye-ratchet lapho kufihlwa umkhono onyakazayo;

• Ungayeki ikhava yangemuva, ukuze ungashintshi umugqa onguziro;

• Ungafaki amafutha enjini ajwayelekile phakathi komkhono ongashintshi nomkhono onyakazayo;

• Ngemva kokusetshenziswa, sula amafutha bese uwafaka ebhokisini elikhethekile endaweni eyomile.

Ukuphishekela i-Anebon kanye nenhloso yebhizinisi ukuthi “Njalo ukwanelisa izidingo zamakhasimende ethu”. I-Anebon qhubeka nokusungula kanye nesitayela nokuklama izimpahla ezisezingeni eliphezulu zekhwalithi ephezulu yakho kokubili okuphelelwe yisikhathi namathemba amasha futhi ibone ithuba lokuwina-wini kumakhasimende ethu njengoba nje senza ngendlela oyifisayo amaphrofayili e-extrusion anembayo, izingxenye ze-aluminium ezishintshayo ze-cnc nezingxenye zokugaya i-aluminium zamakhasimende. . I-Anebon enezandla ezivulekile, imeme bonke abathengi abanentshisekelo ukuthi bavakashele iwebhusayithi yethu noma baxhumane nathi ngqo ukuze uthole imininingwane eyengeziwe.

Ifekthri Yenziwe Ngokwezifiso I-China CNC Machine kanye ne-CNC Engraving Machine, umkhiqizo we-Anebon waziwa kabanzi futhi wethenjwa ngabasebenzisi futhi ungahlangabezana ngokuqhubekayo nezidingo zomnotho nezenhlalo. I-Anebon yamukela amakhasimende amasha namadala avela kuyo yonke imikhakha yempilo ukuze asithinte ukuze athole ubudlelwano bebhizinisi besikhathi esizayo futhi azuze impumelelo efanayo!

Isikhathi sokuthumela: Jul-03-2023